Miller Edge ME123 User manual

www.milleredge.com info@milleredge.com 800-220-3343 1/4

The Miller Edge ME123 Style Sensing Edge is a UL Recognized Component that meets the UL 325 requirement. Compatible with most operator brands,

Sensing Edges are touch sensitive sensors designed to protect entrapment zones along the leading edge of automated doors or other motorized equipment.

Consult your manual for detailed instructions about connecting to the motor.

CONTENTS

• Miller Edge ME123 Sensing Edge

REQUIRED

• 18-22 gauge wire

• Miller Edge mounting channel

• Mounting channel mounting screws

OPTIONAL

• Connection methods:

Miller Edge wireless

edge transmitter/receiver

Coil cord

Retracting reel

Junction box(es)

• Signature Module (SM-101, SM-102)

SUGGESTED

• Operator installation manual

• Edge Tester (MET-101)

• Ohm meter (capable of measuring 10K)

1. INSTALLATION SETUP

1. All Miller Edge sensing edges are inspected and tested prior to shipment to ensure quality. Upon opening the shipping box, inspect your sensing

edge and wiring for shipping damage. If the shipping container appears to be damaged, please notify carrier immediately.

2. Un-box and lay the sensing edge out straight. This will allow the edge to relax and return to its original shape.

INSTALLATION INSTRUCTIONS

SENSING EDGE

ME123

IMPORTANT

Read and understand all instructions before beginning installation. All Miller Sensing Edges are inspected and tested before being

shipped to ensure against damage. If the shipping container appears to be damaged, please notify the carrier immediately.

2A.MOUNTING CHANNEL INSTALLATION (DOORS)

1. Slide the edge into the mounting channel.

2. Align the edge and mounting channel to the leading edge of the door.

3. Adjust the close limits on the motor for a maximum compression of

.25” (6 mm).

4. Attach the channel to the by drilling self-tapping screws into the

mounting channel, starting 3” (7 cm) from the ends and spaced

approximately every 24”.

TECH TIP

To compensate for floor irregularities, gently curve the mounting channel

up or down to close any gaps between the edge and the floor, wall, or

other permanent fixture.

2B.MOUNTING CHANNEL INSTALLATION (OTHER)

1. Attach the channel to the by drilling self-tapping screws into the

mounting channel, starting 3” (7 cm) from the ends and spaced

approximately every 24”.

2. Slide the edge into the mounting channel.

3. Adjust the close limits on the motor for a maximum compression

of .25” (6 mm).

MOUNTING CHANNEL STYLES &

POSSIBLE HARDWARE PLACEMENT

ME123-C7

PVC

ME123-C1

PVC

ME123-C3

PVC

1.5”H x 2”W

ME123-C2175

PVC

ME123-C

PVC

1.5”H x 2”W

ME123-CA3

Aluminum

ME123_Inst_20180926

www.milleredge.com info@milleredge.com 800-220-3343 2/4

ME123 SENSING EDGE

WIRELESS METHOD REQUIRED

Miller Edge wireless edge transmitter/receiver system

INSTALLATION

1. Consult the Miller Edge transmitter/receiver installation

instructions for wiring of the sensing edge.

2. For proper connection to operator inputs, please consult

the operator manual.

COIL CORD METHOD

Note: For specific operator input connection diagrams

and instructions, please consult your operator manual.

REQUIRED

Junction boxes (2) Mounting screws

Wire end caps 18-22 gauge wire

INSTALLATION

1. Mount the first junction box on the end stile or bottom bar

of the door.

2. Run the sensing edge lead wire into the junction box.

3. Mount the second junction box on an adjoining wall,

midway between the floor and the operator.

4. With the door in the closed position, secure the coil cord

to the first junction box.

5. Then run it, fully stretched, to the second wall mounted

junction box so the stretched length is equal to one-half of

the door opening.

6. Secure the coil cord into the wall junction box and trim the

coil cord. This assures the excess coil cord will not get

caught or hang in the opening of the door.

7. Secure 18-22 gauge wire into the second wall-mounted

junction box and hard wire to the operator sensing edge

terminals.

RETRACTING REEL METHOD

Note: For specific operator input connection diagrams

and instructions, please consult your operator manual.

REQUIRED

Junction box (1) Mounting screws

Wire end caps 18-22 gauge wire

INSTALLATION

NOT SUITABLE FOR MONITORED SENSING EDGES

1. Mount the junction box on the end stile or bottom bar of

the door.

2. Run the sensing edge lead wire into the junction box.

3. Mount the retracting reel on an adjoining wall, near the

operator.

4. With the door in the closed position, secure the retracting

reel cable to the junction box. The cable should freely

extend, without rubbing, in and out of the retracting reel for

the duration of the open/close cycle.

5. Using the 18-22 gauge wire, hardwire the retracting reel to

the sensing edge terminals of the operator.

3. SENSING EDGE INSTALLATION

www.milleredge.com info@milleredge.com 800-220-3343 3/4

TECH SUPPORT

For additional assistance, contact Miller Edge Tech Support: 800-220-3343

4. TROUBLESHOOTING

SENSING EDGE SHIFTING

REQUIRED

• (2) #6 x 1/2” self-drilling hex head screws

• 1/4” standard socket

INSTALLATION

To prevent the Sensing Edge from shifting within

the mounting channel:

1. Mount the Miller Edge mounting channel and

Sensing Edge in accordance with Step 3:

Sensing Edge Installation.

2. Insert self-drilling screws horizontally

into the face of the mounting channel T-Slot

2”-6” from the end of the interior side of the

door.

3. Repeat step 2 on the opposite end of the

inside of the door.

Caution: Keep all tools away from the body of

the Sensing Edge.

ME123 SENSING EDGE

BLINKING =

LOW BATTERY

DC(T3) 10K(T2) NON-TERM

POWER ON / AUTO OFF

EDGE TESTER

800-220-3343

www.milleredge.com

Model:MET-101

INSTRUCTIONS

TurnTester ON

Select Switch Position

Connect Edge ToLeads

EDGE ACTIVE

/FAULT

GREEN = PWR/OK

RED = EDGE ACTIVATED

BLINKING RED = FAULT

10K

EDGE TESTER (MET-101)

BLINKING =

LOW BATTERY

DC(T3) 10K(T2) NON-TERM

POWER ON / AUTO OFF

EDGE TESTER

800-220-3343

www.milleredge.com

Model:MET-101

INSTRUCTIONS

TurnTester ON

Select Switch Position

Connect Edge ToLeads

EDGE ACTIVE

/FAULT

GREEN = PWR/OK

RED = EDGE ACTIVATED

BLINKING RED = FAULT

10K

OHM METER

TECH TIP

To determine sensing edge termination, note

the colored band on the sensing edge cable:

BAND COLOR TERMINATION TYPE

Green 8.2K Ohm Resistor T1

Blue* 10K Ohm Resistor T2

Red* Diode Capacitor T3

White Capacitor T4

Orange 6.8K Ohm Resistor T5

Purple 270K Ohm Resistor T6

None Non-terminated –

*Most Commonly used.

SENSING EDGE CHECK

SUGGESTED

• Edge Tester (MET-101)

• Ohm meter (capable of measuring 10K)

TEST

Test the sensing edge for function:

1. To verify the termination of a 10K ohm (T2) sensing edge, use a Edge Tester (MET-101) or an ohm meter; the edge resistance should

be ~10K ohms (9.5-10.5K).

2. To verify the termination of a diode capacitor (T3) sensing edge, use a Edge Tester (MET-101); this is the only method to test a T3

sensing edge.

3. Press the Sensing Edge to confirm the resistance is less than 5 ohms.

MOUNTING

CHANNEL

T-SLOT

SENSING

EDGE T

2”-6”

#6 X 1/2” HEX HEAD

SELF-DRILLING SCREW

INTERIOR SIDE OF DOOR

www.milleredge.com info@milleredge.com 800-220-3343 4/4

GENERAL SPECIFICATIONS

Length Per spec to +/- .25” or 6 mm

Lead Wire 2 ft. length of 18 or 22 gauge SJTO

Sensitivity Nominal 6-11 lbf

Electrical Maximum 24 VAC/DC, 1/2 amp

Contact Element Alumaglas®

Materials Extruded flexible PVC

Temperature Rating -30°F to +155°F or -34°C to +68°C

Warranty 1 year

Ratings UL 325 Recognized Component

ELECTRICAL CONFIGURATION OPTIONS

• 2-Wire 8.2K Ohm Resistive (T1/green band)

• 2-Wire 10K Ohm Resistive (T2/blue band)

• 2-Wire Diode Capacitor (T3/red band)

• 2-Wire Capacitor (T4/white band)

• 2-Wire 6.8K Ohm Resistive (T5/orange band)

• 2-Wire 270K Ohm Resistive (T6/violet band)

• 2-Wire Non-Monitored

• 4-Wire Monitored

• Bumper (no sensor)

MAINTENANCE

It is strongly recommended that end users test the Sensing Edge at least once per month. Check the Sensing Edge for cuts, loss of sensitivity, or water

damage. Also check for signs of damage to cables or connection points. Starting 2” from the ends, compress the Sensing Edge 1/2” throughout the

length of the edge and observe that it sends an electric signal to the controls.

REPLACEMENT

To replace your Miller Edge Sensing Edge, contact your Miller Edge sales representative. Attempt to repair your Miller Edge sensing edge is not

recommended and will void the manufacturer warranty.

WARRANTY

Miller Edge, Inc. will replace within one year of shipment from factory any Sensing Edge subject to normal use, which is found to have defective

materials or workmanship, as determined solely by our factory representative. Replacements will be shipped to you freight collect. This warranty is

void where evidence of misuse or abuse is present.

ACCESSORIES

Contact your Miller Edge sales representative for sensing edge accessories:

MOUNTING CHANNELS JUNCTION BOXES COIL CORDS RETRACTING REELS TRANSMITTERS/

RECEIVERS

MODULES

ME123 SENSING EDGE

Table of contents

Other Miller Edge Accessories manuals

Popular Accessories manuals by other brands

LMI Technologies

LMI Technologies Gocator 2300 Series user manual

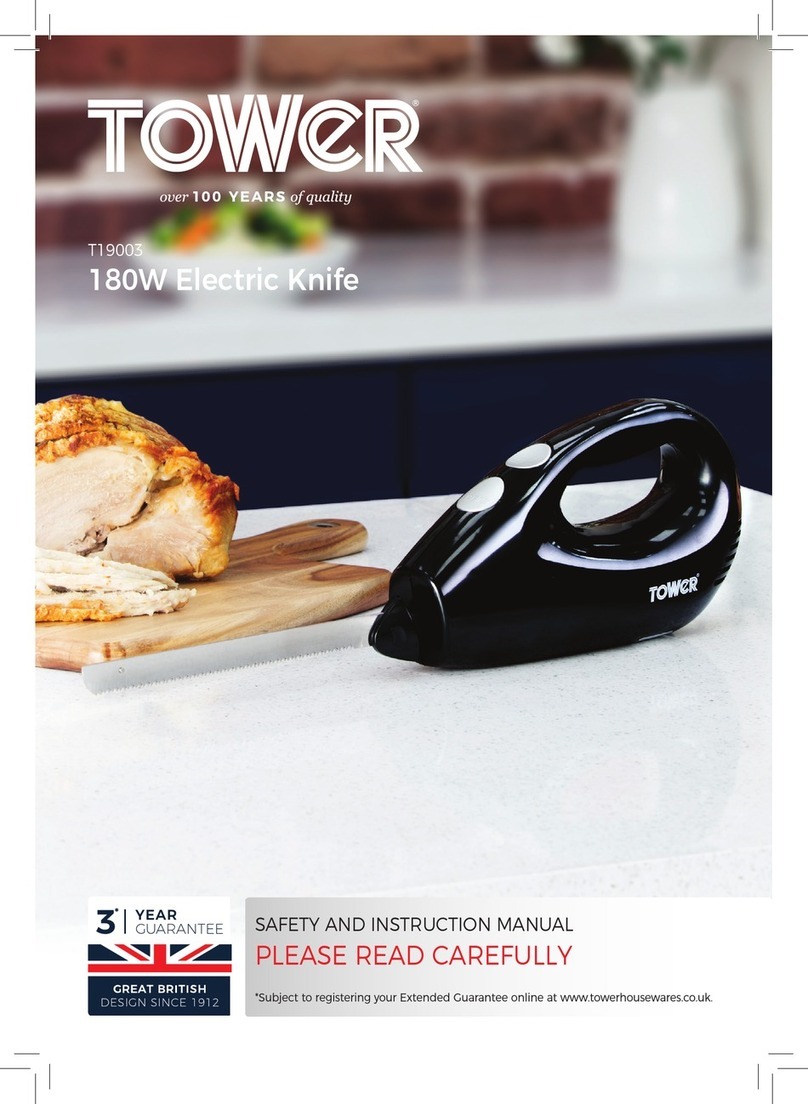

Tower Hobbies

Tower Hobbies T19003 Safety and instruction manual

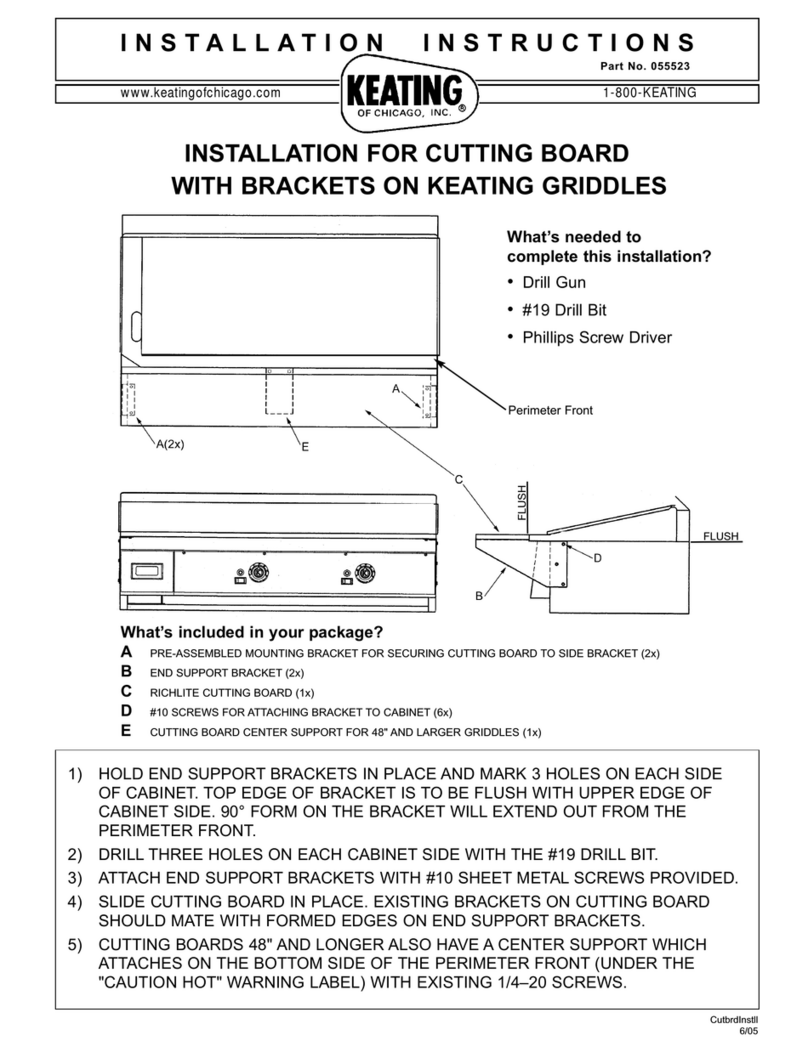

Keating Of Chicago

Keating Of Chicago Cutting Board with Brackets 055523 installation instructions

Philips

Philips SAC2520W/10 user manual

Monoprice

Monoprice 33124 user manual

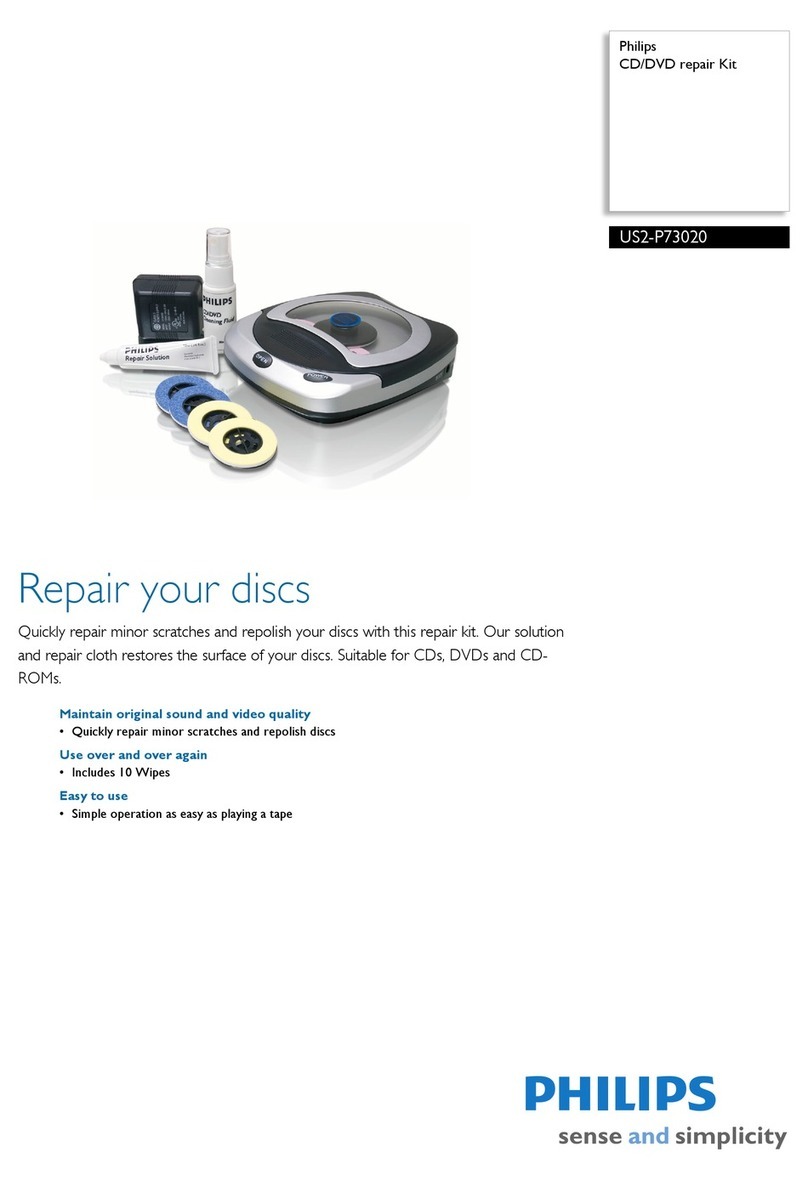

Philips

Philips SVC1215/10 user manual