Operator’s manual

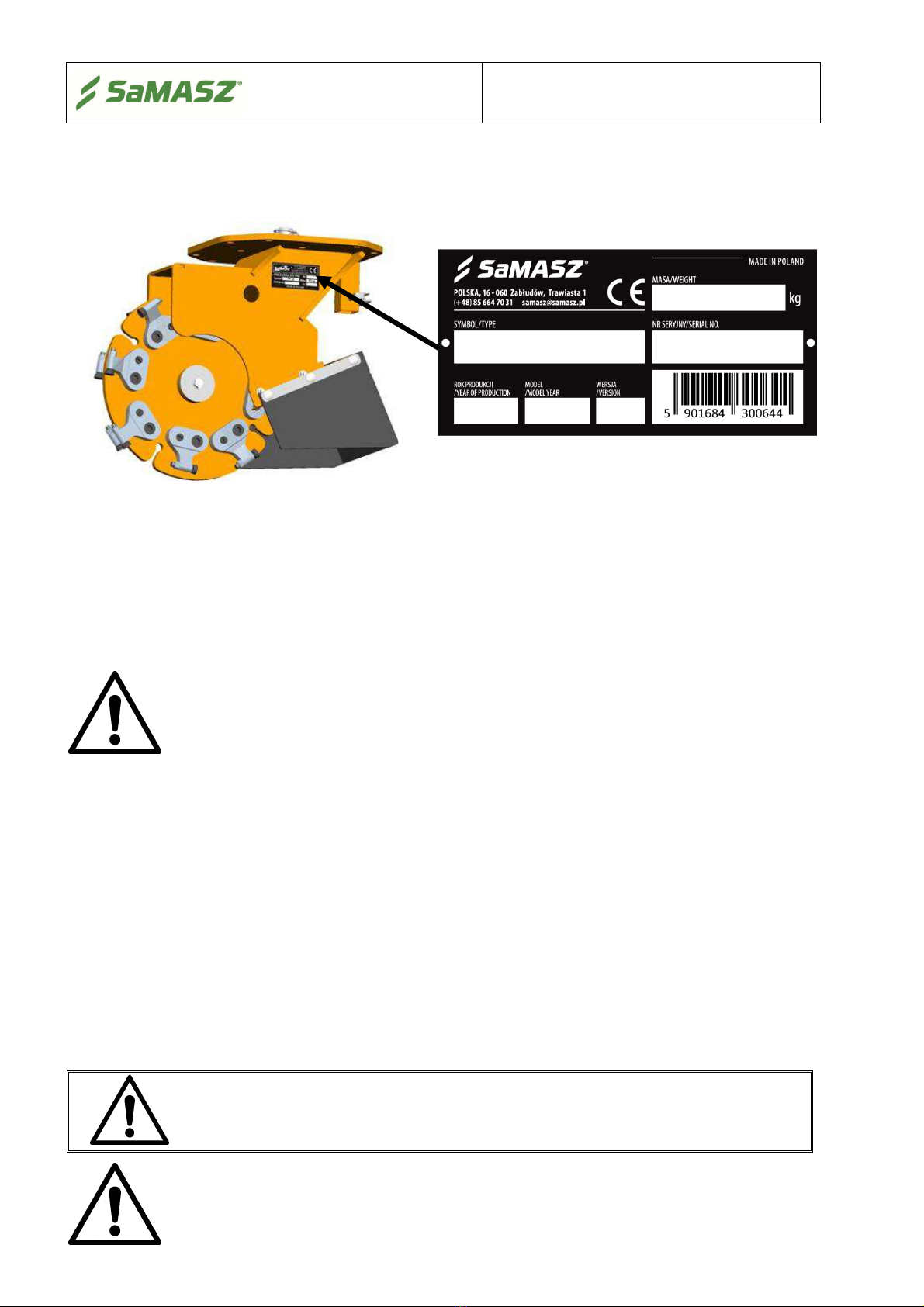

TREE STUMP GRINDER

FP 20

- 7-

Operate the grinder only when the tractor is not moving, and move the grinder only by the

extension arm and adjust the operation to conditions such as size and number of tree stumps to

be ground.

Do not operate the tree stump grinder after dusk.

Do not leave the aggregation of tractor and extension arm on slopes or other inclinations

without providing any additional protection.

Do not operate with damaged or missing guards (Journal of Laws No. 12/98 item 51.)

In case of a fatal failure, stop the machine's drive, turn the tractor's engine off and take out the

ignition key. Then call for technical service, and if an accident (in this case: road accident)

occurs, respect first aid rules and contact responsible authorities.

4.1.4 Inspection and repair

Perform any inspection, repair and maintenance works as well as cleaning parts or assemblies

when the drive is switched off and there is no pressure in the hydraulics, having taken the

ignition key off and set the aggregation of tractor and machine in a standstill position (Journal

of Laws No. 12/98 item 51.)

Inspect bolts and other fasteners regularly. Do not operate with damaged or worn fasteners.

Do not operate with damaged or worn fasteners. When the rubber guard shows signs of ageing

(e.g. micro cracks over the surface), it should be replaced.

Do not perform any repair works underneath the lifted machine’s assemblies, unless protected

against free falling (Journal of Laws No. 12/98 item 51.)

Replace damaged or worn (aged 5 years or older) hydraulic hoses and other hydraulic parts as

recommended by the Manufacturer.

Never repair damaged hydraulic hoses with tape.

Before any operation, check the condition of cutting knives. If blunt, rotate the knife by 1/3 turn

(3 sharp cutting edges per a single knife can be achieved), or handle it for a recovery. Damaged

or worn blades must be replaced.

Use only original spare parts ordered at our store or at your dealer.

During operation, maintenance and adjustment, always wear protective gloves, shoes and

clothing without loose elements, belts, etc. Always respect warnings on safety labels attached to

the machine.

When operating the hydraulics, always wear protective eyewear and gloves. Hydraulic oil

leaking under pressure (40 MPa) may penetrate the skin and cause its irritation thereafter. In

such case, visit a doctor immediately.

In the event of a serious failure, please call for technical service, and if an accident (in this case:

road accident) occurs, respect first aid rules and contact responsible authorities.

CAUTION:

Prior to maintenance and repair the machine, turn off the engine of tractor. All

rotating parts should be stopped.

4.1.5 Replacement of damaged or worn parts

Any works related to replacement of worn or damaged parts should be done only after the

machine has been switched off, and having previously learned the contents herein.

When conducting repair works or replacing worn or damaged parts wear protective gloves,

protective footwear as well as protective clothing without any loose elements.

When operating with the machine lifted up, protect it properly with supports and when

replacing parts with sharp edges, use personal protective equipment and corresponding tools.

Once works related to replacement of defective parts are completed, mount back all elements of

guards and safety devices.

CAUTION:

When conducting repair works or replacing worn or damaged parts wear

protective gloves.