Milkotester Master Series User manual

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

Measurement of pH

General information

PH probe is a unit, measuring the solution acidity or alkalinity degree. It is measured on

scale of 0 to 14. The term pH is derived from "p", the mathematical symbol for the negative

logarithm, and "H", the chemical symbol of Hydrogen. The formal definition of pH is the

negative logarithm of the Hydrogen ion activity.

pH Electrode

For pH measurement the milk analyzer needs a combination electrode, compatible with

most pH electrodes that have BNC connectors and zero potential (the pH where the mill volt

output of the electrode equals 0) near 7 pH.

Electrode part

The electrode is the most important part of the pH measurement. The electrode glass

membrane is fragile and must be handled with care. To protect the glass membrane and to

maintain activation, a protective rubber cap containing a suitable storage solution covers the

glass membrane.

Electrode care & Electrode maintenance

pH Electrodes are susceptible to dirt and contamination and need to be clean regularly

depending on the extent and condition of use. At no time should one touch or rub the glass

bulb as this causes the build-up of electrostatic charge.

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

Storage

For best results, always keep the pH bulb wet. An optimal storage solution for

combination electrode is pH 4 buffer with 225 grams of KCl per liter. Table salt, NaCl, can be

used if KCl is not really available. Other pH buffers or tap water are also acceptable storage

media, but avoid storage in de-ionized water. The protective rubber cap filled with the buffer

solution provides ideal storage for long periods.

After Use

After measurement is completed, follow the sequence below for storage.

- Wash the electrode and reference junction in de-ionized water.

- Close the refilling hole by returning its rubber sleeve or stopper cap.

(Necessary for only refillable electrode).

- Store the electrode as mentioned above (see section Storage).

Electrolyte Replacement (for refillable electrode only)

The reference electrolyte needs to be refilled when the electrode has been used for a

long period, or when the internal electrolyte has dried up. To accomplish this, follow the

procedure described below.

- Remove the protective rubber cap or sleeve;

- Remove the protective rubber sleeve to expose the filling port of the electrode;

- Remove the old reference electrolyte with a syringe;

- Fill the new reference electrolyte.

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

New electrolyte preparation

- Open the KCl container;

- Add in de-ionized water until it reaches the level of 20 ml;

- Close the container and shake it to dissolve the KCl;

- Add in fresh electrolyte until it reaches the level of the refilling port. The reference

electrolyte used should be 3M(Mol) KCl;

- Replace the rubber sleeve.

Re-use the electrode

- Rinse the liquid junction with de-ionized water.

If these steps fail to restore normal electrode response, you may attempt to

rejuvenate it (See: Electrode Rejuvenation).

Electrode cleaning

Electrodes which are mechanically intact can often be restored to normal performance

by one or combination of the following procedures.

- Salt deposits:

Dissolve the deposit by immersing the electrode in tap water for ten to fifteen minutes.

Then thoroughly rinse with de-ionized water. Wash the electrode pH bulb in a little

detergent and water. Rinse electrode tip in with de-ionized water.

- Oil/Grease films:

Wash electrode pH bulb in a little detergent and water. Rinse electrode tip with de-ionized

water.

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

- Clogged Reference Junction:

pH electrodes have junction, which allows the internal fill solution of the measuring

electrode to leak out into the solution being measured. The junction can become clogged by

contamination in the solution. If a clogged junction is suspected it is best to clear the

junction. Heat up the diluted KCl solution to 60-80°C. Place the sensing part of the pH

electrode into the heated KCl solution for approximately 10 minutes. Allow the electrode to

cool while immersed in some unheated KCl solution.

- Protein Deposits

Prepare 1% pepsin solution in 0.1 M HCI. Allow the electrode to stand in this solution for

five to ten minutes. Rinse the electrode with de-ionized water.

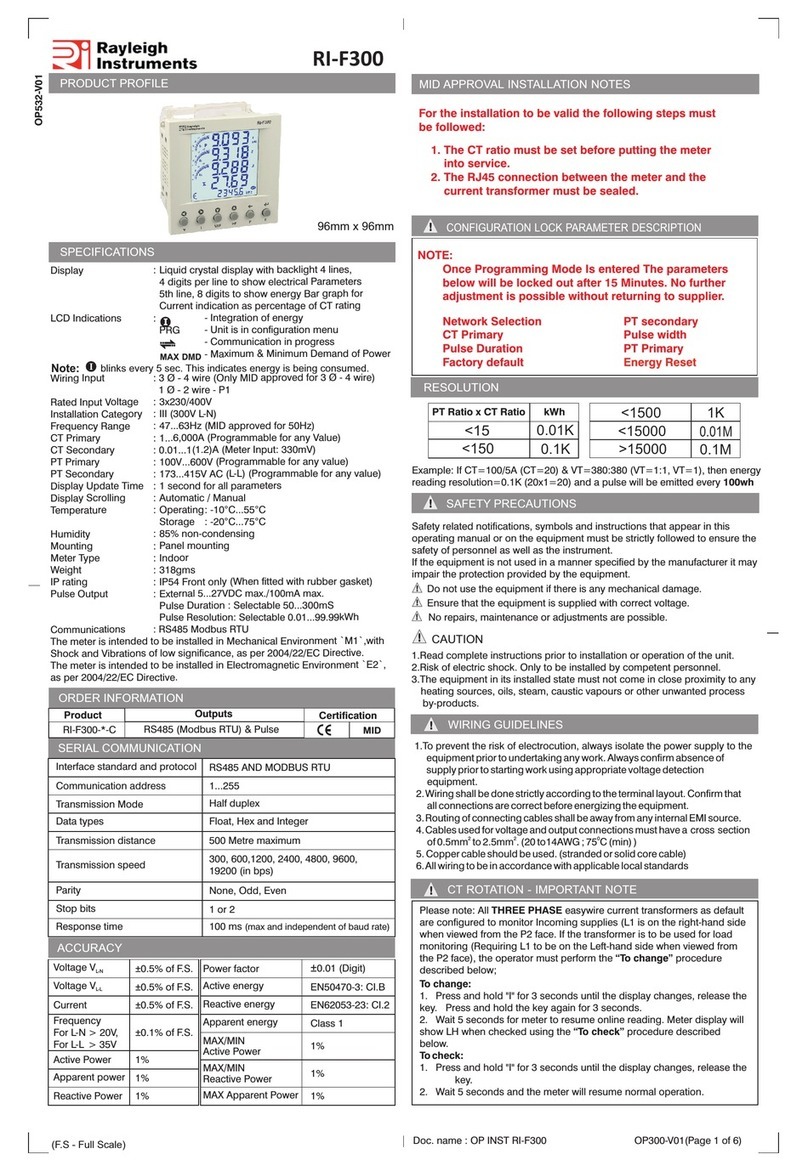

Table of errors of pH measurement according to ambient temperature:

ºC

ºF

2

3

4

5

6

pH7

8

9

10

11

12

5

41

0,30

0,24

0,18

0,12

0,06

0

0,06

0,12

0,18

0,24

0,30

15

59

0,15

0,12

0,09

0,06

0,03

0

0,03

0,06

0,09

0,12

0,15

25

77

0

0

0

0

0

0

0

0

0

0

0

35

95

0,15

0,12

0,09

0,06

0,03

0

0,03

0,06

0,09

0,12

0,15

45

113

0,30

0,24

0,18

0,12

0,06

0

0,06

0,12

0,18

0,24

0,30

55

131

0,45

0,36

0,27

0,18

0,09

0

0,09

0,18

0,27

0,36

0,45

65

149

0,60

0,48

0,36

0,24

0,12

0

0,12

0,24

0,36

0,48

0,60

75

167

0,75

0,60

0,45

0,30

0,15

0

0,15

0,30

0,45

0,60

0,75

85

185

0,90

0,72

0,54

0,36

0,18

0

0,18

0,36

0,54

0,72

0,90

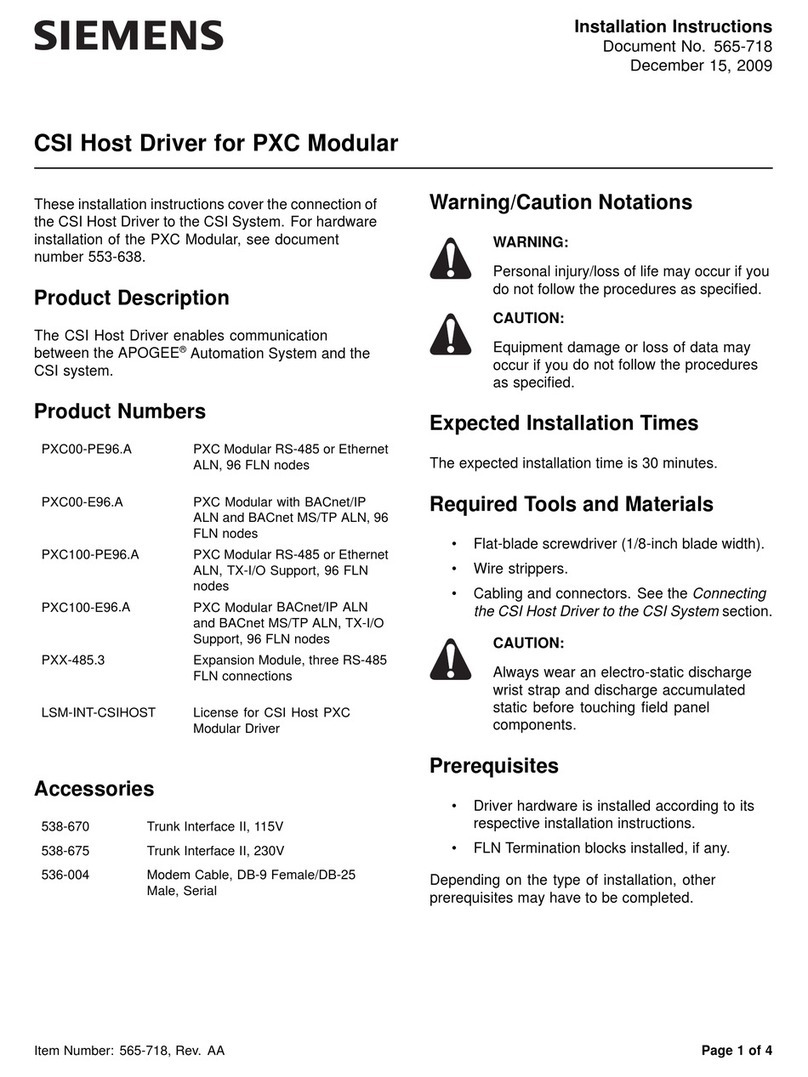

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

T (ºC)

pH

0

4.01

7.12

9.52

10

4.00

7.06

9.38

20

4.00

7.02

9.26

25

4.01

7.00

9.21

30

4.01

6.99

9.16

40

4.03

6.97

9.06

50

4.06

6.97

8.99

60

4.10

6.98

8.93

70

4.16

7.00

8.88

80

4.22

7.04

8.83

90

4.30

7.09

8.79

In order to calibrate the device you will need two buffer solutions with known values, for

example –one with value of pH 3 /low value/ and the other –pH 7 /high value/.After

choosing Set pH the following text will appear on the display

Temperature effects on the value of pH buffers

Set

pH low buffer:

x.xx

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

Remove the protective cup of the electrode.

Dip the electrode into the low value buffer solution and make sure that the junction

zone of the electrode is at least at 30 mm below the surface of the buffer solution and leave

it at rest. Now you have to enter the known value of the “low” buffer solution. Use ↑↓ (Up

and Down) arrows to enter the new value and Press ENTER to confirm. After dialing the last

symbol press ENTER to confirm the new value.

The following text will appear on the display:

Wait until the electrode and the buffer stabilize /the reference value should change

the least possible/. Press ENTER to set the value.

The following text will appear on the display:

Dip the electrode into the high value buffer solution and make sure that the junction

zone of the electrode is at least at 30 mm below the surface of the buffer solution and leave

it at rest. Now you have to enter the known value of the “high” buffer solution. Use ↑↓ (Up

and Down) arrows to enter the new value and Press ENTER to confirm. After dialing the last

symbol press ENTER to confirm the new value.

The following text will appear on the display:

Setting

Ref. Value: xxxxx

Set

pH high buffer:

x.xx

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

Wait until the electrode and the buffer stabilize /the reference value should change

the least possible/. Press ENTER to set the value

Please note:

The pH electrode must be calibrated on a regular base in order to obtain high

accuracy results of the measurement.

For calibration use buffer solutions with values as close as possible to the pH values

of the milk samples.

After each measurement of pH rinse the tip of the electrode with

de- ionized water.

After each measurement or calibration put on the protective cup of the electrode.

The pH electrode is fragile and must be handled with care.

MENU > Settings > Set pH > pH mode

The milk analyzer has two service menus of work –manual and automatic. They are

selected from MENU > Settings > set pH > pH service menu

Choose pH service menu and press ENTER.

Setting

Ref. Value: xxxxx

pH calibration

pH mode

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

Under the manual service menu, the milk sample is put under the pH probe, then you

press the pH button and the measurement will last without interruption (until the pH button

is pressed again). In order to measure pH the device must be in a working condition.

Measurement of pH is not possible when the device is in the following service menu:

In this service menu the device is measuring all the other components.

To start measurement of pH press pH button. The milk analyzer now is operating as a

pH meter. The following text will appear on the display:

Press the EXIT button to stop measurement of pH and enter the service menu:

Auto pH measure

Manual pH measure

MEASURING…

Please Wait

pH result:

X.XX

Cow Milk

Sheep Milk

UHT Milk

Appendices towards the Operation Manual of Ultrasonic milk analyzer Master

Now you can start measuring the other components of milk.

MENU > Settings > Set Thermometer

Press ENTER and the following text will appear on the display:

Put a sample of water with temperature 15and press ENTER

The following text will appear on the display:

Repeat the procedure with a sample of 25C

Put probe 15C

and press ENTER

Put probe 25C

and press ENTER

Table of contents

Other Milkotester Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

NCTE

NCTE 2300 Series Technical information and instructions

Absolute Process Instruments

Absolute Process Instruments Cecomp Test+ CTP3B instructions

Bridge Technologies

Bridge Technologies VB60 QAM Initial setup guide

Campbell

Campbell TDR200 product manual

ABB

ABB 4690 Series Upgrade Procedure

DMMetering

DMMetering PRO-1TE Series user manual