Minarik SL10U User manual

User’s Manual

SL10U

Adjustable Speed Control

for Hurst Permanent Magnet

90 VDC Motors

250-0021r5_readers.qxd 7/11/01 9:18 AM Page i

Copyright 2001 by

Minarik Corporation

All rights reserved. No part of this manual may be reproduced or transmitted in any form

without written permission from Minarik Corporation. The information and technical data

in this manual are subject to change without notice. Minarik Corporation and its

Divisions make no warranty of any kind with respect to this material, including, but not

limited to, the implied warranties of its merchantability and fitness for a given purpose.

Minarik Corporation and its Divisions assume no responsibility for any errors that may

appear in this manual and make no commitment to update or to keep current the

information in this manual.

Printed in the United States of America.

250-0021r5_readers.qxd 7/11/01 9:18 AM Page ii

Safety Warnings

Note: This symbol denotes an important safety message. Please read

these sections carefully before performing any instructions contained in this

manual.

• Have a qualified electrical maintenance technician install,

adjust and service this equipment. Follow the National

Electrical Code and all other applicable electrical and safety

codes, including the provisions of the Occupational Safety

and Health Act (OSHA), when installing equipment.

• Reduce the chance of an electrical fire, shock, or explosion

by proper grounding, over current protection, thermal

protection, and enclosure. Follow sound maintenance

procedures.

i

250-0021r5_readers.qxd 7/11/01 9:18 AM Page i

ii

Table of Contents

General Information .................................................1

Features .........................................................2

Specifications .....................................................3

Dimensional Data ..................................................4

Installation........................................................6

Alternative Wiring .....................................................8

Calibration........................................................9

Maximum Speed and Regulation (IR COMP) Adjustment ......................9

Standard Calibration .................................................11

ApplicationNotes .................................................14

Speed Adjustment ...................................................15

Adjustable / Maximum Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....16

Multiple Fixed Speeds .................................................17

Adjustable Speeds in Two or More Non-Overlapping Speed Ranges ..............18

Multiple Full Range Adjustable Speeds ....................................19

Independent Forward and Reverse Speeds ................................20

External Signal Control ................................................21

Simultaneous Speed Control of Multiple Systems . . . . . . . . . . . . . . . . . . . . . . ......22

Run/StopCircuits ................................................23

Run / Stop Using Normally Closed Contacts ................................23

250-0021r5_readers.qxd 7/11/01 9:18 AM Page ii

iiiTable of Contents

Run / Stop Using Normally Open Contacts .................................24

Reversing Circuits .................................................25

Reversing with a Toggle or Rotary Switch ..................................26

Reversing with Relays ................................................27

Dynamic Braking ..................................................29

DC Permanent Magnet Motor Dynamic Braking Theory .......................29

Dynamic Braking Circuit Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Run/Stop with Dynamic Braking using a Toggle Switch ........................32

Run/Stop Dynamic Braking using a Relay ..................................33

Reversing with Dynamic Braking Circuits ................................35

Reversing with Dynamic Braking using a Rotary Switch .......................35

Reversing with Dynamic Braking using Relays . . . . . . . . . . . . . . . . . . . . . . . . . . ....37

LimitSwitchCircuits ...............................................39

Toggle Switch Reversing with Limit Switches ................................40

Relay Reversing with Dynamic Braking and Limit Switches .....................42

Troubleshooting ...................................................45

Parts List ..........................................................49

Unconditional Warranty .................................insideback cover

250-0021r5_readers.qxd 7/11/01 9:18 AM Page iii

iv

Illustrations

Figure1. Dimensions .......................................................4

Figure 2. SL10U Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............5

Figure 3. Maximum Speed and Regulation Trimpot Locations . . . . . . . . . ...............13

Figure 4. Adjustable / Fixed Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............16

Figure 5. Multiple Fixed Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .............17

Figure 6. Two Non-Overlapping Speed Ranges . . . . . . . . . . . . . . . . . . . . . . . ............18

Figure 7. Two Full Range Adjustable Speeds . . . . . . . . . . . . . . . . . . . . . . . . .............19

Figure 8. Independent Forward and Reverse Speeds . . . . . . . . . . . . . . . . . .............20

Figure 9. External Signal Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .............21

Figure 10. Simultaneous Speed Control of Multiple Systems . . . . . . . . . . . ...............22

Figure 11. Run / Stop Using Normally Closed Contacts . . . . . . . . . . . . . . . . . .............23

Figure12. Run/StopUsingNormallyOpenContacts ...............................24

Figure 13. Reversing with Toggle Switch . . . . . . . . . . . . . . . . . . . . . . . . .................26

Figure14. ReversingwithRelays ..............................................28

Figure 15. Run / Stop Dynamic Braking with Toggle Switch . . . . . . . . . . .................32

Figure 16. Run / Stop Dynamic Braking using a Relay . . . . . . . . . . . . . . . . ...............34

Figure 17. Rotary Switch Reversing with Dynamic Braking . . . . . . . . . . .................36

Figure18. ReversingwithDynamicBrakingusingRelays ............................38

Figure 19. Toggle Switch Reversing with Limit Switches . . . . . . . . . . . . . . . . . ............41

Figure 20. Relay Reversing / Braking with Limit Switches . . . . . . . . . . . . . . . . ............44

250-0021r5_readers.qxd 7/11/01 9:18 AM Page iv

The Model SL10U Minarik adjustable speed control is a full-wave,

solid-state device that is designed to control and vary the speed of

Hurst 90 VDC permanent magnet motors. The control has

choke/capacitor filtering to ensure quiet, smooth and cool running.

In a typical application, 2% base speed regulation is provided with

the help of temperature, line voltage and IR compensation. The

control has a speed range of 15:1, also has adjustable IR

compensation and a maximum speed adjustment to limit high-

speed operation.

1

General Information

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 1

2General Information

Features

• Choke/Capacitor Filtering

• Temperature Compensation

• 2% Base Speed Regulation (Typical Application)

• Maximum Speed Adjustment

• Adjustable IR Compensation

• Line Starting and Stopping

• Line Voltage Compensation

• Full Wave Armature Supply

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 2

3

Input Voltage 115 VAC, 50/60 Hz Single Phase

Maximum Input Current 0.12 Amperes

Output Armature Voltage 0 - 90 VDC

Output Armature Current 0.07 Amperes

Horsepower Range 1/250 – 1/50

Weight 8.0 Ounces

Ambient Temperature Range 10° – 40° C

Specifications

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 3

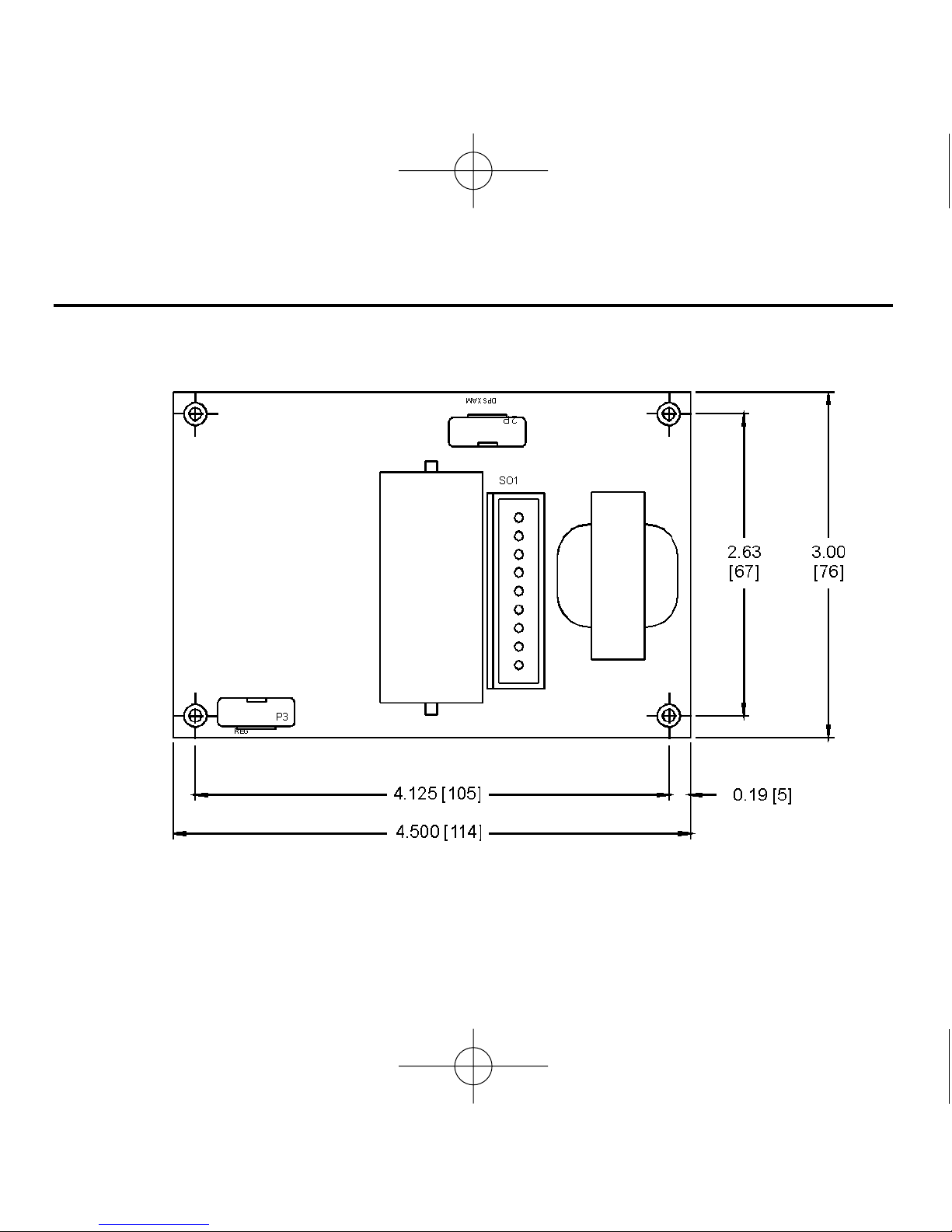

4

Dimensional Data

Figure 1. Dimensions

ALL DIMENSIONS IN INCHES [MILLIMETERS]

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 4

5

Figure 2. SL10U Connections

PL1

CW

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 5

6 Installation

The SL10U is an uncased chassis model and is designed to be

installed in original equipment. The speed adjust pot (P1) and its

mounting hardware is supplied with the control. Mount the speed

adjust pot through a 3/8" hole with the insulator disc between the pot

and the inside of the panel. The lock washer is placed between the

outside of the panel and the locknut. Mount the chassis to

appropriate subplates using the four threaded (6-32) mounting

stand-offs (refer to figure 1 on page 4 for mounting dimensions).

The chassis has adequate heat sinking to properly dissipate the

load-generated heat and can be either vertically or horizontally

mounted.

Installation

The SL10U is not isolated from earth ground. Unless

an isolation transformer is used, circuit components

are at a potential of 115 volts above ground. Please

refer to Safety Warnings on page i before installing.

Warning

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 6

7

Leave enough room around the outer dimensions of the chassis to

allow access to the chassis after installation for removal, installing

wiring, calibration and other related reasons. Connect the SL10U

as shown in Figure 2 (page 5), and as described below.

1. Connect the speed adjust pot to its appropriate wires. These 3

wires should NOT be bundled with the motor and power line

leads because induced voltages could cause erratic operation.

If the speed adjust pot requires wiring longer than 18 inches

(0.5m), a shielded cable must be used. Do not ground both ends

of the shield.

2. Connect the motor to its appropriate wires. If the motor rotates

in the wrong direction, remove line voltage and reverse the

motor armature leads. Do NOT plug reverse the motor.

Installation

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 7

8 Installation

3. Connect the power line to its appropriate wires. The hot leg of

the power line should be fused with a fast blow 0.5 amp fuse to

protect the control. The motor may be started and stopped with

the power line at any speed setting on the speed adjust pot. The

motor coasts to a stop when the power line is disconnected. If

dynamic braking is desired, see

Dynamic Braking

on page 29.

Minarik strongly recommends the installation of an emergency

stop switch as shown in Figure 2 (page 5). The switch must be

rated at a minimum of 250 VAC and 150% of the maximum

motor armature rating.

Alternative Wiring

By utilizing additional components the SL10U may be operated by

external signal control, have multiple preset speeds, dynamic

braking, limit switch operation, etc. Please refer to

Application

Notes

(page 14) for these and other modes of operation.

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 8

9

IMPORTANT: A non-metallic screwdriver should be used when

adjusting the trim pots to avoid any possibility of the screwdriver’s

blad contacting live circuitry and shorting the circuitry or allowing

contact with any dangerous or fatal voltages.

Dangerous voltages exist on the printed circuit

board. Contact with components and/or printed

circuitry could cause serious injury or fatality. Please

refer to the Safety Warnings on page i.

Warning

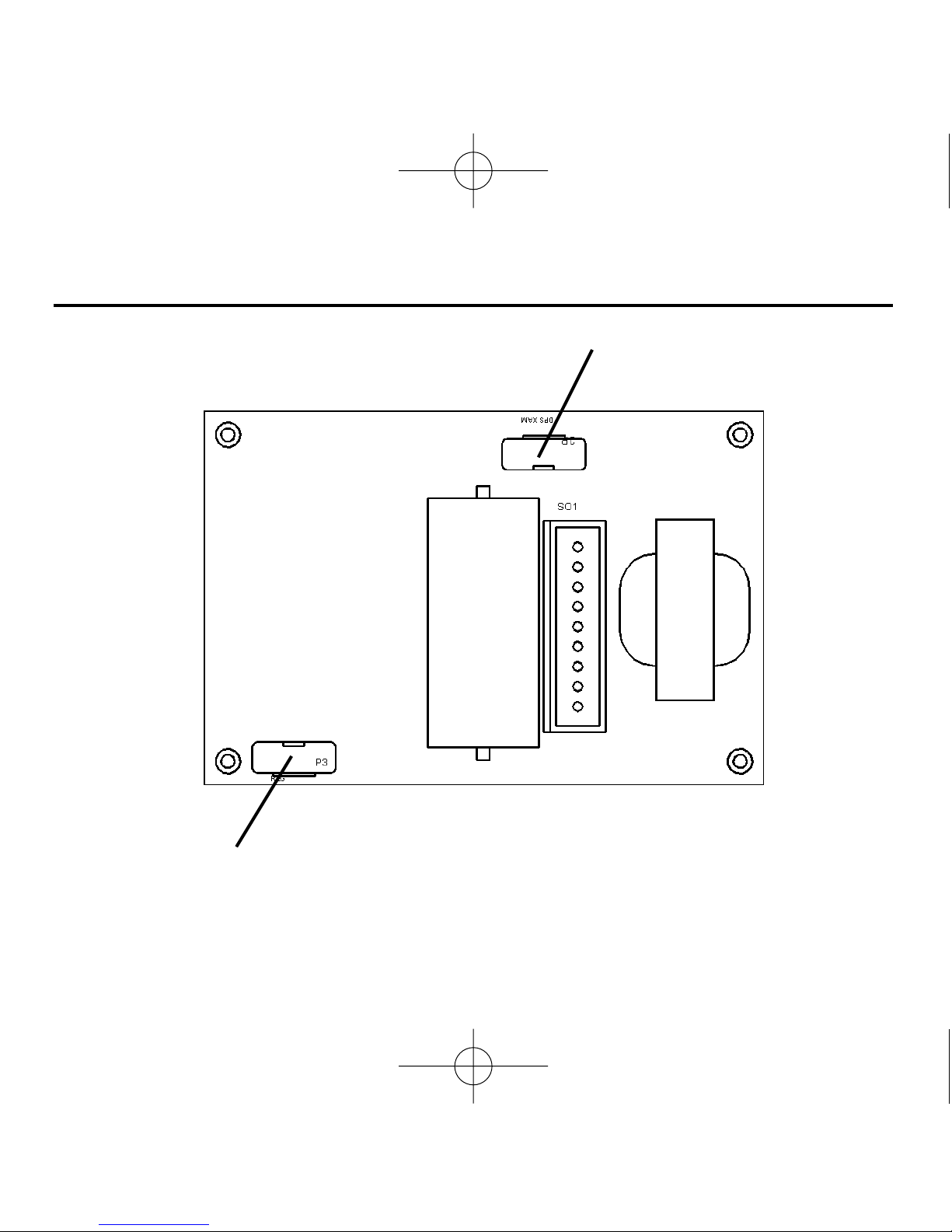

Maximum Speed and Regulation (IR COMP) Adjustment

Two potentiometers, located on the control PC board, are provided

for adjustment of the maximum motor speed and regulation of the

motor’s speed.

Calibration

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 9

10 Calibration

MAXIMUM SPEED ADJUSTMENT

This feature is provided to allow the motor speed to be adjusted

between 85 to 115% of motor name plate rated speed when the

speed adjust knob is set at maximum.

REGULATION (IR COMPENSATION)

Regulation is obtained by circuitry which raises the armature

voltage to maintain speed when increased loading tends to slow the

motor down.

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 10

11Calibration

The control has been factory calibrated and no further adjustments

should be necessary. However, since the control was calibrated

using a speed adjust pot (P1) of 10K ohms and the pot shipped with

the control has a tolerance of ± 5%, the maximum speed could be

higher or lower than 1800 RPM. If the maximum speed is not

satisfactory, if the control has been repaired, or if you want to make

any changes, then follow the procedure listed below.

1. Disconnect the power line.

2. Set the speed adjust knob to “0” (full CCW).

3. Set the MAXIMUM SPEED trim pot to full CCW (refer to Figure

3 on page 13).

4. Set the REGULATION trim pot to full CCW (refer to Figure 3 on

page 13).

5. Read and follow the SAFETY WARNING on page i.

6. With no load on the motor, apply 115 VAC to the control and

advance the speed adjust knob to “100” (full CW).

Standard Calibration

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 11

12 Calibration

7. Adjust the MAXIMUM SPEED trim pot for motor base speed at

no load.

8. Load the motor to full load and adjust the REGULATION trimpot

to obtain the same speed as at no load.

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 12

13Calibration

Figure 3. Maximum Speed and Regulation Trimpot Locations

MAXIMUM SPEED

REGULATION (IR COMP)

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 13

14

DISCLAIMER - The following circuitry does not purport to cover all

possible details or variations, nor to provide for every possible

contingency to be met with connection, installation, operation, or

maintenance, and no warranty of fitness for purpose is expressed or

implied. Furthermore, Minarik Corporation assumes no

responsibility for the use of any circuitry described and makes no

representation that they are free from patent infringement.

Application Notes

The components shown in the following circuitry

should only be connected by qualified electrical

personnel familiar with the construction, operation,

and hazards of all the components used. Personal

injury and/or equipment damage may occur if

components are improperly connected, installed,

adjusted, or serviced. Also refer to the Safety

Warnings on page i.

Warning

250-0021r5_readers.qxd 7/11/01 9:18 AM Page 14

Table of contents

Other Minarik Control Unit manuals

Popular Control Unit manuals by other brands

Z-World

Z-World RabbitCore user manual

Homelife

Homelife CT2 24 UNI DL Instructions and warnings for installation, use and maintenance

Alfalaval

Alfalaval 660 instruction manual

SimCom

SimCom SIM300DZ Guidelines

Circa Enterprises Inc.

Circa Enterprises Inc. Guardian Telecom PTR Installation & operation

Redline

Redline RDL-3000 Series product manual

BOSSCO

BOSSCO Ecomaxx Supplemental manual

Texas

Texas TPS25940EVM-635 user guide

Panasonic

Panasonic PAN1326C2 quick start guide

3Com

3Com CoreBuilder 9000 ATM Interface Module quick start guide

Richter

Richter GU/F Series Installation and operating manual

AVR

AVR AVK Series Installation, operation and maintenance manual