Midwest Model 220 Technical specifications

Installation & Maintenance Instructions

Model 220

Hazardous Locations Division Classified

Electrical Configurations: A,B, J, & K

Reading Office

Cutbush Park, Danehill, Lower Earley,

Reading, Berkshire. RG6 4UT. UK.

Tel: +44 (0)118 9311188

Email: [email protected]

Aberdeen Office

Unit 6 Airside Business Park, Kirkhill Industrial Estate,

Dyce, Aberdeen. AB21 0GT. UK.

Tel: +44 (0)1224 725999

Email: [email protected]

Internet: www.able.co.uk

e-procurement: www.247able.com

Registered in England No: 01851002

VAT No: GB 417 2481 61

BULLETIN NO.ELEC IM220 ATEX/12A

Supersedes IM220 ATEX/11A

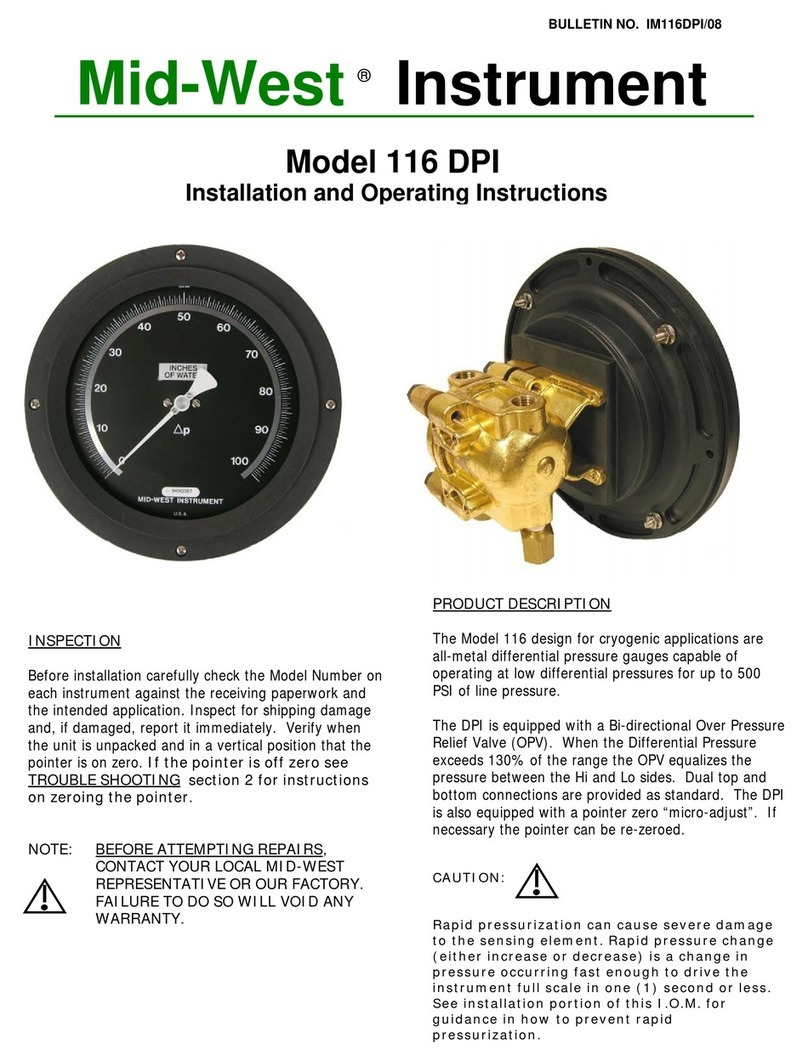

Instrument

Mid-West

®

ELECTRICAL

Upon receipt of your order, please review the ratings plate to

verify that the model number and the electrical ratings match

the product that you ordered. Electrical configuration option

R & S units are CE marked in accordance with the ATEX

directive. In addition the units will carry 3rd party markings

per the Division classification system. Please read the

Cautions listed on the Rating Plate as they are different

for each Electrical Configuration. The markings and

warnings identified on each plate are applicable only to

their respective Hazardous Locations classifications. Ie;

if the assembly is installed in an ATEX classified

location, then the ATEX ratings plate shall govern.

FIGURE 1

FIGURE 2

WARNING: This product should be installed by

personnel trained in installation of

equipment in Hazardous Locations and

meet the representative country’s National

Electrical Code.

WARNING: Electrostatic Hazard: Clean all exposed

plastic surfaces with a damp cloth. Do not

use solvents

WARNING: Failure to connect to the protective

conductor terminal may result in a shock

hazard.

WARNING: To meet Hazardous Location’s

Requirements, torque the cover bolts to the

specified values on the Ratings plate.

WARNING: The maximum gap permitted between the

body and cover is less than the maximum

permitted in the standard. Therefore it is the

responsibility of the user of this equipment

to ensure the maximum gap between the

body and the cover is not greater than

0.038mm (0.0015’’).

CAUTION: Do not scratch, nick, or dent mating

surfaces of the gauge body and the cover

during maintenance. The integrity of the

flame-proof enclosure is dependent upon

this metal to metal seal.

If cover bolts are lost or damaged, they

SHALL be purchased from Mid-West

Instrument for replacement. The bolts are

non-standard and have been designed

specifically for the referenced Hazardous

Locations in this document.

Clean Metal joint area with non-abrasive

cloth after any maintenance activity that

requires the cover to be removed. A small

amount of non-hardening grease may be

applied in the joint area.

In dust environments some minor surface

layering may occur. Routine cleaning shall

be performed for removal of the dust layer.

DIVISION 1 LOCATIONS:

Electrical Configurations R & S are 3rd Part Certified for

Class 1, Division 1, Groups B, C & D; Class 2, Division 1,

Groups E, F, & G Hazardous Locations. All Electrical

Specification Input & Output Combinations are approved

for this classification.

This configuration has T6 Temperature classification for all

input and output combinations except for the H input option

which has a T4A Temperature classification.

For Electrical Specification Input Option A in combination with

Output Options A through H, a seal is not required. This

configuration can also be classified as a “Simple Apparatus”

for use in an Intrinsically Safe System.

For Electrical Specification Input options B through H in

combination with Output option R, a seal is required within

18” of the enclosure. Please refer to National Electrical Code

requirements.

ATEX CERTIFIED

(Group II Category 2 Gas & Dust Atmospheres):

Electrical Configurations R & S are ATEX and IECEx

Certified for Gas & Dust Atmospheres as:

Ex d IIB + H

2

T 6 (-40ºC ≤Ta ≤70ºC)Gb

T 5(-40ºC < Ta < 85ºC)Gb

Ex tb IIIC IP65 T85ºC (-40ºC ≤Ta ≤70ºC)Db

T100ºC (-40ºC < Ta < 85º

C)Gb

II 2GD IP65

for Electrical input options A in combination with Electrical

Output options A, E, & H

Model 220 Electrical:

Installation and Operating Instructions

Ex d IIB + H

2

T 6 (-40ºC ≤Ta ≤70ºC)Gb

Ex tb IIIC IP65 T85ºC (-40ºC ≤Ta ≤70ºC)Db

II 2GD IP65

for Electrical input options A in combination with Electrical

Output options A, E, & H and input options B thru G in

combination with Output Option R

Ex d IIB + H

2

T 4 (-40ºC ≤Ta ≤70ºC)Gb

Ex tb IIIC IP65 T135ºC (-40ºC ≤Ta ≤70ºC)Db

II 2GD IP65

for Electrical input option H in combination with Electrical

Output option R

Installation

Tools Required: 8mm deep metric socket.

Torque wrench

Adjustable or 1.125” wrench (process

connections)

CAUTION: Do not exceed the maximum rated working

pressure stated on the ratings plate.

CAUTION: Always use a wrench (1.125”) on the

switch’s process connections to keep them

in place while loosening and tightening

customer supplied process fittings.

WARNING: Verify media compatibility with all wetted

parts. Range spring is manufactured from

316SS. Media incompatibility with the

spring or the body of the gauge can result in

an ignition hazard due to corrosion.

WARNING: Use pressure limiting devices to limit

pressure spikes below the proof pressure of

the gauge / switch.

Locate unit where temperatures will be within the limits of the

device hazardous’ locations ratings.

On liquid service the instrument should be mounted

below the process connections to facilitate self bleeding. On

gas service it should be located above the process

connections to promote self-draining. If the process contains

particulates, a “pigtail” loop or drop leg (manometer “U-tube”

configuration) in the tubing will minimize the possibility of it

migrating into the instrument. An optional pipe mounting kit is

available for mounting the gauge to a 2” vertical or horizontal

pipe.

A provision for special mounting is provided on the back of

the gauge.

Connect process piping or tubing to the pressure ports

stamped High and Low on the gauge body. Connections are

either ¼” FNPT or ½” FNPT dependent upon the option

selected when the order was placed.

Reverse pressure will not damage the instrument, however

the switch and indicator (if supplied) will not function properly.

CAUTION: Use cable suitable for the specified

temperature class. Maximum internal cable

entry temperature rise is 15 ºC – Cabling to

be suitable.

WARNING: Electrical connection shall be made with a

cable entry or stopping box certified for use

for the desired hazardous location, certified

for condition of use, and correctly installed.

The cable entry device and any thread

adaptor shall be suitable for the equipment,

the cable, and the conditions of use, and

shall be certified as equipment (Not an EC

component) under the EC Type Examination

Certificate to directive 94/9/EC.

WARNING: When used in an explosive dust

atmosphere, the cable entry device and

thread adaptor shall maintain the ingress

protection of the enclosure.

WARNING: During maintenance do not disconnect from

external earth conductor until all power

generation systems have been turned off.

WARNING: In Hazardous Locations remove power from

the unit before removing the cover.

WARNING: Do not touch the surface of the printed

circuit board if the unit is powered. High

Voltage may be present.

Remove the cover by using an 8mm hex driver to loosen the

bolts from the underside of the gauge body. (see previous

cautions and warnings). The bolts are captive in the body of

the gauge. A deep metric socket is recommended in order to

clear an interference near the bezel of the gauge. (0.48

diameter min 1” long).

Connections to the terminal strip are identified in the following

sections. The terminal strip is compatible for wire ranges

from 12-22 AWG ( 3.3 - .32 mm

2

). Optionally, each

connection can be field wired with multiple wires connected

to one contact. You may connect two (2) 22 – 16 AWG (0.33

-1.3 mm

2

) wires into one connection. Recommended screw

torque is 6 in. lbs. (0.113 newton-meter) to tighten the

terminal strip screw.

Each Assembly is provided with strain relief clamps. Use

these clamps to provide strain relief when field wiring the

instrument.

For the non-gasketed assembly, clean both mating metal

surfaces prior to re-assembly (see previous cautions and

warnings). A small application of a suitable, non-hardening

grease may be applied to the mating metal surfaces.

Replace cover making sure there are no wires pinched

between the cover and the gauge body. Re-tighten the

screws within the range of 60 to 75 in-lbs.

Switch Configurations:

The Model 220 indicating / non-indicating differential

pressure switch is configured with one of the outputs

identified in the table below.

OUTPUT RATINGS (Resistive Load)

Type SPST SPDT SPDT DPDT

Relay

ELEC Spec. A A A B,C,D,E,F,

G, H

Output

Option Code

E, F, or G H A R

*Power 60 W 60 W 3W N/A

Max. Current

3 Amps 1.0 Amps 0.25 Amps 10 Amps

Max. Volts

VAC/ VDC

240 240 125 277 / 30

Setting

(F.S.)

15% to 90%

25% to 90%

10% to 90%

15% to 90%

Hysterisis

(Max/Nom)

20% / 9%

Full

Scale(F.S.)

20% / 18%

Full

Scale(F.S.)

10% / 6%

Full

Scale(F.S.)

20% / 10%

Full

Scale(F.S.)

Repeatability

1% F.S. 1% F.S. 1% F.S. 1% F.S.

Table I

* Product of the switching voltage and current shall not

exceed the power rating of the device.

Hermetically Sealed Switch Outputs:

Electrical Specification Input Option “A” identifies that your

unit does not need input power to operate the switch output

and that your unit is equipped with Hermetically Sealed Reed

switches. The “A” option matched with Output Options A, E,

& H identifies the output capability of your unit. Depending on

the electrical configuration specified on the order (A, B, R, or

S), your unit will be equipped with 1 or 2 independently

adjustable reed switches.

Interface to the 16 position terminal strip shown in Figure 3 is

defined in Table II.

Terminal Connections

Electrical

Options

Qty

Sw. Function Switch Adjust

Low Port

Switch Adjust

Hi Port

RAA, RAH 1 SPDT 1(COM), 2(NO),

3 (NC) No Connection

SAA, SAH 2 SPDT 1(COM), 2(NO)

3 (NC)

8(COM), 7(NO)

6 (NC)

RAE 1 SPST

NO 1,2 No Connection

RAF 1 SPST

NC 1,3 No Connection

SAE 2 SPST

NO 1,2 8,7

SAF 2 SPST

NC 1,3 8,6

SAG 2 SPST 1

NO, 1NC 1, 3 NC 8, 7 NO

Table II

Chassis connection is to position 12 or 13.

Customer Interface for the Reed Switch Output Option will be

via connections 1 through 8 and connections 12 or 13. Do

not loosen the connections at positions 9, 10, 11, 14, 15 , or

16.

All switch types are field adjustable. The defined range of the

adjustment is specified in Table I above. All switches come

with a decal to identify adjustment direction to increase the

set point. Do not use excessive force when rotating the

adjustment screw as the adjustment mechanism may be

damaged (See Figure 4).

Note: Switches can be set below the defined minimum set

point however, the switch may not remain activated at

maximum PSID. If the unit is set below the defined minimum

set point, the customer should verify that the switch remains

activated from the set point to full over range of the gauge.

Provide standard protection techniques for the switch

contacts for capacitive and inductive loads. Use current

limiting techniques near the switch to protect the contacts

due to high inrush (i.e.; in line resistor or inductor) for long

cable interfaces. Provide clamping devices at or near

inductive loads (i.e.; relay). Maximum wire length between

the 3W switch and its load, should not exceed 70 – 100

Feet. for 120 VAC applications. Contact the factory for

assistance regarding this condition.

FIGURE 4

Figure 3: Reed Switch Terminal Strip Output Interface

Customer

Interface

Low

Port

High

Port

Switch

Adjust

Low Port

High Port

Pro

tective

Terminal

Simple Apparatus:

Electrical configurations R & S in combination with Input

option A, in combination with output options A, E, F,G or H

are classified as “Simple Apparatus” when used in

Intrinsically Safe circuits. These configurations comply with

EN50020:2002 clause 5.4. In addition, per the agreement of

CENELEC sub-committee SC31-3, simple apparatus do not

fulfill the definition in Article 1 of Directive 94/9/EC and

therefore fall outside the scope of the Directive. Also, they do

not require a declaration of conformity or CE mark related to

this directive.

If the product is used as “Simple Apparatus within a

Hazardous atmosphere please note the following items:

1) The switch shall be installed by personnel trained in

the installation of equipment in Hazardous Locations.

2) The configurations classified as intrinsically safe have

no source of internal heating. For temperature

classification, take into account the temperature of

the process and the maximum temperature specified

in this document.

3) It is the responsibility of the user to identify that the

installed device is identified as a “Simple Apparatus”

device. For the identified configurations it is possible

that for an intrinsic safe system that the switch could

be installed in a location outside of the Hazardous

Locations marking identified on the ratings plates(s)

Relay Output Interface

Electrical Specification Input Option “B” through “H” identifies

that your unit will need input power to operate the relay

output (output option R). Depending on the electrical

configuration specified on the order (R or S) your unit will be

equipped with 1 DPDT output or 2 independently adjustable

SPDT Relay outputs. Table I identifies the load ratings and

the adjustability range of the output.

Interface to the 16 position terminal strip shown in Figure 5 is

defined in Table III.

The relay outputs are uncommitted and may be connected to

any load provided the load is within the output ratings of the

relay. The terminal strip is compatible with 22 – 12 Awg. wire.

Deviations from the above configurations may exist.

Therefore check the description block of your order to verify

your configuration.

FIGURE 6

FIGURE 5

Terminal Connections

Switch Adjust

Lo Port

Switch Adjust

Hi Port

Electrical

Options

Qty

Sw. Func.

Com NO NC Com NO NC

R*R, 1 DPDT 1

9

2

10

3

11

X X

X

S*R, 2 SPDT

1

2

3

8

7 6

TABLE III

* = Input Power Options B, C, D, E, F, G, & H

Input Power = Position 4 + for DC; Hot for AC

Position 5 Rtn. for DC, Neutral for AC

Connection 13

See Decal on Inside Cover for additional connection

information.

Reed Sw Output

Relay Output

(AC Input0

Relay Output:

(DC Input)

TROUBLE SHOOTING

1. Gauge does not indicate differential.

A. Check for proper hook up, high to “hi” and low

to “lo”.

B. Make certain block valves are open and, if using

a 3-valve manifold, that the equalizer (balance)

valve is closed.

C. If A & B check out correctly, loosen or disconnect

the high pressure line to determine if there is

pressure to the instrument.

D. If there is pressure to the instrument, check to

determine that there is differential across the

unit being monitored. If so, contact the factory

for assistance and/or an “RGA” (return goods

authorization) number to return the instrument

for repair or replacement.

2. Switch doesn't function

A. Make sure you have supplied power (proper voltage)

to the unit if you ordered the power relay unit. The

reed switch output units do not require power.

B. Check that you are wiring to the correct Interface

terminals.

C. Check the reed switch interfaces to the terminal board

for loose connections. For the power relay the reed

switch(es) connect to the terminal strip on the

underside of the PCB. For the reed switch outputs the

reed switch(es) connect to positions on the bottom row

of the terminal strip on the top of the PCB (see Figure

4).

D. Make sure that the switch load does not exceed the

specified wattage rating of the switch. (steady-

state and transient). For this condition you must

contact the factory

3. Gauge accuracy and set point problems:

A. Verify gauge is not in an electromagnetic /

magnetic environment. i.e.; close proximity to high

current power lines.

B. All others, contact the factory for assistance

FIGURE 6

STANDARD MODEL SPECIFICATIONS

220-AC-02-0(RAA), 3000 P.S.I.G. Working Pressure, Aluminum wetted pressure containing body assembly, stainless steel/ceramic

magnet internals, Buna N Seals, 4 1/2" Round Dial, 1/4" FNPT End Connections, Engineering Plastic Gauge Case with Shatter

Resistant Acrylic Lens. One 3W, 0.25 AMP, 125 VAC/VDC SPDT Reed Switch with terminal strip in an Aluminum Explosion-proof

switch enclosure with 1/2" FNPT Electrical Access ATEX Certified

220-SC-02-0(RAA), 3000 P.S.I.G. Working Pressure, 316 S.S. wetted pressure containing body assembly, , stainless steel/ceramic

magnet internals, Buna N Seals, 4 1/2" Round Dial, 1/4" FNPT End Connections, Engineering Plastic Gauge Case with Shatter

Resistant Acrylic Lens. One 3W, 0.25 AMP, 125 VAC/VDC SPDT Reed Switch with terminal strip in an Aluminum Explosion-proof

switch enclosure with 1/2" FNPT Electrical Access. ATEX Certified

PART NUMBERING SYSTEM

1. BASIC MODEL NUMBER

2. MATERIAL

S. Aluminum Body, 316 S.S. Bore,

S.S. Piston

Z. Special

10

3. DIAL SIZE

(Engineering Plastic Housing Unless Stated)

C. 4-1/2” Round Dial Uni-Directional Dial

F. 4-1/2” Round Aluminum Dial Housing

T. Differential Pressure Switch Only (Without Indication)

Z. Special (Uncoded Options)

10

4.

SEALS

0. Buna N (Standard)

1. *Viton®

2. Neoprene

5. Ethylene Propylene

6. Perfluoroelastomer

9. Special (Uncoded Options)

10

5.

CONNECTIONS

2. 1/4" FNPT End Connections (Standard)

7. 1/2” FNPT End Connected

9. Special (Uncoded Options)

10

6.

OPTIONS

(Up to four options)

0. None

B. DIN2353 12-S (12 mm) Steel Tube Fittings (2)

F. Pipe Mounting Kit (Carbon Steel)

G. Pipe Mounting Kit (Stainless Steel)

M. Maximum Indicator Follower Pointer

10

Q. CRN (Canadian Registration Number)

S. Shatterproof lens (4 1/2 Metal Front Only).

T. Oxygen Cleaning

U. S.S. Tag with S.S. Wire

V. S.S. Tag with S.S. Screw

Y. S.S. End Fittings with Al Body (Material Option A)

Z. Special (Uncoded Options)

10

NOTE: Not all options available in combination with

Other options.

* Viton® is a Registered Trademark of DuPont Dow Elastomers

7.

ELECTRICAL CONFIGURATIONS (Select One)

(Switch Adjustable Range 10-90% except where stated

below) (T6 Temperature Class unless specified otherwise)

A. One Control Switch in NEMA4X Enclosure

1,6,8

B. Two (2) Control Switches in NEMA4X Enclosure

1,6,7,8

J. One (1) Control Switch in NEMA7 (Exp. Proof Encl.)

2

K. Two (2) Control Switches in NEMA7 (Exp. Proof Encl.)

2,7

R. One (1) Control Switch in Ex d encl. ( CE Marked)

2,9

S. Two (2) Control Switches in Ex d encl. (CE Marked)

2,7,9

.

Z. Special

10

8.

ELECTRICAL

SPECIFICATIONS (Select 1 Input and 1

Output)

INPUT OPTIONS:

A. No Input Power (For Reed Outputs A, E, F, G, H)

B. 5/6 VDC

C. 12 VDC

D. 24 VDC

E. 48 VDC

F. 24 VAC

G. 120 VAC

H. 240 VAC

(FOR H OPTION T4-ATEX; T4A NORTH AMER.) TEMP CLASS

9.

OUTPUT OPTIONS: (Resistive Load)

3

A. S.P.D.T., Reed, 3 W, 0.25 Amp, 125 VAC/VDC

E. S.P.S.T., Reed, 60 W, 3 Amp, 240 VAC/VDC (N.O.)

(4)

F. S.P.S.T., Reed, 60 W, 3 Amp, 240 VAC/VDC (N.C.)

(4)

G. Two (2) S.P.S.T., Reeds, 60 W, 3 Amp, 240 VAC/VDC

(One Normally Open, One Normally Closed B, K & S

Electrical Configurations Only)

(4)

H. S.P.D.T., Reed, 60 W, 1 Amp, 240 VAC / VDC

(5)

R. D.P.D.T. Relay, 10 A, @ 30 VDC, 120 / 240 VAC

(4)(8)

Z. Special (Contact Factory)

10

(1) Complete Assembly 3rd Party Certified, Rated Class I, Div II, Groups

A,B,C, & D; Class II Division II, Groups F & G. (R Output option

excluded)

(2) Complete Assembly 3rd Party Certified, Rated Class I, Div I, Groups B C,

& D; Class II Division I, Groups E, F, & G.

(3) For output options A through H, the product of the switching

voltage and current shall not exceed the power rating.

(4) Switch adjustable range 15 – 90 % of the gauge full scale range.

(5) Switch adjustable range 25 – 90 % of the gauge full scale range.

(6) Enclosure Type 4/4X

(7) For Electrical configurations B, K, & S SPDT relay output only.

(8) Electrical configuration A & B in combination with Output Option R

is not rated

for hazardous locations.

(9) ATEX / IECEx RATED; CE MARKED Ex d IIB + H2, Ex tb IIIC

II 2GD IP65 (Temp classifications vary dependent on Electrical

Input and Output options. See IM 220_atex for more detail),

(10) Not available with Electrical Configurations R & S.

2

2

0

R RELAY

OUTPUT OPTION

PROOF PRESSURE: 12,000

WORKING PRESSURE: 3000 PSI

TEMPERATURE LIMITS:

- 40ºC < Ta < 70ºC for output option R (Relay Output).

- 40ºC < Ta < 85ºC for Electrical Input Options A in combination with Electrical Output options A, E,F,G & H.

- These limits are based on the entire instrument being saturated to these temperatures. System (process) temperatures may

exceed these limitations with proper installation. Contact our customer service representative for details.

STANDARDS: The Model 220 Series differential pressure gauges either conform to and/or are designed to the requirements

of the following standards:

ASME B1.20.1 ASME B40.1

NEMA Std. No. 250 SAE J514

CSA-C22.2 No. 14, 25, and 30 EN60079-0, EN60079-1

UL Std. No. 50, 508, 698, and 1203 EN60079-31, EN13463-1

Pressure Equipment Directive:

The products manufactured by Mid-West Instrument have very small internal volumes. The small internal volumes

result in Mid-West Instrument products falling below category I for non-hazardous gases, hazardous liquids, and

non-hazardous liquids. They also fall below category I for hazardous gases at or below pressures of 200 bar. Per

article 3, paragraph 3 these products shall not bear the CE marking and shall be designed and manufactured with

“sound engineering practice”. Our sound engineering practice is supported by our quality system in accordance

with CSA B51-03 Annex F third party certified by QMI.

Applications for hazardous gases at pressures above 200 bar will require evaluation to the Pressure Equipment

Directive which may be performed in the future.

Warning:

The suitability of the application and installation of this differential pressure switch is the

responsibility of the end user. The applicable certifications, listings apply to the differential

pressure switch only.

Mid-West

Instrument

6500 Dobry Dr. Sterling Heights, MI 48314

(586)254-6500 FAX (586)254-6509

E-Mail: sales@midwestinstrument.com

Web Page: www.midwestinstrument.com

BULLETIN NO.ELEC IM220/11A

Supersedes: Elec IM220/10A

Instrument

Mid-West®

ELECTRICAL

Upon receipt of your order, please review the ratings plate to

verify that the model number and the electrical ratings match

the product that you ordered. Figure 1 is the ratings plate for

Electrical Configuration J or K (Division 1 approval) and

Figure 2 is the Rating Plate for Electrical Configuration A or

B (Division 2 approval). Please read the Cautions listed on

the Rating Plate as they are different for each Electrical

Configuration.

FIGURE 1

FIGURE 2

WARNING: IN HAZARDOUS LOCATIONS REMOVE

POWER FROM THE UNIT BEFORE

REMOVING THE COVER.

WARNING: DO NOT TOUCH SURFACE OF THE

PRINTED CIRCUIT BOARD IF THE UNIT IS

POWERED. HIGH VOLTAGE MAY BE

PRESENT.

WARNING: ELECTRICAL CONNECTIONS SHOULD

BE PERFORMED BY QUALIFIED

PERSONNEL AND MEET THE

REPRESENTATIVE COUNTRY'S

NATIONAL ELECTRICAL CODE.

WARNING: FAILURE TO CONNECT TO THE

PROTECTIVE CONDUCTOR TERMINAL

MAY RESULT IN A SHOCK HAZARD.

DIVISION 1 LOCATIONS:

Electrical Configurations J & K are 3rd Party Certified for

Class 1, Division 1, Groups B,C & D; Class 2, Division 1,

Groups E, F, & G Hazardous Locations. All Electrical

Specification Input & Output Combinations are approved

for this classification. This enclosure does not have a

NEMA 4X rating.

This configuration has T6 Temperature classification for all

input and output combinations except for the H input option

which has a T4A Temperature classification.

For Electrical Specification Input Option A in combination with

Output Options A through H, a seal is not required. This

configuration can also be classified as a “Simple Apparatus”

for use in an Intrinsically Safe System.

For Electrical Specification Input options B through H in

combination with Output option R, a seal is required within

18” of the enclosure. Please refer to National Electrical Code

requirements.

Caution: Do not scratch, nick, or dent mating surfaces

of the gauge body and the cover during

maintenance. The integrity of the flame-proof

enclosure is dependent upon this metal to

metal seal.

If cover bolts are lost contact Mid-West

Instrument for Replacement.

Clean Metal joint area with non-abrasive cloth

after any maintenance activity that requires

the cover to be removed. A small amount of

non-hardening grease may be applied in the

joint area.

WARNING: To meet Hazardous Location’s Requirements,

torque the cover bolts to the specified values

on the Ratings plate.

DIVISION 2 LOCATIONS:

Electrical Configurations A & B (without Relay Output) are

3rd Party Certified for Class I, Division 2, Groups A, B, C, &

D; Class 2, Division 2 Groups F & G Hazardous Locations.

Only Electrical Specification Input Option A in

combination with Output Options A through H are

approved for this location. This enclosure does have a

NEMA 4X rating.

This configuration has a T6 Temperature classification.

This configuration can also be classified as a “Simple

Apparatus” for use in an intrinsically safe System.

Note: The assembly may be ordered with a relay output

and NEMA 4X rating; however it will not carry a 3rd party

certification for use in Hazardous Locations.

Model 220 Electrical: Installation and Operating Instructions

Hazardous Locations Division Classified Electrical Configurations: A,B, J, & K

General Information:

FIGURE 3

Switch Configurations:

The Model 220 indicating / non-indicating differential

pressure switch is configured with one of the outputs

identified in the table below.

OUTPUT RATINGS (Resistive Load)

Type SPST SPDT SPDT DPDT

Relay

ELEC Spec. A A A B,C,D,E,F,

G, H

Output

Option Code E, F, or G H A R

*Power 60 W 60 W 3W N/A

Max. Current 3 Amps 1.0 Amps 0.25 Amps 10 Amps

Max. Volts

VAC/ VDC 240 240 125 277 / 30

Setting

(F.S.) 15% to 90% 25% to 90% 10% to 90% 15% to 90%

Hysteresis

(Max/Nom) 20% / 9%

Full

Scale(F.S.)

20% / 18%

Full

Scale(F.S.)

10% / 6%

Full

Scale(F.S.)

20% / 10%

Full

Scale(F.S.)

Repeatability 1% F.S. 1% F.S. 1% F.S. 1% F.S.

Table I

* Product of the switching voltage and current shall not

exceed the power rating of the device.

Hermetically Sealed Switch Outputs:

Electrical Specification Input Option “A” identifies that your

unit does not need input power to operate the switch output

and that your unit is equipped with Hermetically Sealed Reed

switches. The “A” option matched with Output Options A, E,

F, G, & H identifies the output capability of your unit.

Depending on the electrical configuration specified on the

order (A, B, J, or K), your unit will be equipped with 1 or 2

independently adjustable reed switches.

Interface to the 16 position terminal strip shown in Figure 1 is

defined in Table II.

Terminal Connections

Electrical

Options Qty

Sw. Function Switch Adjust

Low Port Switch Adjust

Hi Port

AAA, JAA,

AAH, JAH 1 SPDT

1(COM), 2(NO),

3 (NC) No Connection

BAA, KAA,

BAH, KAH 2 SPDT

1(COM), 2(NO)

3 (NC) 8(COM), 7(NO)

6 (NC)

AAE, JAE 1 SPST

NO 1,2 No Connection

AAF, JAF 1 SPST

NC 1,3 No Connection

BAE, KAE 2 SPST

NO 1,2 8,7

BAF, KAF 2 SPST

NC 1,3 8,6

BAG, KAG 2 SPST 1

NO, 1NC 1, 3 NC 8, 7 NO

Table II

Chassis connection is to position 13

Customer Interface for the Reed Switch Output Option will be

via connections 1 through 8 and connections 12. Do not

loosen the connections at positions 9, 10, 11, 13 14, 15 , or

16.

Figure 4: Reed Switch Terminal Strip Output Interface

Custome

r

Interface

Low

Port High

Port

All switch types are field adjustable. The defined range of the

adjustment is specified in Table I above. All switches come

with a decal to identify adjustment direction to increase the

set point. Do not use excessive force when rotating the

adjustment screw as the adjustment mechanism may be

damaged (See Figure 5).

FIGURE 5

Note: Switches can be set below the defined minimum set

point however, the switch may not remain activated at

maximum PSID. If the unit is set below the defined minimum

set point, the customer should verify that the switch remains

activated from the set point to full over range of the gauge.

Provide standard protection techniques for the switch

contacts for capacitive and inductive loads. Use current

limiting techniques near the switch to protect the contacts

due to high inrush (i.e.; in line resistor or inductor) for long

cable interfaces. Provide clamping devices at or near

inductive loads (i.e.; relay). Maximum wire length between

the 3W switch and its load, should not exceed 70 – 100

Feet. for 120 VAC applications. Contact the factory for

assistance regarding this condition.

Relay Output Interface

Electrical Specification Input Option “B” through “H” identifies

that your unit will need input power to operate the relay

output (output option R). Depending on the electrical

configuration specified on the order (A, B, J, or K) your unit

will be equipped with 1 DPDT relay output or 2 independently

adjustable SPDT relay outputs. Table I identifies the load

ratings and the adjustability range of the output.

Interface to the 16 position terminal strip shown in Figure 6 is

defined in Table III.

The relay outputs are uncommitted and may be connected to

any load provided the load is within the output ratings of the

relay. The terminal strip is compatible with 22 – 12 Awg. wire.

Deviations from the above configurations may exist.

Therefore check the description block of your order to verify

your configuration.

FIGURE 6

FIGURE 6

Terminal Connections

Switch Adjust

Low Port Switch Adjust

Hi Port

Electrical

Options Qty

Sw. Func. Com NO NC Com NO NC

A*R, J*R 1 DPDT 1

9 2

10 3

11 X X X

B*R **,

K*R 2 SPDT 1 2 3 8 7 6

TABLE III

* = Input Power Options B, C, D, E, F, G, & H

** = NOT CSA / UL Listed configuration

Input Power = Position 4 + for DC; Hot for AC

Position 5 Rtn. for DC, Neutral for AC

Connections 13

See Decal on Inside Cover for additional connection

information.

Switch Output:

Relay Output:

(AC Input)

Relay Output:

(DC Input)

HIGH PORT

LOW PORT

INSTALLATION

Tools Required: 8mm deep metric socket.

Torque wrench

Adjustable or 1.125” wrench (process

connections)

CAUTION: DO NOT EXCEED THE MAXIMUM RATED

WORKING PRESSURE STATED ON THE

RATINGS PLATE.

CAUTION: ALWAYS USE A WRENCH (1.125” ) ON THE

SWITCH’S PROCESS CONNECTIONS TO

KEEP THEM IN PLACE WHILE TIGHTENING

AND LOOSENING CUSTOMER SUPPLIED

PROCESS FITTINGS.

Model 220 Series "Filter Minder" is calibrated and tested prior

to shipment and is ready for immediate installation. Use of

the following installation procedures should eliminate

potential damage and provide optimum trouble-free

operation.

CONNECTIONS

1/4” FNPT are provided as standard however check your

paperwork for connections ordered. There are two

connections on the housing identified as “High” and “Low” for

high pressure and low pressure (Fig. 5). Be sure these get

plumbed to the proper connections on your system. Improper

connection will not damage the instrument, but it will not

function properly. Flexible tubing is recommended to

minimize the effect of any vibration that may exist.

On liquid service the instrument should be mounted

below the process connections to facilitate self bleeding. On

gas service it should be located above the process

connections to promote self-draining. If the process contains

particulates, a “pigtail” loop or drop leg (manometer “U-tube”

configuration) in the tubing will minimize the possibility of it

migrating into the instrument.

An optional pipe mounting kit is available for mounting the

gauge to a 2” vertical or horizontal pipe (Fig. 3).

WARNING: IN HAZARDOUS LOCATIONS REMOVE

POWER FROM THE UNIT BEFORE

REMOVING THE COVER.

WARNING: DO NOT TOUCH SURFACE OF THE

PRINTED CIRCUIT BOARD IF THE UNIT IS

POWERED. HIGH VOLTAGE MAY BE

PRESENT.

Remove the cover by using an 8mm hex driver to loosen the

bolts from the underside of the gauge body. (see previous

cautions and warnings). The bolts are captive in the body of

the gauge. A deep metric socket is recommended in order to

clear an interference near the bezel of the gauge. (0.48

diameter min 1” long).

Connections to the terminal strip are identified in the following

sections. The terminal strip is compatible for wire ranges

from 12-22 AWG ( 3.3 - .32 mm2). Optionally, each

connection can be field wired with multiple wires connected

to one contact. You may connect two (2) 22 – 16 AWG (0.33

-1.3 mm2) wires into one connection. Recommended screw

torque is 6 in. lbs. (0.113 newton-meter) to tighten the

terminal strip screw.

Each Assembly is provided with strain relief clamps. Use

these clamps to provide strain relief when field wiring the

instrument.

For the non-gasketed assembly, clean both mating metal

surfaces prior to re-assembly (see previous cautions and

warnings). A small application of a suitable, non-hardening

grease may be applied to the mating metal surfaces.

Replace cover making sure there are no wires pinched

between the cover and the gauge body. Re-tighten the

screws within the range of 60 to 75 in-lbs.

TROUBLE SHOOTING

1. Gauge does not indicate differential.

A. Check for proper hook up, high to “hi” and low

to “lo”.

B. Make certain block valves are open and, if using

a 3-valve manifold, that the equalizer (balance)

valve is closed.

C. If A & B check out correctly, loosen or disconnect

the high pressure line to determine if there is

pressure to the instrument.

D. If there is pressure to the instrument, check to

determine that there is differential across the

unit being monitored. If so, contact the factory

for assistance and/or an “RGA” (return goods

authorization) number to return the instrument

for repair or replacement.

2. Switch doesn't function

A. Make sure you have supplied power (proper voltage)

to the unit if you ordered the power relay unit. The

reed switch output units do not require power.

B. Check that you are wiring to the correct Interface

terminals.

C. Check the reed switch interfaces to the terminal board

for loose connections. For the power relay the reed

switch(es) connect to the terminal strip on the

underside of the PCB. For the reed switch outputs the

reed switch(es) connect to positions on the bottom row

of the terminal strip on the top of the PCB (see Figure

4).

D. Make sure that the switch load does not exceed the

specified wattage rating of the switch. (steady-

state and transient). For this condition you must

contact the factory

3. Gauge accuracy and set point problems:

A. Verify gauge is not in an electromagnetic /

magnetic environment. i.e.; close proximity to high

current power lines.

B. All others, contact the factory for assistance.

STANDARD MODEL SPECIFICATIONS

220-AC-02-0(JAA), 4000 P.S.I.G. Working Pressure, Aluminum wetted pressure containing body assembly, stainless steel/ceramic

magnet internals, Buna N Seals, 4 1/2" Round Dial, 1/4" FNPT End Connections, Engineering Plastic Gauge Case with Shatter

Resistant Acrylic Lens. One 3W, 0.25 AMP, 125 VAC/VDC SPDT Reed Switch with terminal strip in an Aluminum Explosion-proof

switch enclosure with 1/2" FNPT Electrical Access 3rd Party Certified .

220-SC-02-0(JAA), 4000 P.S.I.G. Working Pressure, 316 S.S. wetted pressure containing body assembly, , stainless steel/ceramic

magnet internals, Buna N Seals, 4 1/2" Round Dial, 1/4" FNPT End Connections, Engineering Plastic Gauge Case with Shatter

Resistant Acrylic Lens. One 3W, 0.25 AMP, 125 VAC/VDC SPDT Reed Switch with terminal strip in an Aluminum Explosion-proof

switch enclosure with 1/2" FNPT Electrical Access. 3rd Party Certified

PART NUMBERING SYSTEM

1. BASIC MODEL NUMBER

2. MATERIAL

A. Aluminum Body, Aluminum Bore ,

S.S. Piston

S. Aluminum Body, 316 S.S. Bore,

S.S. Piston

Z. Special

3. DIAL SIZE (Engineering Plastic Housing Unless Stated)

C. 4-1/2” Round Dial Uni-Directional Dial

F. 4-1/2” Round Aluminum Dial Housing

T. Differential Pressure Switch Only (Without Indication)

Z. Special (Uncoded Options)

4.SEALS

0. Buna N (Standard)

1. *Viton®

2. Neoprene

5. Ethylene Propylene

6. Perfluoroelastomer

9. Special (Uncoded Options)

5. CONNECTIONS

2. 1/4" FNPT End Connections (Standard)

7. ½” FNPT End Connections

9. Special (Uncoded Options)

6. OPTIONS (Up to four options)

0. None

F. Pipe Mounting Kit (Carbon Steel)

G. Pipe Mounting Kit (Stainless Steel)

M. Maximum Indicator Follower Pointer

Q. CRN (Canadian Registration Number)

S. Shatterproof Lens (4 1/2" Metal Front Only)

T. Oxygen Cleaning

U. S.S. Tag with S.S. Wire

V. S.S. Tag with S.S. Screw

Y. S.S. End Fittings with Al Body (Material Option A)

Z. Special (Uncoded Options)

NOTE: Not all options available in combination with

Other options.

* Viton® is a Registered Trademark of DuPont Dow Elastomers

** Teflon® is a Registered Trademark of DuPont

7.ELECTRICAL CONFIGURATIONS (Select One)

(Switch Adjustable Range 10-90% except where stated

below) (T6 Temperature Class unless specified otherwise)

A. One Control Switch in NEMA4X Enclosure1,6,8

B. Two (2) Control Switches in NEMA4X Enclosure 1,6,7,8

J. One (1) Control Switch in NEMA7 (Exp. Proof Enclosure) 2

K. Two (2) Control Switches in NEMA7 (Exp. Proof Enclosure) 2

R.

S.

Z. Special

8. ELECTRICAL SPECIFICATIONS (Select 1 Input and 1

Output)

INPUT OPTIONS:

A. No Input Power (For Reed Outputs A, E, F, G, H)

B. 5/6 VDC

C. 12 VDC

D. 24 VDC

E. 48 VDC

F. 24 VAC

G. 120 VAC

H. 240 VAC T4A Temp Class

9. OUTPUT OPTIONS: (Resistive Load) 3

A. S.P.D.T., Reed, 3 W, 0.25 Amp, 125 VAC/VDC

E. S.P.S.T., Reed, 60 W, 3 Amp, 240 VAC/VDC (N.O.)(4)

F. S.P.S.T., Reed, 60 W, 3 Amp, 240 VAC/VDC (N.C.)(4)

G. Two (2) S.P.S.T., Reeds, 60 W, 3 Amp, 240 VAC/VDC

(One Normally Open, One Normally Closed B, K & S

Electrical Configurations Only) (4)

H. S.P.D.T., Reed, 60 W, 1 Amp, 240 VAC / VDC(5)

R. D.P.D.T. Relay, 10 A, @ 30 VDC, 120 / 240 VAC (4)(8)

Z. Special (Contact Factory)

(1) Complete Assembly 3rd Party Certified, Rated Class I, Div II, Groups

A,B,C, & D; Class II Division II, Groups F & G. (R Output option

excluded)

(2) Complete Assembly 3rd Party Certified, Rated Class I, Div I, Groups B C,

& D; Class II Division I, Groups E, F, & G.

(3) For output options A through H, the product of the switching

voltage and current shall not exceed the power rating.

(4) Switch adjustable range 15 – 90 % of the gauge full scale range.

(5) Switch adjustable range 25 – 90 % of the gauge full scale range.

(6) Enclosure Type 4/4X

(7) For Electrical configurations B, K, & S SPDT relay output only.

(8) Electrical configuration A & B in combination with Output Option R

is not rated for hazardous locations.

2

2

0

2

2

0

R RELAY

OUTPUT OPTION

PROOF PRESSURE: 16,000 PSI

WORKING PRESSURE: 4000 PSI

TEMPERATURE LIMITS: -40F (-40C) TO + 185F (+85C)** - These limits are based on the entire instrument being

saturated to these temperatures. System (process) temperatures may exceed these limitations with proper installation. Contact

our customer service representative for details.

** -40F (-40C) TO + 160F (+70C) For Output Option R (Relay Output)

STANDARDS: The Model 220 Series differential pressure gauges either conform to and/or are designed to the requirements

of the following standards:

ASME B1.20.1 UL Std. No. 50, 508, 698, and 1203

ASME B40.1 NEMA Std. No. 250

CSA-C22.2 No. 14, 25, and 30 SAE J514

Warning: The suitability of the application and installation of this differential pressure switch is the

responsibility of the end user. The applicable certifications, listings apply to the differential

pressure switch only.

Mid-West

Instrument

6500 Dobry Dr. Sterling Heights, MI 48314

(586)254-6500 FAX (586)254-6509

E-Mail: [email protected]

Web Page: www.midwestinstrument.com

Table of contents

Other Midwest Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Mindfield

Mindfield eSense Muscle quick guide

Hanna Instruments

Hanna Instruments HI 8014 instruction manual

Secure

Secure APEX 100 user manual

National Instruments

National Instruments NI 9227 CALIBRATION PROCEDURE

Onicon

Onicon F-4600 Series Installation and operation guide

Televes

Televes RG3000 quick start guide