Midwest 140 User manual

Mid-West

®

Instrument

Electrical Installation and O

p

eratin

g

Instructions - Model 140

Bulletin No: Elec IM140/18A

Supersedes Elec IM 140/16B

6500dobrydrsterlingheights,mi48314

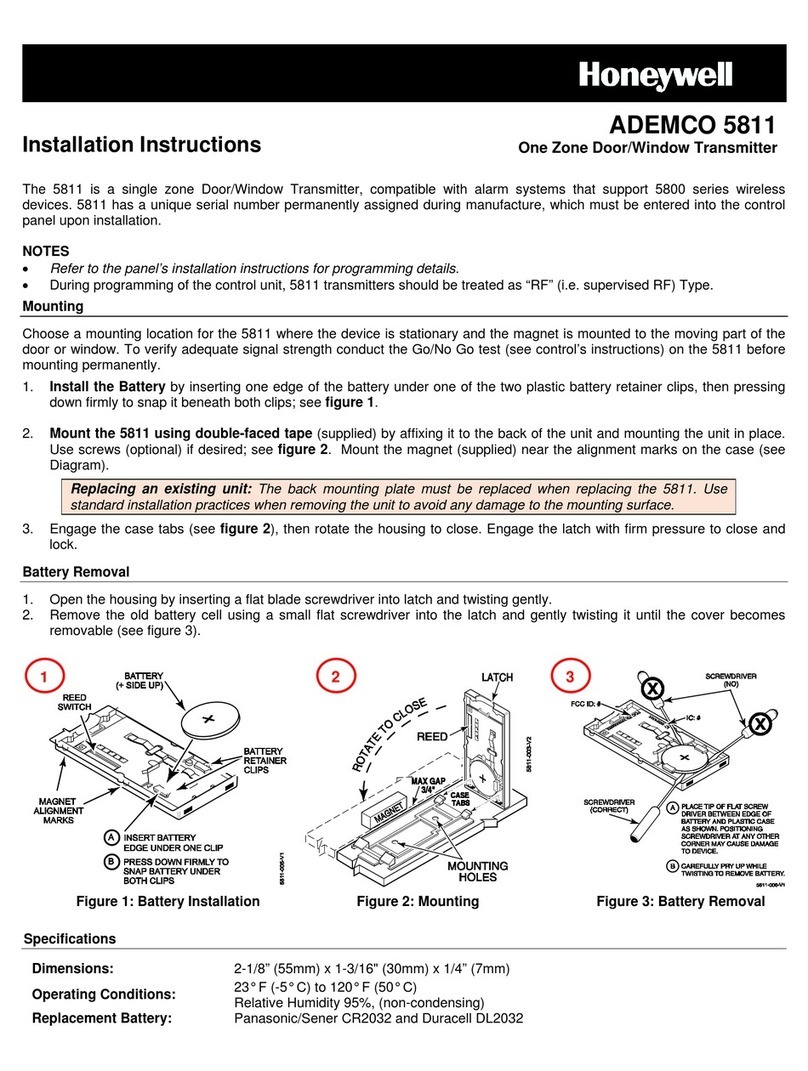

1.0 Safety

Beforeinstalling,checktheModelNumberandverifycompatibilitytotheprocessmediaand

temperatureincontactwiththewettedparts.Incompatiblemediaand/oroperationat

temperatureextremescancauseprematuredegradationofmaterialswhichcouldresultinsafety

risktopersonnel.

Verifytheselectedpressurerange(differentialpressureandworkingpressure)andtheswitch

ratingsarewithinspecificationforyourapplication.

Warning!Performallelectricaladjustmentswithpowerremoved.

TheModel140productutilizesadiaphragmdesignwhichisolatesthehighprocessfromthelow

process.Foroverpressureconditions(HighoverLowandLowoverHigh)thediaphragmis

supportedattheendoftravelfortheratedworkingpressureofthegauge.However,itis

recommendedthatiflargepressurespikesexist,somesortofpressurelimitingdeviceshouldbe

installedforprotection.

Warning!Remainingmediamayresultinarisktopersonnel,environmentetc.Usesufficient

precautionarymeasureswhenremovingandtransportingtheproduct.

Warning!Ifinstallingproductwithinanotherenclosurethatispressuretight,pleaseverifyall

processconnectionareleaktight.Leakagewithinapressuretight(ieNEMA4X)enclosurecould

causeapressurebuildupwithintheenclosureandcauseaburstscenario.

1.1 Intendeduse

Theindicating/non‐indicatingdifferentialpressureswitchesortransmitterareusedformonitoring

differentialpressuresinindustrialapplications.

Themanufacturershallnotbeliableforanyclaimsiftheproductisusedinapplicationscontrarytothe

intendeduse.

1.2 Personnel

Personnelinstallingandputtingthisinstrumentationintoserviceshallbesuitablytrainedandqualifiedin

accordancewithlocalcodes,practicesandregulations.

1.3 Labeling/Marking

ThefollowingElectricalConfigurationsbearthismarkandcomplywiththerelevantEuropeanDirectives

identifiedonthedeclarationofconformity:A,B,E,F,T,W

Thefollowingelectricalconfigurationsbear1orbothofthesethirdpartylistingagencymarksfor

productevaluatedtobothUSandCanadianStandards:E,F,W

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page2

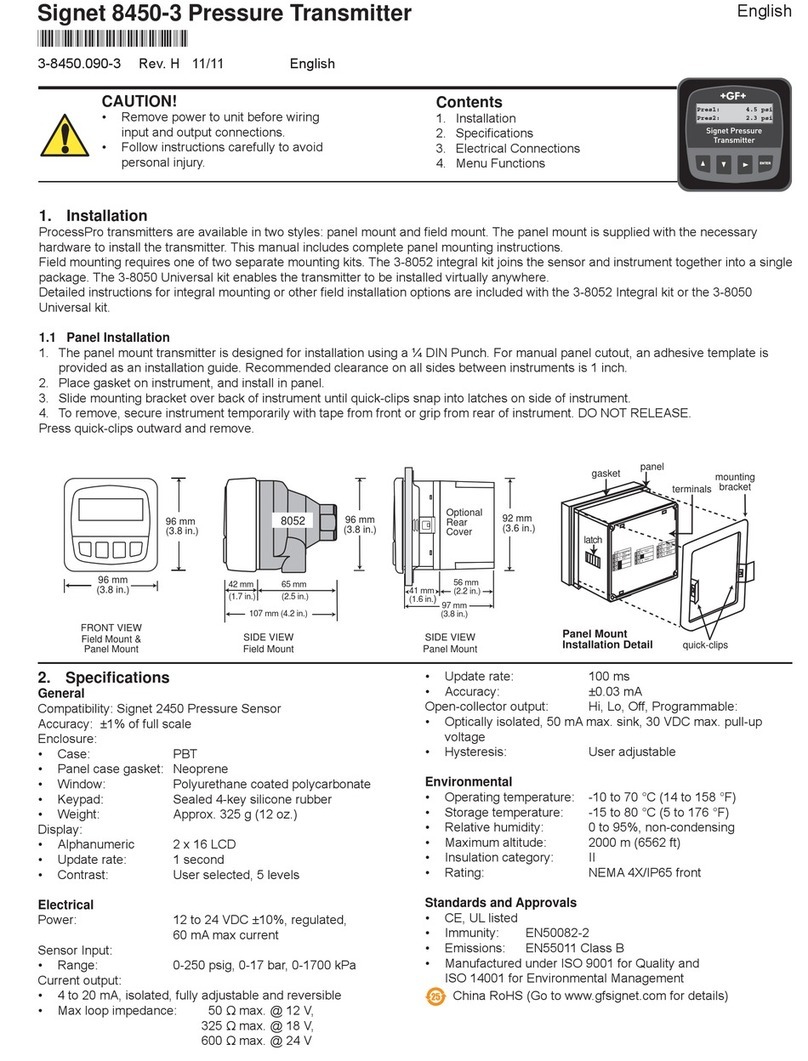

2.0 GeneralSpecifications

Non‐electrical

Electrical

*Productoftheswitchingvoltageandcurrentshallnotexceedthepowerratingofthedevice.

**Exceptwhereotherwisenoted

ParameterLimits(Std)Limits

(HazardousLocations)

WorkingPressure(PSI)

3000(AL)*NonHaz‐Loc

1500(Br)NonHaz‐Loc

3000(SS)*NonHaz‐Loc

1500(BrNonEnd)

3000(Al/SSNonEnd)

2000(AL/SSEndConn.)

1625(Al/SSNace)

ProofPressure4XRatedWorkingPressure

Temperature‐40°to200°F(Switches)

-20F to 150F (Transmitter)

DifferentialPressureRange

(PSID)0‐50”H2Oto0to100PSID

IndicatorAccuracy

ASMEB40.1002%

DPOver‐Range+/‐Proofpressure

SwitchSpecification

Parameter SPST (NO) SPDT

Option:BA

*Power25W3W

Max.Current0.5Amps0.25Amps

Max.Voltage

VAC/VDC240125

**Setting

(%F.S.)15to9515to95

Hysterisis

(Max/Nom)

15%/8%

(F.S.)

10%/5%

(F.S.)

Repeatability1%F.S.1%F.S.

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page3

Transmitter

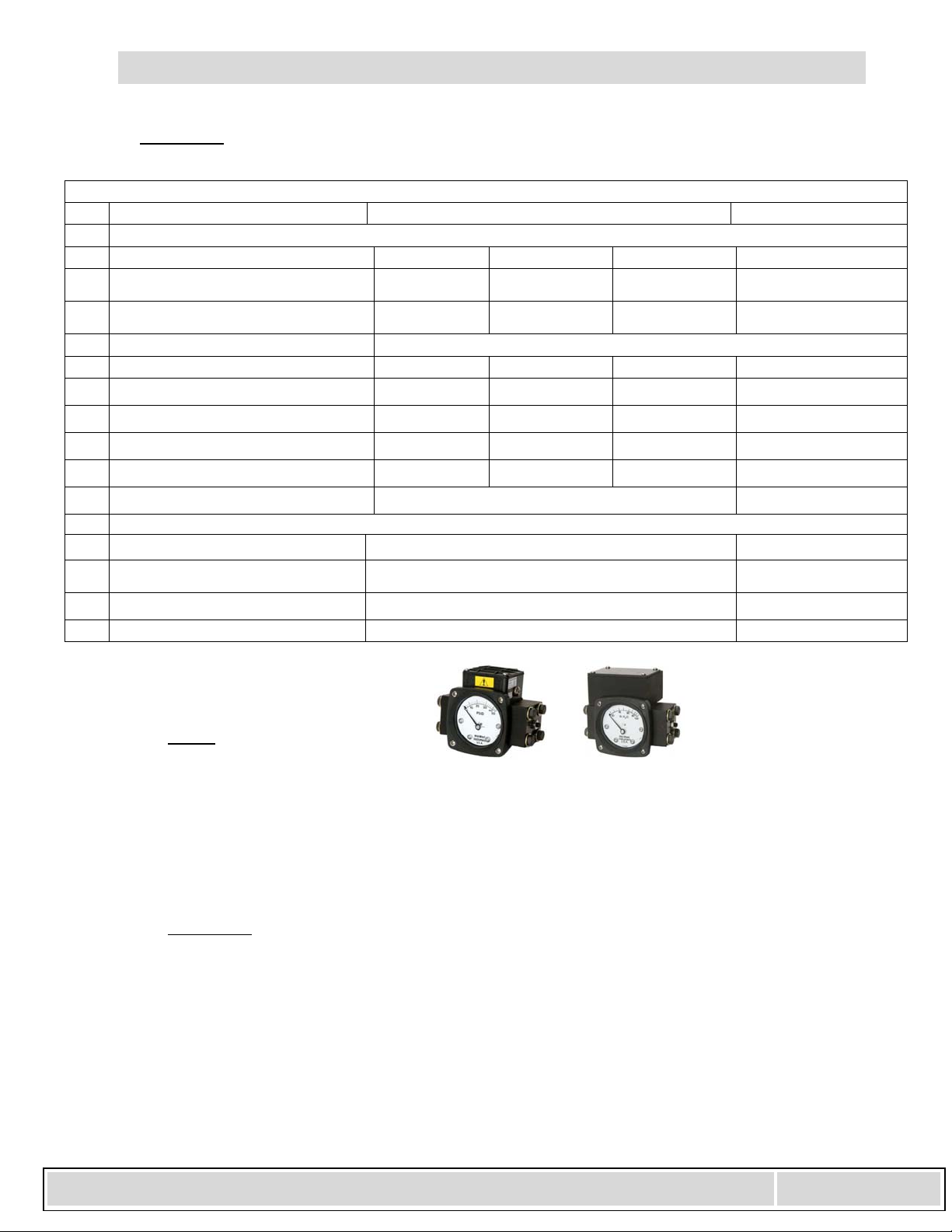

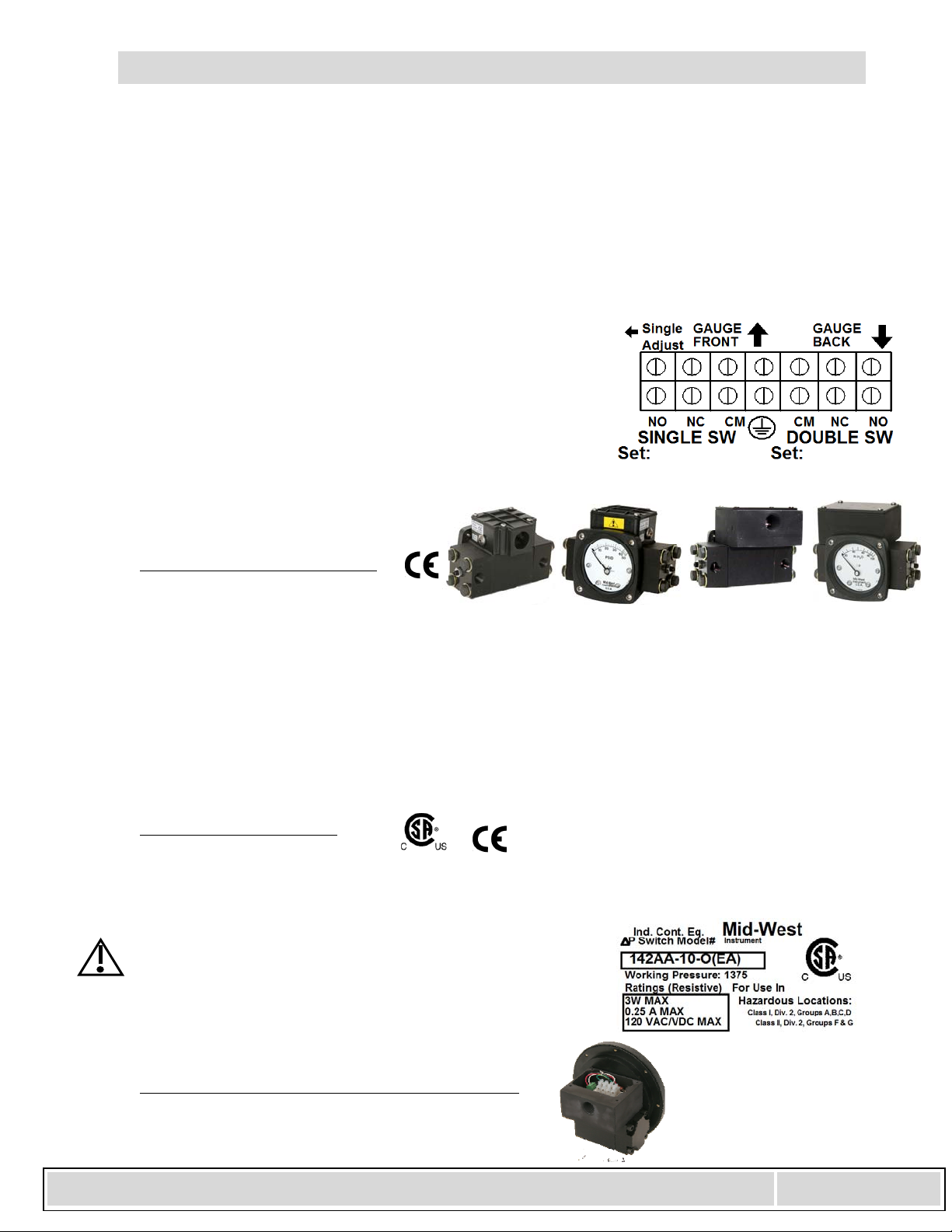

3.0 ProductDescription:

Switch

Aflexibleelastomerdiaphragmandcalibratedrangespringaremovedbydifferentialpressure.A

magnet,coupledwiththediaphragm,transmitthismotionthroughthewallofthepressurehousingtoa

followermagnetattachedtoanindicatingpointer.Therotationofthefollowermagnetcausesthe

pointertotrackthemovementoftheinternalmagnetandindicatethedifferentialpressureonthedial

scale.Theswitchesarealsomagneticallyoperatedandarelocatedoutsideofthepressurehousing.The

switchesaremechanicallyadjustableallowingthecustomertosettheswitchwithinadefined

adjustmentspanoftherangeoftheinstrument.

Transmitter

TheModel140indicating/non‐indicatingdifferentialpressuretransmitterisa2wirelooppowered

microprocessorbased4‐20matransmitter.Themagneticanglesensor&electronicssensestheangle

(relativetothetransmittersensor)ofthemagnetwhichmoveslinearlyinthebore.Eachtransmitteris

individuallycalibratedtothegaugeusingan11pointcalibrationlinearizationtechnique.Thismethod

resultsina<2%fullscaleaccuracyfortheupper80%oftherange.

Transmitter Specifications: (Calibrated on Increasing pressure) Comments:

Operating Temperature (Max.) -20F - 150F

ELECTRICAL:

Min Typ Max

Transmitter Accuracy (FSR) 2% Upper 80% of Full Scale

Range

Supply Voltage (3) (Vdc) 8 28 Pin 3 Reverse Polarity

Protected

Output Current (ma)

Zero Floating (2) 4.0 – 20.1 ma 4.0 – 21.0 4.0 – 22.0 Pin 2

Zeroed (1 connected to 2) 8

V

oltage (Pin 2 to 1) 4.8 6.3

Zero Time (seconds) 2

Max Loop Resistance (ohms) 1000

Max Loop Resistance Formula ((Vs – 8)*1000)/ 20

INTERFACE:

Electrical:

Connections: 4 Position Terminal Strip; ½” NPT Conduit

1= Rtn, 2= Zero, 3 = 8-28 Vdc In 4= Chassis 22 Awg – 16Awg Wire

Environmental Rating: NEMA 4X

Certifications: CSA (Canadian & US Standards; Division 2 Locations)

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page4

4.0 Installation:

MechanicalConnections

¼”FNPTareprovidedstandard,howevercheckyourpaperworktoconfirmtheconnectionsordered.

Thereare2connectionsidentifiedonthegaugebodyas“Hi”and“Lo”forHighpressureandLow

pressurerespectively.Besuretheseareplumbedproperlyinyoursystem.Improperconnectionwillnot

damagetheinstrument,butitwillnotfunctionproperly.

Donotallowgaugefittingstorotatewhenmakingprocessconnections.Calibrationand/or

pressureratingoftheproductmaybecompromised.

Forendconnectedorgaugessuppliedwithadapterfittingsusetwowrencheswhenmakingconnections.

Useonewrenchtoholdthepressureportfittingonthegaugeandtheothertotightentheprocesspipe

oftubefitting.

InstrumentLocation:

Onliquidservicetheinstrumentshouldbemountedbelowtheprocessconnectionstofacilitateself‐

bleeding.Ongasserviceitshouldbelocatedabovetheprocessconnectionstopromoteself‐draining.If

theprocesscontainsparticulates,apigtailloopordropleg(manometer“U‐tube”configuration)inthe

tubingwillminimizethepossibilityofitmigratingintotheinstrument.

TemperatureLimitations:

Forprocesstemperatureshigherthantheratedtemperatureofthedpgauge/switch,useprocess

tubingtoreducethetemperature.Ageneral“ruleofthumb”isthatforhorizontaltubingrunsthetemp

dropis100°F/ft.Anotheroptionistouse“coolingtowers”toprotecttheinstrument.

Verifytheselectedelastomeroptionisappropriateforyouroperatingtemperature.

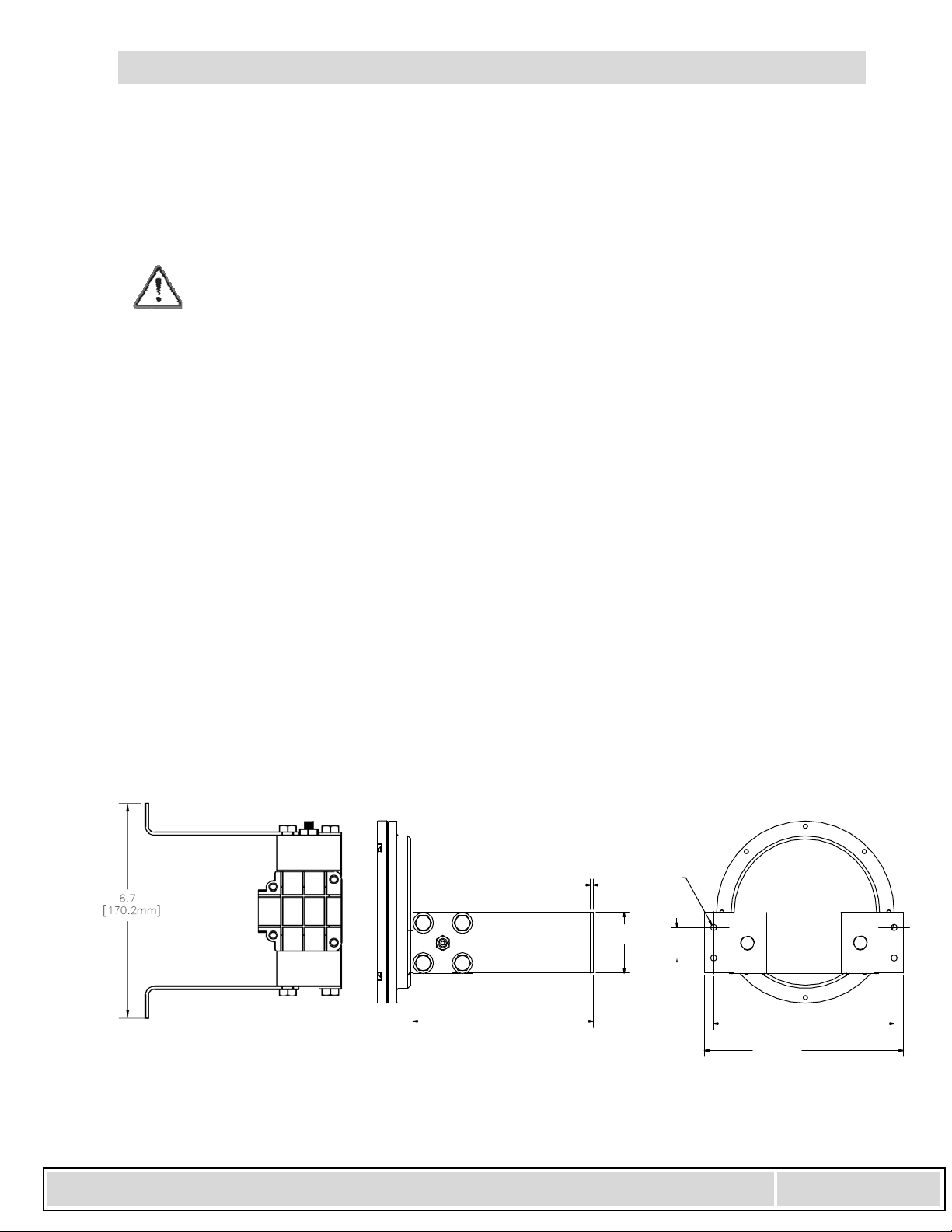

Wall/Pipe/PanelMounting:

Notallcombinationofoptionscanbewall,pipe,orpanelmounted.Ifyourunitissuppliedwithawallor

panelmountpossibleconfigurationsareshownbelow:

WallMountConfigurations:

WALLMOUNTBRACKET(NoSwitchShown)

0.09

[2.3mm]

1.00

[25.4mm]

2.00

[50.8mm]

Ø.205[5.2mm]

THRU

(4)HOLES

6.07

[154.2mm]

6.70

[170.2mm]

6.08

[154.4mm]

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page5

PipeMounting

PipemountingbracketsarenotavailableforanyElectricalConfigurationsinthereverseport

configuration.

PanelMount

Gaugeswith2½”dialscanonlybemountedthroughtherearofthepanel.Maketheproperpanel

cutoutasshownbelow.Removethe(4)bezelscrewsandinsertthegaugefrontthroughtherearofthe

panel.Reinstallthebezelscrewsthroughthefrontofthepanelandintothegaugebezel.Tightenscrews

securelyinanalternatingdiagonalpattern.

Gaugeswith3½”dialsshouldbemountedfromthefrontofthepanel.Contactthefactoryformounting

anddimensionalinformation.

Gaugeswith4½”dialsshouldbemountedfromthefrontofthepanel.Makethecutoutasindicted

below.Insertthe(4)panelstuds,fingertight,intothemetalinsertslocatedintherearofthebezel.

Insertthegaugethroughthepanel,aligningthepanelmountingstudswiththeholesinthepanel.Install

the(4)8‐32nutsontothestudsandtightensecurely.

6.22

5.24

P

2.81

3.80

2.81

.70

.15

1.16

Typical2”PipeMounting

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page6

45°

Ø3.00(76.2)

Ø3.50(88.9)

Ø0.19(4.7)

(4HOLES)

Typical2½”PanelMount

3.30

3.39

.56

5.30

1.10

Ø5.30(134.6)

Ø5.63 (143.0)

Ø0.19 (4.7)

(4 HOLES)

BOLT CIRCLE

Typical4½”PanelMount

6 in. DIAL PANEL CUT-OUT

MODEL 140

BOLT CIRCLE

Ø0.19 (4.7)

(4 HOLES)

Ø6.50 (165.1)

Ø7.00 (177.8)

#8‐32SCREW

(4PLACES)

PANEL

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page7

5.0 Electrical:

Warning:Electricalconnectionsshouldbeperformedbyqualifiedpersonnelandmeetthe

representativecountry'snationalelectricalcode.

Warning:Failuretoconnecttotheprotectiveconductorterminalmayresultinashockhazard.

Warning:Performallswitchadjustmentswithpowerremoved.Useanohmmeterorequivalentto

monitorcontactoperation.

Caution: Preferenceshouldbegiventosettingtheswitchpriortoinstallation.Itisalsorecommended

toperformadjustmentsusinganon‐magneticPhilipsscrewdriver.

General

Allswitchtypesarefieldadjustable.Thedefinedrangeoftheadjustmentisspecifiedinthetableabove.All

switchescomewithadecaltoidentifyadjustmentdirectiontoincreasethesetpoint.

SwitchSetPointAdjustment

Caution:Donotconfusetheswitchadjustaccessastheswitchadjustscrew.

Note:Switchescanbesetbelowthedefinedminimumsetpointhowever,theswitchmaynotremain

activatedatmaximumPSID.Iftheunitissetbelowthedefinedminimumsetpoint,thecustomershould

verifythattheswitchremainsactivatedfromthesetpointto

overrangeofthegauge.

Theswitchmaybesetusingtheindicatingdialasa

reference(unitswithadial)orbyusingareferencepressure

gauge.

Forsettingonincreasingpressureincreaseyourpressureto

thedesiredsetpoint.Increasetheswitchsetpointabove

thedesiredswitchset(switchdeactivated).Slowlydecrease

theswitchsetpointuntilthecontactactivates.

ContactProtection:

Providestandardprotectiontechniquesfortheswitchcontactsforcapacitiveandinductiveloads.Use

currentlimitingtechniquesneartheswitchtoprotectthecontactsduetohighinrush(i.e.;inlineresistoror

inductor)forlongcableinterfaces.Provideclampingdevicesatornearinductiveloads(i.e.;relay).

Maximumwirelengthbetweenthe3Wswitchanditsloadshouldnotexceed70–100Feet

for120VACapplications.WerecommendthatyouusetheSPSTswitchoruseacurrent

limitingresistorwiredinseriesandlocatedneartheswitch.Contactthefactoryforassistance

regardingthiscondition.(ForhazardousLocationstheresistoroptionisnotallowed)

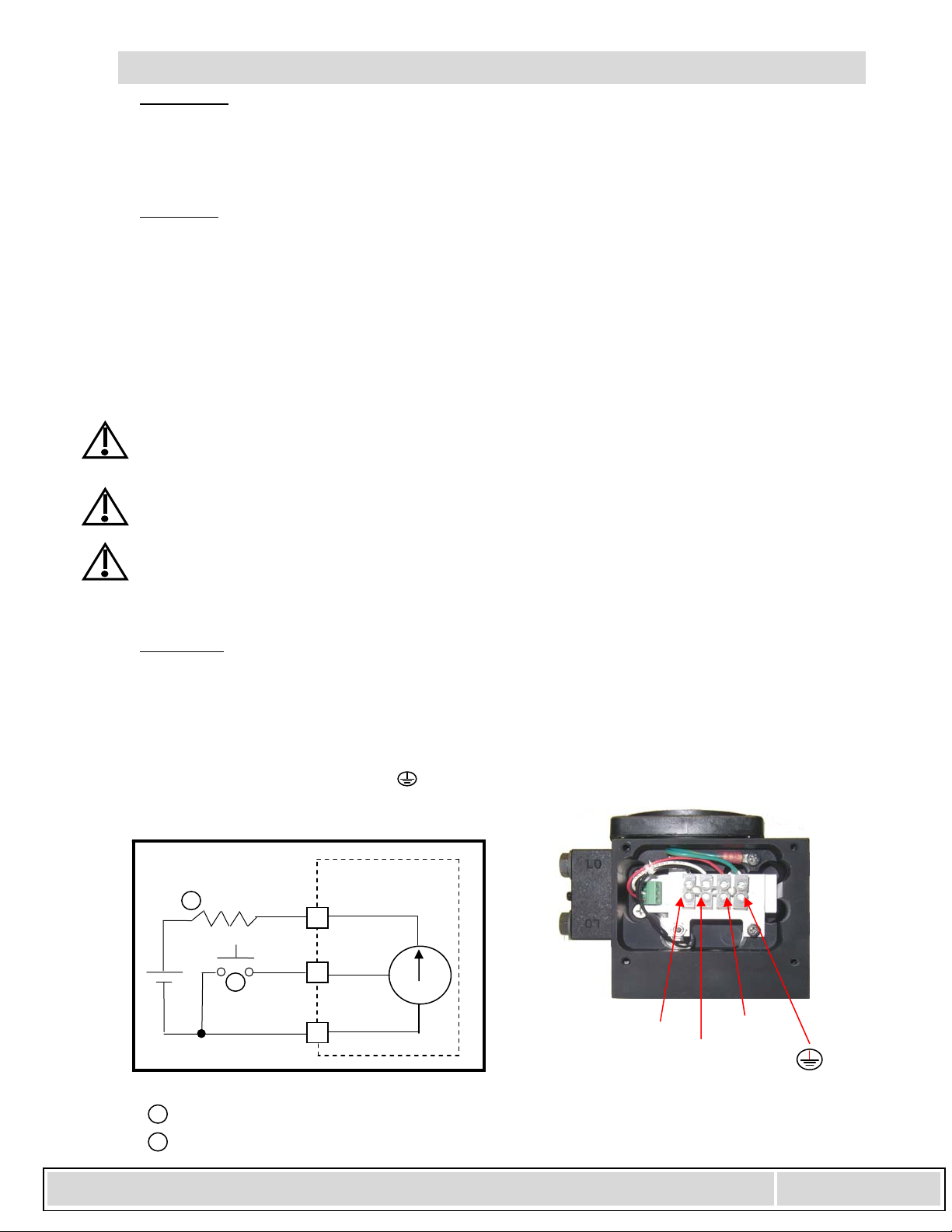

Connections:

Warning:Whenwiringtotheterminalstrip,makesureallwirestrandsarecontainedwithin

theterminalconnection.

SwitchAdjust

Access

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page8

Thereedswitch(es)arelocatedinsidetheenclosure,onthetopofthepressurehousing(standardport),and

areconnectedtoa7positionterminalstrip.Anopeningisprovidedattherearoftheenclosurefora1/2"

flexibleweather‐proofcableorconduitconnector(suppliedbycustomer)(A&BElectricalConfiguration)ora

½”FNPTconduitinterface(E&FElectricalConfiguration).Uponrequesttheholemaybesizedto

accommodateaPG‐11cableglandconnector.

Toaccesstheterminalstripremovetheswitchenclosurecoverbyremovingthe(4)screws.Insertwires

throughanappropriate(notsupplied)weatherproofconnectorintotheenclosureandconnecttothe

terminalstrippertheterminalstripdiagramshownbeloworontheundersideoftheswitchenclosurecover.

Thecenterconnectionisforconnectionofaprotectiveconductorandisconnectedtothebodyofthe

pressuregauge.

Theterminalstripwillacceptwiresintherangeof22Awg‐16Awg..

Reinstallthecover,gasket,and(4)screws.(Fig.3)afterconnectionof

fieldwiring.

WiringfortheSPSTswitchesisconnectedbetweenNOandCM

connectionsontheterminalstrip.Normallyclosedswitchesare

generallynotavailable.Pre‐setswitcheswillhavetheirsetpoints

identifiedonthelabel.

ElectricalConfigurationsA,B,E,F

ElectricalconfigurationsA,B,E,&Fcan

beusedinPollutiondegree3IndustrialtypeareasTheseconfigurationsareratedNEMA4XIP65.

TheenclosureforConfigurationA&Bisamoldedplastic,whereastheenclosureforconfiguration’sE&Fare

madefromAluminum.

Note:ConfigurationA,&B,hasanelectricalaccesshole(.875).ConfigurationsE&Fhasa1/2”FNPT

conduitinterface.ThesafetyevaluationandtheNEMAratingsfortheseconfigurationswasperformed

withthisaccesssealed.

Areverseportgaugehastheswitchhousinglocatedonthebottomofthegaugebody

ElectricalConfigurationsE&F:

TheE&FElectricalConfigurationare3RDpartycertifiedforClassI,DivisionII,GroupsA,B,C,&D,ClassII,

GroupsF&Ghazardousenvironments.TheCSAmarkidentifiestheproducthasbeentestedtothe

applicableUSstandardsandCanadianstandards.

Warning!Pleasenotethepressureratingsonthe

HazardousLocationsTag.Maxworkingpressures

arereducedforHazardousLocationsto1375PSID

forallmaterials

ElectricalConfigurationsTorW:(TransmitterOption)

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page9

Intendeduse:

TheModel142TransmitterisintendedforuseinGeneralPurposeLocations(Telectricalconfiguration)or

Division2hazardouslocations(Welectricalconfiguration).InbothcasestheenclosurecarriesaNEMA4X

IP65environmentalrating.

Description:

ThetransmitterassemblyifCEmarkedisalsocompliantwithEMCDirective2004/108/EC.Thetransmitter

hasafactoryprogrammedlow‐passfilter.Thefilterissettoapproximately1second.Thiscanbeincreased

ordecreaseduponcustomerrequestatthetimeoforder.

Note:Thetransmittercircuitrysensesthepositionofamagnet.Anymagneticobjectlocatednearthegauge

mayaffecttransmitteraccuracy.

Thetransmitterifnecessarycanbezeroedbyjumperingpin2toGndpin1momentarilyfor2seconds(with

theunitpowered).Inmostcasesthiswillneverbenecessaryasthetransmitterisprogrammedtogeneratea

4maoutputforthefirst4%oftheFSR.

Warning: IfzeroingintheHazardousLocationenvironmentuseaswitchapprovedforthatlocation.

Caution: Donotzerothetransmitterwithpressureapplied.Otherwiseyourproductwillhavea

negativeoffsetequivalenttothepressurewhenthezerowasactivated.

Caution:Donotattempttorepositionthetransmitterassemblywithintheenclosure.Thisvoidsthe

warrantyandwill“knock”theunitoutofcalibration.Disassemblyandre‐assemblyofany

internalprocesspartswillalsorequiretheunittobere‐calibrated.Calibrationmustbe

performedatthefactory.

Connections:

Theweather‐proofenclosurecomesstandardwitha½”FNPTconduitinterface.Theinternal4position

terminalstripacceptswiresizes22AWG–16AWG.

Toaccessthe4positionterminalstrip,removethe4coverscrewsfromtheenclosure.Connectlooppower

betweentheconnectionslabeled8‐28VdcandReturn(seeFigurebelow).Connecttheprotectiveconductor

wiretotheterminalidentifiedwiththesymbol.SeetheInterfaceschematicbelow.Pleasenotethatthe

looppowersensingdevicecanalsobelocatedinthegroundleg.

RLoo

p

To Transmitter

8-28 Vdc Pin 3

To Transmitter

GND Pin 1

Interface Schematic

8-28Vdc To Transmitter

Zero Pin 2

4-20 ma

3

2

1

DP Transmitter

Customer Interface

1

2

1 Optional remote zero (customer supplied)

2 Loop Resistor can be located in the ground leg

Zero

Return

8-28

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page10

Warning:Whenwiringtotheterminalstrip,makesureallwirestrandsarecontainedwithin

theterminalconnection.

Themaximumloopresistanceis1000ohms(@28VdcInput).Usethefollowingformulatodeterminethe

maximumloopresistanceatotherinputvoltages:((Vs–8)*1000)/20)

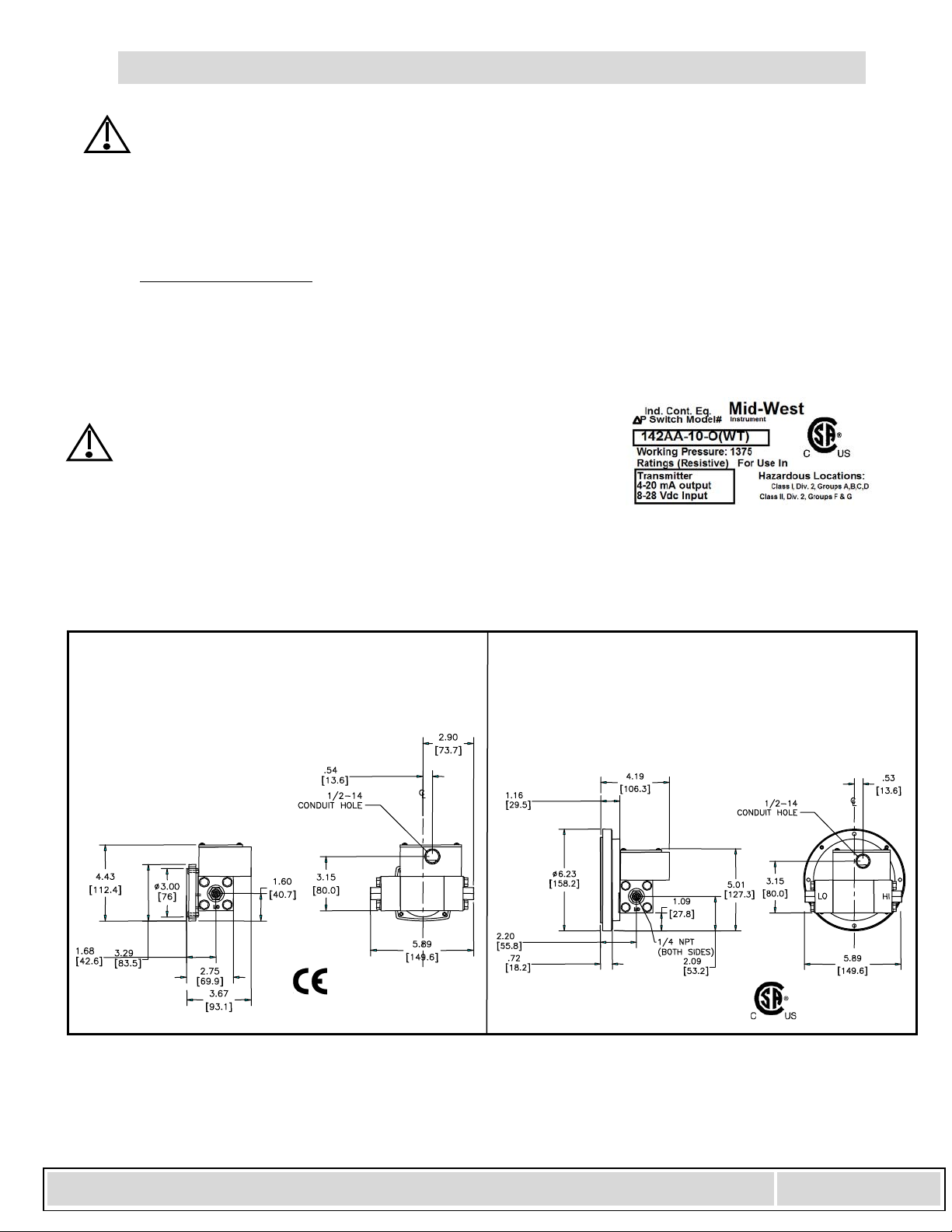

ElectricalConfigurationW:(Transmitter)

TheWElectricalConfigurationis3RDpartycertifiedforClassI,DivisionII,GroupsA,B,C,&D,ClassII,

GroupsF&Ghazardousenvironments.TheCSAmarkidentifiestheproducthasbeentestedtothe

applicableUSstandardsandCanadianstandards.

Warning:PleasenotethepressureratingsontheHazardous

LocationsTag.Maxworkingpressuresarereducedfor

HazardousLocationsto1375PSIDforallmaterials

6.0 Dimensions

ElectricalConfiguration:TorW

Model140/141EndConnected

WithTransmitter2½”Dial

ElectricalConfiguration:TorW

Model140/141EndConnected

WithTransmitter4½”Dial

Woption=ClassI,Div.2,GroupsA,B,C,D

ClassII,Div2,GroupsF& G

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page11

6.0Dimensions(cont.)

DIM 2 ½ 2 ½ 4 ½

A 7.12

(180.9) 6.53

(163.3) 8.50

(215.9)

B 4.15

(105.4) 2.12

(53.84) 2.50

(62.5)

C 3.15

(80.01) 3.12

(79.24) 4.35

(110.5)

D 6.00

(152.4) 6.56

(166.6) 6.25

(158.8)

E 8.75

(222.2) 7.75

(196.9) 9.12

(231.6)

F 7.35

(186.7) 6.68

(169.7) 7.75

(196.9)

G 3.80

(96.52) 3.80

(96.52) 3.80

(96.52)

H 8.12

(206.3) 7.43

(188.7) 7.75

(196.9)

2½”DIAL

DialSize

ElectricalConfiguration:AorB

NEMA4X4½INCHDIAL

ElectricalConfiguration:AorB

NEMA4X2½INCHDIAL

ElectricalConfiguration:EorF

NEMA4XMETALENLOSURECLASSI,DIV.2,GROUPSA,B,

C,DCLASSII,DIV2,GROUPSF&G

ElectricalConfiguration:CorD

Explosion‐proofEnclosuresClassI,GroupsC&D

ClassII,GroupsE,F&G

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page12

7.0Troubleshooting

A. Gaugeaccuracyandsetpointproblems:

i. Verifyyourprocessconnectionsareplumbedproperly

ii. Verifygaugeisnotinanelectromagnetic/magneticenvironment.i.e.;closeproximitytohighcurrent

powerlines.

iii. Verifythepointerhasfluidmovementaspressureincreases.Nomovementmayindicateablown

diaphragm.

iv. Allotherscontactthefactoryforassistance.

B Switchdoesn'tfunction

i. Makesurethattheswitchloaddoesnotexceedthespecifiedwattageratingoftheswitch.(steady‐state

andtransient).Contactfactoryforassistanceforexcessiveloads,otherwiseproceedtothenextstep.

ii. Performacontinuitycheckoftheswitchcontactsbytryingtoactuatetheswitchusinganexternal

magnet.Anoperationalswitchusuallyindicatesaproblemwiththegauge.Ifnotoperationalproceed

tothenextstep.

iii. Verifythereedswitchwiresareconnectedtotheterminalstrip(NEMA4Xenclosureonly).Contact

thefactoryforassistanceiftheswitchisconnectedand/orrequestan"RGA"number.

C.Transmitterdoesn'tfunction

i. Makesureyouhavesuppliedpower(propervoltage)totheunit.

ii. CheckthatyouarewiringtothecorrectInterfaceterminals.

iii. Checkthetransmitterinterfacestotheterminalboardforlooseconnections.

iv. Makesurethattheloopresistancedoesnotexceedthespecifiedrating.

v. Makesureyoudidnotzerotheunitwithpressureapplied.Tryare‐zeroat0pressure.

8.0Misc:

CEMarkingStatements:

LowVoltageDirective

TheElectricalConfigurationsA,B,E,F,ofthisproductareCEmarkedincompliancewiththeLowVoltage

DirectivetoEN‐61010‐1.ElectricalconfigurationsTandWfalloutsidethescopeofthedirective.

ATEXDirective94/9/EC

Model140producthasnotbeenevaluatedtotheATEXdirective.

Electrical Installation and O

p

eratin

g

Instructions - Model 140

6500dobrydrsterlingheights,mi48314Page13

PressureEquipmentDirective:

ThePressureEquipmentDirectivehasbeendeterminedtobenon‐applicableforCEmarkingforGroup1

applicationsbelow200barorGroup2applicationsbelow1000bar..Theseproductsaremanufacturedin

accordancewitharticle3,paragraph3ofthedirective,“soundengineeringpractice”.Theyfallbelow

categoryIfornon‐hazardousgases,hazardousliquids,&non‐hazardousliquids.Thisproductalsofallsbelow

categoryIforhazardousgasesatorbelow200bar.

EMCDirective(2004/108/EC):

Optionally,transmitters(ElectricalConfigurationsT&W)maybeCEmarkedforcompliancewiththeEMC

Directive2004/108/EC.Thetransmitterdesignhasbeenevaluatedtoandpassedthefollowing“EN”

StandardsastheyrelatetotheEMCdirective.

EN 61326:2013 Environment Industrial, Electrical Equipment for measurement, Control and

Laboratory use,

EMC requirements from which:

EN55011:2009 + A1:2010 Emission, Class B

EN61000-4-2:2009 Electrostatic discharge (ESD) immunity

EN61000-4-3:2006 +A1:2008 Radiated EM field immunity

+A2:2010

ENV50204:1995 Radiated EM field immunity from digital telephones (GSM)

EN61000-4-4:2004 +A1:2010 Electrical fast transient (EFT) immunity

EN61000-4-5:2006 Surge transient immunity

EN61000-4-6:2009 RF conducted immunity

EN61000-4-8:2010 Power Frequency magnetic field immunity

ForallotherconfigurationstheEMCDirectiveisnon‐applicable.

ROHSDirective:

TheelectricalConfigurationsA,B,E,FofthisproductareCEmarkedincompliancewiththeRoHsdirective

2011/65/EU(RoHs2).ElectricalConfigurationsT&WwillbeCEmarkedforcompliancewithRoHS2whenthe

productismarkedforcompliancewiththeEMCDirective.

Warning: Thesuitabilityoftheapplicationandinstallationofthisdifferentialpressure

switch/transmitteristheresponsibilityoftheenduser.Theapplicable

certifications,listingsapplytothedifferentialpressureswitch/transmitteronly.

STANDARDS:AllModel142Seriesdifferentialpressuregaugeseitherconformtoand/oraredesignedtothe

requirementsofthefollowingstandards:

ASMEB1.20.1 NACEMR0175

ASMEB40.1 NEMAStd.250

EN‐61010‐1 ULStd.No.50,508,&1604

CSA‐C22.2No.14,25,,&213

Table of contents