Mid-tech Legacy 6000 User manual

Legacy 6000

User Guide

98-05053

FieldwareFieldware

For Legacy 6000

USER GUIDE

PN - 98-05053

R0

Chapter 1 - System Introduction...................................................................................... 1-1

System Introduction ...................................................................................................... 1-2

Mid-Tech CAN Bus System Overview......................................................................... 1-5

The Legacy 6000 Console ......................................................................................... 1-5

CAN Modules (PCM, SSM, PSM).......................................................................... 1-10

Typical Legacy 6000 Configurations.......................................................................... 1-13

Single Channel Liquid Flow Meter ......................................................................... 1-13

Chapter Notes............................................................................................................... 1-19

Chapter 2 - Getting Started .............................................................................................. 2-1

Software Overview......................................................................................................... 2-2

Powering Up .............................................................................................................. 2-2

Standard Pages........................................................................................................... 2-3

System Setup .................................................................................................................. 2-9

Console Setup ............................................................................................................... 2-10

Lightbar Setup ............................................................................................................. 2-12

GPS Receiver Setup ..................................................................................................... 2-14

Product Control Module Setup .................................................................................. 2-16

Implement Setup .......................................................................................................... 2-29

The Vehicle Coordinate System .............................................................................. 2-29

System Tools................................................................................................................. 2-42

Chapter Notes............................................................................................................... 2-48

Chapter 3 - Real-time Setup............................................................................................. 3-1

Operation Overview ...................................................................................................... 3-2

Starting a Job ................................................................................................................. 3-4

Selecting an Existing Job........................................................................................... 3-4

ARM Launcher .............................................................................................................. 3-7

No PCMCIA Card Setup ........................................................................................... 3-7

Performing a Calibration.............................................................................................. 3-9

Introduction................................................................................................................ 3-9

Entering Job Information ........................................................................................... 3-25

Running ARM Setup ................................................................................................... 3-33

No PCMCIA Card Selected ..................................................................................... 3-35

Running Product Setup ............................................................................................... 3-43

The Select PCM Page .............................................................................................. 3-44

Chapter Notes............................................................................................................... 3-54

Chapter 4 - Real-time Operation...................................................................................... 4-1

Product Application....................................................................................................... 4-2

System, Warning and Error Messages ..................................................................... 4-10

Real-time Guidance Operation................................................................................... 4-14

Lightbar Curved Guidance Graphics ........................................................................ 4-26

Applied Area Detection ............................................................................................... 4-27

Detecting A Previously Applied Area ..................................................................... 4-27

Detecting Neighboring Swath.................................................................................. 4-27

Mapping a Field Boundary ......................................................................................... 4-29

Mapping Points and Hazards ..................................................................................... 4-31

Exiting Real-Time Operation ..................................................................................... 4-34

Lightbar Index ............................................................................................................. 4-35

Data Transfer and Report Generation ...................................................................... 4-38

Transferring Data ..................................................................................................... 4-38

Creating an Application Report in Map Manager ................................................... 4-38

Chapter Notes............................................................................................................... 4-39

Midwest Technologies IL, LLC

Fieldware for the Legacy 6000

Chapter 1 - System Introduction

An introduction to the Legacy 6000 System.

Fieldware for the Legacy 6000 Version 1

1-2 Chapter 1 - System Introduction

System Introduction

Fieldware for The Legacy 6000

Software Version 1

System Introduction

The Legacy 6000 system allows the control of all product types, plus GPS mapping, guidance, and

data collection in a single console. Replacing multiple consoles in the cab with one robust system,

Mid-Tech's Legacy 6000 sets a new standard for control systems of the future.

The Legacy 6000 runs Fieldware software in a Windows CE environment, an extremely depend-

able and stable operating system. Operation is intuitive with on-screen menu choices and

prompts. An on-board help menu is built in. The heart of the Legacy console is an Intel processor

operating at 206 Megahertz for maximum efficiency.

System Features

System features include:

• Product control with optional integrated guidance

• Three guidance modes, Headland, Parallel and Center Pivot.

• Single console in the cab with a single cable connection to the console

• Simplifies operation of product control and GPS record keeping

• Works with Mid-Tech's Swath XL lightbar

• Comes fully loaded with “Fieldware for the Legacy 6000” software

• Precise control of liquid & dry products on common delivery systems

• Flow- or pressure-based liquid control with multiple sensor inputs for each product

• Handles up to 20 individual boom sections and 4 swaths

• Up to 5 application rates per product can be preset and accessed on the go

• Supports granular application control using 2 rate sensors per product

• Compatible with most sensors, valves, and D.C. drives

• Operates bi-directional or PWM valves

• Operator selectable gain settings for control valves

• Adding additional product control is easy

• Single high speed bus cable coming into cab

Fieldware for The Legacy 6000

Software Version 1

Chapter 1 - System Introduction 1-3

System Introduction

CAN Bus Versatility and Value

The Legacy 6000 utilizes CAN Bus technology, a new industry standard, which Mid-Tech uses to

execute precise product control in an environment more robust than any of its predecessors.

What is a CAN Bus and why use one?

Controller Area Network (CAN) is a system comprised of independent, intelligent modules con-

nected by a single high-speed cable, known as a bus, over which all the data in the system travels.

CAN was originally developed for the automotive industry to provide a cost effective means for a

large number of electronic functions or systems to be interconnected without large, expensive and

troublesome wiring harnesses.

Within a CAN system, each module contains its own microprocessor. All modules share a stan-

dard protocol or communication sequence, which conforms to the ISO 11898 standard. Since

modules have built-in computing power, a CAN system is extremely flexible and easily expands to

meet a customer's needs.

Individual modules have a specific and unique function to execute, as well as the responsibility to

constantly report that function and its current status. Data on the CAN is available many times a

second allowing the operation of a very fast, responsive control system.

The Legacy 6000 uses 4 types of modules, each having a unique function. Each described in

more detail below. The console in the cab is one of these modules and serves as the user inter-

face. The remaining modules are positioned around the chassis close to the area they influence.

For instance, the Product Control Module (PCM) connects to the actuator and sensor and controls

the actual release of the product. To upgrade from one-product to three-product application (or

more) is simply a matter of adding additional PCM's to the system.

1-4 Chapter 1 - System Introduction

System Introduction

Fieldware for The Legacy 6000

Software Version 1

Fieldware for the Legacy 6000

Plug any standard submeter GPS receiver and Mid-Tech's CAN based Swath XL lightbar into the

Legacy 6000 system, and enjoy straight-line, curved or center pivot guidance at your command.

Application maps can be viewed on the Legacy 6000 display as you apply. Cross track error, area

applied, application rates, and other vital information display on the Swath XL lightbar in real time.

Features of Mid-Tech's Fieldware software, developed specifically for the Legacy 6000, include:

• Application Rate Management - permits precise fixed or variable rate application.

• Extensive Product Control Module setup.

• Full system calibration including, granular, liquid, liquid injection and distance.

• CAN Bus, GPS receiver and lightbar diagnostics.

• Create application jobs keeping track of customer, weather and product information.

• Large product database with over 4000 entries containing product name, formulation, and EPA

number.

• Integrated guidance using straight line, headland, or center pivot modes, plus text reporting to

the lightbar, in one easy to use format.

• Report generation - full application reports and maps can be generated in Fieldware Map Man-

ager PC software at the end of the day. An application report contains a map of the applica-

tion, customer information, product information, as well as weather, field, and soil conditions.

Fieldware for The Legacy 6000

Software Version 1

Chapter 1 - System Introduction 1-5

Mid-Tech CAN Bus System Overview

Mid-Tech CAN Bus System Overview

The Mid-Tech CAN bus system is comprised of several components (modules). The Console, the

Power Speed Module (PSM), the Switch Sense Module (SSM), a Product Control Module (PCM),

and a Lightbar. At a minimum, four of these modules are required to have a fully functional Legacy

6000 single product control system. The lightbar is optional. To control more than one product, you

will need to add an additional PCM for each additional product you choose to control.

The Legacy 6000 Console

Dimensions: 8.0" Wide x 7.7" High x 4.5" Deep (203 x 196 x 114 mm)

Weight: 2.3 lbs. (1.0 kg)

Enclosure: High impact plastic; back lighted, tactile feed-back switches on front panel

Display: 5.7" diagonal (120 x 90 mm), transflective, QVGA with CCFL back lighting. Brightness

and contrast controlled by switches on the front panel of the console.

Input/Output: CAN, Bosch 2.0B, Mid-Tech proprietary protocol

Serial: RS 232 (2)

USB: (1)

Memory: 32 Mbytes DRAM, 32 Mbytes Flash

Microprocessor: 32-bit Intel StrongArm, SA 1110 with SA 1111 companion chip. 206 MHz.

Drives: PCMCIA type II, single slot

Operating System: Microsoft Windows CE 3.0

Power Requirement: 9 to 16 volts DC

Connector: Sealed, 31 pin Deutsch

GPS Receiver Compatibility: Compatible with any differentially corrected submeter GPS (DGPS)

receiver which outputs NMEA 0183 at 2 to 10 Hz.

Alarm: Audible alarm

Other:

* Real-time clock with battery back-up

* Simple, yet versatile, RAM mounting system.

1-6 Chapter 1 - System Introduction

Mid-Tech CAN Bus System Overview

Fieldware for The Legacy 6000

Software Version 1

Power Speed Module

The Power Speed Module (PSM) is the primary arbitrator of the Bus. This module includes the

input point for the speed sensor, the input for power for the CAN bus, a gateway to communicate

with a parallel CAN bus and provides a fully functional RS-232 port as alternative I/O.

Inputs

Speed 1: digital, 0-12 VDC, optimized for 50% duty cycle, 0-5 KHz, primary input

Speed 2: digital, 0-12 VDC, optimized for 50% duty cycle, 0-5 KHz, secondary input

Ignition sense: digital, 0-12 VDC, (Hi state is ON)

Inputs/Outputs

Mid-Tech CAN: Bosch 2.0B, 29 bit ID, 250K baud

Gateway CAN: Bosch 2.0B, 11 or 29 bit ID, 250K baud

Serial RS 232: Txd, Rxd, Rts, Cts and ground.

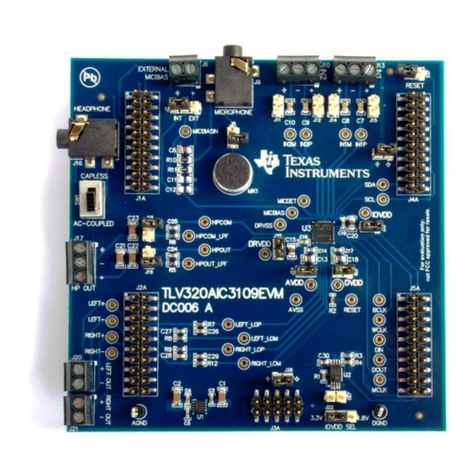

Figure 1-1: Power Speed Module

Fieldware for The Legacy 6000

Software Version 1

Chapter 1 - System Introduction 1-7

Mid-Tech CAN Bus System Overview

Switch Sense Module

The Switch Sense Module (SSM) senses the status of switches aboard the machine and trans-

forms the switch state into messages meaningful to the CAN Bus.

Inputs

Booms inputs: up to 20, digital, 0-12 VDC, HI/LO sensing

Ground speed override:1 input, digital, 0-12 VDC, HI/LO sensing

Machine status: 1 input, digital, 0-12 VDC, HI/LO sensing

Input/Outputs

Mid-Tech CAN: Bosch 2.0B, 29 bit ID, 250K baud

Figure 1-2: Switch Sense Module (SSM)

1-8 Chapter 1 - System Introduction

Mid-Tech CAN Bus System Overview

Fieldware for The Legacy 6000

Software Version 1

Product Control Module

The Product Control Module (PCM) performs the actual control function for the Mid-Tech CAN Bus

and connects the actuator and sensor. Control outputs can be bi-directional. One PCM is required

for each product you wish to control.

Inputs

Digital sensor: 4 inputs, digital, 0-12 VDC, 0-5 KHz

Analog sensor: 2 inputs, analog, 0-5 VDC. One of these inputs can be converted to a 4-20 ma sen-

sor input by software command.

Battery: 1 Battery Power for the actuator outputs, 12-24 VDC, 10 amp

Outputs

Actuator: 2 outputs, 0-12 VDC, 5 amp each

Regulated: 1 output, 11 VDC, 3 amp

Switched: 1 output, 12 VDC, 5 amp

Sensor power: 3 outputs, 12 VDC, 300 mA total

Input/Outputs

Mid-Tech CAN: Bosch 2.0B, 29 bit ID, 250 K baud

Serial: Asynchronous RS 232, Rxd and Txd only

Figure 1-3: Product Control Module

Fieldware for The Legacy 6000

Software Version 1

Chapter 1 - System Introduction 1-9

Mid-Tech CAN Bus System Overview

Swath XL Lightbar

A CAN based Swath XL Lightbar was developed specifically for the Legacy 6000 system. The

Lightbar is required for applications using guidance and recommended for non-guidance uses as

well. In non-guidance use (logging data only) the lightbar can provide area and rate feed back.

Dimensions: 16.0" Wide x 3.0" High x 3.0” Deep (405 x 76 x 76 mm)

Weight: 8 oz. (0.22 kg)

Enclosure: Sealed ABS / Poly carbonate alloy construction. Can be mounted to the exterior of the

vehicle.

Cable: Mid-Tech proprietary CAN Bus cable. Cable extension available.

Front Panel LEDs: High-lumen red, yellow and green, adjustable brightness.

Text Display: 8-character, high intensity LED alphanumeric text display, brightness adjustment.

Mounting Bracket: Big grippy knobs, can be mounted on dash, from ceiling on vertical plane,

interior or exterior.

Figure 1-4: Swath XL Lightbar

1-10 Chapter 1 - System Introduction

Mid-Tech CAN Bus System Overview

Fieldware for The Legacy 6000

Software Version 1

CAN Bus Cable Specifications

5-wire cable with molded connectors. Male or female terminator required on each end.

Pin 1: Ground

Pin 2: +12V

Pin 3: Reserved

Pin 4: CAN High

Pin 5: CAN Low

Speed: 250k baud message update

Module Processor: Siemens C167

Module CAN interface: Siemens 82C250

Message Protocol: Bosch 2.0B

CAN Modules (PCM, SSM, PSM)

Dimensions: 4.7" W x 2.3" H x 6.0" D (120 x 60 x 150 mm)

Weight: 1.9 lbs. (0.9 kg)

Materials: Powder coated cast aluminum

Figure 1-5: CAN Modules

Fieldware for The Legacy 6000

Software Version 1

Chapter 1 - System Introduction 1-11

Mid-Tech CAN Bus System Overview

Cable Harnesses

Power Speed Module (PSM)

Switch Sense Module

Figure 1-6: Power Speed Module Harness

Figure 1-7: Switch Sense Module Harness Options

1-12 Chapter 1 - System Introduction

Mid-Tech CAN Bus System Overview

Fieldware for The Legacy 6000

Software Version 1

Product Control Module

Figure 1-8: Power Control Module Harness

PCM Cable Options

Sensor Inputs

Part Number A B C D E F CAN PWR Valve Sen. Description

45-06300 X X X X 1 Single Sensor

45-06301 X X X X X 2 Single Sensor w/rpm

45-06302 X X X X X X 3 Dual Sensor w/rpm

45-06303 X X X X X 2 Single Sensor w/press

45-06304 X X X X 1 Pressure Control Single

45-06305 X X X X X 2 Pressure Control, Dual

Table 1-1: PCM Cable Options

Fieldware for The Legacy 6000

Software Version 1

Chapter 1 - System Introduction 1-13

Typical Legacy 6000 Configurations

Typical Legacy 6000 Configurations

The following schematics reflect some typical Legacy 6000 configurations. Due to the variety of

possible configurations, these schematics should be used for general reference. Contact Midwest

Technologies or your dealer for detailed information regarding your specific configuration and

installation.

Single Channel Liquid Flow Meter

Figure 1-9: Single Channel Liquid Flow Meter Configuration

1-14 Chapter 1 - System Introduction

Typical Legacy 6000 Configurations

Fieldware for The Legacy 6000

Software Version 1

Single Channel Granular Spreader

This is a typical single product granular configuration with spreader control.

Figure 1-10: Single Channel Granular Spreader Configuration

Table of contents

Popular Control Unit manuals by other brands

CleaverBrooks

CleaverBrooks CB780 Operation and maintenance manual

ABB

ABB REC650 ANSI Applications manual

Harvia

Harvia SIGMA COMBI CS110C Instructions for installation

GEM

GEM 762 Installation, operating and maintenance instructions

Huawei

Huawei MU609 Development kit guide

AT&T

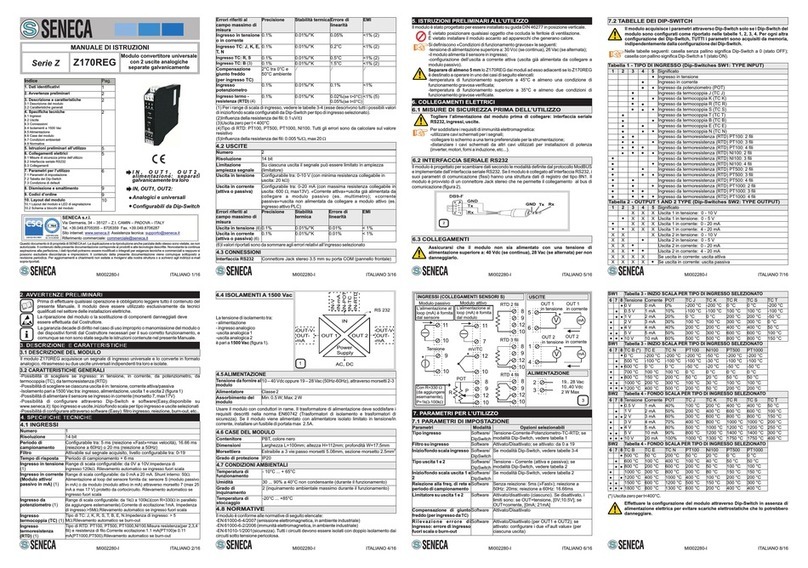

AT&T 6386/33 Hardware installation