4

ENGLISH

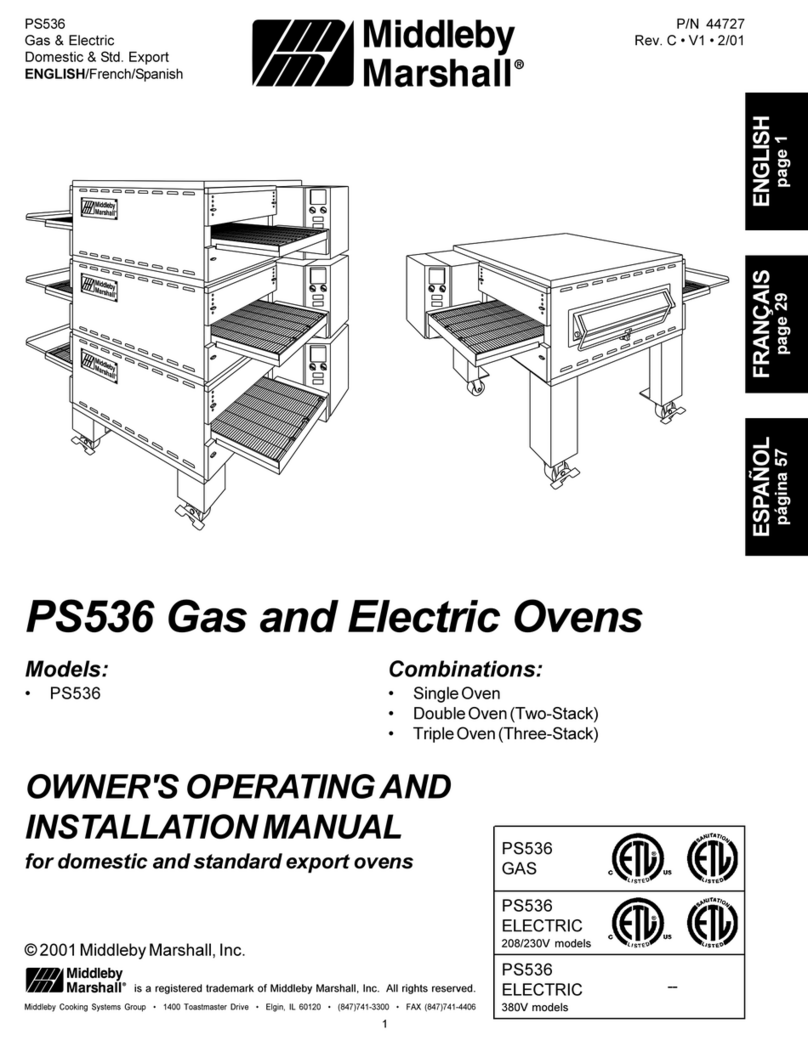

SECTION 1 - DESCRIPTION

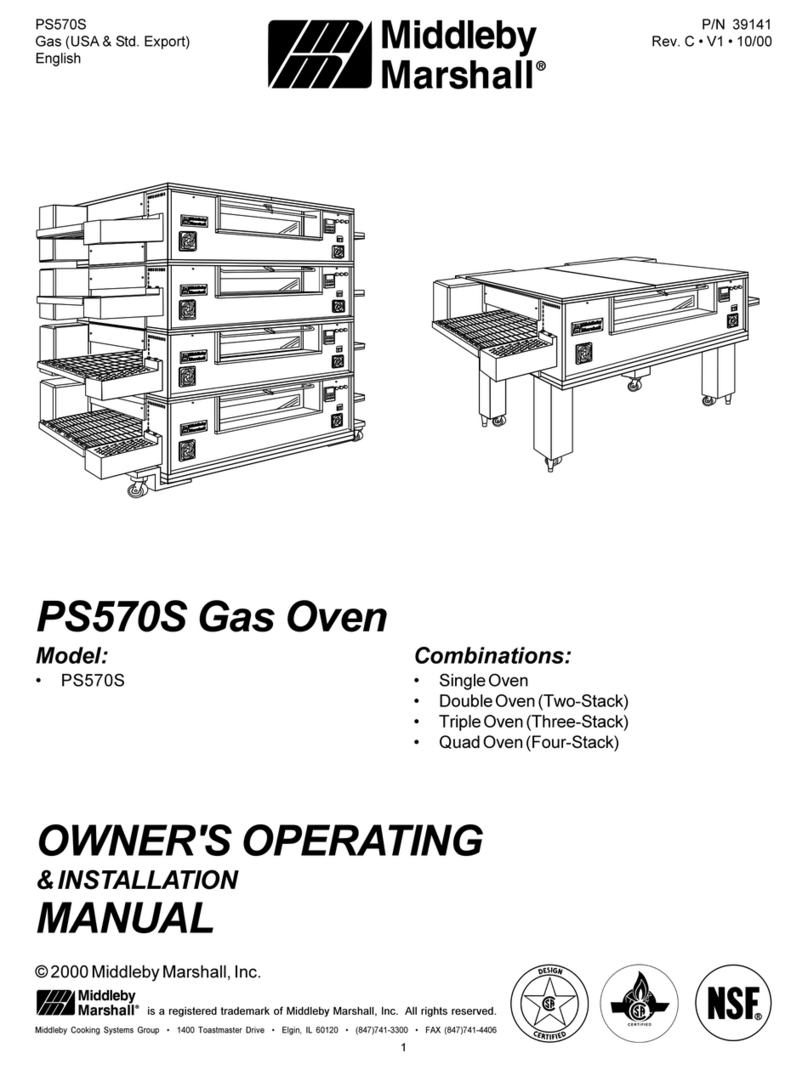

II. OVEN COMPONENTS - see Figure 1-1.

A. Conveyor Drive Motor: Moves the conveyor.

B. Crumb Pans: Catch crumbs and other material that drop

through the conveyor belt. One crumb pan is located at

each end of the conveyor.

C,D. ConveyorEnd StopandRear Stop: Preventsfood products

from falling off the end or rear of the moving conveyor.

E. Conveyor: Moves the food product through the oven.

F. End Plugs: Allow access to the oven's interior.

G. Eyebrows: Can be adjusted to various heights to prevent

heat loss into the environment.

H. Window: Allows the user to see and access food products

inside the baking chamber.

I. Machinery Compartment Access Panel: Allows access

to the oven's interior and control components. No user-

servicable parts are located in the machinery compart-

ment.

I. OVEN USES

PS500 Series Ovens can be used to bake and/or cook a

wide variety of food products, such as pizza, pizza-type

products, cookies, sandwiches and others.

J. Serial Plate: Provides specifications for the oven that affect

installation and operation. Refer to Section 2, Installation,

for details.

K. Control Panel: Location of the operating controls for the

oven. Refer to Section 3, Operation, for details.

Not Shown:

L. Gas Burner: Heats air, which is then projected to the air

fingers by the blowers.

M. Blowers: Project hot air from the burner to the air fingers.

N. Air Fingers: Project streams of hot air onto the food product.

Figure 1-1 - Oven Components

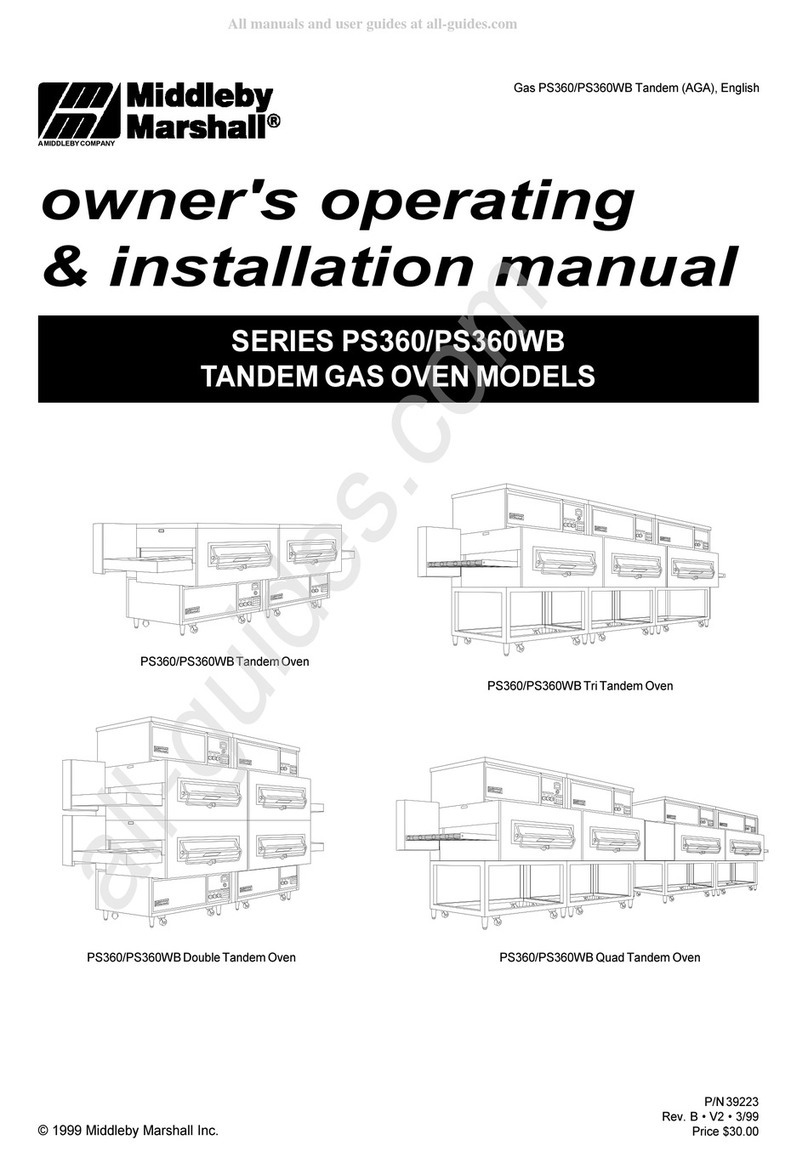

Single Oven Double Oven Triple Oven Quad Oven

Table 1-1: Dimensions PS555 PS570S PS555 PS570S PS555 PS570S PS555 PS570S

Overall Height

46-1/8 46-1/8 60-1/8 60-1/8 62-1/2 62-1/2 78 78

(inc. top and legs, as appropriate) 1172mm 1172mm 1527mm 1527mm 1588mm 1588mm 1981mm 1981mm

Overall Depth

63-3/8 63-3/8 63-3/8 63-3/8 63-3/8 63-3/8 63-3/8 63-3/8

(inc. rear shrouds) 1610mm 1610mm 1610mm 1610mm 1610mm 1610mm 1610mm 1610mm

Overall Length

91 106 91 106 91 106 91 106

2311mm 2692mm 2311mm 2692mm 2311mm 2692mm 2311mm 2692mm

Conveyor Width

32 32 32 32 32 32 32 32

813mm 813mm 813mm 813mm 813mm 813mm 813mm 813mm

Recommended Minimum Clearances

Rear of Oven (inc. rear shrouds) to Wall 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm)

Conveyor Extension to Wall (both ends) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm) 0 (0mm)

Table 1-2: General Specifications (per oven cavity) PS555 PS570S

Weight 900 lbs. (408.6kg) 1400 lbs. (634kg)

ShippingWeight 1250 lbs. (567.5 kg) 1750 lbs. (780kg)

ShippingCube 160.3 ft

3

(4.5m

3

) 160.3 ft.

3

(4.57m

3

)

Rated Heat Input 135,000 BTU (34,020 kcal, 40 kW/hr) 170,000 BTU (42,840 kcal, 50 kW/hr)

MaximumOperating Temperature < - - - - - - - - - 550°F / 288°C - - - - - - - - - >

Air Blowers Two blowers at 1400 ft.

3

/min. (39.6m

3

/min.) at 2050 RPM, 0.40" (1.0cm) Water Static Pressure

Average Air Jet Velocity < - - - - - - - - - 2600 ft./min. (1320cm/sec.) average - - - - - - - - - >

WarmupTime < - - - - - - - - - 15 min. - - - - - - - - - >

Table 1-3: Gas orifice and pressure specifications (per oven cavity)

Main Orifice Main Orifice Orifice (Manifold)

Gas Type I.D. - PS555 I.D. - PS570S Pilot Orifice I.D. Supply (Inlet) Pressure Pressure

Natural 0.219(5.56mm) 0.250 (6.35mm) 0.028 (0.71mm) 6-12 W.C. (14.9-29.9mbar) 3.5 W.C. (8.7mbar)

Propane 0.134(3.40mm) 0.152 (3.86mm) 0.018(0.46mm) 11-14W.C. (27.4-34.9mbar) 10 W.C. (24.9mbar)

Table 1-4: Electrical specifications (per oven cavity)

Main Blower Voltage Control Circuit Voltage Phase Freq Current Draw Poles Wires

208-240V 120V conveyor speed controller (w/transformer); 1 Ph 50/60Hz 12A 2 Pole 3 Wire (2 hot, 1 gd)

all other control circuits as per line (208-240V)

IMPORTANT: Additional electrical information is provided on the oven's serial plate, and on the wiring diagram inside the

machinery compartment.

III. OVEN SPECIFICATIONS

C

BA

EFG H

J

I

K

D