BOSSCO Ecomaxx Owner's manual

BOSS PRODUCTS NORTH AMERICAN

SUPPLEMENTAL MANUAL FOR

ECOMAXX NO RETURN VALVE (EM-NRV)

TABLE OF CONTENTS

PAGE 2 – INTRODUCTION / WARRANTY

PAGE 3 – SUPPLEMENTAL MANUAL INFORMATION

PAGE 4 – SAFETY

PAGE 5 – NFPA COMPLIANCE

PAGES 6 THRU 8 – ECOMXX EM-NRV SPECIFICATIONS

PAGE 9 – O-EM-NRV-CP02 SPECIFICATIONS

PAGE 10 – RECEIVING THE ECOMAXX EM-NRV

PAGE 11 – ASSEMBLY INSTRUCTIONS (SIZES 7” THRU 10”)

PAGES 12 THRU 13 --

PAGES 14 THRU 17 --

PAGES 18 THRU 20 –

ASSEMBLY INSTRUCTIONS (SIZES 12” THRU 28”)

ASSEMBLY INSTRUCTIONS (SIZES 32” THRU 40”)

INSTALLING THE MICROSWITCH – O-EM-NRV-MS

PAGES 21 THRU 22 – INSTALLING THE DUST LEVEL SENSOR – O-EM-NRV-DLS

PAGES 23 THRU 24 – WIRING PANEL O-EM-NRV-CP02 TO MAIN CONTROL PANEL

PAGE 25 – 120VAC INPUT POWER WIRING

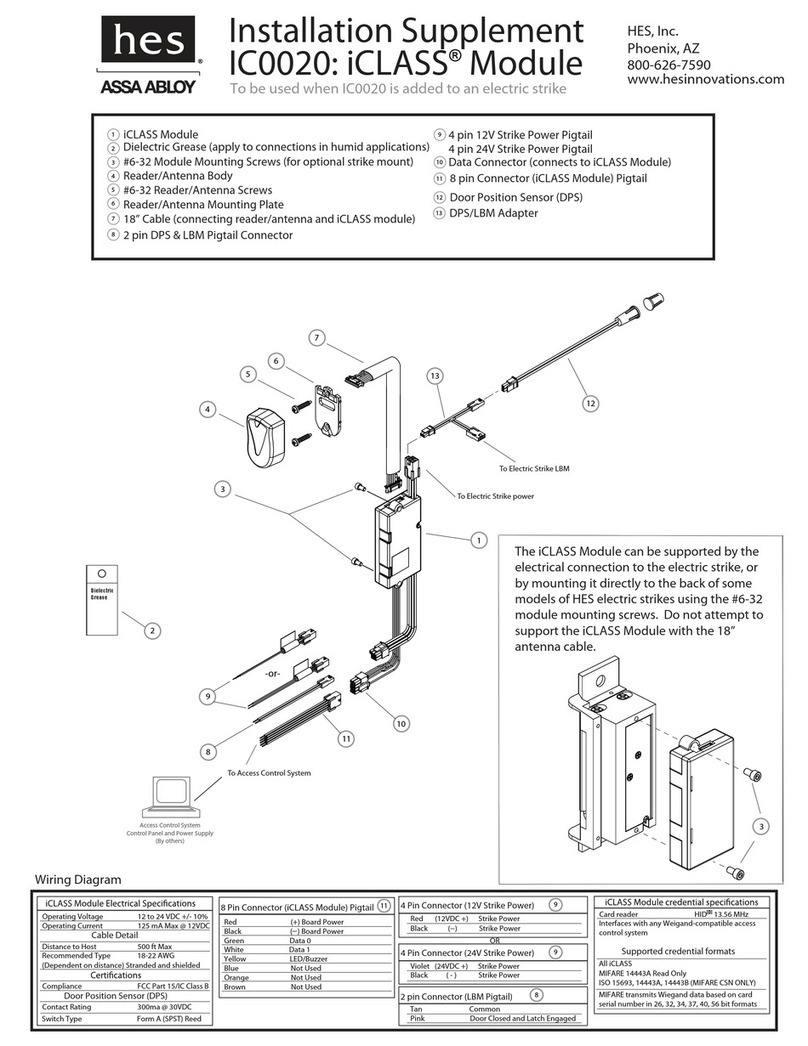

PAGE 26 – GENERAL WIRING DIAGRAM

PAGE 27 – EM-NRV PRODUCT GROUP SPARE PARTS

PAGE 28 – CONTACT INFORMATION

P.O. BOX 953 – 33100 NE IVY AVENUE - LA CENTER, WA 98629 – USA

PH: 360-263-2360 – FAX: 360-263-9772

INFO@BOSSPRODUCTSAMERICA.COM – WWW.BOSSPRODUCTSAMERICA.COM

Page 2 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

INTRODUCTION

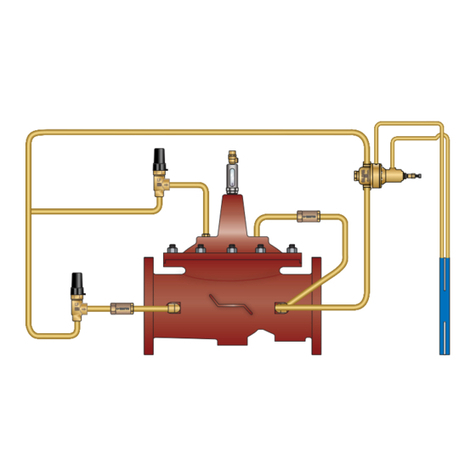

Thank you for purchasing the EcoMAXX EM-NRV No Return Valve. The EM-NRV is an

Explosion Isolation Device specifically designed to prevent deflagration propagation between

connected equipment. The EM-NRV is ATEX certified and NFPA 69 compliant.

Required Items for NFPA 69 Compliance:

O-EM-NRV-CP02, Intrinsically Safe Control Panel

O-EM-NRV-MS, Microswitch

O-EM-NRV-DLS, Dust Level Sensor

Complimentary Products:

EM-HSAG line of High Speed Abort Gates

EM-FBS line of Firebreak Shutters

EM-XV line of Explosion Vents

EM-FCS Spark Detection and Extinguishment Systems

EM-IMS line of Dust Monitoring (Emissions) Systems

ECOBOSS Line of Energy Management Control Systems

WARRANTY:

1. Boss Products, LLC warrants to the Buyer that the material sold to Buyer will be free

from manufacturing defects at the time of shipping of such material to the job site.

2. Boss Products, LLC further warrants to the Buyer that the workmanship and material

supplied to the Buyer will be free from defects under proper usage for a period of 12

months from the shipping date so long as Buyer can demonstrate (i) that such material

was installed in accordance with the National Electrical Code, NFPA guidelines, and

local codes and ordinances, and (ii) that Buyer has property maintained such material as

per the maintenance requirements related to such material. The warranty provided under

this Section 2, shall become null and void if Buyer fails to prove proper installation and

maintenance of materials provided by Boss Products, LLC.

3. The Buyer shall be responsible for remedies to problems with material and services not

provided by Boss Products, LLC.

4. Boss Products, LLC, at their sole discretion, will repair or replace defective material or

workmanship originally supplied by them. Said defective material or workmanship shall

be returned to Boss Products, LLC freight prepaid. Repaired or replaced materials will

be returned to the customer freight prepaid.

THERE ARE NO WARRANTIES EITHER EXPRESSED OR IMPLIED, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, WHICH EXTEND BEYOND THE WARRANTIES CONTAINED IN THIS

DOCUMENT. BOSS PRODUCTS, LLC SHALL NOT BE LIABLE FOR ANY

INCIDENTAL, CONSEQUENTIAL, DIRECT, INDIRECT OR OTHER DAMAGES, ARISING

UNDER ANY THEORY OF LAW WHATSOEVER.

Page 3 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

THIS MANUAL IS A SUPPLEMENT TO THE AIRCOM

INSTALLATION, USE AND MAINTENANCE MANUAL

FOR NO RETURN VALVES.

IT HAS BEEN COMPILED BY BOSS PRODUCTS, LLC

FOR THE NORTH AMERICAN MARKET

THE INSTALLER AND END USER MUST BE FAMILIAR

WITH BOTH, THE AIRCOM MANUAL AND BOSS

PRODUCTS SUPPLIMENT

Page 4 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

SAFETY

ELECTRIC SHOCK HAZARD

ONLY QUALIFIED PERSONELL SHOULD INSTALL,

MAINTAIN OR WORK ON THIS EQUIPMENT!

ALWAYS PERFORM WORK WITH THE POWER OFF!

ARC FLASH HAZARD

APPROPRIATE PPE REQUIRED! FOLLOW ALL

REQUIREMENTS IN NFPA 70E

ALWAYS MAINTAIN PROPPER CONVEYING

VELOCITIES AS REQUIRED BY NFPA 652 & 654 FOR

COMBUSTIBLE DUSTS

WARNING! DO NOT SUBSTITUTE COMPONENTS

READ ALL DISCLAIMERS IN CORRESPONDING

AIRCOM MANUAL

IT IS THE INSTALLERS RESPONSIBILITY TO VERIFY

THAT THEIR INSTALLATION COMPLIES WITH

REQUIREMENTS SET BY THE AUTHORITY HAVING

JURISDICTION ALL NATIONAL, LOCAL, NEC AND

NFPA CODES AND/OR GUIDELINES.

Page 5 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

NFPA COMPLIANCE

NFPA 652 – STANDARD ON THE FUNDAMENTALS OF COMBUSTIBLE DUST – 2016

EDITION

8.9.4 – Equipment Isolation

o 8.9.4 – Where an explosion hazard exists, isolation devices shall be provided to

prevent deflagration propagation between connected equipment in accordance

with NFPA 69.

o 8.9.4.4 – Isolation of Upstream Work Areas. Where a dust explosion hazard

exists, isolation devices shall be provided to prevent deflagration propagation

from equipment through upstream ductwork to the work areas in accordance with

NFPA 69.

NFPA 69 – STANDARD ON EXPLOSION PREVENTION SYSTEMS – 2014 EDITION

CHAPTER 12 DEFLAGRATION CONTROL BY PASSIVE ISOLATION

o 12.2.2.3 FLOW ACTUATED FLAP VALVE

The EM-NRV meets all requirements of this section when installed with all options and

conveying ductwork per 12.2.3.4.6

KEY POINTS

12.2.3.4.2 Requires a locking mechanism which is provided standard.

12.2.3.4.3 Requires an Inspection door which is provided standard.

12.2.3.4.4 Requires an immediate, automatic shutdown of the protected process.

Accomplished with O-EM-NRV-MS Microswitch which is an available option that mounts

on the NRV locking mechanism and sends a signal upon an event.

12.2.3.4.5 and 12.2.3.4.5.1 requires a continuous signal to ensure valve operation is not

compromised by the accumulation of a dust layer on the bottom interior of the valve and

requires an immediate, automatic and orderly shutdown of the protected process.

Accomplished with O-EM-NRV-DLS capacitive style Dust Level Sensor (DLS) which

sends a signal when 0.15”-0.20” of dust has accumulated. The DLS is located in the

airstream and requires an intrinsically safe barrier.

12.2.3.5 Requires System Certification by a recognized testing organization. A.10.4.2.1

allows for European CEN ATEX certification being acceptable.

Page 6 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

ECOMAXX EM-NRV

NO RETURN VALVE SPECIFICATIONS

STANDARD FEATURES (ALL SIZES)

Heavy Duty Welded Steel Construction * Epoxy Powder Coated Safety Red Finish

Flanged Inlet and Outlet with Co-Flanges * Grounding Lugs * Locking Mechanism(s)

ATEX Certification

Sizes 7” Thru 28”

o Certified ATEX EN16447 & EN15089

Certified: CE0477 II D

Certified N. EUT 14 ATEX 1954

o Application Class: ST3 (Kst max 400 bar m/s)

o P

red Max: 0.5 Bar

o Maximum Velocity: 5905 FPM

o Maximum Pressure: 200.93” H2O / 14.76” Hg

o Process Temperature Range: -4° F to 140° F (- 20° C to +60° C)

o Pressure Drop @ 5905 FPM (Sizes 7” - 18”): 0.25” H2O

o Pressure Drop @ 5905 FPM (Sizes 20” - 28”): 0.40” H2O

o Minimum Distance (Sizes 7”- 16”) From Collector: 2 meters / 6.56 feet

o Maximum Distance (Sizes 7”-16”) From Collector: 4 meters / 13.12 feet

o Minimum Distance (Sizes 18”- 28”) From Collector: 3 meters / 9.84 feet

o Maximum Distance (Sizes 18”-28”) From Collector: 6 meters / 19.69 feet

o Horizontal Installation Only

Sizes 32” Thru 40”

o Certified ATEX EN15089

Certified: CE2049 II D

Certified N. EUM1 12 ATEX 0714

o Application Class: ST2 (Kst max 299 bar m/s)

o P

red Max: 0.25 Bar

o Maximum Velocity: 5905 FPM

o Maximum Pressure: 100.47” H2O / 7.38” Hg

o Process Temperature Range: -4° F to 140° F (- 20° C to +60° C)

o Pressure Drop @ 5905 FPM: 0.63” H2O

o Minimum Distance From Collector: 3 meters / 9.84 feet

o Maximum Distance From Collector: 6 meters / 19.69 feet

o Horizontal Installation Only

Page 7 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

*NFPA 69-2014 (A.12.2.3.4.6) STATES: The minimum design pressure for the ductwork is typically 2 x P

red

because

the pressure wave reflects off the closed valve. Depending on the distance between the flap valve and the enclosure,

pressure piling could further increase the expected peak pressure.

** See Minimum/Maximum Distance Specifications (Page 6 of This Manual)

DIMENSIONS FOR SIZES 7” THRU 28”

Model ᴓ A B C D E F G H ILBS

EM-NRV07 7.09” / 180mm 14.1 13.3 21.6 13.3 11.8 7 6.6 - - 45

EM-NRV08 7.87” / 200mm 14.1 13.3 21.6 13.3 11.8 7 6.6 - - 45

EM-NRV10 9.84” / 250mm 16.1 15.3 23.6 15.3 12.7 8 7.6 - - 56

EM-NRV12 11.81” / 300mm 18.1 17.3 26.3 23.6 13.7 9 8.6 - 4.5 84

EM-NRV14 13.78” / 350mm 20 19.2 28.3 25.5 14.7 10 9.6 - 4.5 100

EM-NRV16 15.75” / 400mm 22 23.2 30.3 29.5 15.7 11 10.6 13.7 6.4 120

EM-NRV18 17.72” / 450mm 24 25.1 32.2 33.2 16.7 12 11.6 15.7 8.4 150

EM-NRV20 19.69” / 500mm 25.9 27.1 34.2 38.7 17.7 12.9 12.5 18.1 12.4 177

EM-NRV22 21.65” / 550mm 27.9 29.1 36.2 37.4 18.7 13.9 13.5 19.6 8.4 221

EM-NRV24 23.62” / 600mm 29.9 31.1 38.1 41.1 19.6 14.9 14.5 21.6 10.4 254

EM-NRV26 25.59” / 650mm 31.8 33 40.1 45 20.6 15.9 15.5 23.8 12.4 276

EM-NRV28 27.56” / 700mm 33.8 35 42.1 47 21.6 16.9 16.5 25.5 12.4 298

DUCTWORKOFSUFFICIENT

STRENGTHTOWITHSTANDTHE

PEAKEXPLOSIONPRESSURE*

DUSTCOLLECTOR

DISTANCE**

EM‐NRV

NORETURNVALVE

Page 8 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

DIMENSIONS FOR SIZES 32” THRU 40”

Model ᴓ A B C D E F G H ILBS

EM-NRV32 31.49” / 800mm 38.5 40.1 52.3 56.4 25.9 25.9 18.8 28.1 14.1 728

EM-NRV36 35.43” / 900mm 42.5 44.4 56.2 60.4 27.9 27.9 20.8 27.9 14.1 860

EM-NRV40 39.37” / 1000mm 46.4 48 60.2 64.3 29.9 29.9 22.8 35.8 14.1 999

FLANGE AND CO-FLANGE DIMENSIONS

I.D. 1 Dimensions are the inner diameter

dimensions of the flanges installed on

EM-NRV

I.D. 2 Dimensions are the inner diameter

dimensions of the co-flanges provided with

EM-NRV

Model I.D. 1 I.D. 2 B.C. O.D. Holes Thickness

EB-FL07 7.20” 7.125” 8.38” 9.56” 5 @ 0.4” 0.15”

EB-FL08 7.99” 8.125” 9.17” 10.35” 6 @ 0.4” 0.15”

EB-FL10 9.96” 10.125” 11.14” 12.32” 6 @ 0.4” 0.15”

EB-FL12 11.93” 12.125” 13.30” 14.67” 6 @ 0.4” 0.15”

EB-FL14 13.90” 14.125” 15.27” 16.64” 8 @ 0.4” 0.15”

EB-FL16 15.87” 16.125” 17.24” 18.61” 8 @ 0.4” 0.15”

EB-FL18 17.84” 18.125” 19.21” 20.58” 10 @ 0.4” 0.15”

EB-FL20 19.81” 20.125” 21.18” 22.55” 10 @ 0.4” 0.15”

EB-FL22 21.77” 22.125” 23.14” 24.51” 12 @ 0.5” 0.15”

EB-FL24 23.73” 24.125” 25.30” 26.87” 14 @ 0.5” 0.23”

EB-FL26 25.71” 26.125” 27.28” 28.85” 14 @ 0.5” 0.23”

EB-FL28 27.68” 28.125” 29.25” 30.82” 14 @ 0.5” 0.23”

EB-FL32 31.61” 32.125” 33.18” 34.75” 14 @ 0.5”0.23”

EB-FL36 35.55” 36.125” 37.12” 38.69” 16 @ 0.5”0.23”

EB-FL40 39.49” 40.125” 41.06” 42.63” 18 @ 0.5”0.23”

Page 9 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

ECOMAXX O-EM-NRV-CP02

INTRINSIC PANEL SPECIFICATIONS

4 Models Available*

o Model: O-EM-NRV-CP02

(1 NRV)

o Model: O-EM-NRV-CP02X2

(Up-to 2 NRVs)

o Model: O-EM-NRV-CP02X3

(Up-to 3 NRVs)

o Model: O-EM-NRV-CP02X4

(Up-to 4 NRVs)

*Larger Panels are available on request

All Models Feature the following:

o NEMA 4 Enclosure

o Status lights (Green = System OK / RED = System Trouble),

o Terminals for Microswitch

o Intrinsic circuit with barrier and physical separation

o Drawings

o 120VAC Input Power

o UL S1861* Intrinsically Safe Label

Required Sensors

O-EM-NRV-MS: Microswitch for No Return Valve. (Shipped Loose)

O-EM-NRV-DLS: Dust Level Sensor (Capacitive) to ensure the NRV is not compromised

by a layer of dust accumulation. (Shipped Loose)

ON REQUEST O-EM-NRV-CP02 COMPONENTS MAY BE

BUILT INTO AN ECOBOSS ENERGY CONTROL PANEL

Page 10 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

RECEIVING THE ECOMAXX EM-NRV

The EcoMAXX EM-NRV typically ships shrink-wrapped and strapped on a wooden

pallet. Customer must inspect the equipment for damage upon receipt. If damage is

present, receiver must note damaged on the shipping documents in order to file a claim.

All Counterweights are shipped inside the No Return Valve. NOTE: Sizes 7, 8 & 10 do

not have counterweights. Sizes 12 thru 28 have 1 counter weight. Sizes 32” + Utilize 2

counterweights with patented breaking elements.

Dependent on the size of the No Return valve, the O-EM-NRV-CP02 control panel, O-

EM-NRV-MS Microswitch and O-EM-NRV-DLS are shipped in a cardboard box placed

on top of the valve or inside it.*

* Control Panel, Microswitch and dust level sensor are required options for NFPA compliance and are ordered

separately. Dependent on order, any combination of these may be shipped.

O-EM-NRV-CP02, Intrinsic Panel with NFPA Compliant Options

Contains O-EM-NRV-DLS (Dust Level Sensor), O-EM-NRV-MS (Microswitch) and Wiring Diagram

Page 11 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

ASSEMBLY INSTRUCTIONS

(SIZES 7”-10”)

No Return Valve Sizes 7”-10” have a locking arm without a counterweight

and come assembled as shown in the above picture.

For mounting the microswitch and dust level sensor, refer to pages 18-22.

Page 12 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

ASSEMBLY INSTRUCTIONS

(SIZES 12”-28”)

Counter Weight

Locking

Mechanism

Manual with

Metric Allen

Wrench

Page 13 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

For mounting the microswitch and dust level sensor, refer to pages 18-22.

Replace Bolt on

Counter Weight

Mounting Shaft

Remove Bolt

on Counter

Weight

Mounting

Shaft Using

Provided

Allen

Wrench.

Position Counter

Weight in the

Locked Position

in the Locking

Mechanism.

Slide Counter Weight

onto Shaft as Shown

Tighten

the Two

Bolts to

Clamp

Counter

Weight in

Place.

Page 14 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

ASSEMBLY INSTRUCTIONS

(SIZES 32”+)

Manual with Metric Allen Wrenches

Locking Mechanism

Counter Weight Arm

(Lower Section)

Breaking Elements

Counter Weight (Upper Section)

Page 15 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

Counter Weight Arm (Lower Section)

**NOTE** Lower Section may be Installed at

Factory and This Step May not be Necessary.

Slide Arm until it Fits over the Key

Stop. Secure Arm in Place by

Tightening the Set Screw. **NOTE**

You Will Need to Adjust Arm Once

Locking Mechanism is In Place.

Remove Bolt and

Washer and Slide

Arm on to Shaft

Page 16 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

Locking Mechanism, Counter Weight,

and Breaking Element

1. Install Locking Mechanism

onto mounting bracket of the

EcoMAXX NRV.

2. Ensure handle is

centered in the locking

mechanism. If incorrectly

installed, handle may rub

or stick preventing the

counter weight from locking

in place during an event.

5. Insert safety pin to keep

counter weight in place.

4. Remove Bolt and Washer (if

arm was installed at factory) and

slide counter weight onto shaft

3. Ensure Set Screw has

Been Tightened Down.

Page 17 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

6. Insert bolt and washer

to secure counterweight.

7. With Safety pin in

place, remove breaking

element bolts.

8. Mount breaking

element to

counter weight

and tighten bolts.

Do not over-

tighten. Bolts

need to be snug.

Over-tightening

may damage

breaking element.

IMPORTANT!! Be sure to remove safety

pin from counterweight! Failure to do so

will cause the EcoMAXX No Return Valve

to not close fast enough during an event.

Page 18 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

O-EM-NRV-MS (Microswitch)

with Mounting Bolts

1. Remove screw

and rotate lever to

correct position

2. Line up

arrows

3. Insert

and tighten

Screw

Page 19 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

Mounting O-EM-NRV-MS (Microswitch) to

EcoMAXX No Return Valve

1. Mount microswitch to

locking mechanism using

provided bolts

2. Rotate counterweight arm into the locked position. Ensure arm is

centered in the locking mechanism to avoid obstruction or rubbing. If not

centered, the arm may not fully close or lock during an event.

**NOTE** Do Not Forget to Unlock Counter Weight Prior to Initial Start-up.

The “System Fault” Light Will Turn On and System Will Not Start.

Page 20 of 28

EM-NRV NORTH AMERICAN SUPPLEMENTAL MANUAL - V2016NRV-ELE

Wiring O-EM-NRV-MS (Microswitch) to

O-EM-NRV-CP02 Intrinsic Panel

1. When looking at the wiring

diagram you will notice only the

black and grey wires are used for

the microswitch connection.

2. Connect the black wire to the

terminal labeled 1.

3. Connect the grey wire to the terminal labeled 2

Table of contents

Other BOSSCO Control Unit manuals