No. CODE NAME Qty.

1 GB 846-85 M3X8 Screw M3X8 2

2 X1P-0230 Motor cover 1

3 ZYT-150 Motor 1

4 3J-300 Timing belt 1

5 X1P-0206 Motor pulley 1

6 GB 79 M4 x 10 Cap screw M4X10 1

7 X1P-0205 Motor base 1

8 X1P-0207 Motor base cover 1

9 GB 846-85 M3X8 Screw M3X8 1

10 X1P-0223 Arm 1

11 GB 70 M5 x 16 Cap screw M5X16 2

12 GB 6170 M5 Nut M5 4

13 GB 70 M5 X 55 Cap screw M5X55 4

14 LX20212 Spindle cover 1

15 GB 79 M4 x 10 Cap screw M4X10 1

16 X1P-0212 Spindle pulley 1

17 GB 894 - 20 Ext retaining ring 42 1

18 GB 893 - 42 Int snap ring 42 1

19 6004-2Z GB276 Ball bearing 80104 1

20 6004-2Z GB276 Ball bearing 80104 1

21 X1P-0211 Spindle 1

22 GB 893 - 42 Int snap ring 42 1

23 X1P-0222 Spindle box 1

24 9506.23-04 Washer 2

25 9506.23-02 Plate 1

26 GB818 M4X12 Screw M4X12 2

27 9506.23-03 Small shaft 1

28 12X 8X220 Rubber pipe 1

29 GB 818 M4 x 8 Screw M4x8 2

30 X1P-0225 Z wedge (gib) 1

31 GB 6170 M4 Nut M4 2

32 GB71 M4 x 20 Set screw M4X20 2

33 GB 70 M4 x 16 Cap screw M4X16 1

34 X1P-0208 Z screw nut 1

35 GB 862-87 4 Lock washer 4 2

36 GB 93-87 4 Spring washer 4 2

37 GB 818 M4 x 10 Screw M4X10 2

38 X1P-0204 Z COVER 1

39 GB 818 M4 x 8 Screw M4X8 2

40 X1P-0110 Handle wheel screw 4

41 X1P-0109 Handle wheel circle 4

42 X1P-0124T Handle wheel 4

43 GB 70 M4 x 12 Cap screw M4X12 2

44 X1P-0118 X bearing seat 2

45 X1P-0221 Fuselage 1

46 GB 6170 M8 Nut M8 4

47 GB862 8 Washer 8 4

48 GB 273 51200 ball bearing 51200 7

49 GB 1096 3 x 6 Key 3X6 4

50 X1P-0209 Z screw 1

51 X1P-0123T High point circle 1

52 X1P-0122T point circle 3

53 GB77 M5X8 Screw M5X8 1

54 X1P-0224 Z screw cover 1

55 GB 818 M4 x 8 Screw M4X8 4

56 X1P-0215 Handle 1

57 X1P-0217 Making screw 1

58 X1P-0218 Spring 1.2 1

59 GB 70 M10 x 50 Cap screw M10X50 1

60 GB 93-87 10 Spring Washer 10 1

No. CODE NAME Qty.

61 X1P-0220 Fuselage base 1

62 GB 70 M4 x 20 Cap screw M4X20 2

63 X1P-0219 Angle circle 1

64 GB 70 M4 x 20 Cap screw M4X20 2

65 X1P-0214 Fuselage circle 1

66 GB 70 M6 x 50 Cap screw M6X50 4

67 XJ9506.23-01 Dust guard 1

68 GB2089-80 Spring 0.5X5X5 1

69 GB 6170 M4 Nut M4 1

70 23 Speed control knob 1

71 WH24-2 Potential device 1

72 Warning lamp 1

73 M12 Strain relief 1

74 MF527 Fuse box 1

75 XD73 Green lamp 1

76 X1P-0213 Point plate 1

77 X1P-0201 Electronic box 1

78 GB 819 M4 x 10 Screw M4X10 4

79 XMT2325/1115 Electronic circuit 1

80 X1P-0112 Y screw 1

81 GB 846M3X8 Screw M3X8 3

82 X1P-0202 Electronic box cover 1

83 SMT-2 Switch 1

84 GB 845 M3X16 Screw M3X16 2

85 C045 Cord base 1

86 GB 846 M3X8 Screw M3X8 2

87 GB 845 M3X8 Screw M3X8 3

88 Cord 1

89 X1P-0121 Table 1

90 X1P-0111 Y front bearing seat 1

91 GB 818 M4 x 8 Screw M4X8 2

92 X1P-0106 Y front plate 1

93 GB 70 M5 x 12 Cap screw M5X12 4

94 X1P-0107 Y screw nut 1

95 X1P-0102 Y cover 2

96 X1P-0105 Y middle plate 1

97 GB 70 M4 x 10 Cap screw M4X10 1

98 GB 70 M4 x 10 Cap screw M4X10 4

99 X1P-0115 Y wedge (gib) 1

100 X1P-0104 X wedge (gib) 1

101 GB71 M4X20 Set screw M4X20 2

102 GB 70 M4 x 25 Cap screw M4X25 1

103 GB 78 M4X30 Set screw M4X30 2

104 GB 6170 M4 Nut M4 2

105 X1P-0117 X screw 1

106 X1P-0105 Y middle plate 1

107 X1P-0113 Saddle 1

108 X1P-0114 X screw nut 1

109 X1P-0118 X bearing seat 1

110 GB 70 M4 x 12 Cap screw M4X12 2

111 X1P-0116 Y screw base 1

113 X1P-0106 Y front plate 1

114 GB 818 M4 x 8 Screw M4X8 2

115 X1P-0101 Base 1

116 X1P-0216 Angle shaft 1

117 GB879 2X16 Spring pin 2X16 1

118 GB845 M4X10 Screw M4X10 4

119 GB818 M4X25 M4X25 1

120 X1P-0228 Up cord pressing 1

121 X1P-0229 Down cord pressing 1

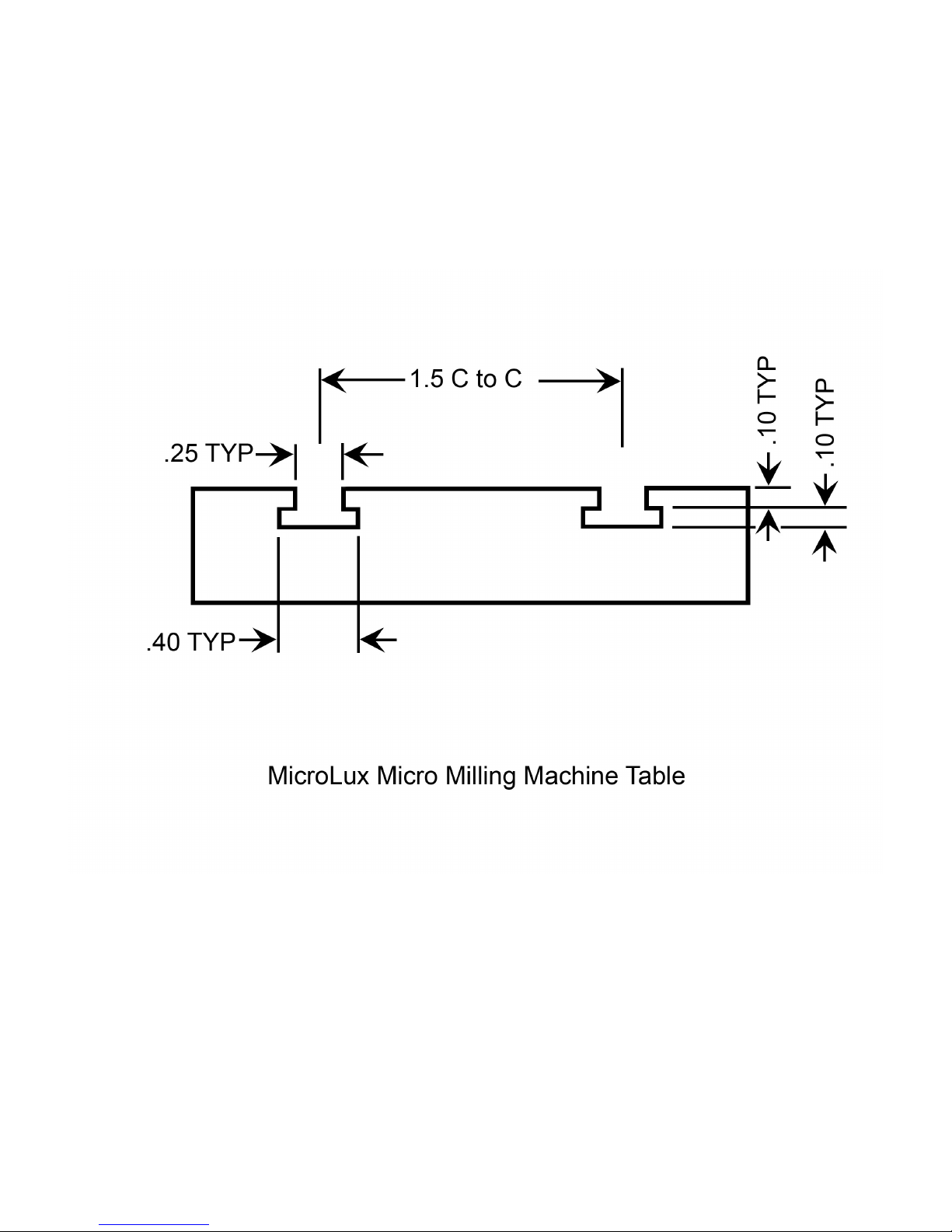

#84659 MicroLux Micro Milling Machine

Parts List

6