6

Every 6 months, 1800 operating hours or after each

50,000 miles:

Remove the discharge head fittings and inspect the

compressordischargeportanddischargelineforexcessive

carbondeposits.Ifexcessivebuildup is noted in either,the

discharge line must be cleaned or replaced and the

compressor checked more thoroughly, paying special

attention to the air induction system, oil supply and return

system, and proper cooling. If necessary, repair or replace

thecompressor.Checkforproper belt andpulleyalignment

andbelt tension.Adjustifnecessary,payingspecialattention

not to over tighten the belt tension. Check for noisy

compressor operation, which could indicate a worn drive

gear coupling or a loose pulley. Adjust and/or replace as

necessary. Check all compressor mounting bolts and

retightenevenlyif necessary.Checkfor leakageandproper

unloadermechanismoperation.Replace if defectiveinany

way.

Every 24 months, 7200 operating hours or after each

200,000 miles:

Perform a thorough inspection as indicated below and

dependinguponthe resultsofthis inspectionorexperience,

disassemble the compressor, clean and inspect all parts

thoroughly,repairorreplace allwornordamagedpartsusing

only genuine Bendix replacements or replace the

compressorwithagenuine Bendix remanufacturedunit.

Important:Shoulditbenecessarytodraintheenginecooling

systemtopreventdamage from freezing,thecylinderhead

of the compressor must also be drained.

GENERAL SERVICE CHECKS

INSPECTION

Itisoftheutmost importance that the compressorreceives

a clean supply of air. The air strainer must be properly

installedandkeptclean.Ifthecompressorintakeisconnected

to the engine air cleaner, supercharger, etc., these

connections must be properly installed and maintained.

Checkthecompressormountingstobesuretheyaresecure.

Checkthedriveforproperalignment, belt tension, etc.

Inspect the oil supply and return lines. Be sure these lines

areproperlyinstalled and thatthecompressor is gettingthe

proper supply of oil, and just as important, that the oil is

returningtotheengine. Checkthecoolantlinesto and from

the compressor and see that the cooling fins on the

crankcasearenotcloggedwith dirt, grease, etc.Checkthe

unloadermechanismfor properandpromptoperation.

OPERATING TESTS

Vehicles manufactured after the effective date of FMVSS

121,with theminimum requiredreservoirvolume,musthave

a compressor capable of raising air system pressure from

85-100 P.S.I. in 25 seconds or less. This test is performed

withthe engineoperatingatmaximumgovernedspeed.The

vehiclemanufacturermustcertify this performance onnew

vehicles with appropriate allowances for air systems with

greaterthanthe minimumrequiredreservoir volume.

AIR LEAKAGE TESTS

Leakage past the discharge valves can be detected by

removingthedischarge line,applyingshop airbackthrough

the discharge port and listening for escaping air. Also, the

dischargevalvesandthe unloader pistons canbechecked

forleakagebybuildinguptheairsystem until the governor

cutsout,thenstoppingthe engine.Withtheenginestopped,

listenforescapingair at the compressorintake.To pinpoint

leakage if noted, apply a small quantity of oil around the

unloader pistons. If there is no noticeable leakage at the

unloader pistons, the discharge valves may be leaking. If

the compressor does not function as described above, or

leakageisexcessive,itis recommended that itbereturned

to the nearest authorized Bendix Distributor for a factory

remanufactured compressor. If this is not possible, the

compressor can be repaired using genuine Bendix

replacementparts,inwhich case, the followinginformation

shouldprove helpful.

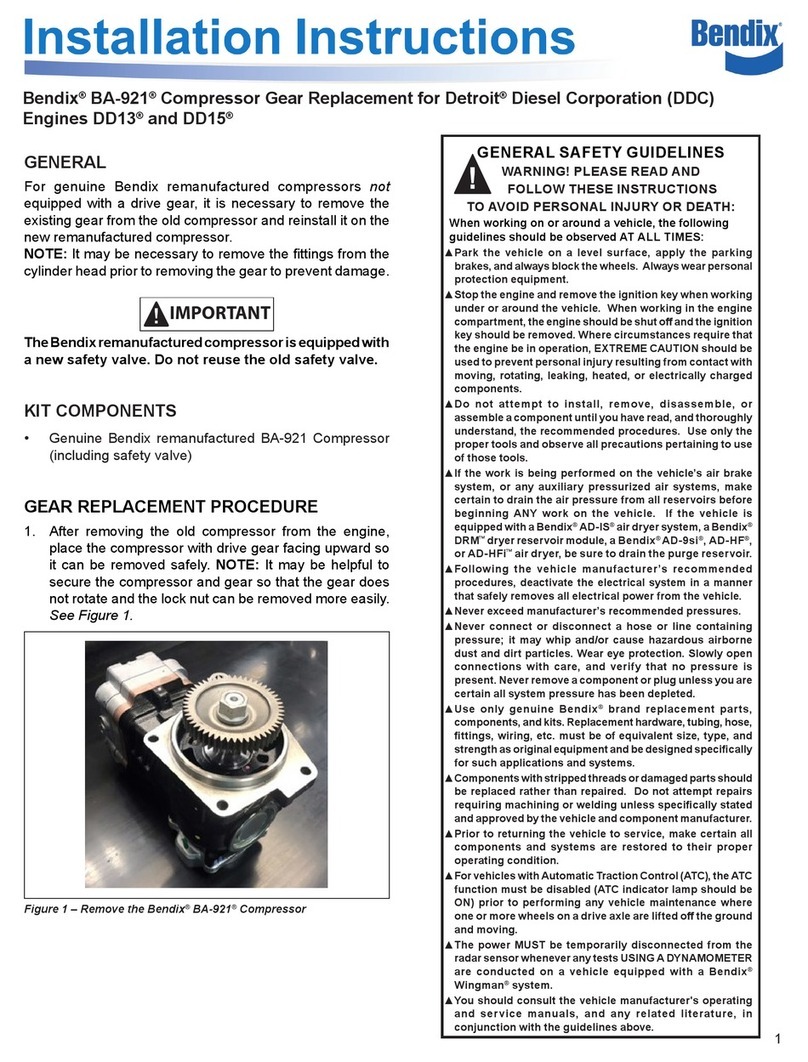

REMOVING AND DISASSEMBLY

REMOVING

These instructions are general and are intended to be a

guide,insomecasesadditionalpreparationsandprecautions

are necessary. Chock the wheels of the vehicle and drain

theairpressurefromallthe reservoirs in the system. Drain

the engine cooling system and the cylinder head of the

compressor. Disconnect all air, water and oil lines leading

to and from the compressor. Remove the drive gear(s) or

pulley from the compressor crankshaft using a gear puller.

Inspect the pulley or gear and associated parts for visible

wearordamage. Sincetheseparts areprecisionfitted,they

mustbereplacediftheyareworn or damaged.

DISASSEMBLY

GENERAL

Remove road dirt and grease from the exterior of the

compressorwitha cleaningsolvent.Before thecompressor

is disassembled, the following items should be marked to

showtheirrelationship whenthecompressoris assembled.

Mark both the front and rear end cover in relation to the

crankcase. Mark the drive end of the crankshaft in relation

tothefrontendcover and the crankcase.Markthecylinder

head in relation to the block and the block in relation to the

crankcase. Mark the base plate or base adapter in relation

to the crankcase.