18 19

PLH 32 XE

4322 94 05 XXXXXX MJJJJ

900 W

450 W

3,8 J

0-1040

min

-1

0-800

min

-1

0-4500

min

-1

32 mm

16 mm

40 mm

82 mm

43 mm

3,6 kg

98 dB(A) / 3 dB(A)

106 dB(A) / 3 dB(A)

25 m/s2/ 2,3 m/s2

20 m/s2/ 1,5 m/s2

ENGLISH ENGLISH

TECHNICAL DATA

Type

Production code

Rated input

Output

Impact energy per stroke according to EPTA-Procedure 05/2009

No-load speed

Speed under load max.

Rate of percussion under load max.

Drilling capacity in concrete

Drilling capacity in steel

Drilling capacity in wood

Light core cutter in bricks and limestone

Chuck neck diameter

Weight according EPTA-Procedure 01/2014

Noise Information:

Measured values determined according to EN 62841.

Typically, the A-weighted noise levels of the tool are:

Sound pressure level / Uncertainty K

Sound power level / Uncertainty K

Wear ear protectors.

Vibration Information: Total vibration values (vector sum in the three

axes) determined according to EN 62841.

Vibration emission value ah/ Uncertainty K

Hammer-drilling in concrete:

Chiselling:

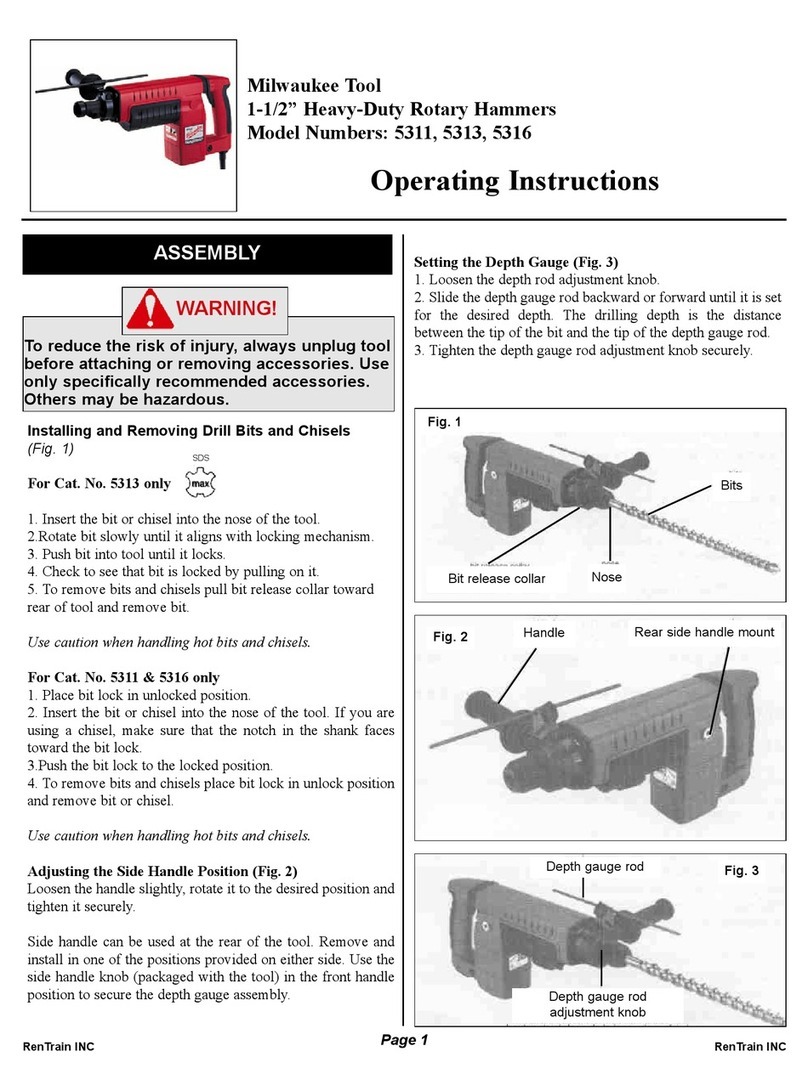

WARNING! Read all safety warnings, instructions,

illustrations and specifications provided with this power tool. Failure

to follow all instructions listed below may result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for future reference.

HAMMER SAFETY WARNINGS

Safety instructions for all operations

Wear ear protectors. Exposure to noise can cause hearing loss.

Use auxiliary handles supplied with the tool. Loss of control can cause

personal injury.

Hold the power tool by insulated gripping surfaces only, when

performing an operation where the cutting accessory may contact

hidden wiring or its own cord. Cutting accessory contacting a "live" wire

may make exposed metal parts of the power tool "live" and could give the

operator an electric shock.

Safety instructions when using long drill bits with rotary hammer

Always start drilling at low speed and with the bit tip in contact

with the workpiece. At higher speeds, the bit is likely to bend if allowed

to rotate freely without contacting the workpiece, resulting the personal

injury.

Apply pressure only in direct line with the bit and do not apply

excessive pressure. Bits can bend causing breakage or loss of control,

resulting in personal injury.

ADDITIONAL SAFETY AND WORKING INSTRUCTIONS

Use personal protective equipment. Always wear eye protection.

Protective equipment such as a dust mask, non-skid safety shoes, hard

hat or hearing protection used for appropriate conditions will reduce

personal injuries.

The dust produced when using this tool may be harmful to health. Do not

inhale the dust. Wear a suitable dust protection mask.

Do not machine any materials that present a danger to health (e.g.

asbestos).

Switch the device oimmediately if the insertion tool stalls! Do not switch

the device on again while the insertion tool is stalled, as doing so could

trigger a sudden recoil with a high reactive force. Determine why the

insertion tool stalled and rectify this, paying heed to the safety instructions.

The possible causes may be:

• it is tilted in the workpiece to be machined

• it has pierced through the material to be machined

• the power tool is overloaded

Do not reach into the machine while it is running.

The insertion tool is sharp-edged and can become hot during use.

WARNING! Danger of cuts and burns

- when handling the insertion tools

- when setting the device down.

Wear protective gloves when handling insertion tools.

Chips and splinters must not be removed while the machine is running.

Keep mains lead clear from working range of the machine. Always lead

the cable away behind you.

When working in walls ceiling, or floor, take care to avoid electric cables

WARNING

The vibration and noise emission level given in this information sheet has been measured in accordance with a standardized test given in EN 62841 and

may be used to compare one tool with another. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for dierent applications, with dierent

accessories or poorly maintained, the vibration emission may dier. This may significantly increase the exposure level over the total working period.

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched oor when it is running but not

actually doing the job. This may significantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator from the eects of vibration and/or noise such as: maintain the tool and the accessories, keep

the hands warm, organization of work patterns.

and gas or waterpipes.

Clamp your workpiece with a clamping device. Unclamped workpieces

can cause severe injury and damage.

Always disconnect the plug from the socket before carrying out any work

on the machine.

When working with large drill diameters, the auxiliary handle must be

fastened in a right angle with the main handle (see illustrations, section

"Twisting the handle").

SPECIFIED CONDITIONS OF USE

The rotary pneumatic hammer can be used for hammer drilling, chiselling in

stone and concrete and drilling in wood, metal as well as plastic.

Do not use this product in any other way as stated for normal use.

RESIDUAL RISK

Even when the product is used as prescribed, it is still impossible to

completely eliminate certain residual risk factors. The following hazards

may arise in use and the operator should pay special attention to avoid

the following:

• Injury caused by vibration.

Hold the product by designated handles and restrict working time and

exposure.

• Exposure to noise can cause hearing injury.

Wear ear protection and limit exposure.

• Injury due to flying debris

Wear eye protection, heavy long trousers and substancial footwear at

all times.

• Inhalation of toxic dusts.

MAINS CONNECTION

Appliances used at many dierent locations including wet room and open

air must be connected via a residual current device (FI, RCD, PRCD) of

30mA or less.

Connect only to single-phase AC current and only to the system voltage

indicated on the rating plate. It is also possible to connect to sockets

without an earthing contact as the design conforms to safety class II.

Make sure the machine is switched obefore plugging in.

This is a device for professional use which may slightly exceed the guide

values for current harmonics when it is connected to the public low voltage

mains supply. You should therefore contact your energy supply company

before you connect the device to the public low voltage mains supply.

WORKING INSTRUCTIONS

Do not force too much when drilling or hammering. Let the rotary hammer

do the work for you.

WORK WHEN IT'S COLD

If the tool is stored for a long period of time or at cold temperatures, the

lubrication may become stiand the tool may not working initially or the

working may be weak. If this happens:

1. Insert a bit or chisel into the tool.

2. Run the tool against a scrap piece of concrete.

3. Pull and release the trigger every few seconds.

After 15 seconds to 2 minutes, the tool will start hammering normally. The

colder the tool is, the longer it will take to warm up.

CLEANING

The ventilation slots of the machine must be kept clear at all times.

MAINTENANCE

Important note! If the carbon brushes are worn, in addition to exchanging

the brushes the tool should be sent to after-sales service. This will ensure

long service life and top performance.

If the supply cord of this appliance is damaged, it must only be replaced

by a repair shop appointed by the manufacturer, to avoid hazardous

situations.

Use only Milwaukee accessories and Milwaukee spare parts. Should

components need to be replaced which have not been described, please

contact one of our Milwaukee service agents (see our list of guarantee/

service addresses).

If needed, an exploded view of the tool can be ordered. Please state the

machine type printed as well as the six-digit No. on the label and order the

drawing at your local service agents or directly at: Techtronic Industries

GmbH, Max-Eyth-Straße 10, 71364 Winnenden, Germany.

SYMBOLS

Please read the instructions carefully before starting

the machine.

CAUTION! WARNING! DANGER!

Always disconnect the plug from the socket before

carrying out any work on the machine.

Always wear goggles when using the machine.

Wear ear protectors!

Wear a suitable dust protection mask.

Wear gloves!

The anti-vibration system reduces machine vibrations on

the handle.

Accessory - Not included in standard equipment,

available as an accessory.

Do not dispose of waste electrical and electronic

equipment as unsorted municipal waste.

Waste electrical and electronic equipment must be

collected separately.

Waste light sources have to be removed from

equipment. Check with your local authority or retailer for

recycling advice and collection point.

According to local regulations retailers may have an

obligation to take back waste electrical and electronic

equipment free of charge.

Your contribution to re-use and recycling of waste

electrical and electronic equipment helps to reduce the

demand of raw materials.

Waste electrical and electronic equipment contain

valuable, recyclable materials, which can adversely

impact the environment and the human health, if not

disposed of in an environmentally compatible manner.

Delete personal data from waste equipment, if any.

Rotary Hammer