Page 3

Operation and maintenance manual

Jumbo Pump

SAFETY AND WARNING INSTRUCTIONS

Always follow the safety and warning instructions. Operation and Maintenance must comply with local regulations

and accepted codes of practice, including wearing of Personal Protective Equipment (PPE). The following

instructions apply to the standard version of the product operating in normal conditions. The data in the

documentation and the product itself may be subject to modification without the manufacturer being obliged to give

prior notice. Failure to comply with the instructions herein, improper use of the product or unauthorized modification

to the product shall void all forms of warranty, while the manufacturer shall not be held responsible for any damages

resulting to persons or property.

Before performing any work on the product, always make sure that the electrical parts of the system on which work

is to be carried out are disconnected from the electric power source. Any operating, servicing, repair and/or

dismantling of the product may only be undertaken by specialized personnel possessing the necessary qualifications

and equipped with adequate tools. Such personnel must have become fully familiar with the contents of these

instructions and any other documentation supplied with the product.

WARRANTY

Tru‐Flo Pumping Systems warrants the product to be free from defects in workmanship and materials under normal

use and service for a period of twelve calendar months from the date of delivery or 1000 hours of operation,

whichever occurs first.

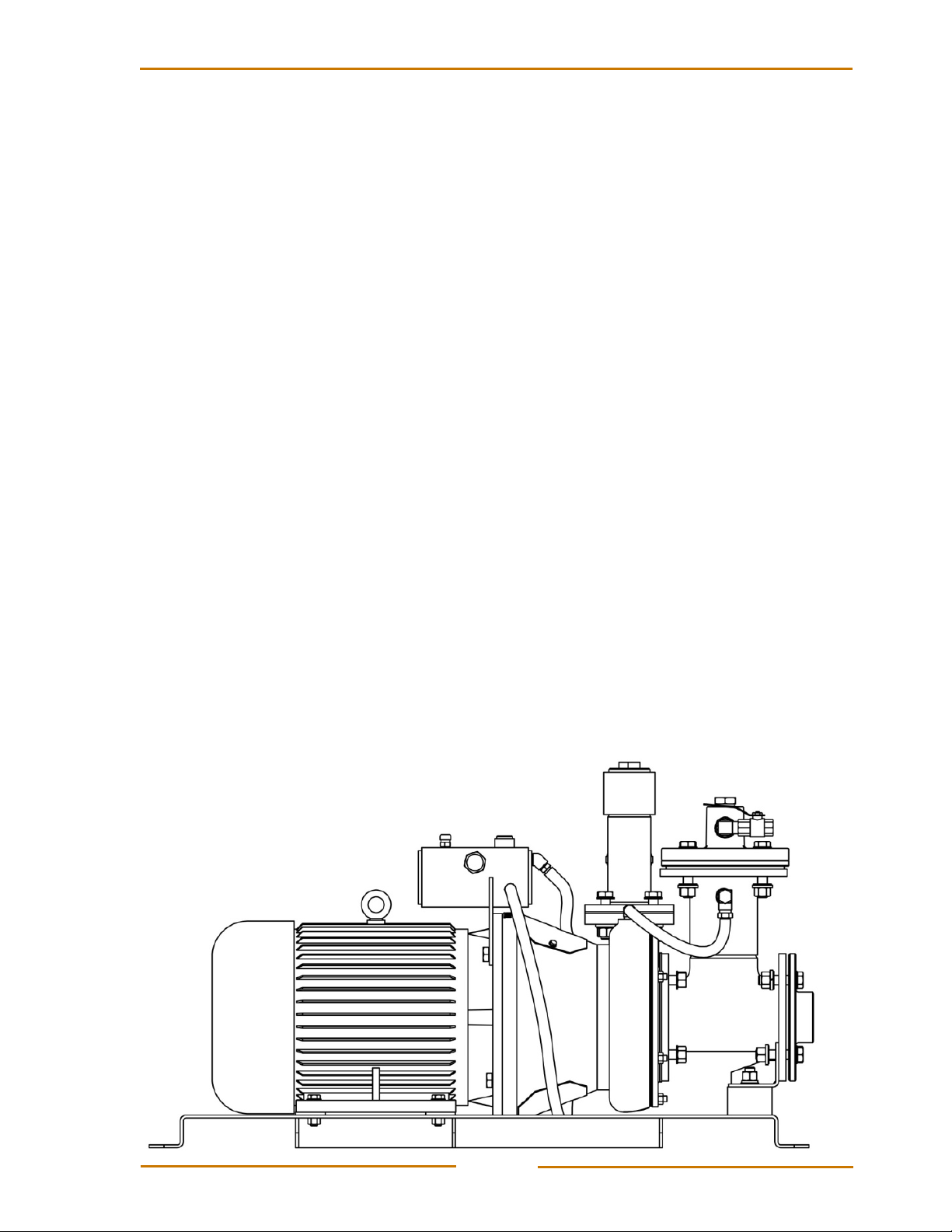

DESCRIPTION OF THE PRODUCT

The Jumbo pump has been specifically designed for the underground mining industry and is supplied with a flotation

suction strainer intended for use in sumps at the development face. The strainer floats on the water and draws from

one inch below the surface, thereby reducing shotcrete fibers in the pumping system.

OPERATION

PRIMING

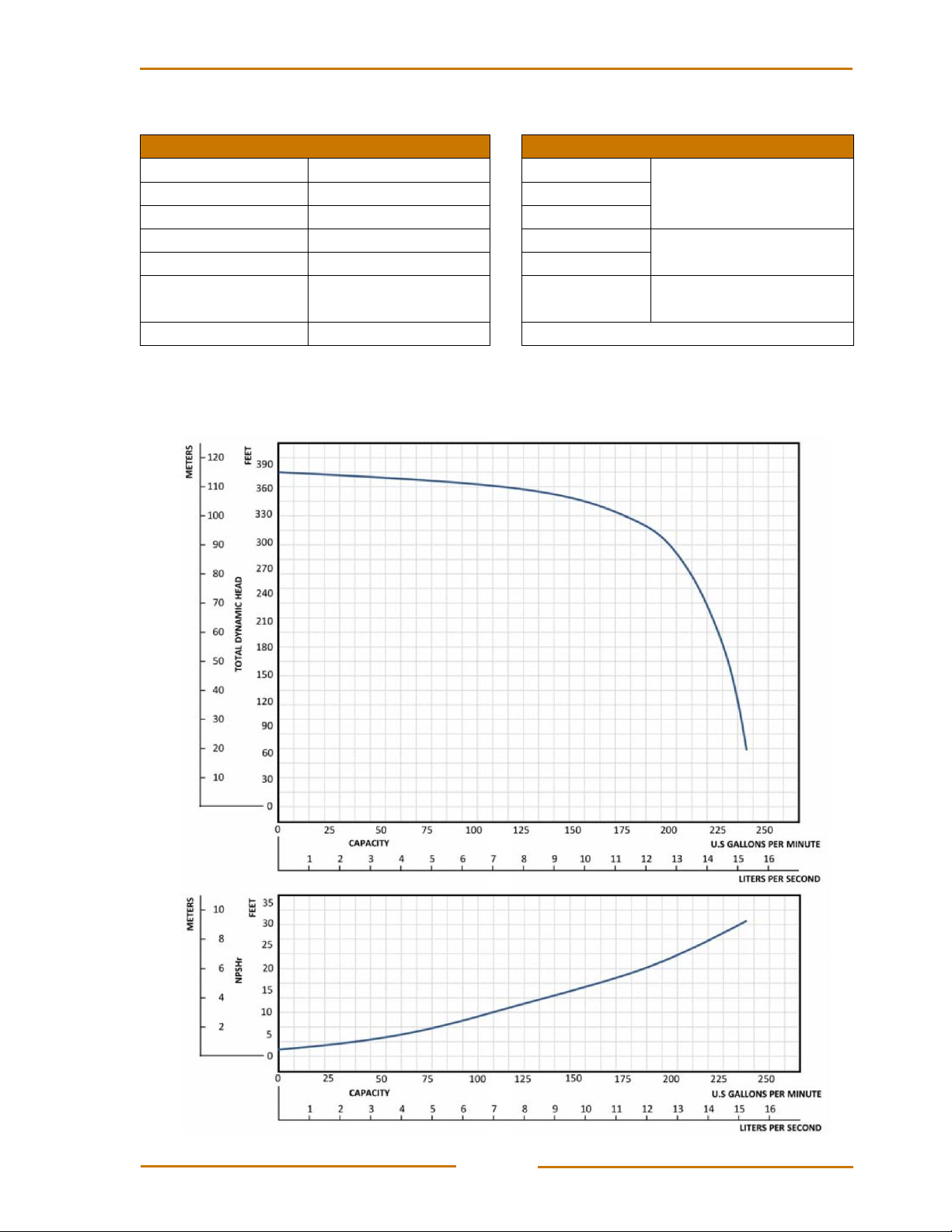

The water from the drilling equipment’s hydraulic coolers (that normally drains to the ground), is piped through the

venturi on the Jumbo pump, producing a vacuum to lift water from the face to prime the pump. (Vacuum prime: ‐60

to ‐80kPa, 20 to 26Ft head lift). This lifts the venture ball off its seat, allowing air to be displaced from the vacuum

canister and pump casting. The outlet reflux ball seals on its seat to prevent air being drawn into the vacuum canister.

When the air has been displaced, a vacuum is present in the canister and the pump casting, which draws the water

into the pump. After the pump has primed, normal operation will occur. At this point the venturi ball is drawn on to its

seat to prevent the pump from sucking air from the air discharge port.

When the sump has been emptied, the pump will continue to run until enough water is available to re‐prime itself

and the above process begins again.