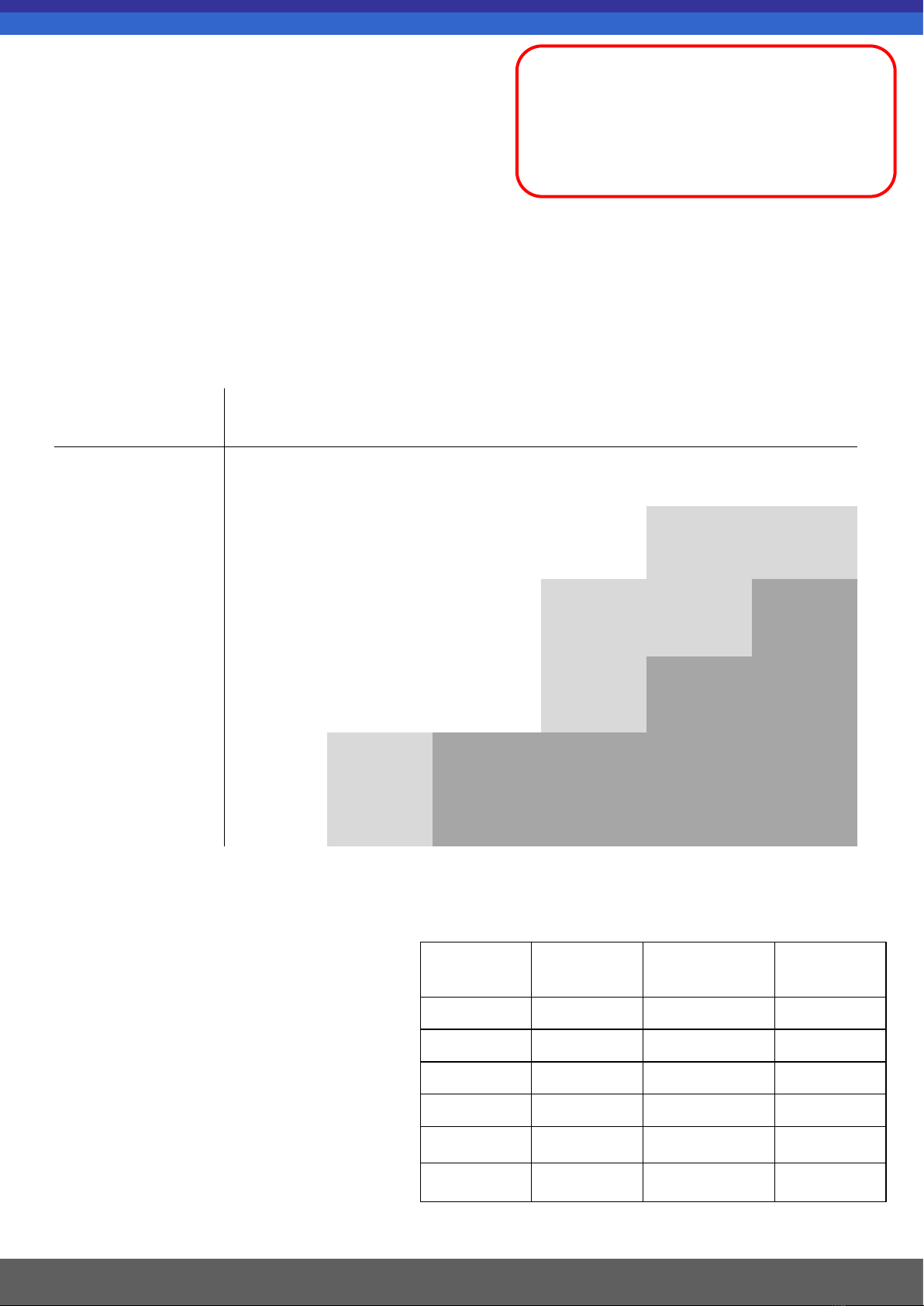

1M 2M 3M 4M 5M 6M

Slam 100x100 100x100 100x100 100x100 100x100 100x100

Single Hang 100x100 100x100 100x100 100x100 120x120 120x120

Double Hang

90 deg 100x100 100x100 100x100 120x120 120x120 150x150

Double Hang

Inline 100x100 100x100 100x100 120x120 150x150 150x150

Triple Hang 100x100 120x120 150x150 150x150 150x150 150x150

Quad Hang 100x100 120x120 150x150 150x150 150x150 150x150

2.1. Post Selection

It is important to consider post selection at the

beginning of an AG-fit project install. The AG-fit posts

are available in a variety of different widths and lengths,

to ensure that you have selected the right post for your desired application you must consider

the following:-

• Gate or barrier length, see table below

• Post type i.e. hang or slam, see table below

• Height out of ground

Gate / Barrier Length (0.55M - 6M)

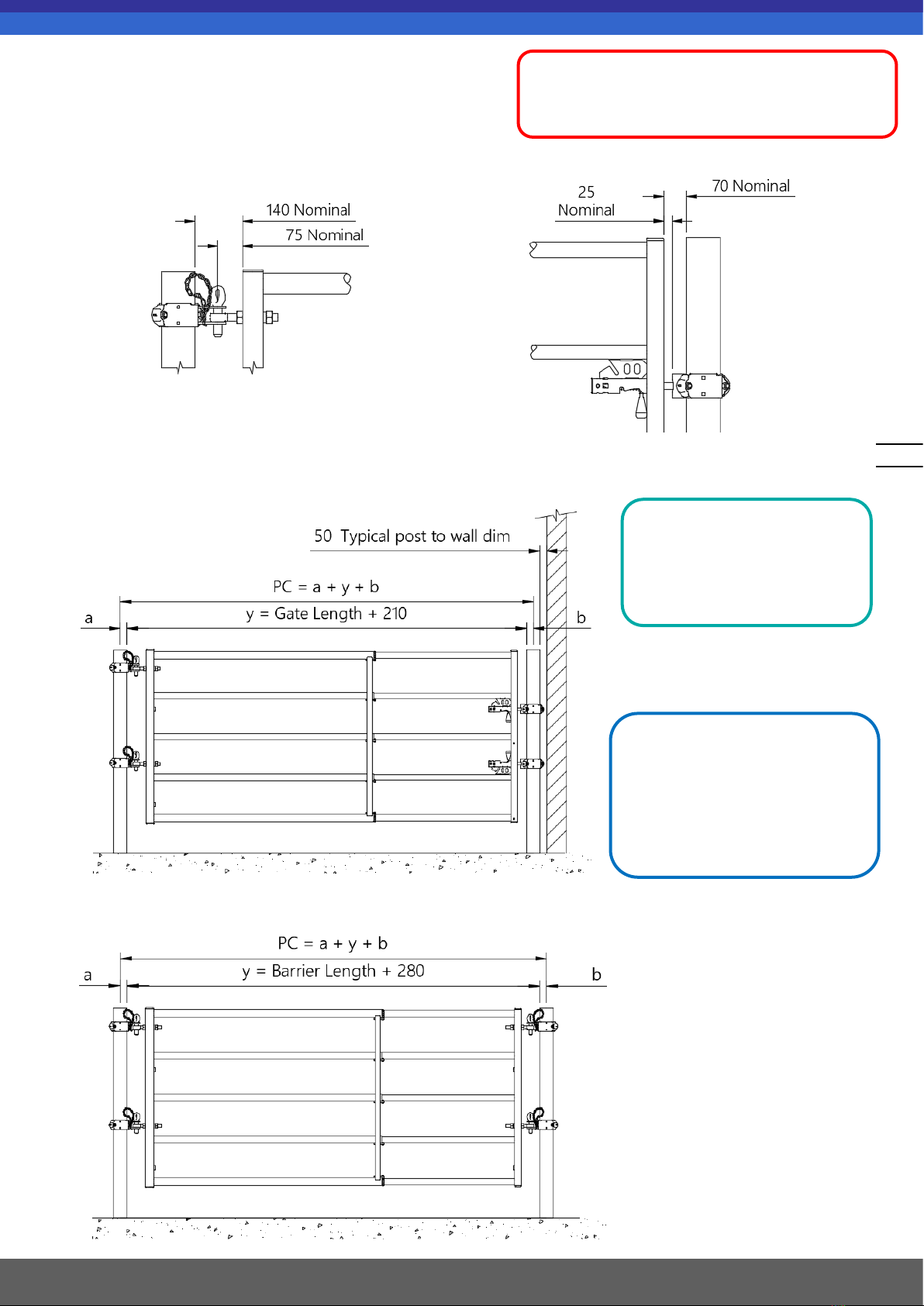

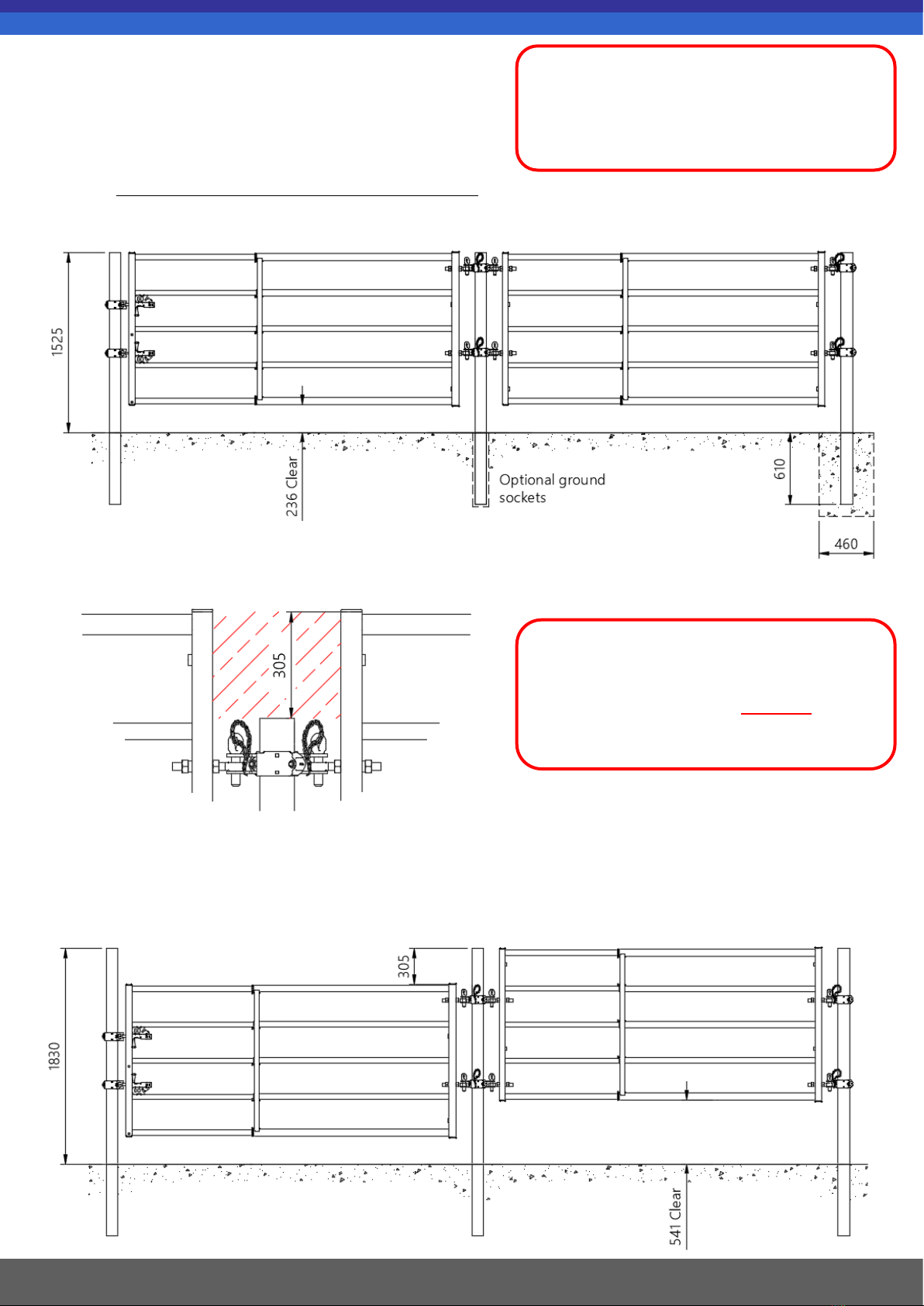

IMPORTANT:

Before inserting posts into ground be sure

to consider both; the depth of bedding

underneath (where 305mm rise is required

2440mm post must be used) and any steps

caused by discrepancy in the floor level.

Heights Out Of Ground

Gates and barriers hanging at

1525mm as standard, use a 2135mm

post set 610mm deep into ground.

Gates and barriers with a 305mm rise

hanging at 1830mm, use a 2440mm

post set 610mm deep into ground.

Feed fence standing at 1370mm as

standard, use a 1830mm post set

460mm deep into ground.

Post Width

(mm) Post Length

(mm) Code Pack Size

100x100 1830 F030 2012 13 8

100x100 2135 F002 2009 01 8

120x120 2135 F002 2009 03 8

120x120 2440 1000197 2

150x150 2135 F002 2009 05 2

150x150 2440 1000193 2

2

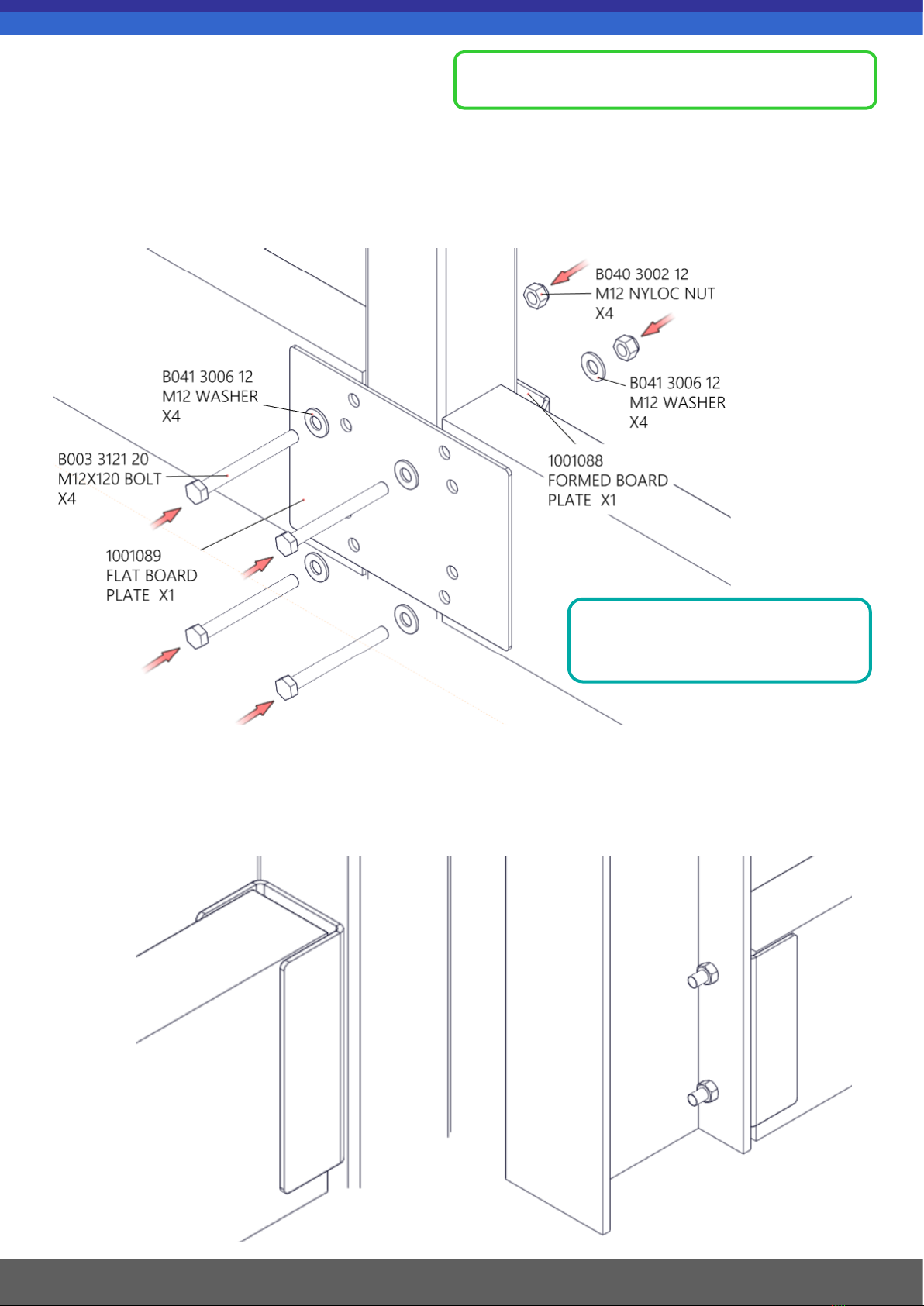

2. Post Installation

3

Guide For Available Posts;-

1001270 Volume 3.1 Issue Date: March 2021