340 Snyder Avenue, Berkeley Heights, NJ 07922

Tech Support: 908-464-1094, 1 pm–5pm ET

#83507 MICROLUXTM DRUM THICKNESS SANDER INSTRUCTIONS

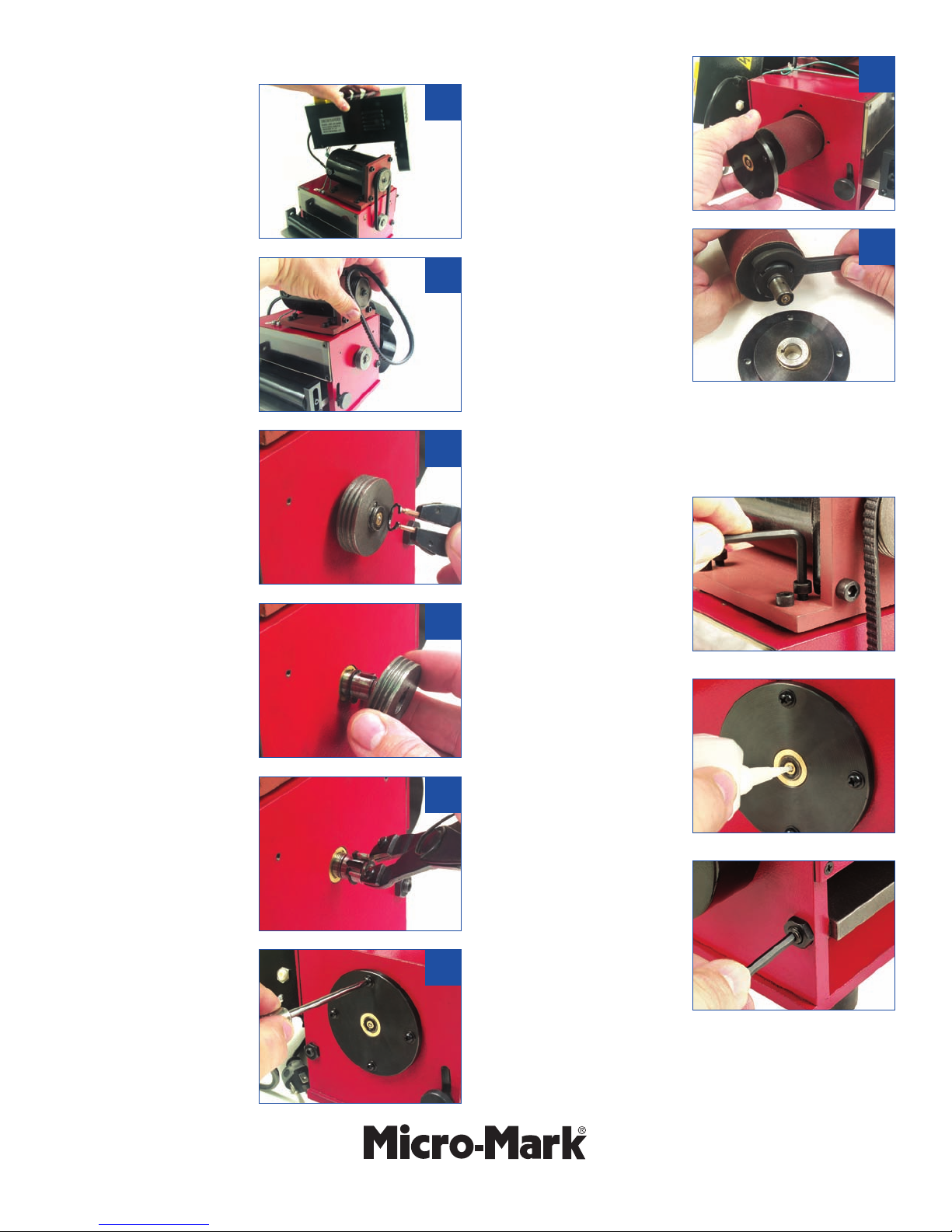

Before using your Drum

Thickness Sander, install

the heavy steel roller on the

in-feed side of the machine.

To do this, loosen the screws

that hold the roller guide block

to the side of the table; the

screws should be loose

enough so that the block may

be tipped far enough to allow

the roller to be put in place.

Then, tighten the screws and

make sure the roller “floats”

vertically freely. The purpose of

the roller is to hold the wood

sheet in contact with the table

(this is the in-feed side of the

machine).

The hex head screw located

under the table is used to set

the gap between the table and

the sanding drum.

We recommend you use a

scrap piece of the wood you

intend to sand as a gauge to set

the gap. Be sure to tighten the

thumb screws before sanding.

The fitting on the rear of the

sander is used to connect a

standard 1-1/4” hose from your

shop vacuum cleaner.

2

The thumb screws located on

each side of the machine lock

the table in position.

3

4

This label indicates the

direction to feed the wood

sheet.

7

Set the gap so that the drum is

in light contact with your test

piece. Remove the test piece,

then turn on the machine.

Feed the test piece slowly and

steadily into the machine; be

sure to hold the wood down

against the table while doing

so. As the wood progresses

through the sander, use one

hand to continue the in-feed while your other hand reaches

around to pull the wood from the exit side of the machine.

Maintain a constant rate of feed to avoid burning sanding marks

in the surface of the wood.

The Drum Thickness Sander is a table top machine. It is quite

heavy and should stay in place during use; however, be careful

not to use excessive force while using the machine and cause it

to tip over.

Practice with some scrap wood to get the “feel” of the machine.

In a couple of passes, you'll be able to determine the correct gap

and feed rate for the material you are sanding.

Safety Precautions

Warning! The use of this machine may generate dust which

contains chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm. The use

of dust masks, vacuum systems and other devices to eliminate

exposure to this dust is highly recommended. Persons using this

machine or in the vicinity of this machine while in operation

should wear safety glasses at all times.

Warning! This machine contains high-speed rotating parts.

Do not insert your fingers or any other part of your body into the

in-feed side, exit-side or vacuum port of this machine; otherwise,

severe injury could result. This machine is intended for sanding

the surfaces of wood sheets only; we recommend that gloves

are worn when handling wood sheets with a rough texture.

Warning! This machine does not employ a mechanism that

controls the feed rate of the wood sheets being sanded. The

wood sheets are fed into the machine and propelled through the

machine by hand. Please observe the feed direction indicated on

the label located on the side of the machine. Do not release your

grip of the wood sheet or it may be expelled from the machine at

a fast speed, which could cause injury to your person or damage

to nearby equipment.

Unplug the machine from the electrical outlet when not in use.

Always unplug the machine when performing any service, such

as changing the sanding drum sleeve or making adjustments.

8

The ON-OFF switches are

located on the top of the

machine. To turn the machine

on, press the green (I) button.

To turn the machine off, press

the red (O) button.

Instructions for Use

6

1

5