18 19

M18 FOPH-CSA

.......................4697 64 02...

...000001-999999

..................... 0-3700 min-1

..................... 0-4600 min-1

............................8,6 m/s

...........................254 mm

...........................230 mm

...........................140 ml

..........................1,94 kg

.............................85 dB(A)

.............................95 dB(A)

..........................1,54 m/s2

..........................0,65 m/s2

TECHNICAL DATA CORDLESS POLE SAW

Production code...........................................................................

No-load speed, low speed ...........................................................

No-load speed, high speed..........................................................

No-load chain speed....................................................................

Bar length ....................................................................................

Usable cutting length ...................................................................

Chain oil tank capacity.................................................................

Weight according EPTA-Procedure 01/2014 ...............................

Noise/vibration information

Measured values determined according

to EN ISO 22868 / EN ISO 4871.

Typically, the A-weighted noise levels of the tool are:

Sound pressure level (Uncertainty K=1,4dB(A)) ......................

Sound power level (Uncertainty K=1,4dB(A)) ...........................

Wear ear protectors!

Total vibration values (vector sum in the three axes) determined

according to EN ISO 22867.

Vibration ah ...............................................................................

Uncertainty K= ..........................................................................

For technical data and approvals of application heads for use on various powerbases please refer to the operating instructions of the

used application head.

WARNING

The vibration emission level given in this information sheet has been measured in accordance with a standardised test given in EN

ISO 22867 and may be used to compare one tool with another. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for diff erent

applications, with diff erent accessories or poorly maintained, the vibration emission may diff er. This may signifi cantly increase the

exposure level over the total working period.

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched off or when it is

running but not actually doing the job. This may signifi cantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator from the eff ects of vibration such as: maintain the tool and the

accessories, keep the hands warm, organisation of work patterns.

ENGLISH ENGLISH

WARNING Read all safety warnings, instructions,

illustrations and specifi cations provided with this power

tool. Failure to follow all instructions listed below may result in

electric shock, fi re and/or serious injury.

Save all warnings and instructions for future reference.

CORDLESS POLE SAW SAFETY WARNINGS

Keep all parts of the body away from the saw chain when

the Pole saw is operating. Before you start the Pole saw,

make sure the saw chain is not contacting anything. A

moment of inattention while operating Pole saws may cause

entanglement of your clothing or body with the saw chain.

Always hold the Pole saw with your right hand on the rear

handle and your left hand on the front handle. Holding the

Pole saw with a reversed hand confi guration increases the risk

of personal injury and should never be done.

Hold the Pole saw by insulated gripping surfaces only,

because the saw chain may contact hidden wiring. Saw

chains contacting a „live“ wire may make exposed metal parts

of the Pole saw „live“ and could give the operator an electric

shock. (war bei der Astsäge dabei, macht aber eigentlich

keinen Sinn)

Wear eye protection. Further protective equipment for

hearing, head, hands, legs and feet is recommended.

Adequate protective equipment will reduce personal injury from

fl ying debris or accidental contact with the saw chain.

Do not operate a Pole saw in a tree, on a ladder, from a

rooftop, or any unstable support. Operation of a Pole saw in

this manner could result in serious personal injury.

Always keep proper footing and operate the Pole saw only

when standing on fi xed, secure and level surface. Slippery

or unstable surfaces may cause a loss of balance or control of

the Pole saw.

When cutting a limb that is under tension, be alert for

spring back. When the tension in the wood fi bres is released

the spring loaded limb may strike the operator and /or throw the

Pole saw out of control.

Use extreme caution when cutting brush and saplings. The

slender material may catch the saw chain and be whipped

toward you or pull you off balance.

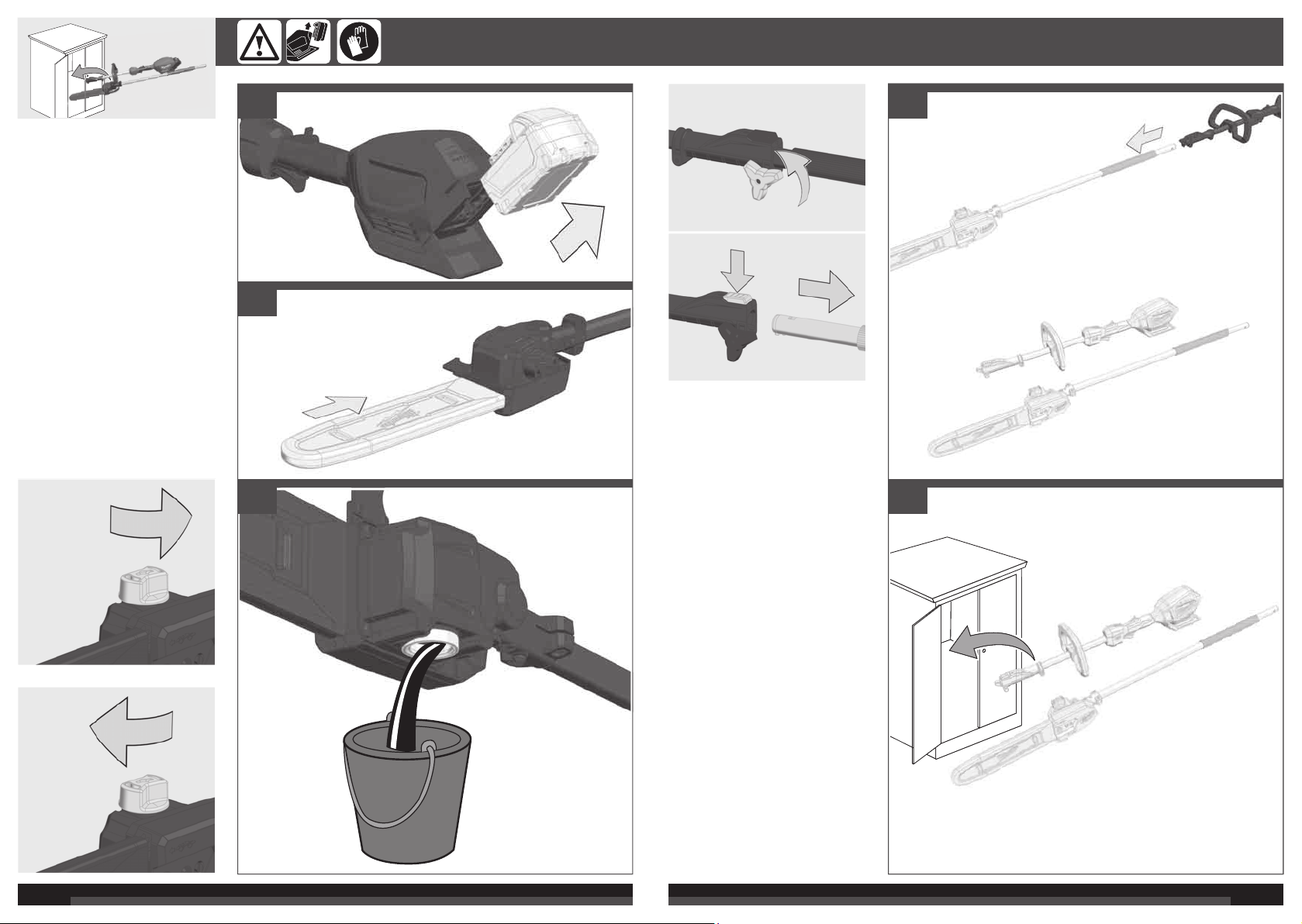

Carry the Pole saw by the front handle with the Pole saw

switched off and away from your body. When transporting

or storing the Pole saw, always fi t the guide bar cover.

Proper handling of the Pole saw will reduce the likelihood of

accidental contact with the moving saw chain.

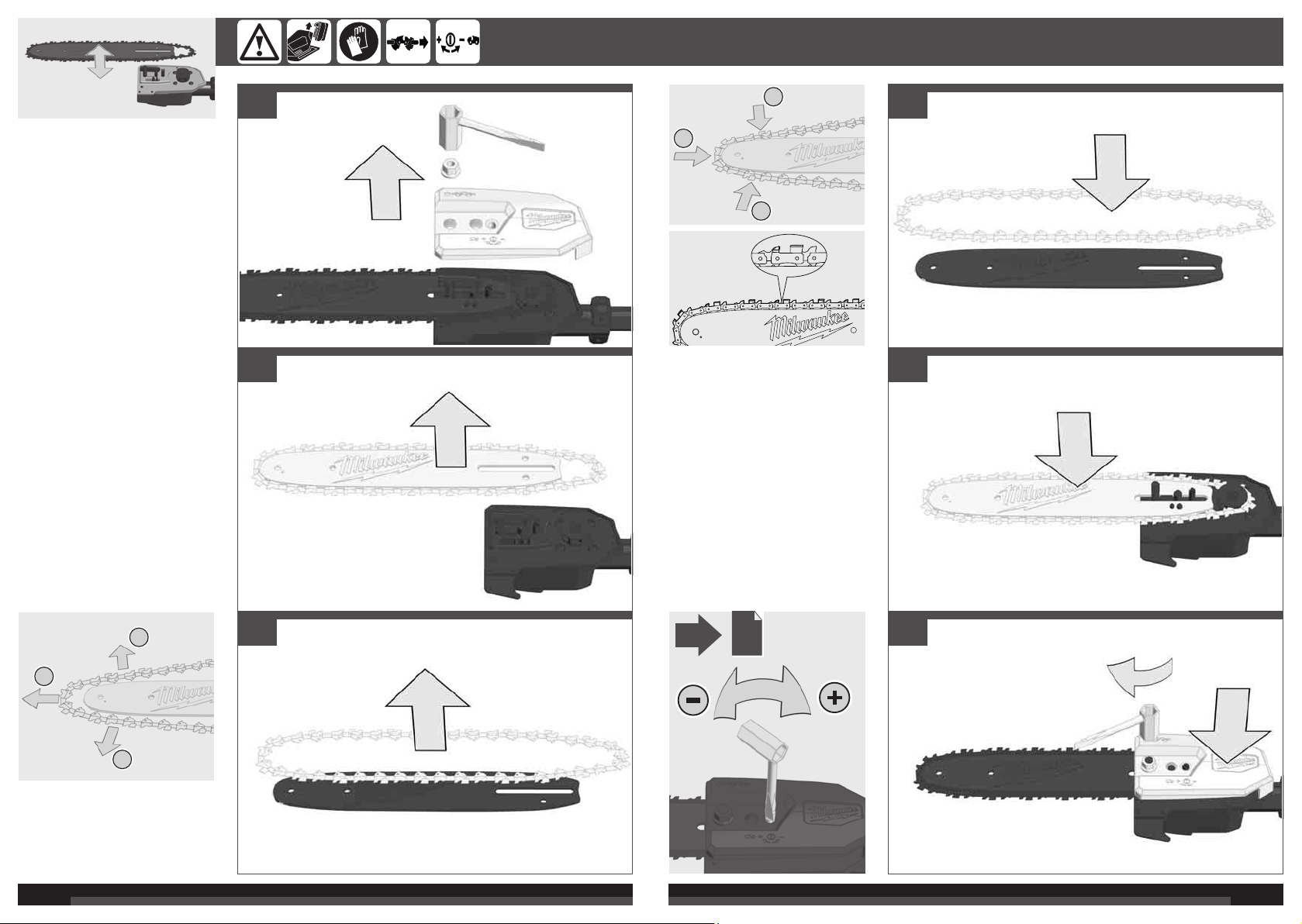

Follow instructions for lubricating, chain tensioning and

changing the bar and chain. Improperly tensioned or

lubricated chain may either break or increase the chance for

kickback.

Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery causing loss of control.

Cut wood only. Do not use Pole saw for purposes not

intended. For example: do not use Pole saw for cutting

metal, plastic, masonry or non-wood building materials.

Use of the Pole saw for operations diff erent than intended

could result in a hazardous situation.

Do not attempt to fell a tree. Serious injury could occur to the

operator or bystanders while felling a tree.

Follow all instructions when clearing jammed material,

storing or servicing the Pole saw. Make sure the switch is

off and the battery pack is removed. Unexpected actuation

of the Pole saw while clearing jammed material or servicing

may result in serious personal injury.

Causes and operator prevention of kickback:

Kickback may occur when the nose or tip of the guide bar

touches an object, or when the wood closes in and pinches the

saw chain in the cut.

Tip contact in some cases may cause a sudden reverse

reaction, kicking the guide bar up and back towards the

operator.

Pinching the saw chain along the top of the guide bar may push

the guide bar rapidly back towards the operator.

Either of these reactions may cause you to lose control of the

saw which could result in serious personal injury. Do not rely

exclusively upon the safety devices built into your saw.

As a Pole saw user, you should take several steps to keep your

cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

Maintain a fi rm grip, with thumbs and fi ngers encircling the

Pole saw handles, with both hands on the saw and

position your body and arm to allow you to resist kickback

forces. Kickback forces can be controlled by the operator, if

proper precautions are taken. Do not let go of the Pole saw.

Do not overreach. This helps prevent unintended tip contact

and enables better control of the Pole saw in unexpected

situations.

Only use replacement bars and chains specifi ed by the

manufacturer. IIncorrect replacement guide bars and chains

may cause chain breakage and/or kickback.

Follow the manufacturer’s sharpening and maintenance

instructions for the saw chain. Decreasing the depth gauge

height can lead to increased kickback.

National regulations may restrict the use of the Pole saw.

Note the local regulations.

ADDITIONAL SAFETY AND WORKING INSTRUCTIONS

Ensure all guards, handles, are properly fi tted and are in good

condition.

Persons using the Pole saw should be in good health. The Pole

saw is heavy, so the operator must be physically fi t.

The operator should be alert, have a good vision, mobility,

balance, and manual dexterity. If there is any doubt, do not

operate the Pole saw.

Do not start using the Pole saw until you have a clear work

area and secure footing. Beware of the emission of lubricant

mist and saw dust.Wear a mask or respirator, if required.

Do not cut vines and/or small undergrowth (less than 75 mm in

diameter).

Always hold the Pole saw with both hands during operation.

Use a fi rm grip with thumbs and fi ngers encircling the Pole saw

handles. Right hand must be on the rear handle and left hand

on the front handle.

Before starting the Pole saw, make sure the saw chain is not

contacting any object.

Do not modify the Pole saw in any way or use it to power any

attachments or devices not recommended by the manufacturer

for your Pole saw.

There should be a fi rst-aid kit containing large wound dressings

and a means to summon attention (e.g., whistle) close to the

operator. A larger more comprehensive kit should be

reasonably nearby.

An incorrectly tensioned chain can jump off the guide bar and

could result in serious injury or fatality. The length of the chain

depends on the temperature. Check the tension frequently.

You should get used to your new Pole saw by making simple

cuts on securely supported wood. Do this whenever you have

not operated the saw for some time. To reduce the risk of injury

associated with contacting moving parts, always stop the

motor, remove the battery pack and make sure all moving parts

have come to a stop before.

• cleaning or clearing a blockage

• leaving the machine unattended

• installing or removing attachments

• checking, conducting maintenance or working on the

machine

Do not cut with your body in line with the guide bar and chain. If

you experience kickback, this will help prevent the chain

coming into contact with your head or body.

Do not use a back-and-forward sawing motion, let the chain do

the work. Keep the chain sharp and do not try to push the chain

through the cut.

Do not put pressure on the saw at the end of the cut. Be ready

to take on the weight of the saw as it cuts free from the wood.

Failure to do so could result in possible serious personal injury.

Do not stop the saw in the middle of a cutting operation.

Keep the saw running until it is already removed from the cut.

Do not fi x the on/off switch in the „on“ position when using the

saw hand-held.

Remove the battery pack before starting any work on the

appliance.

WARNING! To reduce the risk of fi re, personal injury, and

product damage due to a short circuit, never immerse your tool,

battery pack or charger in fl uid or allow a fl uid to fl ow inside

them. Corrosive or conductive fl uids, such as seawater, certain

industrial chemicals, and bleach or bleach containing products,

etc., can cause a short circuit.

Use only System M18 chargers for charging System M18

battery packs. Do not use battery packs from other systems.

Never break open battery packs and chargers and store only in

dry rooms. Keep dry at all times.

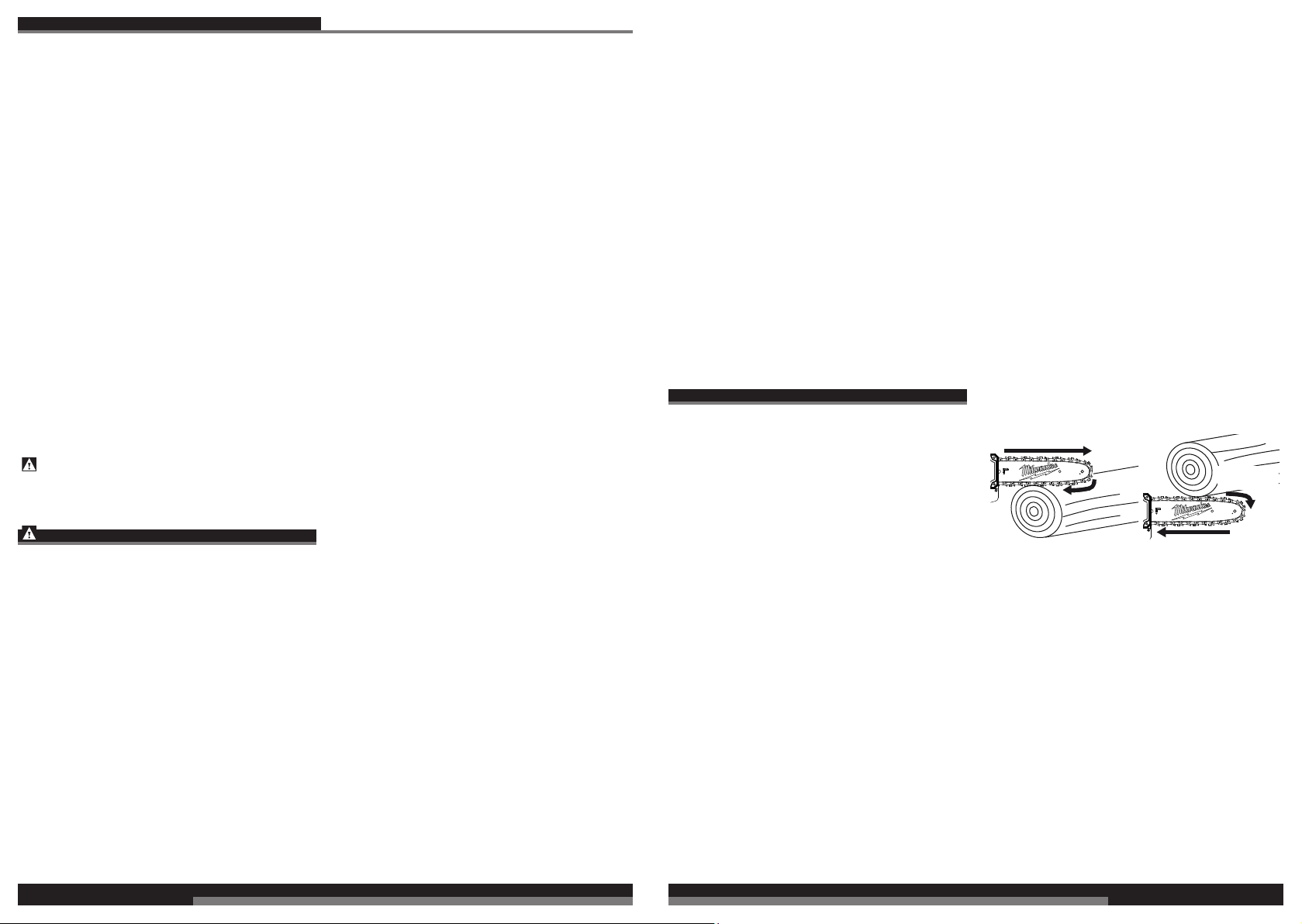

Push and pull

The reaction force is always opposite to the direction the chain

is moving. Thus, the operator must be ready to control the

tendency for the machine to pull away (forward motion) when

cutting on the bottom edge of the bar and the push backwards

(towards the operator) when cutting along the top edge.

Reaction

Reaction

Direction of

rotation

Direction of

rotation

Saw jammed in the cut

Stop the Pole saw and make it safe. Do not try to force the

chain and bar out of the cut as this is likely to break the chain,

which may swing back and strike the operator. This situation

normally occurs because the wood is incorrectly supported

which forces the cut to close under compression, thereby

pinching the blade. If adjusting the support does not release the

bar and chain, use wooden wedges or a lever to open the cut

and release the saw. Never try to start the Pole saw when the

guide bar is already in a cut or kerf.

Skating / Bouncing

When the Pole saw fails to dig in during a cut, the guide bar

can begin hopping or dangerously skidding along the surface of

the log or branch, possibly resulting in the loss of control of the

Pole saw. To prevent or reduce skating or bouncing, always

use the saw with both hands make sure the saw chain

establishes a groove for cutting.Never cut small, fl exible

branches or brushes with your Pole saw. Their size and

fl exibility can easily cause the saw to bounce towards you or

bind up with enough force to cause a kickback. The best tool

for that kind of work is a hand saw, pruning shears, an axe or

other hand tools.