Midwest Mid-Tech TASC 6000 Owner's manual

999-1512

TASC ROADSIDE SPRAYER SUPPLEMENT

1

R1

V 3.10

TASC 6000, 6300 OR 6600

ROADSIDE SPRAYER OPERATIONS

TASC MANUAL SUPPLEMENT

MIDWEST TECHNOLOGIES, INC. 2733 E. ASH STREET, SPRINGFIELD, IL, USA

TEL: 217-753-8424 FAX: 217-753-8426

999-1512

SOFTWARE VERSION 3.10

Date Code: 98084

MID-TECH

R

Specialists In Control System Electronics Since 1983

MIDWEST TECHNOLOGIES, INC.

TASC ROADSIDE SPRAYER SUPPLEMENT 999-1512

2R1

V 3.10

TABLE OF CONTENTS

999-1512

Date Code: 98084

Description

Modes of operation

Handgun mode, set-up functions

Handgun mode, operate functions

Handgun mode, special considerations

Handgun mode, typical operation

Handgun mode, manual valve override

Handgun mode, error messages

Handgun mode, printer output samples

Normal mode, automatic pressure operation

Normal mode, special purpose boom widths

Page

1

2

2

3

3

4

5

6

7

7

V 3.10

999-1512

TASC ROADSIDE SPRAYER SUPPLEMENT

3

R1

V 3.10

ROADSIDE SPRAYER OPERATIONS, TASC MANUAL SUPPLEMENT

NORMAL SPRAYING WITH PRESSURE BALANCED ROADSIDE SPRAYER

1) Operate in programmed carrier rate to keep a constant carrier application and

injected chemical application per acre, regarless of speed changes. (pres-

sures will vary with speed.)

2) Operate in Automatic pressure control to keep a constant pressure regard-

less of speed or boom changes. Chemical injection pumps will respond to

speed and boom changes to keep chemical rate per acre constant.

3) Use alternate boom widths to increase injected chemical pump speed when

spraying significant slope, to account for larger area being covered..

HANDGUN

1) Operate at a programmed carrier rate to keep a constant injection pump

speed, regardless of small variations in carrier flow.

2) Operate carrier valve in manual to keep a constant concentration of chemical,

regardless of all variations in carrier flow. (Use when feathering trigger on

handgun for example.)

MODES OF OPERATION

TASC roadside operations require, at least, TASC software level 3.10 or above, Slave software

level 3.0 or above, the inclusion of an external handgun function switch, an interface cable and

a flow switch in the handgun feed line. There are special features of the TASC available to

Roadside Applicators in both the Handgun and Normal modes. The Handgun option allows the

user to set chemical injection rates based on carrier flow rates,(i.e. ounces per 100 gallons of

carrier or the chemical to carrier ratio, e.g. gal:gal or oz:oz). Pumps start and stop in response

to the start of carrier flow sensed by a flow

sensing switch. Chemical injection will only

occur when the handgun trigger is pulled and

flow is established.

In the Normal mode the TASC can control to

a desired pressure (regardless of speed

changes), responding to the activation of

pressure balanced boom sections found on

certain roadside sprayers. The Normal mode

also allows selection of alternate widths "B"

or "C" to accomodate changes in sprayed

area due to roadside slopes rather than boom

sections turned on or off.

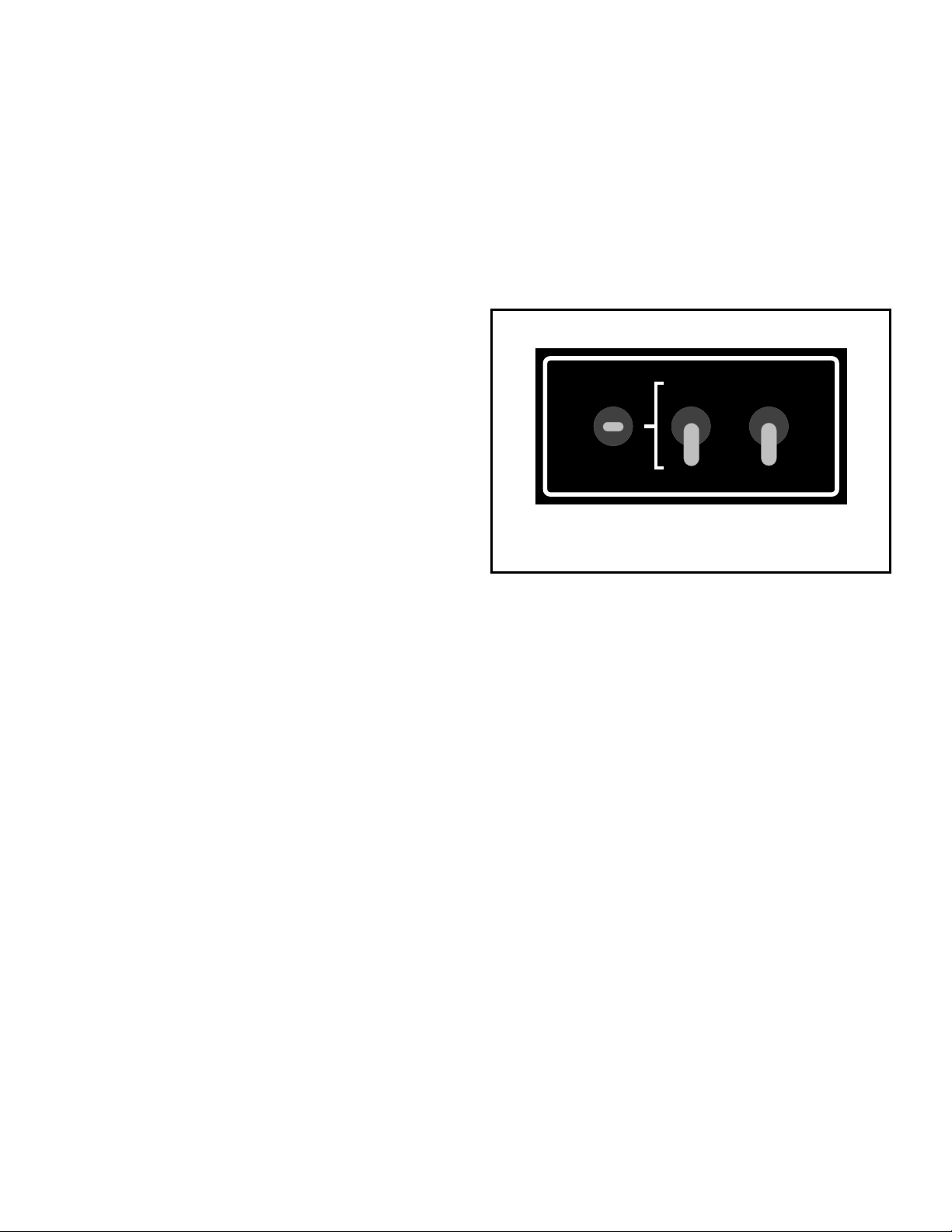

'B' Width Normal Ground Speed

Override

'C' Width Handgun Off

Auto

Boom

Switch

Mode

Switch

Ground

Speed

Override

Example 405-0093 Switch Panel

TASC ROADSIDE SPRAYER SUPPLEMENT 999-1512

4R1

V 3.10

HANDGUN MODE, SET-UP FUNCTIONS: First put the TASC in the Handgun mode. To do this,

set the switches on the boom control panel as follows: 1) set the boom width switch to "Auto",

2) set the mode switch to "Handgun", 3) set the ground speed switch to "OFF". Now, Turn the

TASC power "ON" and put the mode selector switch to "SET-UP".

The following programing functions are available in the TASC console:

SPEED: An "Err" message will appear (GSO is not available in the handgun mode).

AREA: Area will not accumulate in handgun mode.

CHEMICAL, VOL. APPLIED: This is the pump calibration number for each injection pump (see section

4.7 in the TASC Manual).

CHEMICAL, CHEM. RATE: With pump switch in the "ON" position, program the rate as ounces per 100

gallons of carrier (use the INC/DEC switch to set this rate). With pump switch in the "ALT" position,

the display will read as a ratio (i.e. 1:100, gal:gal, or oz:oz, chemical:carrier). The rate can be

programmed with pump switch in either position.

CHEMICALS, % RATE: Use the INC/DEC switch to select the desired rate change % for chemicals or

carrier.

CARRIER RATE: Use the INC/DEC switch to set the desired carrier rate in gallons per minute.

CARRIER TOTAL APPLIED: The flow meter calibration number (section 4.5 in the TASC Manual).

WIDTH: The message "none" will appear (boom width is not used in the handgun mode).

DISTANCE: The distance calibration number (section 4.6 in the TASC Manual).

PRIME: The prime volume for each pump (section 4.7.4 in the TASC Manual).

TEST SPEED: Using the INC/DEC switch, set a test flow rate in gallons per minute (this rate is required

before pumps can be accurately calibrated).

SCAN: An "Err" message will appear (there is no programming in SCAN).

HANDGUN MODE, OPERATE FUNCTIONS: Now put the TASC mode selector switch to

"OPERATE". The following programing functions are available in the TASC console:

SPEED: This is a direct reading of ground speed.

AREA: Area will not accumulate in the handgun mode.

CHEMICAL, VOL. APPLIED: Accumulated ounces as they are applied, switches to hundredths of gal-

lons after 256 ounces are accumulated.

CHEMICAL, CHEM. RATE: This register will indicate the programmed standard rate (oz per 100 gal-

lons) regardless of the switch position "ON" or "ALT" , With pump switch in the "ALT" position,

the display will read as a ratio (i.e. 1:100, gal:gal, or oz:oz, chemical:carrier).

CHEMICALS, % RATE: Allows changing chemical injection rates a preset percentage (section 5.4.2.1

in the TASC Manual).

CARRIER RATE: Displays target carrier application rate. Actual carrier flow rate in gallons per minute

will be displayed once flow is established. The INC/DEC switch will change the carrier rate by

the percentage amount programmed in the "Chemicals, % Rate" register (injected rates will not

be affected).

CARRIER TOTAL APPLIED: Accumulated gallons applied.

WIDTH: "none" (boom widths are not used in the handgun mode.)

DISTANCE: Accumulated distance in feet or miles.

PRIME: Used for priming the injection pumps (section 5.5 in the TASC Manual).

TEST SPEED: The gallons per minute programmed in the "SET-UP" mode is displayed.

SCAN: Scans information in the accumulators and registers.

999-1512

TASC ROADSIDE SPRAYER SUPPLEMENT

5

R1

V 3.10

HANDGUN MODE, SPECIAL CONSIDERATIONS:

A. Pump Calibrations: The speed of the injection pumps during calibration is determined by

the programmed test speed (gallons per minute) and the programmed chemical application

rate (ounces per 100 gallons or ratio: gal/gal). Set these numbers to your typical operating

conditions before doing the pump calibrations.

B. The injection pumps will operate at the speed necessary to apply the correct amount of

chemical according to the programmed carrier application rate, regardless of small variations

in the actual carrier flow rate. (Large varaitions in the actual flow rate lasting more than 5

seconds will cause an error shutdown of the sprayer). Thus, chemicals will always be applied

correctly, even if there is variation in the carrier output. (If the carrier rate is set to 0.0, see the

Manual Override of Flow Control Valve Section, page 4.)

C. Booms are not used in the handgun mode. If the TASC senses a boom "ON" condition it

will indicate an "Err" and will stop the injection pumps and close the flow control valve.

D. The initial response of the flow control valve to the selection of the handgun mode is to

open fully. Once application has started, the response of the flow control valve to the flow

switch "OFF" condition is to "HOLd" the valve in the partially open condition. The CLOSE

valve response is not selectable while operating in the handgun mode.

E. The values programmed into the TASC console while in either the Handgun or Normal

mode will remain in console memory, even when the opposite mode is selected.

F. Selecting TEST SPEED on the TASC console, while in the "OPERATE" mode, will cause

the flow control valve to adjust flow to the test rate selected and the injection pumps to control

to the programmed test rate.

HANDGUN MODE, TYPICAL OPERATION:

A. Set the Normal/Handgun switch to "Handgun", the Boom switch to "Auto", and the Ground

Speed Override Switch to "OFF".

B. Select "SET-UP" for the TASC console mode selector. Program the TASC console as

necessary (See SET-UP Mode, page 2).

C. Zero the accumulated rates and set the desired carrier flow rate as necessary.

D. Select "OPERATE" with the TASC console mode selector switch. The initial response of

the flow control valve is to drive fully open.

E. Turn "ON" the desired chemical injection pumps.

F. Close the valve leading to the spray boom.

This manual suits for next models

2

Table of contents