Chapter 1 Table of contents

Chapter 1 Table of contents

Cover 1

Chapter 1 Table of contents 3

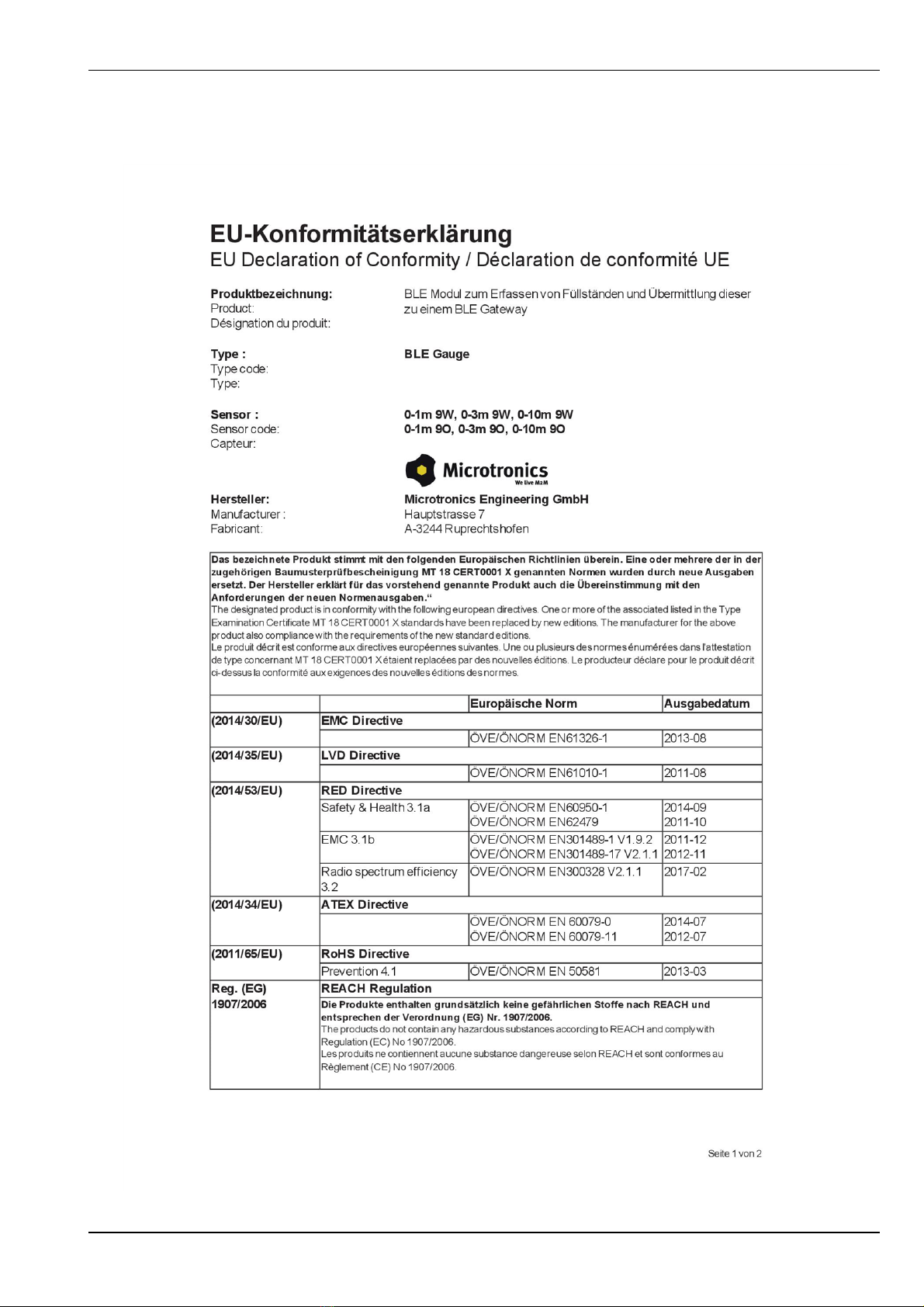

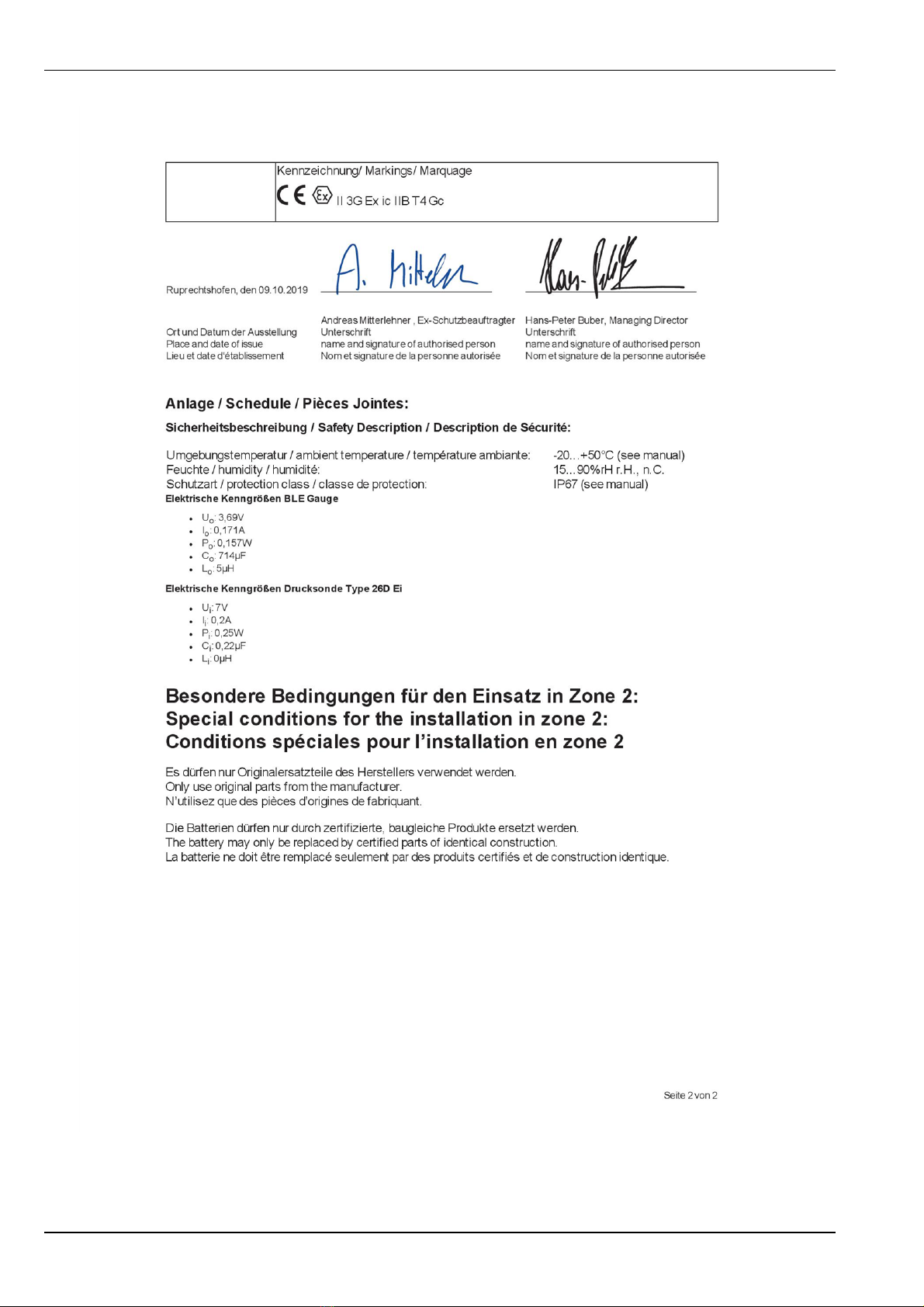

Chapter 2 Declaration of conformity 7

Chapter 3 Specifications 9

3.1 Applicable regardless of the selected pressure sensor 9

3.2 BLE Gauge pressure sensor 0-1m 9W (300872) 9

3.3 BLE Gauge pressure sensor 0-3m 9W (300871) 10

3.4 BLE Gauge pressure sensor 0-10m 9W (300891) 10

Chapter 4 General specifications 11

4.1 Translation 11

4.2 Copyright 11

4.3 General descriptive names 11

4.4 Ex protection 12

4.5 Safety instructions 12

4.5.1 Use of the hazard warnings 13

4.5.2 General safety instructions 13

4.5.3 Safety and preventative measures for handling Bluetooth modules 13

4.5.3.1 Safety and precautionary measures for the Bluetooth module installation 14

4.6 Overview 14

4.6.1 Block diagram 15

4.7 Intended use 15

4.8 General product information 15

4.9 Device labelling 16

4.10 Installation of spare and wear parts 17

4.11 Storage of the product 17

4.12 Obligation of the operator 18

4.13 Personnel requirements 18

Chapter 5 Functional principle 19

5.1 Determining the fill level 20

5.1.1 Determining the raw value (relative pressure) 20

5.1.2 Calculating the fill level 20

Rev. 02 3