Set the heater and wait until it reaches the set temperature. The setting value differs

depending on the media.

Refer to Operation Manual “Chapter2 Preparing for the Heaters” .

Preparing for the Heaters

Refer to Operation Manual “Chapter2 Setting a Media” .

Slightly hold the media with the media holder.

Setting a Media

Turning the Power ON

Visually check the media float on the platen (especially at the both edges of the media).

Check the media float

Refer to Operation Manual “Chapter2 Setting a Media” .

At the media detection, if the head scratches the media or paper jam occurs, perform head

cleaning.

Detect the Media

Refer to Operation Manual “Chapter2 Test Feeding”, Check that the media can be fed normally.

Check that there is no media float between the Platen and the After heater. Also, check that

there is no abnormality of feeding due to the media sticking to the platen.

Strengthen the absorption fan.

(

Operation Manual Chapter3

)

For the roll media, use the take-up device.

(

Operation Manual Chapter2

)

Lower the heater temperature.

To Setting a Media

Test Feeding

Feed the media by 50cm, and check that no media float occurs at the media both edges and

between Clamp - Clamp every time you feed the media.

Check of cockling

When the media floats

Clamp up once and reset the media.

Check that it is not skewed.

Set the temperature of the pre-heater higher.

(Print heater temperature +5 to 10 degrees)

Lower all heater temperatures by 5 degrees

each. (It may not have been dehydrated

enough. Be careful about it.)

Feed the media that was deformed due to

heating (by about 60 to 100cm).

・When you left it for a long time with the

heater ON

・When the media extended to the utmost

limit due to heating

To Setting a Media

If media cockling

occurs

Perform test print to check that there is no line that is missing and no line that is bent.

(Operation Manual Chapter2)

Test Print

Refer to Operation Manual “Chapter2 Set the media feeding amount”

Feed Correction

Refer to Operation Manual “Correct the ink drop position for bidirectional printing”.

Drop Position correct

Referring to the print guide, send the data to print.

Print

Check that the output image has been dehydrated when it passes the UV lamp.

Checking dryness

Print can be started

Perform head cleaning. To Test Print

Result is abnormal

Select more number of passes for the same

resolution.

Set the FEED SPEED lower (lower than

100%). (

Operation Manual

Chapter3

)

Set the DRYING TIME for each scan.

(

Operation Manual Chapter3

)

To Test Print

If it has not been

dehydrated

When you perform the items menti-

oned at the right, the printing speed

lowers. Therefore, check whether

you can raise the heater temperat-

ure before performing them.

Attach the antistatic sheet. (If you attach the

antistatic sheet, the drying performance will

be lowered.) (

Operation Manual Chapter1

)

To Setting a Media

If there an abnormality

of the media feeding

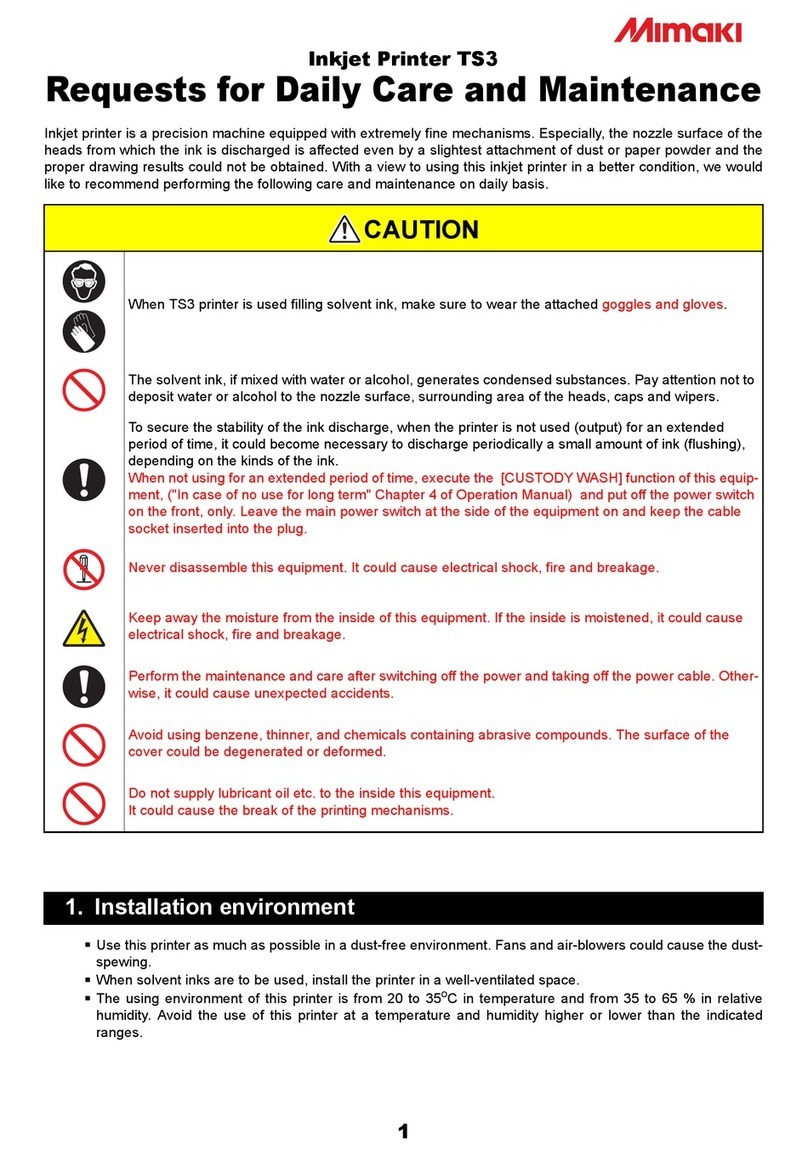

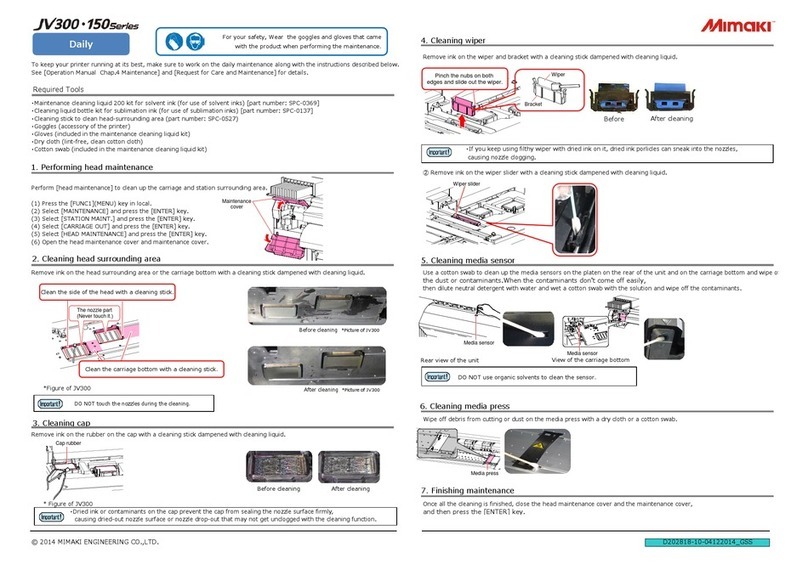

Printer Setting and Checking Items before Printing

When using this product, first turn the power supply ON and then perform/ check the items below before printing.

After clamp up, remove the clogging media.

If the head scratched the media, reset the media.

Move the carriage to the waiting position, and return it to the station with the key.

Remove the Media

By referring to Operation Manual “Chapter 2 Head Cleaning” , perform head cleaning.

Head Cleaning

Perform test print and check that there is no line that is missing and no line that is bent.

Test Print

In case that nozzle missing

and no line that

is bent

is not improved even though you

repeat cleaning,by referring to Operation

Manual “Chapter 4 When Nozzle Clogging

Cannot Be Solved” , perform Washing of

Head nozzle.

To Head Cleaning

After the head recovered, check the items below:

Recovery

If nozzle missing

occurs

・ Check that the media is not skewed.

・ Check the media cockling.

・ Check that the head height (that it is not too low).

If paper jam occurred

If the head scratched the media or paper jam occurred, immediately perform the items below:

Notes when using

■

Do not leave the media for a long time (more than ten minutes) with the heater ON.

■

Check the media float before detecting the media width.

■

If paper jam occurred, immediately perform head cleaning and check by test drawing.

■

If dryness is not enough, make the feeding speed slower or set the dryness time.

■

Do not leave it with capping OFF and the cover opened.

■

Leave the main power turned on to prevent ink clogging.

Printed in Japan

D202374-20-30072020

© MIMAKI ENGINEERING CO., LTD.2012 KM

/