Feider Machines FMT360 Quick start guide

TRANSLATION OF INSTRUCTION MANUAL

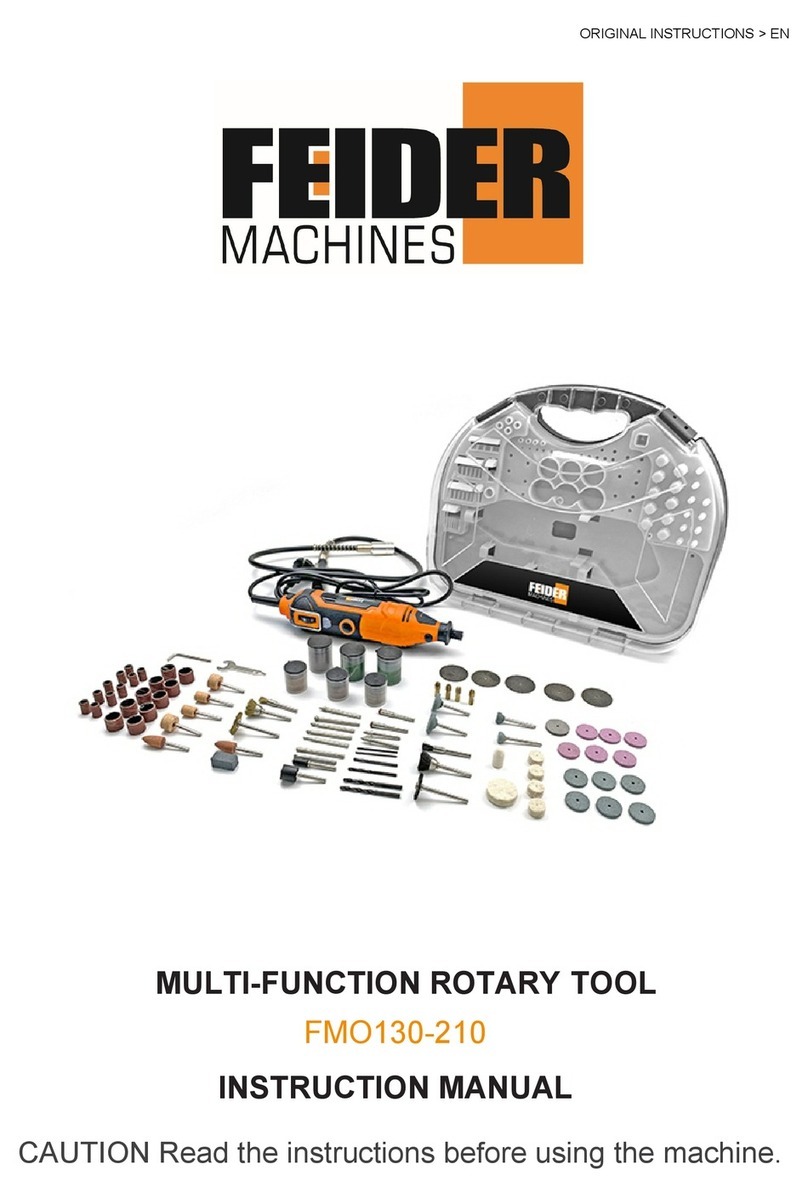

MULTIFUNCTION TOOL

FMT360

FEIDER

32, rue Aristide Bergès - ZI 31270 Cugnaux - France

Warning: Please read the manual carefully before using the unit!

1 USE

2 DESCRIPTION (FIG. A)

3 LIST OF THE PARTS CONTAINED IN THE PACKAGE

4 PICTOGRAMS

5 GENERAL POWER TOOL SAFETY WARNINGS

5.1 Work area

5.2 Electrical safety

5.3 Personal safety

5.4 Power tool use and care

5.5 Service

6 SPECIFIC SAFETY INSTRUCTIONS FOR THE DEVICE

7 ASSEMBLY

7.1 Installation of the slider / saw blade / spatula (Fig. 1)

7.2 Installation/change of abrasive paper (Fig. 2)

7.3 Installation of the dust extraction device (Fig. 3)

8 OPERATION

8.1 On/off switch (Fig. 3)

8.2 Setting the speed (Fig. 4)

8.3 Application tips

8.3.1 Choice of the working tool

8.3.2 Sawing

8.3.3 Sanding

8.3.4 Scratch

9 CLEANING AND MAINTENANCE

10 TECHNICAL DATA

11 NOISE

12 ENVIRONMENT

VERSATILE TOOL

1. USE

Depending on the accessory mounted on this power tool, it is intended for dry sanding of

small areas and for sawing, scraping, polishing, scratching, cutting and peeling.

WARNING! For your own safety, read this manual and the general safety

instructions before using the machine. If you give your device, attach always

this instruction.

2. DESCRIPTION (FIG. A)

1. Fast release lever.

6. Blade for sawing in.

2. Fast slackening plunge flange.

7. Segmental sawblades with.

3. Oscillation frequency controller.

8. Shovel range.

4. On-off switch notch.

9. Slider.

5. Air vents.

3. LIST OF THE PARTS CONTAINED IN THE PACKAGE

• Remove all packing materials.

• Remove the remaining packaging and transport material (if applicable).

• Check that nothing is missing in the box.

• Check that the appliance, power cord, mains plug and all the accessories have not been

damaged during transport.

• Keep the packaging materials as long as possible until the end of the warranty period.

Then discard it according to your system of waste disposal.

WARNING: Packaging materials are not toys! Children

must not play with plastic bags as there is a dangerous

of suffocation!

1 pc. - half moon wood cutting;

20 pcs. - abrasive grain 80;

3 pcs. - wood cutting spatula;

15 pcs. - abrasive grain 120;

1 pc. - scraper;

15 pcs. - abrasive grain 180.

1 pc. - self-grasping abrasive tray;

In the case of damaged or missing parts, contact your dealer.

4. PICTOGRAMS

The following symbols are used in this operating manual and/or on the machine:

Risk of body injury or material

damage.

Wear ear protection.

Read this instruction

manual carefully

Wear protective glasses

Complies with relevant

safety regulations

Wear respiratory protection.

Double isolation

5. GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Read all safety warnings and all instructions.

Failure to follow all warnings and instructions

may result in electric shock, fire and/or serious injury. Save all

warnings and instructions for future reference. The term "power tool" in the

warnings refers to your mains operated (corded) power tool or battery operated

(cordless) power tool.

5.1 Work Area

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may

ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

5.2 Electrical safety

Always check that the power supply corresponds to the voltage on

the

rating plate.

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of

electric shock.

5.3 . Personal safety

a) Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used

whenever conditions require will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off position before

plugging in. Carrying power tools with your finger on the switch or plugging in

power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of these devices

can reduce dust related hazards.

5.4. Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be

repaired.

c) Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or sticking of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to stick and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the work to be performed. Use

of the power tool for operations different from intended could lead to a

hazardous situation.

5.5 Service

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

6. SPECIFIC SAFETY INSTRUCTIONS FOR THE DEVICE

• Use the machine only for dry work. Water penetration into a power tool increases the

risk of an electric shock.

• Keep hands away from cutting area. Do not put your hands under the workpiece. When

in contact with the saw blade, there is risk of injury.

• Use appropriate detectors to detect hidden pipes or visit the local supply businesses. A

contact with power lines can cause a fire or an electric shock. A damage to a gas pipe

may cause an explosion. Penetrating a water line causes property damage and may cause

an electrical shock.

• Always hold the power tool with both hands and always keep a stable working position.

With both hands, the power tool is guided more reliably.

• Secure the workpiece. A workpiece clamped with clamping devices or in a vise is fixed

more reliably than when held with the hands.

• Keep the work place clean. Mixtures of materials are particularly dangerous. Light

metal dust can be flammable or explosive.

• Avoid a starting by mistake. Make sure that the on/off switch is actually turned off

before mounting a battery.Holding the power tool keeping your finger on the on/off

switch or setting up the battery in the power tool while it is running can lead to accidents.

• Do not open the battery. Risk of short circuit. Protect the battery from any source of

heat, such as direct exposure to the sun and fire. There is a risk of explosion.

• In case of damage and use of non-compliant battery, vapours can be emitted. Ventilate

the workplace and in the event of discomfort, consult a doctor. Vapours may cause

irritation of the respiratory tract.

• When the battery is defective, a liquid can leak and spread over the surrounding objects.

Check the elements involved. Clean them or replace them if necessary.

• Only use the battery with your power tool. Just so the battery is protected against a

dangerous overload.

• Wear protective gloves to replace the working tools. Working tools get hot following a

prolonged use.

• Do not scratch moistened materials (e.g. wallpapers) and not on a wet surface. Water

penetration inside an electric tool increases the risk of electric shock.

• Do not treat the working surface with liquids containing solvents. Harmful fumes can be

generated if materials become hot during scratching.

• Be extremely careful when handling the scraper. The tool is very sharp, there is a

danger of injury.

7. ASSEMBLY

WARNING: Always make sure that the power supply corresponds to the

voltage specified on the rating plate. Remove the tool from its packaging. Do

not connect the tool to the electrical outlet before the assembling.

7.1 Installation of the slider / saw blade / spatula (Fig. 1)

WARNING: Before any assembly or adjustment, always unplug

the electrical plug from the electrical outlet.

Beware of sharp tools such as spatulas, saw blades or cutting blades.

• Loosen the clamping plate (b) by pulling on the fast-release lever (1) until it is

completely open.

• Keep the opening of the fast installation saw blade, slider or spatula towards the output

pin between the clamp cover (a) and the clamping plate (b), push the accessory inside and

place it firmly on the location pins (c).

• Tighten using the fast release lever (1) in locking position, as shown in Fig.A of Fig.1.

• To remove the accessory, proceed in the opposite order.

WARNING: This tool is equipped with accessories for quick installation. Do

not use inappropriate accessories.

WARNING: Check that the tool and accessory for the application are firmly

assembled. A tool or an application accessory insufficiently tightened may

loosen during operation and become dangerous.

7.2 Installation/change of abrasive paper (Fig. 2)

With loop fastening.

• Place the sanding paper and press it against the slider.

• Press the sanding paper by pushing briefly and firmly against the flat surface of the

slider (9) and turn the electric tool on.

-This ensures good adhesion and prevents early wear.

• If the tip is worn, remove the sanding paper, turn it at 120° and place it again against the

slider, or change it.

7.3 Installation of the dust extraction device (Fig. 3)

Follow steps 1 through 4.

8. OPERATION

8.1 On/off switch (Fig. 3)

• First make sure that the cable and plug are not damaged.

• Insert the plug into the electrical outlet.

• Turning on the power tool: turn the on-off switch (4) in forward position (I).

• Turning the power tool off: turn the on-off switch back in (O) position.

8.2 Setting the speed (Fig. 4)

The tool can be set at six different speed positions. Position 1 corresponds to the lowest

speed and position 6 at the highest speed. You can set the tool at different speeds by

rotating the speed control knob (3) from position 1 to position 6. The operator may have

to vary the speed to maximize the effectiveness of the task.

8.3 Application tips

8.3.1 Choice of the working tool

Working tool

Materials

Wood cutting saw blades

Wooden plastic, plaster

materials and other soft

materials

Segmental sawblade with nick

Wood, plastic materials

Shovel range

Wood, paint, glue for carpets,

silicone and other elastic

materials

Saw blades grinding plate

Depending on the saw blade

8.3.2 Sawing

Only use saw blades in perfect state. Warped, blunt or otherwise damaged

saw blades can break.

The method of plunge cuts can be applied only on soft materials such as

wood, plaster plate, etc.!

Before cutting with saw blades wood, particle panel, building materials, etc., check that

there is no external object such as nails, screws or similar. If necessary, remove external

objects or use suitable saw blades for the metal.

8.3.3 Sanding

The power of removal of material as well as the state of the surface depend largely on the

selection of the sanding sheet, the preset rotation speed as well as pressure on the unit.

Only flawless sanding sheets provide a good sanding effect and spare the power tool.

Ensure that the working pressure is regular, in order to increase the useful life of abrasive

sheets.

Too much pressure on the appliance does not increase the sanding power,

but determine higher wear of the power tool as well as the sanding sheet.

For sanding of the corners, edges and areas hard to reach with extreme accuracy,

you can also use only the tip or edge of the sanding plate.

When spot sanding, the sanding sheet can strongly get heated. Therefore, reduce the

speed and cool the sanding sheet regularly.

A sanding sheet used for metal should not be used for other materials.

8.3.4 Scratch

Choose a high speed for scratching.

Work on a soft surface (e.g. wood) with a flat angle and minimum pressure.

Otherwise, the scraper can cut into the surface.

9. CLEANING AND MAINTENANCE

Before any work on the machine, disconnect the mains plug.

• Keep the air vents clean to prevent overheating of the motor.

• Regularly clean the frame of the machine with a soft cloth, preferably after

each use.

• Keep the air vents free from dust and dirt.

• If there is tough dirt, use a soft cloth moistened with soapy water.

• Never use solvents such as gasoline, alcohol, ammonia, etc. These solvents

may damage the plastic parts.

Check that the water can never penetrate the power tool!

10. TECHNICAL DATA

Voltage

230-240 V

Frequency

50 Hz

Power

400 W

No-load speed

15 000-22 000 min-1

11. NOISE

Values of sound emissions measured according to the applicable standard. (K=3 dB)

Acoustic pressure, LpA

84 dB (A)

Sound power, LwA

95 dB (A)

CAUTION! When the acoustic pressure exceeds the value of 85 dB (A), you

have to wear individual hearing protection devices.

aw (Vibrations):

3.86 m/s2

K = 1.5 m/s2

Information

The declared vibration total value was measured by a standard test method and may be

used for comparing one tool with another.

The declared total vibration value can also be used in a preliminary exposure estimate.

Warning:

The vibration emission during actual use of the machine tool can differ from the declared

value depending on the way the tool is used.

You have to identify the safety measures to protect the operator, these are based on an

exposure estimation in the actual conditions of use (taking into account all operating

cycle parts such as the times when the tool is on and off and when it's running as well as

its starting time).

Wear a hearing protection.

12. ENVIRONMENT

If, after a certain time, you decide to replace your machine, do not dispose

of it with household waste but dispose of it in a respectful treatment for

the environment.

Electrical waste cannot be processed in the same way as ordinary

household waste. Proceed to their recycling, where there are adequate

facilities. Learn more about the processes of collection and treatment from

local authorities or your dealer.

Table of contents

Other Feider Machines Power Tools manuals

Popular Power Tools manuals by other brands

Metabo

Metabo SX E 450 TurboTec operating instructions

Milwaukee

Milwaukee M18 ROCKET Operator's manual

Rikon Power Tools

Rikon Power Tools 10-342 Operator's manual

Grad-M

Grad-M DA-18N-PDK user manual

Aicon Air

Aicon Air DAC3040 Instructions for use

Bosch

Bosch Professional GSR 12V- 15 FC Original instructions