SECTION

I

INTRODUCTION

This

manual

describes the

Model

lOlA

printer,

manufactured

by

Centronics

Data

Computer

Corporation.

It

provides general information, detailed theory of

operation

and

maintenance

information enabling field service personnel to

main-

tain the printer.

For

serial input or other detailed interface information, a

separate

document

for

each

interface

is

published for

your

reference.

pose.

The

manual

is

grouped

into eight sections,

each

with

its

specific pur-

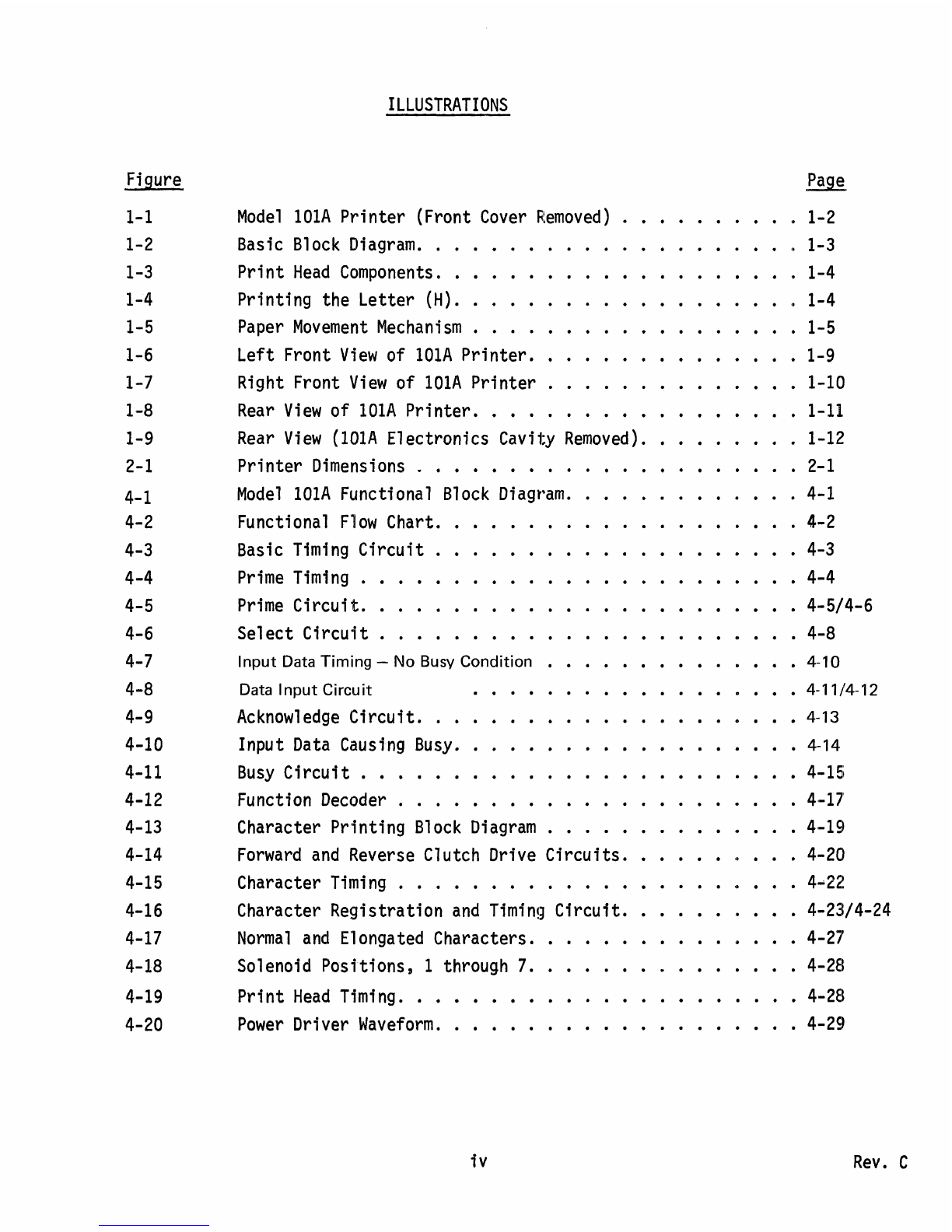

Section I -

INTRODUCTION~

introduces the reader to the

scope

and

content of the

manual,

and

provides the reader

with

a general description of the printer.

Section 2 &3 -

INSTALLATION

&

OPERATION,

contains additional in-

stallation

and

operation data not included

in

the

Operators

Manual.

Section 4 -

Section 5 -

Section 6 -

Section 7 -

Section 8 -

THEORY

OF

OPERATION,

contains a detailed description

of

each

major

operation

performed

by

the printer

electronics, including

flow

chart,

timing

diagrams

and

circuit

diagrams.

REMOVAL,

REPLACEMENT

AND

ADJUSTMENT

PROCEDURES,

includes

step-by-step

removal

and

replacement

proc~dures

for

all

major

assemblies

and

sub-assemblies

in

the printer.

MAINTENANCE,

includes preventive

maintenance

procedures,

and

recommended

spare parts

list.

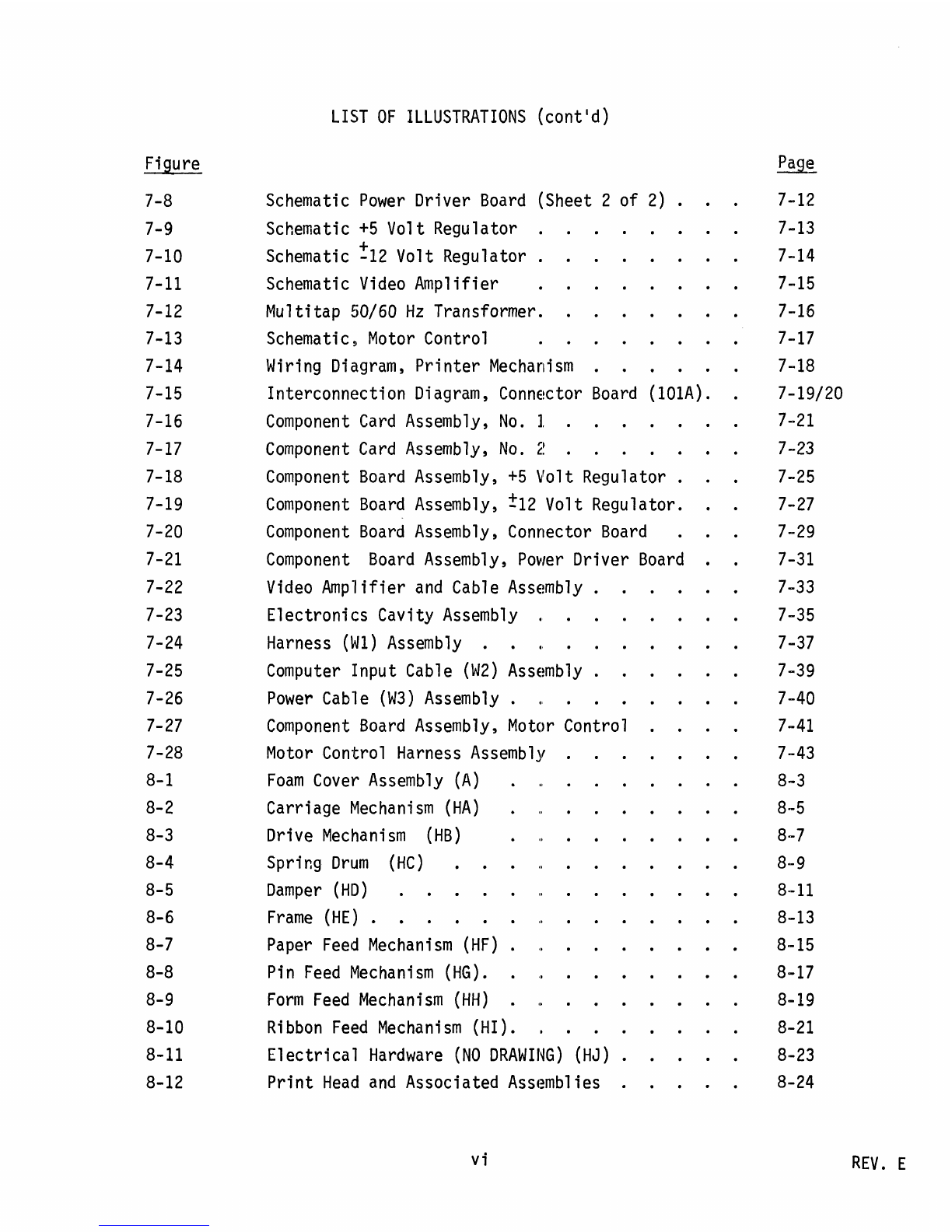

ELECTRICAL

DRAWINGS

AND

LIST

OF

MATERIALS,

contains a

complete

set

of schematic, wiring

and

component

board

layout

diagrams

and

their associated

list

of materials

for the electrical portion of the printer.

MECHANICAL

DRAWINGS

AND

PARTS

LISTS,

includes

all

printer

assembly

drawings

and

their

associated part

lists

for the

mechanical

portion of the printer.

1-1

Rev.

C