MICRONOR

automation components

Page

of

Table of Contents

1. Product Description ................................................................5

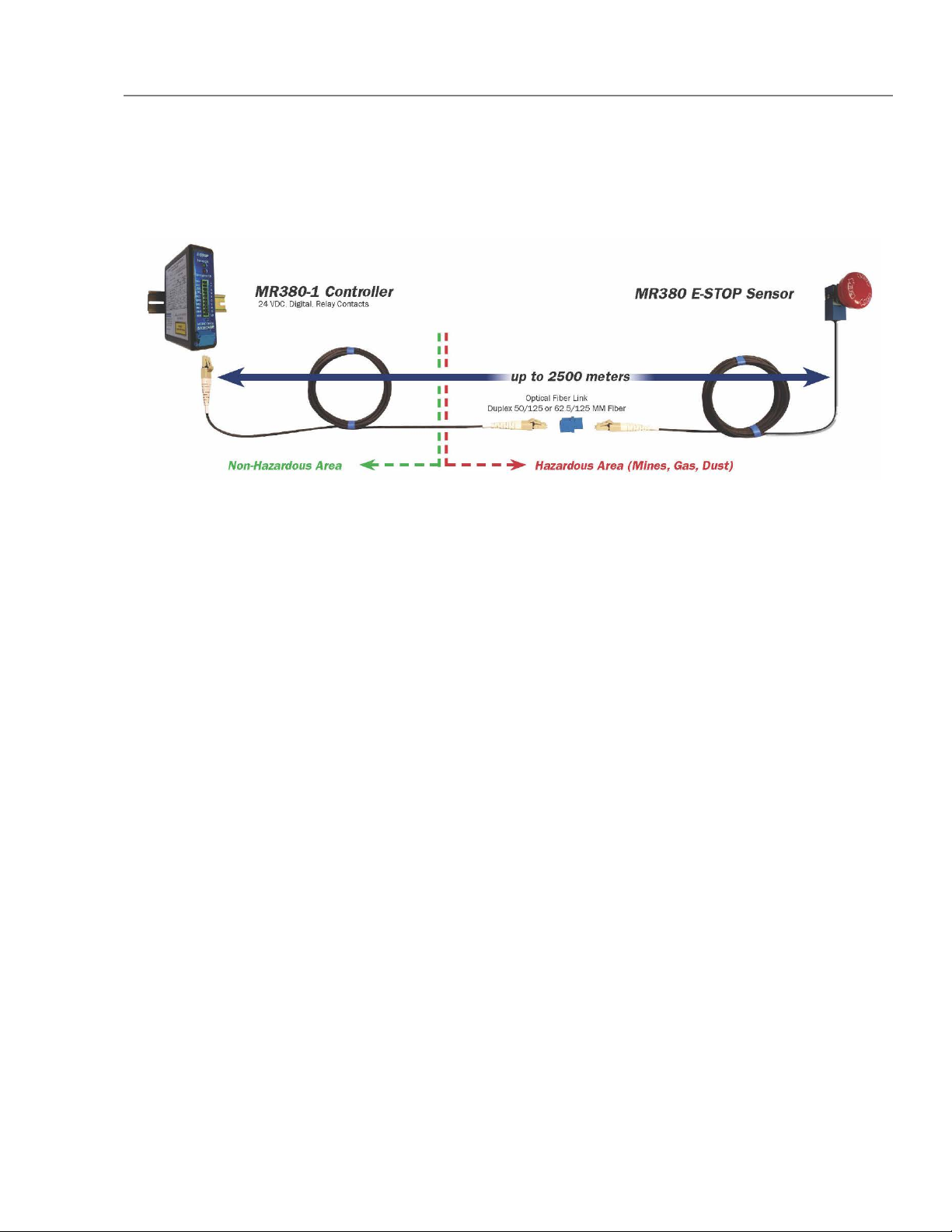

1.1. Fiber Optic Emergency Stop Switch ..................................................................................5

1.2. Fields of Application ...........................................................................................................6

1.3. Features..............................................................................................................................6

2. Standard Contents...................................................................7

3. Installation and Operation ......................................................8

3.1. Mounting the Emergency Switch.......................................................................................8

3.2. Mounting the Controller Module .......................................................................................9

3.3. Connecting the Controller ................................................................................................10

3.4. System Start-Up & Performance Check..........................................................................11

4. Troubleshooting ....................................................................12

4.1. Potential Issues & Solutions............................................................................................12

4.1.1. ‘Power’ not illuminated when controller powered ..................................................12

4.1.2. ‘Emergency ON’ illuminated w/Emergency Switch Connected..............................12

4.1.3. No +24V Digital Out ..................................................................................................12

4.1.4. No +5V Digital Out ....................................................................................................12

4.1.5. Relay Switching Failure.............................................................................................13

4.1.6. Damaged Emergency Switch (Fiber)........................................................................13

4.2. Damaged In Shipment .....................................................................................................14

5. Warranty Information ............................................................15

6. Specifications ........................................................................16

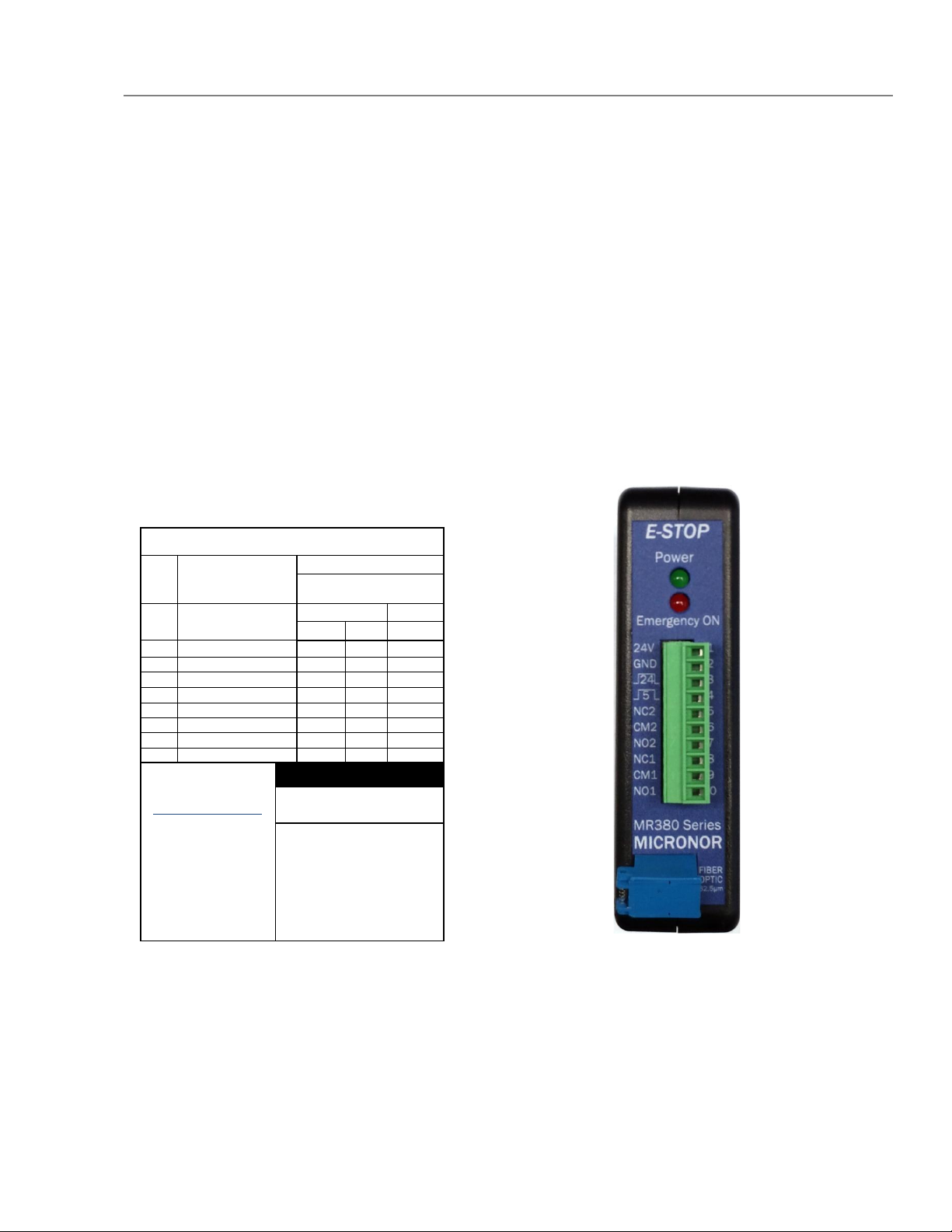

6.1. E-STOP Sensor ..................................................................................................................16

6.2. E-STOP Controller Module................................................................................................18

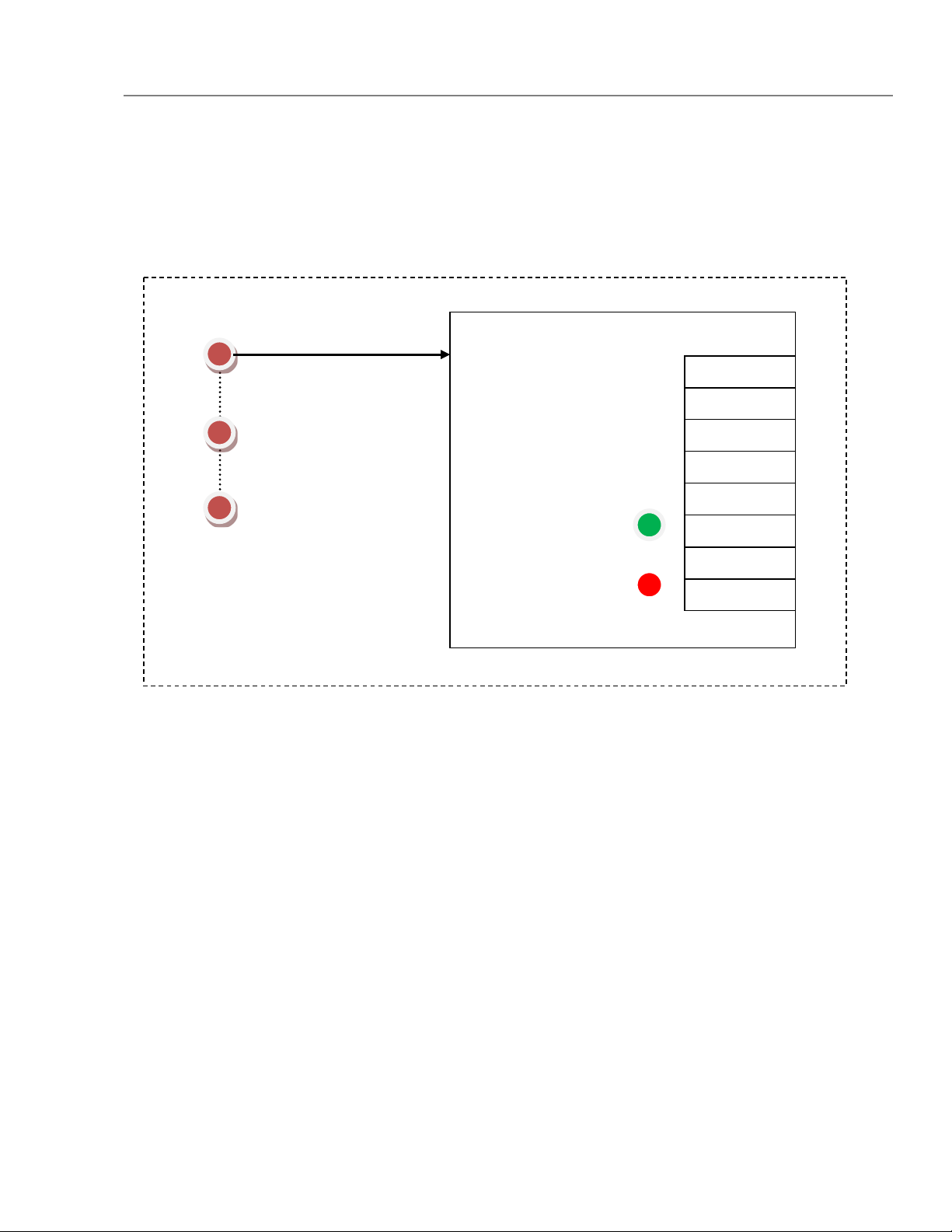

7. Theory of Operation ..............................................................20

8. Application Notes ..................................................................21

8.1. Determining System Loss Budget For Chaining Multiple Switches ..............................21

9. Mechanical Reference Drawings..........................................23

9.1. MR380-1 Controller .........................................................................................................23

9.2. MR382-2 Sensor ..............................................................................................................23