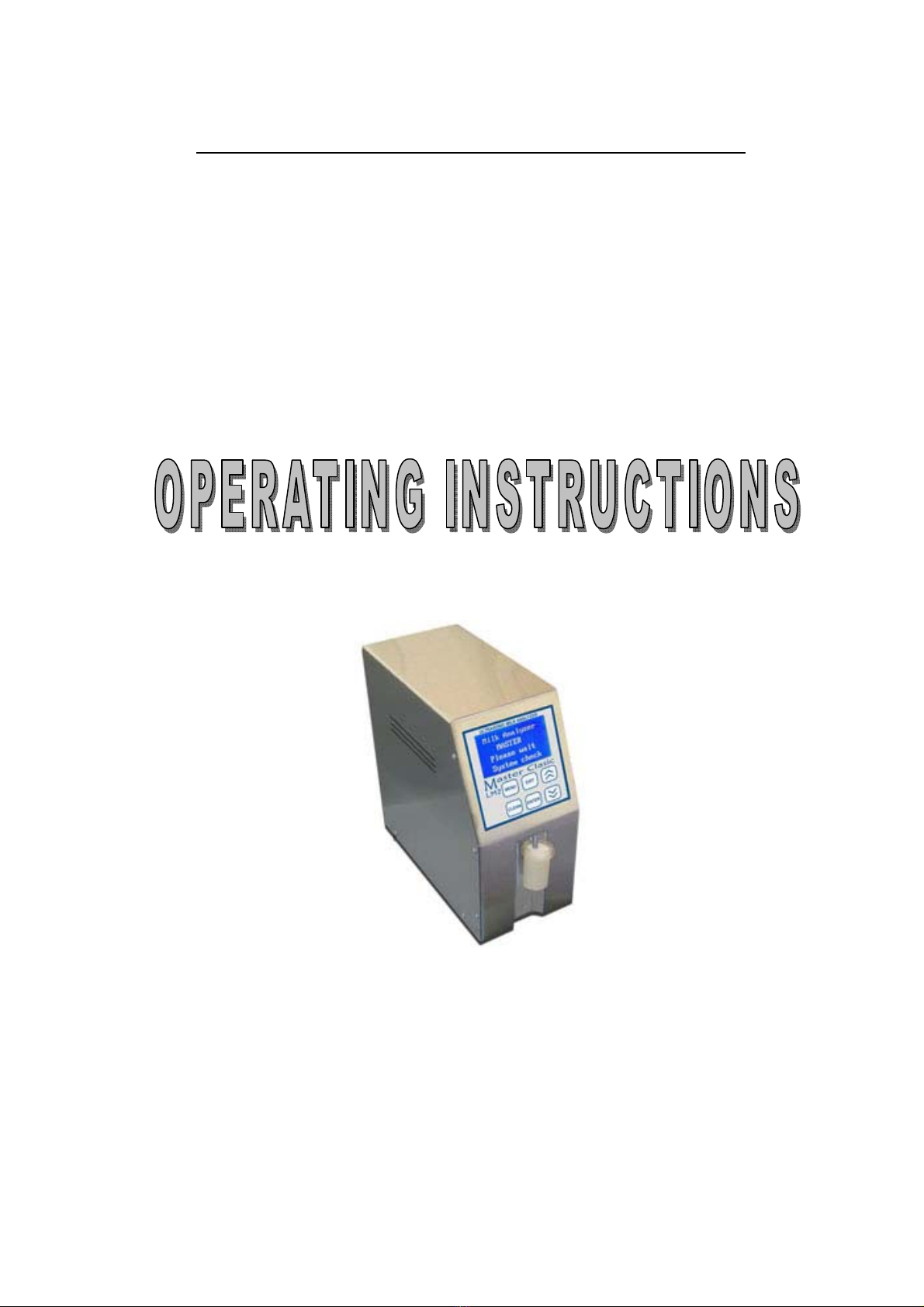

Milkotester MASTER LM2-P2 User manual

Milkotester Ltd.

49, Hristo Botev St., 4470 Belovo, BULGARIA, Phone: +359 889 259 646

MILKOTESTER

Milk analyzing device

Model: MASTER LM2-P2

Fat, Solids-Non-Fat (SNF), Protein, Lactose, Water content,

Temperature (°C), Freezing point, Solids, Density, pH

THE INFORMATION CONTAINED IN THIS MANUAL IS A SUBJECT TO

CHANGE WITHOUT NOTICE. FOR UPDATES, PLEASE CONTACT THE

MANUFACTURER OR USE THE FOLLOWING WEB ADDRESS :

http://www.milkotester.com

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

2

Safety recommendations :

Read carefully and make sure you understand all the

instructions.

After initially turning on the device do recommend 3-4

cycles of "Clean"

Place the device on a leveled and stable surface. If it falls

or is severely shocked its functional systems may be

damaged.

When plugging the device into the electrical outlet, put away

the power cord so it does not stay in the way when

accessing the device and cannot be stepped on.

Unplug the device from the electrical outlet every time

before cleaning. The device must remain unplugged from

the outlet for the entire time during cleaning.

Do not disassemble the device in order to avoid possible

electrical shock. In case of malfunction contact your local

dealer.

Handle the liquids the device works with carefully, following

all the instructions for their preparation.

CAUTION!

This device operates on 100-250V. In order to avoid electrical

shock or to prevent the unit from damage DO NOT REMOVE the

cover!

Please follow the instructions in this manual !

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

3

Table of contents

1. General description ........................................................................ 4

2. Close-up view................................................................................. 5

3.1 Front panel.......................................................................... 5

3.2 Display ................................................................................ 6

3.3 Back panel .......................................................................... 7

3. Samples preparation ...................................................................... 8

4. Working description........................................................................ 10

4.1 Preparing the device ........................................................... 10

4.2 Measuring samples............................................................. 11

4.3 Making corrections and calibration ..................................... 13

4.3.1 Correction ............................................................... 15

4.3.2 Calibration............................................................... 16

4.4 Settings and options ........................................................... 19

4.5 Connecting to printer .......................................................... 23

4.6 Measurement of pH ............................................................ 24

5. Cleaning and maintenance ............................................................ 26

5.1 Routine cleaning ................................................................. 26

5.2 Complete flushing ............................................................... 27

5.3 Weekly cleaning.................................................................. 27

5.4 Peristaltic pump service ...................................................... 27

6. Troubleshooting ............................................................................. 28

7. Technical specifications ................................................................. 29

Appendix Freezing point determination.............................................. 31

Appendix Conductivity measuring ..................................................... 35

Appendix Internal printer .................................................................... 36

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

4

MILKOTESTER MASTER is designed for percentage analysis of Fat,

Solids-Non-Fat (SNF), Protein, and Lactose, Water content,

Temperature (°C), Freezing point, Solids, Density and pH. Тhese

components can all be measured at the same time. The device

measures cow milk, sheep milk, buffalo milk, camel milk, lama milk,

restored milk, UHT, cream, whey and buttermilk.

The factory preset is for cow milk, sheep milk and UHT. Upon user’s

request the device can be calibrated for any of the above mentioned

types of milk.

The device has a compact design with a robust structure and a user-

friendly interface. Most importantly, the one-button operation is

extremely simple – you press only once to start measuring, you press

only once for cleaning. MILKOTESTER MASTER can analyze three

types of milk defined by user. The measurement speed is 50 samples

per hour with cleaning included. The samples are precisely dosed and

small quantities are required – the sample volume is 25 cm³. No

thermal or mechanical treatment of the samples before analysis is

necessary. No use of chemical reagents is required. The working

conditions are as follows – temperatures from 5° to 35 °C, HR from

30% to 80%.

With regard to the “moisture problem” which remains of much

significance the front panel of the device is designed to operate when

with wet hands. In addition to this MILKOTESTER MASTER provides a

one year’s full warranty.

General description

CHAPTER ONE

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

5

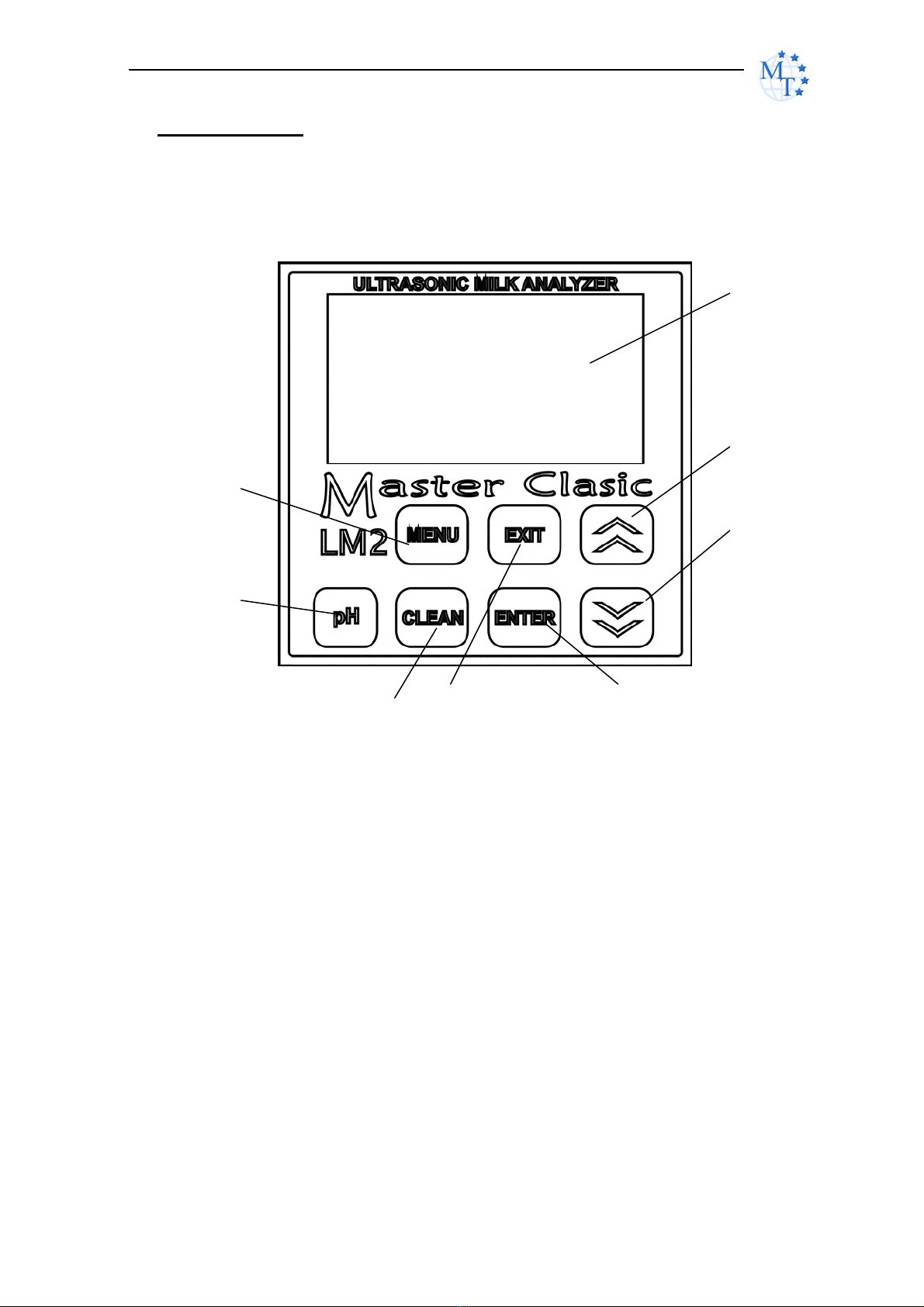

2.1 Front panel

1 – Intake pipette

2 – Sample cup

1

2

Close-up view

IN THIS CHAPTER

Front panel

Display

Back panel

CHAPTER TWO

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

6

Close-up view

2.2 Display

1 – LCD

2 – Arrow UP button

3 – Arrow DOWN button

4 – ENTER button

5 – EXIT button

6 – CLEAN button

7 – pH measurement

8 – MENU button

1

2

3

456

7

8

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

7

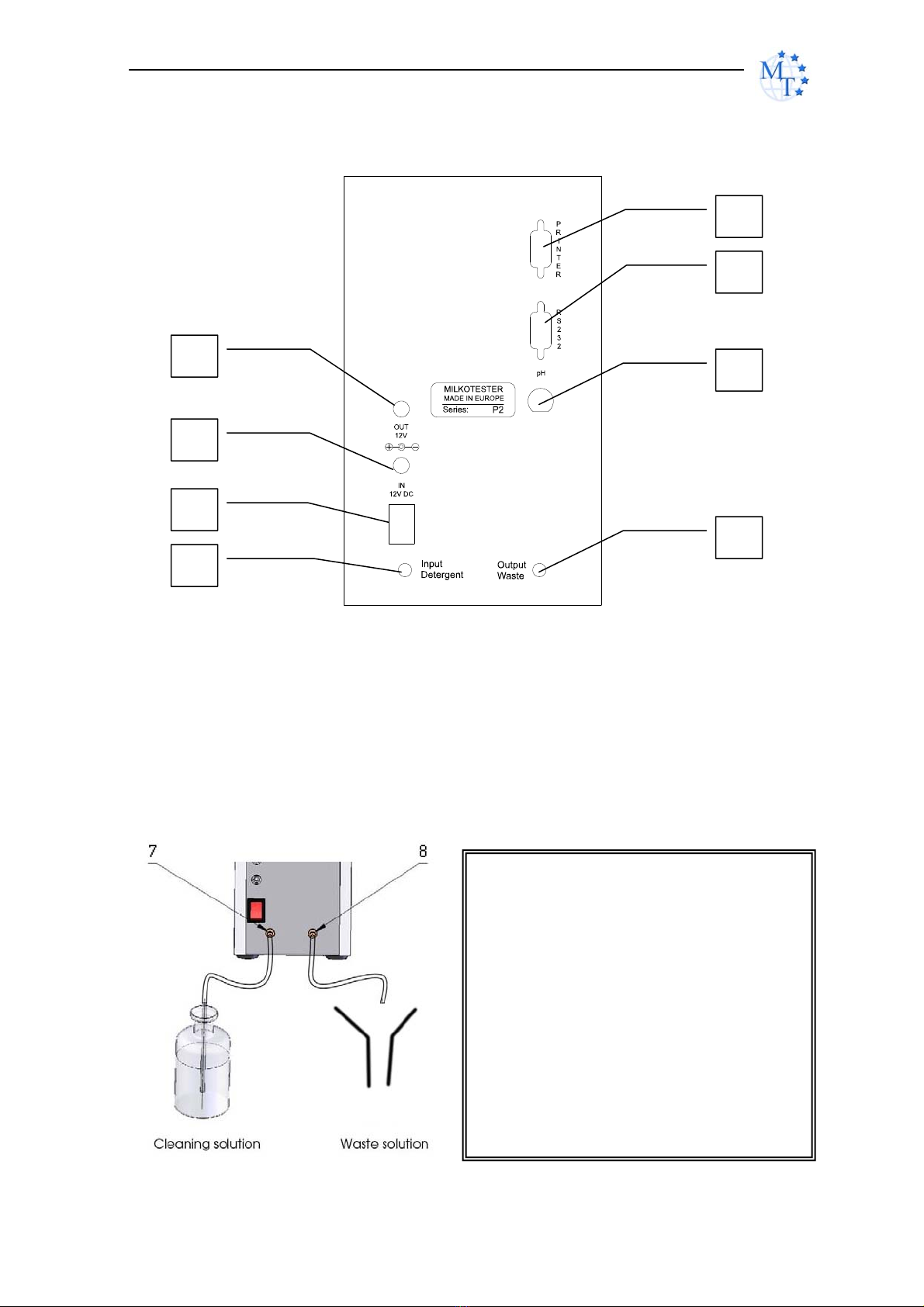

2.3 Back panel

1 – Serial port to printer

2 – Serial port RS 232

3 – Power out 12V (for printer)

4 – Power in socket 12V DC

5 – Power switch

6 – pH connector (feature is available on models pH)

7 – Input Detergent

8 – Output Waste

1

2

6

5

4

3

8

7

Pay attention to the pipes in

both reservoirs. The pipe in the

reservoir with the cleaning

solution has to be well dipped in

the cleaning solution while the

pipe in the reservoir with the

already used samples and

cleaning solution MUST NOT be

dipped in the liquid.

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

8

In order that most accurate results are obtained it is important that the

milk be kept for 2 hours after milking and stirred well before being used

for sample material. A good way to stir up the milk is to pour it several

times out of one vessel into another and back. Before analysis the

samples have to be filtered in order to be free from foreign fragments.

Milk samples should be 5-35 °C. Full cream samples containing fat

over 10% should be heated up to 42-43 °C and then cooled to 25-30

°C. If the sample temperature is over 36 °C the message “Sample

overheated” will appear on the display. Use milk samples only once

and do not return it to the vessel. Samples can be kept for a maximum

of 2 days if they are stored at a temperature not exceeding 5 °С.

Milk stirring

It is a very important condition for receiving exact results. Before

taking samples from big vessels the milk (fresh or thermally treated,

whole-milk or whipped) has to be well stirred for no less than 5 min., by

vertical and circular slow movements. Mixing spoon with long handle is

used, allowing the lowest layers of the liquid to be reached. The milk in

the milk-cans is stirred 5 to 8 times from the surface to the bottom and

reverse with slow circular movements.

Sample preservation

The vessels where the samples will be put have to be clean, dry,

glass, metal or from other suitable material, to be tightly closed with

rubber or other stopples. The stopples not to absorb water and fat and

not to influence the analyses sample content.

In summer the sample fills up to the top the vessel, but in winter

– at least 3/4 from the vessel’s volume. Each sample for analyses has

to be labeled and described in a way not allowing to be mixed up.

Samples preparation

CHAPTER THREE

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

9

The samples are stored in conditions, assuring temperature,

corresponding to the requirements for storing such kind of product

(advisable – 1 oС).

If there is a need of longer sample storing they have to be

preserved; the most commonly used preservative is potassium

dichromate (K2Cr2O7) - 1 g for 1 000 ml. The samples have to be

stored in a cold and dark place after the preservation. Have in mind

that during the analyses the results for SNF% will be increased with

0,1 %. After adding the preservative the sample has to be well stirred.

Preparing the samples for analyses

Milk – raw and thermally treated

When examining samples taken immediately before analyses

and shortly stored, the milk is poured several times from vessel to

vessel in order to distribute the fat content uniformly. To avoid foam

formation or separation of milk fat, the samples have to be carefully

poured using the walls of the vessels, as they are tilted slightly. For a

better mixing the sample it has to be poured at least 3 times. When

needed the same is tempered to the temperature within the measuring

range.

If there is fat stuck on the walls of the vessel and the stopple

(when the samples were stored for a long time), the milk has to be

slowly heated up to 35-40 °С. At the same time it has to be slowly

shaken. The cream, stuck to the walls of the vessel is removed. The

sample is poured several times and is cooled down (advisable up to

20°С).

If there is separated liquefied fat or white particles with irregular form

on the vessel’s walls reliable results could not be expected.

Do not make analyses if the acidity of the milk is more than 17oT.

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

10

4.1 PREPARING THE DEVICE

1. Place the device on a horizontal and stable surface.

Caution: Any sources of hot or cold air can influence the

accuracy of the measurements.

2. Connect the power cord 12V DC to the power socket on the

rear panel of the unit and plug it into the electrical outlet (the

outlet has to be grounded, see “Important Safety

Instructions”).

3. Turn on the POWER switch and MILKOTESTER MASTER will

be ready for use. Before proceeding with using the unit,

please read and follow the rest of the instructions in this

chapter!

Powering by an external 12V DC power source

Milk analyzer MASTER can be used in places where no regular

electrical supply is available, MILKOTESTER MASTER can be

powered by your car battery or other 12V DC external power sources.

Milk analyzer MASTER has provided a cable suitable for this purpose.

To use this option, follow the procedure described below:

IN THIS CHAPTER

Preparing the device

Measuring samples

Corrections

Calibration

Working description

CHAPTER FOUR

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

11

1. Unplug the 12V DC power cable from the socket on the rear

panel of the unit and then from the electrical outlet.

2. Connect the supplied power cord 12V DC to the Power-in

socket 12V DC socket on the rear panel of the unit and plug

the other end of the cable into the electrical lighter socket

inside your vehicle.

3. The device will be turned on immediately. After starting the

unit goes into system check mode and will be ready for

analyses in about 5 minutes.

NOTE:

If the unit does not start up after it is connected to the power source,

check the fuse inside the connector plugged into the electrical lighter

socket.

4.2 MEASURING SAMPLES

After MILKOTESTER MASTER is turned on from the POWER switch,

the display reads first:

Followed by:

You can choose among three types of milk at a time, (upon user’s

request the device can be calibrated for any of the other types of

milk).

Place the cup with the milk sample

Place a second milk sample under the pH probe (the automatic mode

for pH measurement must be turned on).

When you choose the desired type you use the ↑↓(UP and DOWN)

arrow buttons, and then press ENTER to activate analyzing.

Milk Analyzer

MASTER

Please Wait

System prepare

>Cow Milk

Sheep Milk

UHT Milk

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

12

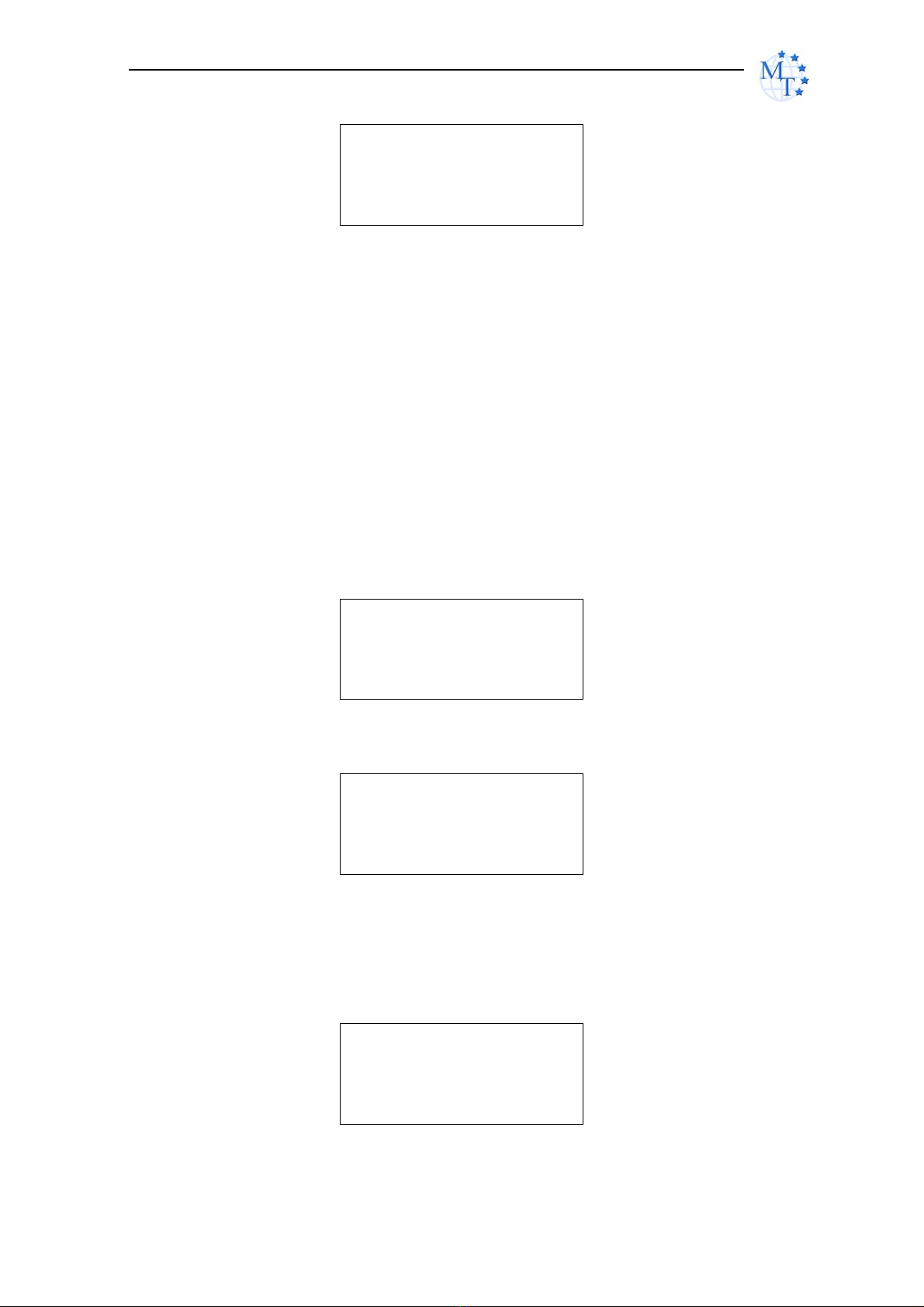

The following text will appear:

In about 60-90 sec. the results of analyzing will appear on the display

as follows:

Where:

F is for Fat

S is for Solids-Non-Fat (SNF)

D is for Density

Fp is for Freezing point

P is for Protein

L is for Lactose

Sl is for Solids

W is for Added water.

In 10 seconds you can check the result of the pH sample by pressing

the button. (active only on request)

Page1

The results will be printed immediately after

they are ready.

By choosing the ENTER button you can

start measuring anew.

Page2

By choosing the EXIT button you can start

from the very beginning and choose to

analyze another type of milk.

When finished analyzing the instrument

issues a beep sound, returns the analyzed sample material back into

the cup, and the values of all measured components appear on the

MEASURING…

Please Wait

F=xx.xx P=xx.xx

S=xx.xx L=xx.xx

D=xx.xx Sl=xx.xx

Fp- x.xxx W=xx.xx

F=xx.xx P=xx.xx

S=xx.xx L=xx.xx

D=xx.xx Sl=xx.xx

Fp=x.xxx W=xx.xx

Temp. xx.xx

pH = xx.xx

Co = xx.xx

↓

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

13

display. If the unit is connected to the printer all results will be

automatically printed out.

At this point the sample cup can be removed from under the pipette.

The instrument will continue to show the measured values until a new

analysis is initiated.

WARNING!

Make sure that the instrument is at rest during analysis. Any shaking of

the device will cause inaccurate results.

NOTE:

Due to the possible presence of water inside the flow system left from

the last flushing procedure, we recommend that you do not take into

account the first analysis after flushing if they appear inaccurate. To

prevent or reduce this inaccuracy due to water in the system, please

refer to chapter “Cleaning and Maintenance”, section “Thorough

Cleaning”.

To access the menu, press the MENU button. The range of functions

is grouped into submenus. Scroll through the menu to select the one

that you need and then select the settings you need to make. Press

ENTER to activate them. Press EXIT to keep the previous settings.

4.3 MAKING CORRECTIONS AND CALIBRATION

In the process of work with the analyser there is a possibility the

results to start differing between the data for some of the measuring

parameters when measured with the milk analyzer and the

corresponding reference method of analyses (Gerber for fat, Kjeldhal

for proteins etc). In order to establish the possible discrepancy and to

correct the readings of the milk analyser do the following:

Taking samples and preparation of samples for checking the accurracy

of the milk analyser, making corrections and recalibration

This is a basic moment for the correct checking the accuracy of the

analyser and for making correct and precise correction and calibration.

It is accomplished according Appendix Taking and preparation of

samples for checking correctness of the milkanalyser, making

corrections and recalibration.

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

14

Determination the type of the discrepancy:

Making measurements

Make measurements with different samples (not less than 3) with

known values of a separate parameter (for example fat content),

determined by the known reference methods of analyses (for example

Gerber's method for determination of fat content). For more accuracy it

is recommended among these samples to be also such with values,

close to the lowest and highest bounds for the measured parameters.

Make 5-time measurement for each of the samples. Calculate the

average value for each sample parameter, without taking into

consideration the first measurement for each sample.

Analyzing the measurement results

Make comparison between the values of the parameter from the

reference sample and measured with the analyser. Make analyses of

the difference received.

If the received differences are relatively constant value for samples

with different content of the analysed parameter, it is necessary to

make correction.

For example

М% of the reference samples: 2,20 3,00 3,80 4,60 5,20

М% average when measuring

with the analyser: 2,38 3,17 4,01 4,79 5,42

Difference: 0,18 0,17 0,21 0,19 0,22

Conclusion: the difference is relatively constant value and correction is

possible to be done with – 0,2 %

If the differences are not a constant value it is necessary recalibration

to be done.

For example.

М% of the reference samples: 2,20 3,00 3,80 4,60 5,20

М% when measured with the

analyser: 2,02 2,93 3,76 4,75 5,44

Difference: -0,18 -0,07 -0,04 0,15 0,24

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

15

Conclusion: It is obvious that the difference is variable value and recalibration have to be

done.

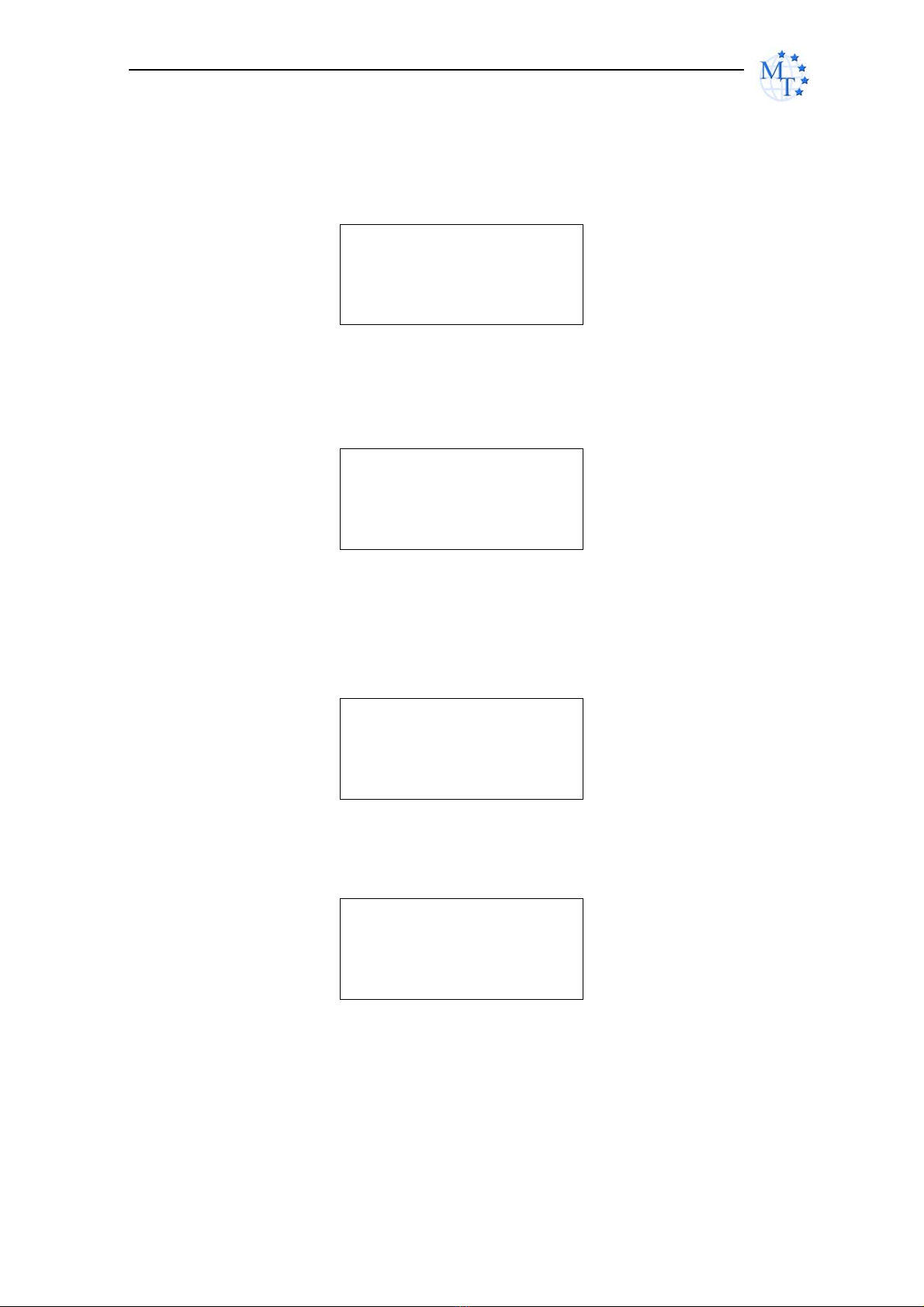

4.3.1 Correction

Example:

MENU > Mode > Correction > Cow milk > Fat.

To select Mode, Options or Settings use the ↑↓ (up and down) arrows

and press ENTER.

In Submenu Mode Use the ↑↓ (up and down) arrows and press

ENTER to select Correction, Calibration, Back up or Restore.

If you choose correction and press ENTER, then use the ↑↓ (up and

down) arrows and press ENTER to select the type of milk.

After choosing the type of milk use the ↑↓ (up and down) arrows and

press ENTER to choose a component for correction (mind that there

are 2 (two) pages of components thus scroll up and down).

Mode

Options

Settings

Correction

Calibration

Back up

Restore

Correction

Cow Milk

Sheep Milk

UHT Milk

Fat

SNF

Density

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

16

Press the ↑↓ (up and down) arrows to correct the value with 0.01.

Press ENTER to validate the correction or EXIT to keep the previous

value.

MENU > Mode > Calibration.

4.3.2 Calibration:

In order to perform calibration of the device for a certain type of milk

/for example – cow milk/. You need two samples of milk with known

values of their parameters – one with comparatively high percentage of

Fat and one with comparatively low percentage of Fat.

After pressing ENTER on the display appears:

Use the ↑↓ (up and down) arrows and press ENTER to select the type

of milk.

The following text will appear on the display:

Protein

Lactose

Salts

Water

Correction

Of Fat

0.01

Calibration

Cow milk

Sheep milk

UHT milk

Set High sample

FAT=x.xx

SNF=x.xx

DEN=x.xx

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

17

Use the ↑↓ (up and down) arrows and press ENTER to select a

parameter. Then the cursor will mark the place to enter a known value.

Use the ↑↓ (up and down) arrows to set the desired figure and press

ENTER to confirm. Then the cursor goes to the figure to the right. Use

the same procedure to enter the second and third figure. After

confirmation of the last figure the cursor goes to the next parameter for

entering new values (mind that there are 2 (two) pages of components

thus scroll up and down).

By confirming the last figure of the last parameter the following text

appears on the display:

And then

By performing the procedure described above enter the known values

of the parameters of the milk with low percentage of Fat.

After confirming the last figure of the last parameter by pressing

ENTER the following text appears on the display:

Set High sample

LAC=x.xx

SAL=x.xx

PRO=x.xx

Set Low sample

FAT=x.xx

SNF=x.xx

DEN=x.xx

Set Low sample

LAC=x.xx

SAL=x.xx

PRO=x.xx

Put sample

High Milk

1/5 times

and Press ENTER

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

18

The sample of milk with high Fat must be measured 5 consecutive

times. Put the first cup with the sample and press ENTER.After

measurement the following text appears on the display:

Follow the procedure until the 5th measurement. After performing the

last measurement the following text appears on the display:

The sample of milk with low Fat must be measured 5 consecutive

times. Put the first cup with the sample and press ENTER.After

measurement the following text appears on the display:

Follow the procedure until the 5th

measurement. After performing the last measurement the following

text appears on the display:

Follow the described above procedure. After the end of the 5th

measurement the calibration procedure is complete.

Please note:

Put Sample

High Milk

2/5 times

and Press ENTER

Put Sample

Low Milk

1/5 times

and Press ENTER

Put Sample

Low Milk

2/5 times

and Press ENTER

Put Sample

Water

1/5 times

and Press ENTER

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

19

Before each sample measurement stir the milk by pouring it from one

vessel to another.

The temperature of the samples should be in the range of 15 to 25

degrees.

Before starting calibration it is recommendable to back up the

parameters of the existing calibration:

MENU > Mode > Back up

Choose the type of milk calibration for back up and press ENTER

In case of unsuccessful calibration / electricity cut, temperature range,

etc / choose Restore from the MENU to validate the last backed up

calibration and press Enter.

MENU > Mode > Restore

4.4 Settings and options

MENU > Options

Choose Options and press ENTER.

MENU > Options > System info.

Choose System info, Language or Time and Date, and press ENTER.

Cow – calibr. 1

Sheep – calibr.2

UHT – Calibr. 3

System Info

Language

Time and Date

pH mode

----------------------------

Memory to print

Clear memory

Printer

ULTRASONIC PORTABLE MILK ANALYZER www.milkotester.com

20

MENU > Options > Language.

Language:

MENU > Options > Time and Date

Time and date:

MENU > Settings > Set Fr. Point.

Choose Settings and press ENTER.

Choose Set Fr. point or Set pH and press ENTER.

Use ↑↓ (Up and Down) arrows to choose a type of milk and press

ENTER. The following text appears on the display:

MILKOTESTER

Model: MASTER LM2

Ver: x.xx

SN: XXXXXX

English

Spanish

Set time

Set date

Set Fr. Point

Set pH

Set thermometer

Conductivity

Set f. Point Cal.1

Set f. Point Cal.2

Set f. Point Cal.3

Table of contents

Other Milkotester Measuring Instrument manuals