Safety notice

Please carefully read the manual before using the product.

Safety operation

Users must follow safety operation rules made by the country and the company.

Mechanical danger

Operation and repair of automation equipment are a little dangerous and are careful. Please

be far away from the working equipment. Please control the equipment by correctly using the

panel’s buttons. Don’t wear so loose clothes when using and repairing the equipment.

High-voltage danger

Be careful of electric shock during operation. Please install the equipment according to its

manual. Don’t touch cables or wires after power on. Only professional maintenance personal

can open the controller. When the equipment has problems, power should be off and then

repair.

Power isolation

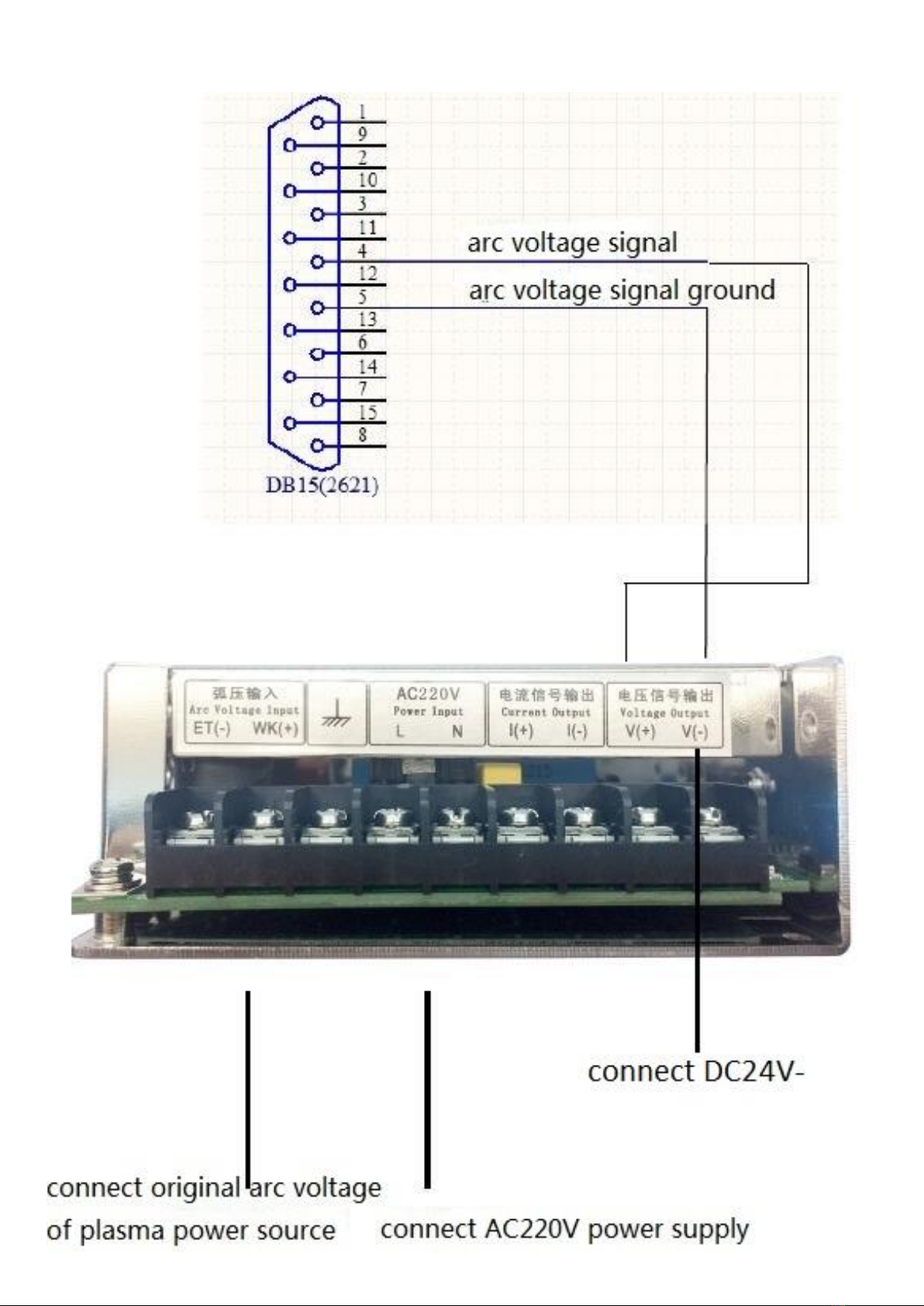

Please check whether power is right, DC24V before power on.

Good ground-connection

All parts of the cutting machine and the controller should connect ground.

The most effective method of reducing plasma interference is to use shielding wire and good

ground-connection. Controller’s ground wire diameter should be over 4 mm², and try to keep a

shorter distance to the ground. DC24V ground (-) must break with ground.

Controller maintenance

When the controller can’t work normally, you need to check relative hardware or wire

connection after power off. Don’t open the controller to repair without professional personnel.

Please feel free to let us know when the controller has problems.

Warranty statement