4650-1 Issue 04

3

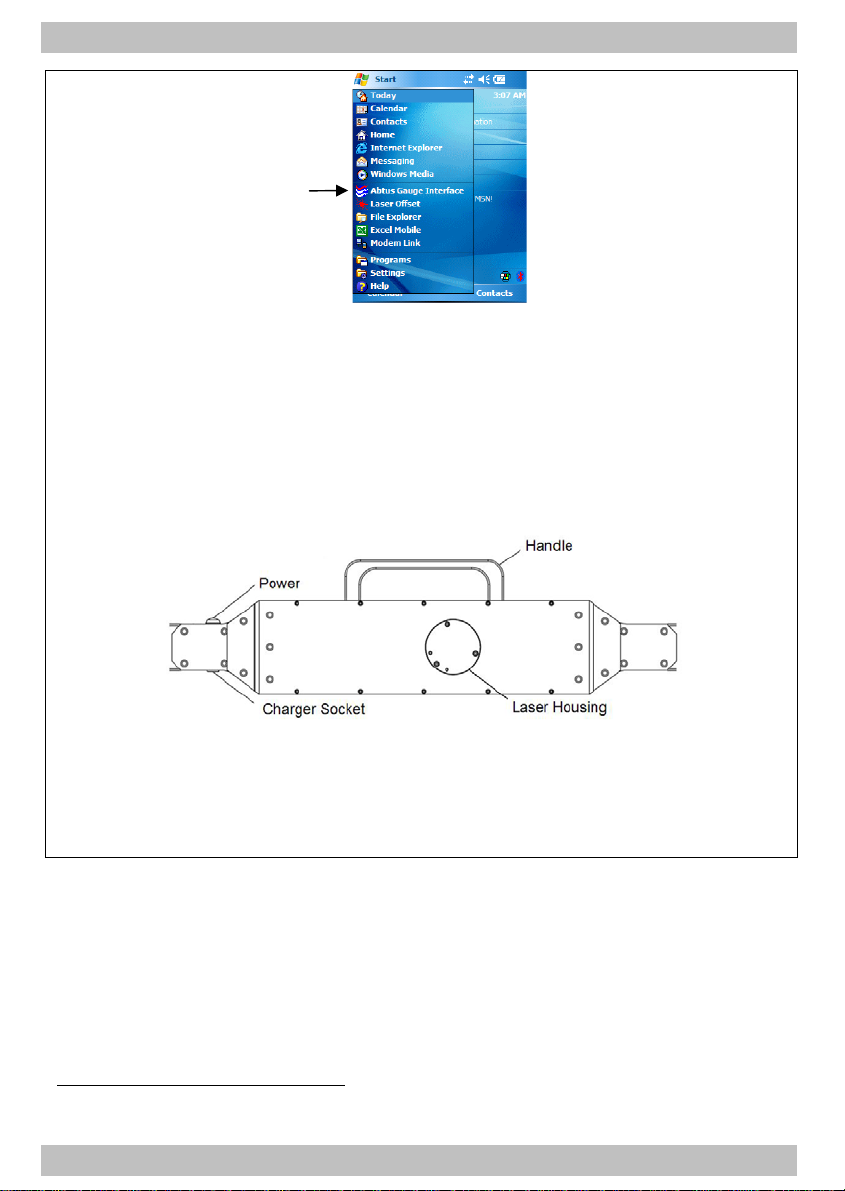

4.0Getting Started

4.1 Overview

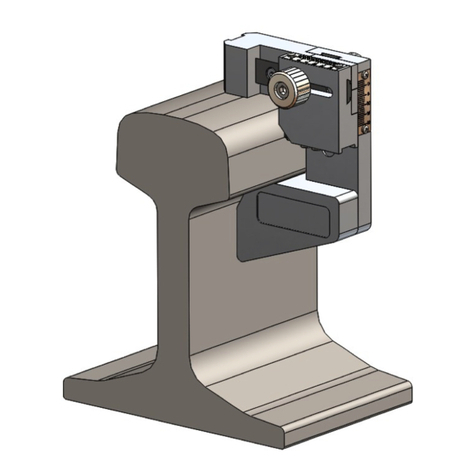

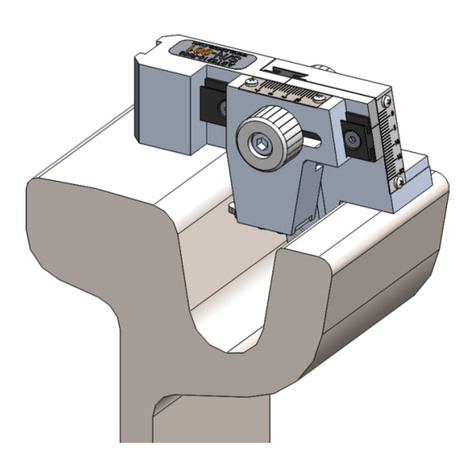

The RouteScan has been developed to provide quick, accurate structure

clearance measurements relative to the Permanent Way. With the RouteScan in

position on the track, the operator is able to control, from a position of safety, the

measurement laser using the Control Unit via a Bluetooth connection.

The unit is a lightweight (9.5kg) and is provided with a protective box for easy

transportation to and from site. All data is shown on a colour screen and is stored

on an SD Memory Card for easy transfer to a PC, where the files can be opened

and viewed in MS Excel.

The use of wireless technology in the RouteScan means that there are two

separate batteries in the ABT4650:

•RouteScan

•Control Unit

The unit has been designed to be user-friendly with only limited training required.

RouteScan is approved for use in the UK in areas of 3rd rail. The following

guidelines should be adhered to when using RouteScan in an area of live 3rd rail:

1. Never touch any part of RouteScan against the electrified 3rd rail

2. When carrying RouteScan on the track, take extra care to avoid tripping.

Carry RouteScan on the opposite side of your body to the 3rd rail

3. When lifting RouteScan on or off the rail, ensure you have a firm footing

and that you are standing between the running rails

4. When pointing the laser dot at a specific point, never place yourself or

others in a position of danger. Wherever possible, control the position of

the laser dot using the PDA from a safe position

Before Use:

Make sure there are no stains or marks on the optical window and

that the optical window is NEVER touched directly.

For cleaning instructions see Section 7.1

RouteScan produces a visible (635nm wavelength) laser beam which emerges

from the Laser Housing (Figure 2)