TABLE OF CONTENTS

1. INTRODUCTION...........................................................................................1

2. SPECIFICATION...........................................................................................2

2.1. Atomiser........................................................................................2

2.2. Segmental Attachment..................................................................2

2.3. Controller ......................................................................................3

3. INSTALLATION.............................................................................................5

3.1. Atomiser........................................................................................5

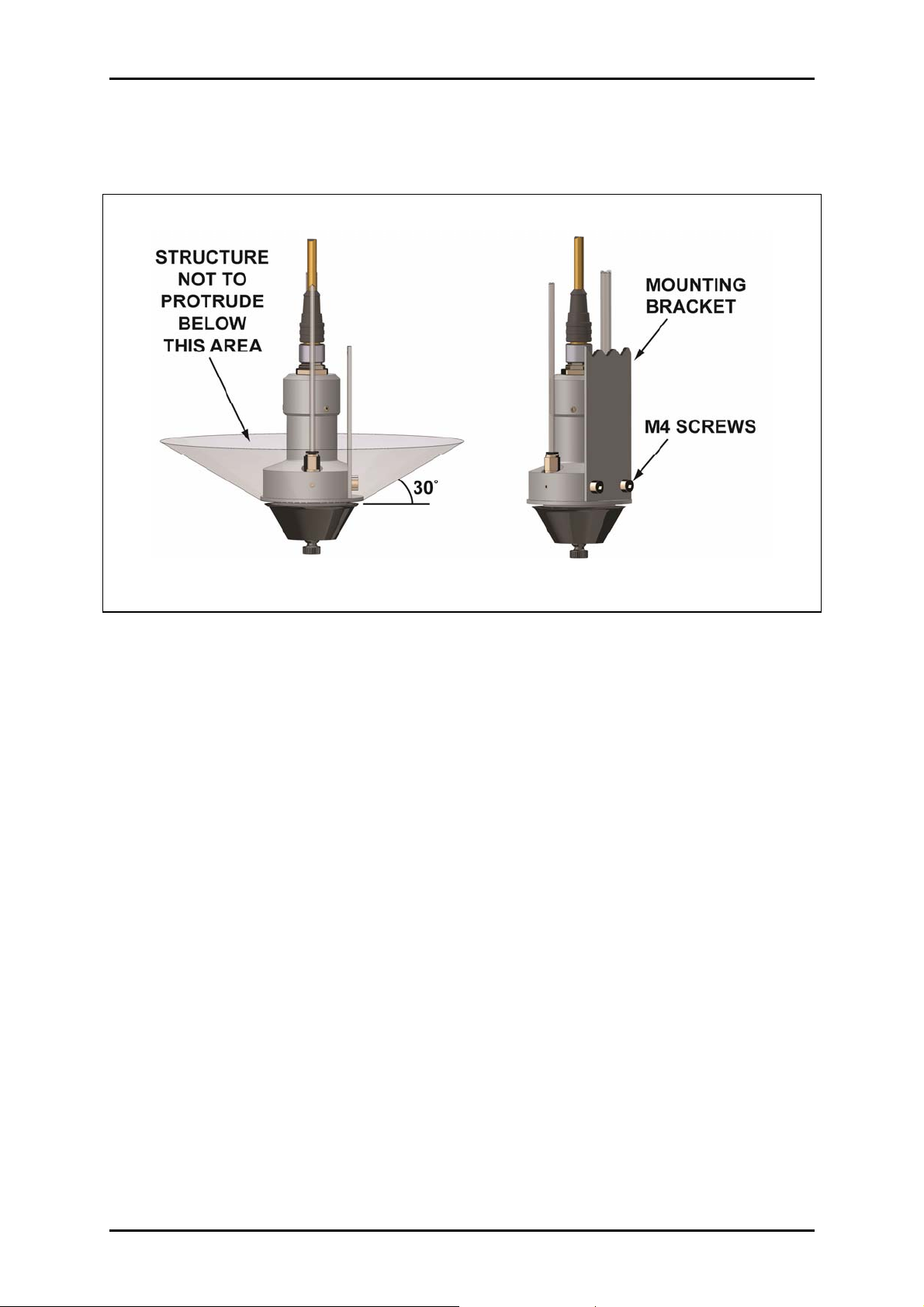

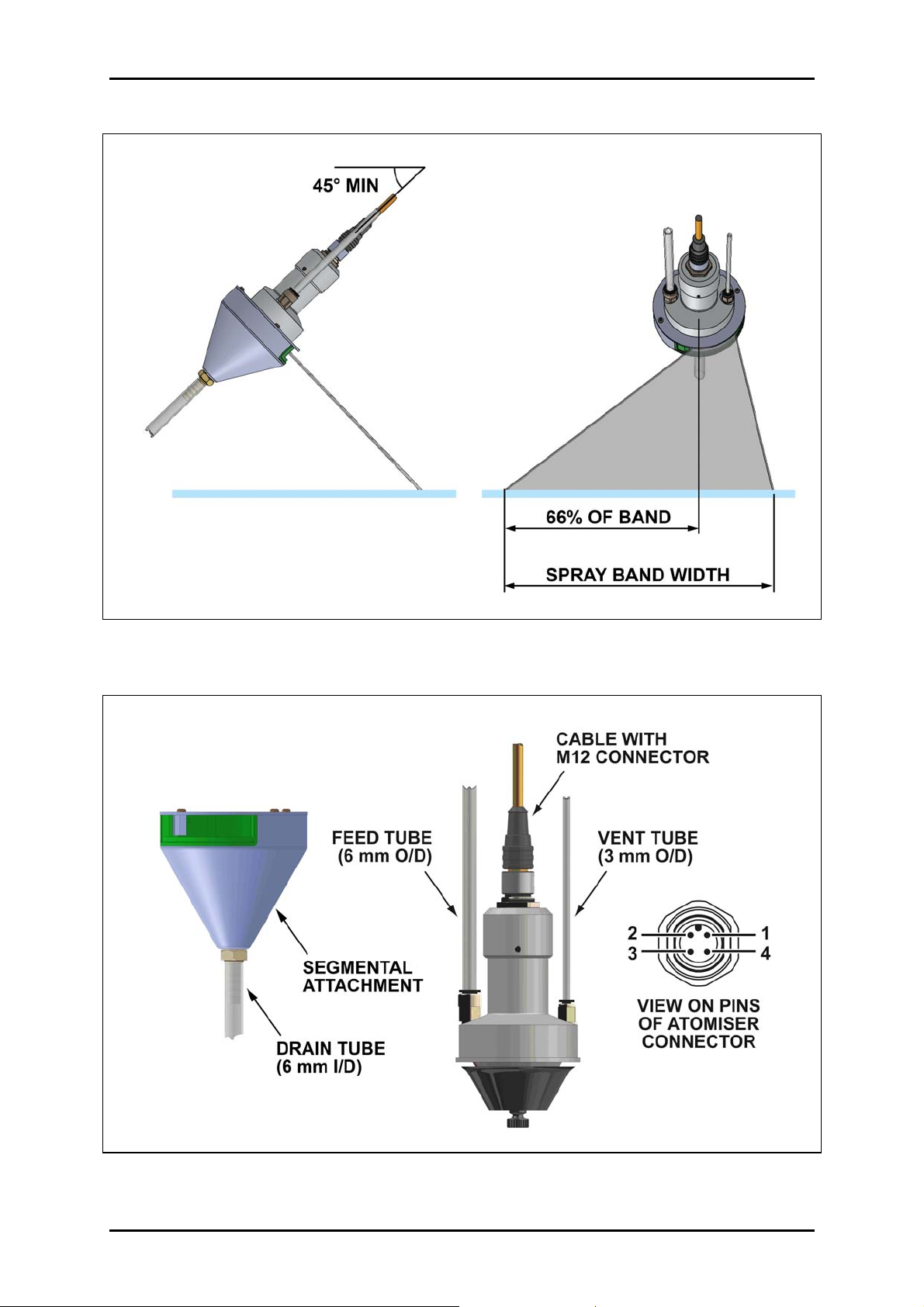

3.1.1. Mounting – Basic Atomiser ...................................................5

3.1.2. Mounting – with Segmental Attachment................................6

3.2. Liquid Feed ...................................................................................8

3.3. Liquid Drain...................................................................................9

3.4. Motor Venting................................................................................9

3.5. Electrical Connections.................................................................10

3.5.1. Use with Micronair Controller ..............................................10

3.5.2. Use with External Power Supply .........................................10

3.5.3. Atomiser Speed Control (Micromiser 12 Only)....................13

3.5.4. Atomiser Speed Output.......................................................14

3.6. Controller ....................................................................................15

3.6.1. Mounting .............................................................................15

3.6.2. Electrical Connections.........................................................16

3.6.2.1. Power Supply.................................................................16

3.6.2.2. Atomiser ........................................................................17

3.6.2.3. Atomiser Speed Control Input........................................17

3.6.2.4. Atomiser Enable Input ...................................................17

3.6.2.5. Atomiser Speed Control Output .....................................17

3.6.2.6. Atomiser Run Output .....................................................18

3.6.2.7. Atomiser RPM Output....................................................18

3.6.2.8. Control Ground ..............................................................18

4. OPERATION ...............................................................................................19

4.1. Atomiser......................................................................................19

4.2. Controller (Micromiser 12 Only) ..................................................19

5. CALIBRATION ............................................................................................20

5.1. Flow Rate....................................................................................20

5.2. Spray Droplet Size ......................................................................21

6. MAINTENANCE ..........................................................................................23

6.1. Routine maintenance – Atomiser ................................................23

6.2. Routine maintenance – Controller...............................................24

6.3. Fault Finding ...............................................................................25

7. PARTS LISTS .............................................................................................27

7.1. Micromiser Atomiser ...................................................................27

7.2. Controller ....................................................................................27

7.3. Cable Assembly ..........................................................................27

7.4. Segmental Attachment................................................................28