Minarik VT7 Series User manual

USER’S MANUAL

Model VT7

VISI-TACH® Multi-Functional

Digital Indicator

250-0257 rev 1.qxd 4/9/01 10:42 AM Page I

Copyright © 1998 by

Minarik Corporation

All rights reserved. No part of this manual may be reproduced or transmitted in any

form without written permission from Minarik Corporation. The information and tech-

nical data in this manual are subject to change without notice. Minarik Corporation

and its Divisions make no warranty of any kind with respect to this material, includ-

ing, but not limited to, the implied warranties of its merchantability and fitness for a

given purpose. Minarik Corporation and its Divisions assume no responsibility for

any errors that may appear in this manual and make no commitment to update or

keep current the information in this manual.

Printed in the United States of America.

250-0257 rev 1.qxd 4/9/01 10:42 AM Page II

Safety Warnings

•This symbol denotes an important safety tip or warning.

Please read these sections carefully prior to performing any of

the instructions contained in that section.

•Have a qualified electrical maintenance technician install,

adjust, and service this equipment. Follow the National

Electrical Code and all other applicable electrical and safety

codes, including the provisions of the Occupational Safety

and Health Act (OSHA) when installing equipment.

•Reduce the chance of an electrical fire, shock, or explosion

by proper grounding, over current protection, thermal pro-

tection, and enclosure. Follow sound maintenance proce-

dures.

•The VISI-TACH®is isolated from earth ground. Circuit

potentials are at 115 VAC or 230 VAC above earth ground.

Avoid direct contact with the printed circuit board or with

circuit elements to prevent the risk of serious injury or

fatality. Use a non-metallic screwdriver for any necessary

adjustments.

250-0257 rev 1.qxd 4/9/01 10:42 AM Page i

ii

250-0257 rev 1.qxd 4/9/01 10:42 AM Page ii

Contents

Specifications 1

Dimensions 2

General Information 3

Installation 4

General installation information ..................................4

Screwterminalblock..........................................5

Mounting...................................................6

Shielded cable ..............................................7

Connections ................................................8

Programming 9

Slideswitch................................................10

DIP switches ...............................................10

Rotary DIP switches - time base calculations .......................12

Application Examples 15

Mode1tachometermode-example1 ...........................15

Mode1tachometermode-example2 ...........................17

Mode2totalizermode........................................22

Mode3ratemonitormode ....................................24

Mode4ratemonitormode(min-secformat) .......................26

iii

250-0257 rev 1.qxd 4/9/01 10:42 AM Page iii

250-0257 rev 1.qxd 4/9/01 10:42 AM Page iv

Specifications

AC Line Voltage

VT7-115 115 VAC +/- 10%, 50/60 Hertz, 5.5 Watts

VT7-230 230 VAC +/- 10%, 50/60 Hertz, 5.5 Watts

Programmable Power Supply Output

5VDC@50mA 50 mA, Regulated Source, +/- 4%

12VDC@25mA 25 mA, Unregulated Source, +/- 20%

Operating Temperature Range 10°C–40°C

Maximum Input Rate 20000 Pulses per Second

Feedback Frequency Range 10 – 20000 Hz

LED Readout Size 0.7 inches

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 1

2

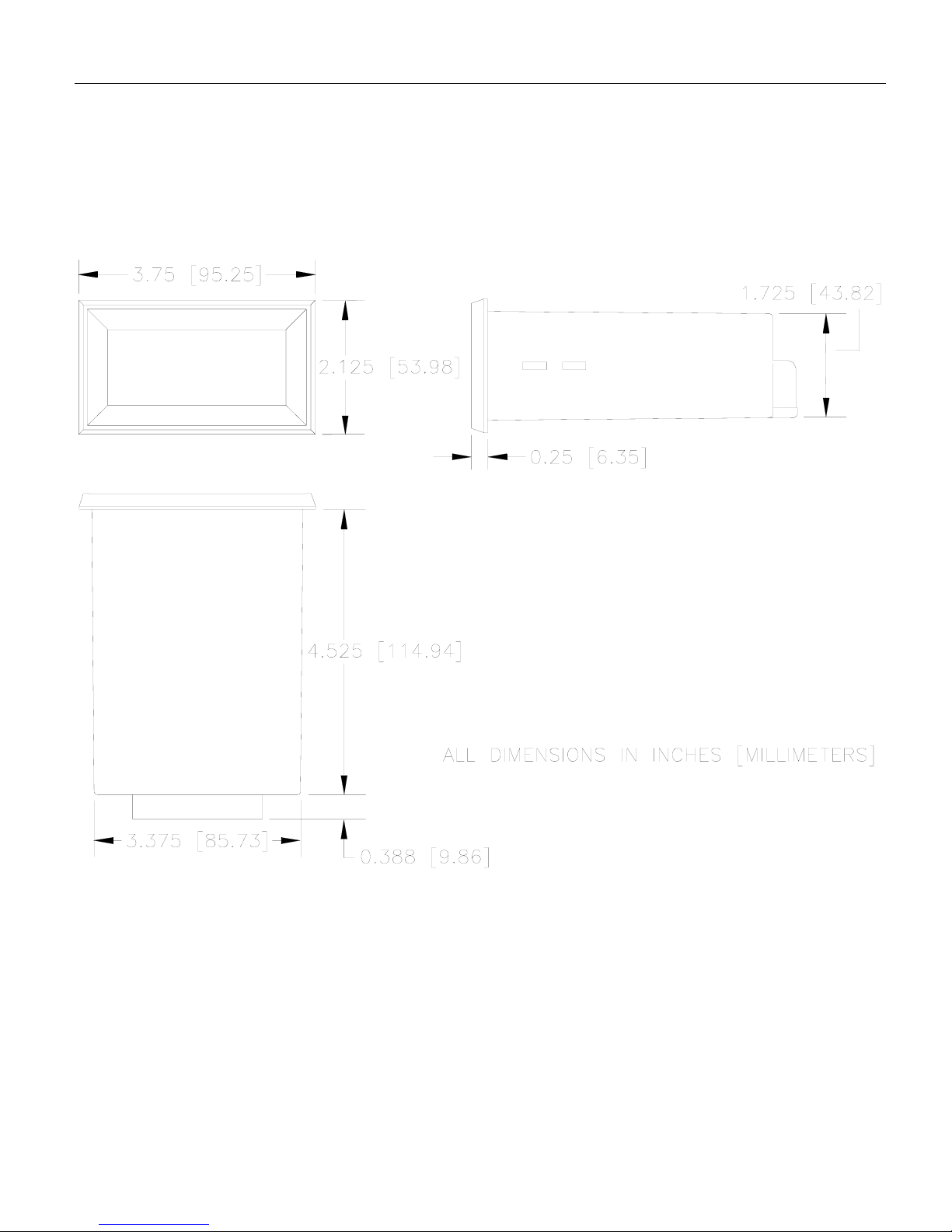

Figure 1. Model VT7-115 and Model VT7-230

Multi-Functional Digital Indicator Dimensions

Dimensions

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 2

3

General Information

Minarik Corporation’s VISI-TACH®models VT7-115 and

VT7-230 provide a means for monitoring the speed of rotat-

ing shafts using a digital velocity transducer. Speed transduc-

ers such as magnetic pickup, optical encoders or hall effect

sensors convert motor speed into a small signal frequency

which is supplied to the VT7.

The VT7 is a multi-functional device and can be programmed

for use as a tachometer for display of revolutions per minute,

feet per minute, etc. It can also be used as a totalizer, a rate

monitor with a display of an inverse frequency, or a rate mon-

itor with a time format in hours and minutes, or minutes and

seconds.

The unit is programmable using a series of switches, located

under the rear panel access cover. The variables programmed

using these switches are the power supply (5 or 12 VDC), the

type of feedback (magnetic pickup or optical encoder), deci-

mal point location, and the mode the unit will operate in. The

rotary switches program the time base in seconds. Detailed

explanations of each one of these items follow in the pro-

gramming section of this manual (page 9).

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 3

4

Installation

General installation information

The VT7 components are sensitive to electrostatic fields.

Avoid contact with the circuit board directly.

Protect the VT7 from dirt and moisture. Provide adequate

clearance for wiring and programming. This takes place at the

back of the unit.

Mount the VT7 away from other heat sources. Operate

within the specified ambient operating temperature range.

The operating temperature range for the VT7 is 10ºC

through 40ºC.

Prevent loose connections by avoiding excessive vibration of

the VT7.

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 4

5

Installation

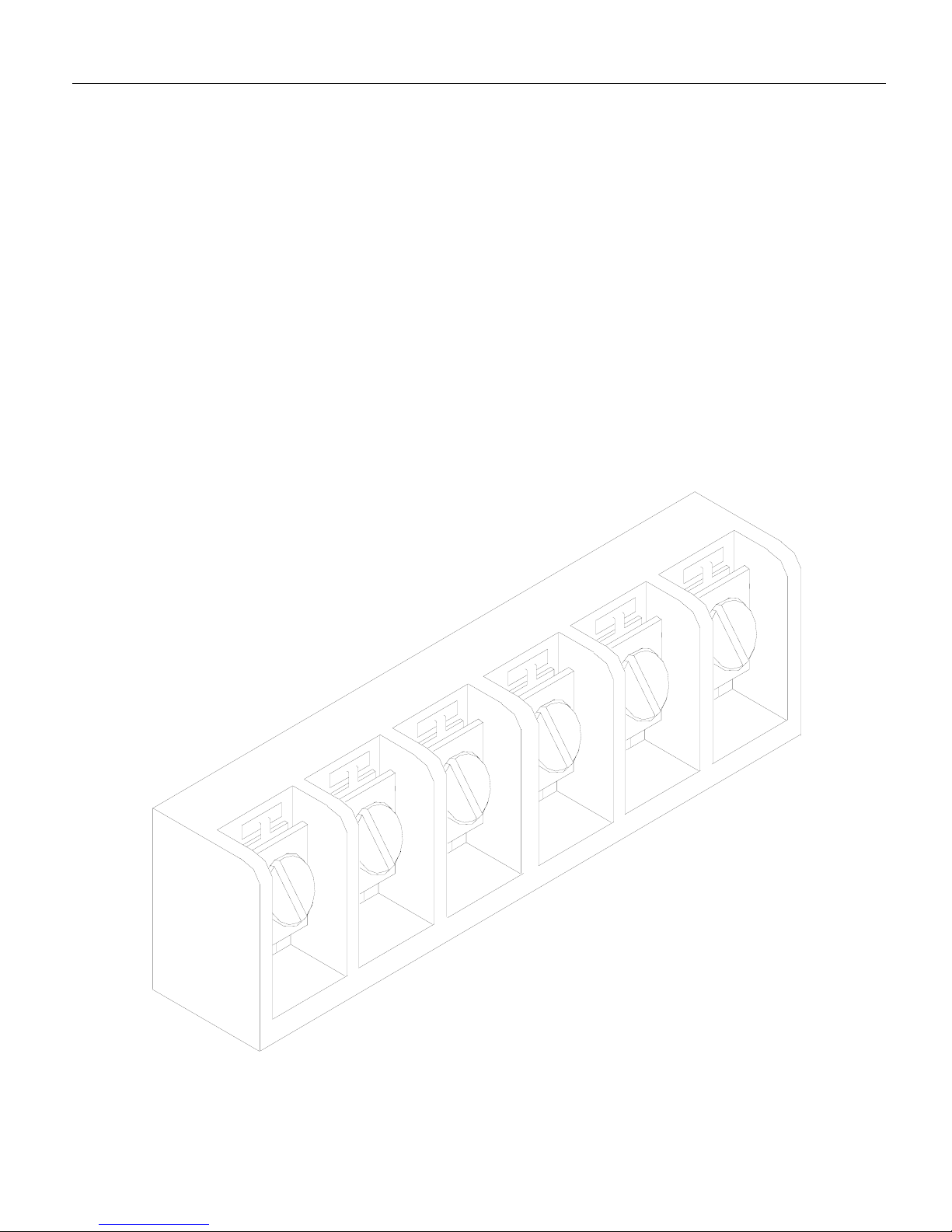

Screw terminal block

Connections to Minarik’s VT7 digital indicator are made to a

screw terminal block. The screw terminal block has a similar

connection style to the one shown below.

Using a screwdriver, turn the terminal block screw counter-

clockwise to open the wire clamp. Insert stripped wire into the

wire clamp. Turn the terminal block screw clockwise to clamp

the wire.

Fig. 2. Screw Terminal Block

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 5

6Installation

Mounting

1. Cut a rectangular opening 1-25/32 inches [45mm] high by

3-3/8 inches [86mm] wide in your panel.

2. Unscrew the two mounting bracket screws until the thread-

ed end is almost flush with the threaded bushing.

3. Place the VISI-TACH®through the panel opening and

install the mounting bracket by engaging the two hooks on

each bracket into the two slots on each side of the unit, with

the threaded end of the screws towards the back of the

panel.

4. Screw the two mounting bracket screws in until they “bite”

into the rear of the panel. The screws should be tight

enough to prevent the VISI-TACH®from moving, but do

NOT over tighten the screws or you may damage your

panel.

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 6

7

Installation

Shielded cable

Use shielded cable when logic lines are longer than 18 inches

(475 mm). Logic lines of this length act as an antenna and can

pick up noise from other devices or other ground wires, or

voltage from power lines that can cause erratic operation.

Attach the shield to the COM terminal on the back of the VT7

or the pickup source only.

It may be necessary to earth ground one end of the shielded

cable. Do not earth ground both ends of the shield.

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 7

Connections

1. Connect the AC power line input on terminals L1 and L2.

This voltage is 115 VAC for the VT7-115 and 230 VAC for

the VT7-230.

2. Connect the pickup, encoder or transducer on the terminals

as indicated in the drawing below.

IMPORTANT! To prevent possible interference do NOT

run pickup, encoder, or transducer cable in same conduit

as the AC line.

Installation

8

Fig. 3. Connection Diagram

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 8

9

Programming

The VT7 may be programmed before installing it into the

panel, and before connecting to the AC line and the pickup,

encoder or transducer, or after the entire system is set up. For

easier handling, it is usually more convenient to program the

VT7 before it is set in the panel.

For access to the programming switches, remove the two

screws holding the rear cover to the case and remove the

cover. The switches are illustrated in Figure 4.

Fig. 4. VT7 Programming Switches

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 9

Programming

10

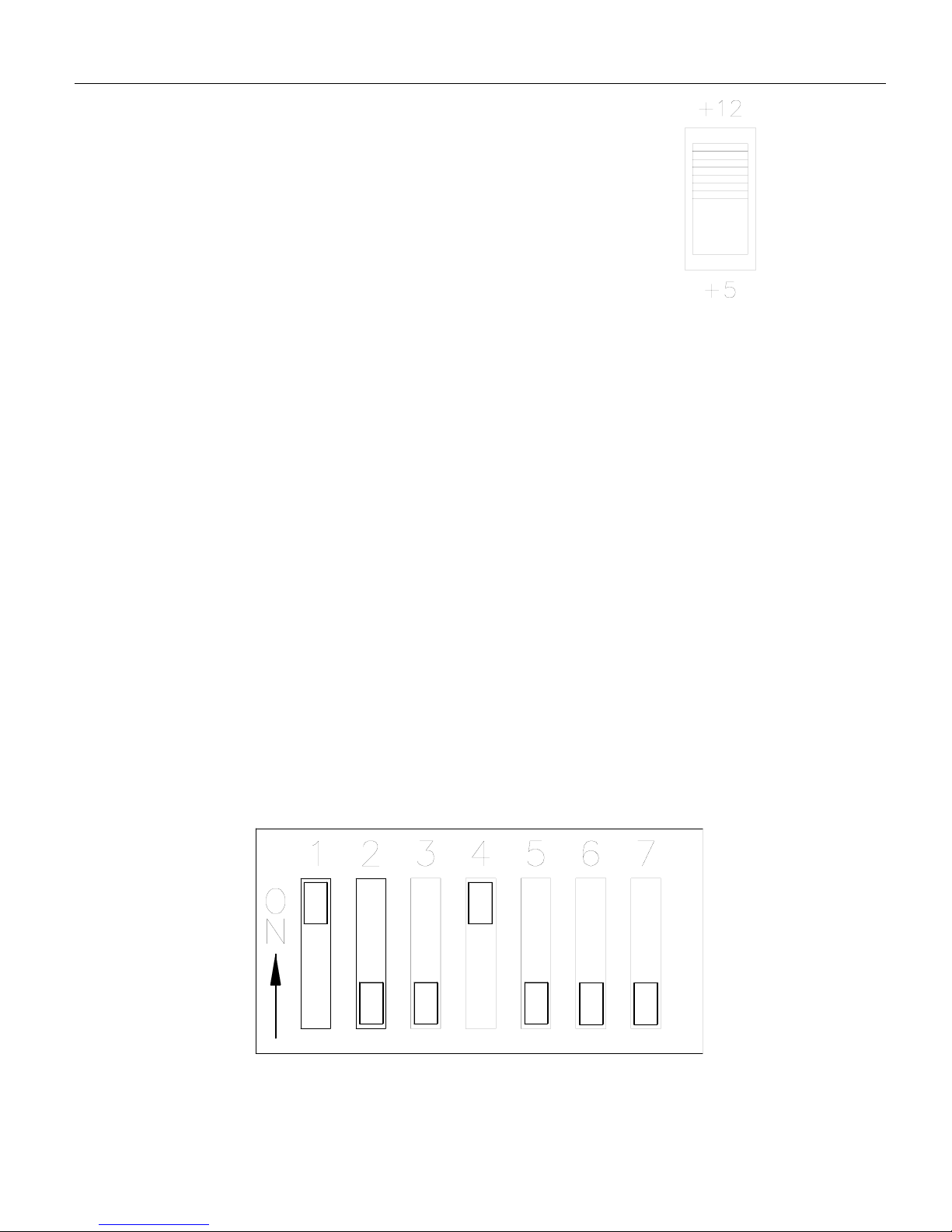

DIP switches

To change the position of the DIP switches use a small screw-

driver to push the DIP to the desired position. The DIP switch

block has a similar construction style to one shown below

(Figure 6). In the figure, the DIP switches are set for:

optical encoder (1 on and 2 off),

decimal point 00.00 (3 off, 4 on,and 5 off) ,

and tachometer mode (6 and 7 off).

Slide switch

The position of the slide switch deter-

mines the power supply output. Set

the slide switch to +5 or +12VDC to

power an optical encoder. For accura-

cy and current output of this

power supply see the specifica-

tions on page 1.

Fig. 6. VT7 DIP Switches

Fig. 5. VT7 Power

Supply Slide Switch

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 10

11

Programming

Feedback type. DIP switches 1 and 2 are dependent upon

which type of feedback has been selected. See the table

below for the settings.

Decimal point selection. DIP switches 3, 4 and 5 determine

where the decimal point will light in the display. See the

table below for the settings. Only one switch may be on at

any time.

Mode selection. To select the mode in which VT7 will oper-

ate, use DIP switches 6 and 7.

Mode1isthetachometer mode (set 6 OFF and 7 OFF).

The tachometer mode displays the monitored shaft speed or

a multiple of it. The display can be frozen to the last reading

by shorting terminal COM to terminal H.

Feedback Type Switch #1 Switch #2

Magnetic pickup OFF ON

Optical encoder ON OFF

Decimal Location SW#3 SW#4 SW# 5

000.0 ON OFF OFF

00.00 OFF ON OFF

0.000 OFF OFF ON

0000 OFF OFF OFF

Mode of Operation SW#6 SW#7

Tachometer (1) OFF OFF

Totalizer (2) OFF ON

Rate Monitor Mode (3) ON OFF

Rate Monitor Mode (4) ON ON

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 11

Programming

12

Mode2isthetotalizer mode (set 6 OFF and 7 ON). In this

mode the unit displays continuous count of pulses received

from the speed transducer. The display will turn over to 0000

after either 10,000 pulses have been received from the speed

transducer or the unit has been reset. The display can be reset

to zero by shorting terminal COM to terminal H.

Mode3istherate monitor mode (set 6 ON and 7 OFF). This

mode displays the time in process (or a linear multiple of it) in

seconds. The display in the rate monitor mode is inversely

proportional to the monitored shaft speed.

Mode 4 is the rate monitor mode (min:sec or hour:min for-

mat) (set 6 ON and 7 ON). In this mode the unit displays the

number in time format. This display can be used to read min-

utes and seconds, or hours and minutes. The display can be

frozen to the last reading by shorting terminal COM to termi-

nal H.

Rotary DIP switches - time base calculations

The programming variable which determines the display read-

ing is called the time base. The time base is the time interval

the VT7 uses to count the pulses from the speed transducer

and issue the result to the display.

The rotary DIP switches program the time base, in seconds,

from 0.01 seconds to 10.00 seconds. Settings of all zeros is

equal to a time base of 10.00 seconds. An explanation of the

time base calculation begins on page 14. The time base is pro-

grammed for modes 1, 3, and 4 only.

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 12

Ideally, the time base should be set between .67 seconds and 2

seconds. If the time base is set below .67 seconds, the display

will update too often and tend to flicker. If the time base is set

greater than two seconds, the display reading will not update

often enough and may lag the actual speed of the application.

To program the rotary switches, use a small screwdriver and

set the pointer mark to the desired number.

The following application variables must be known before cal-

culating the time base (t):

DDN = The desired display number. DDN is the known dis-

play value at a certain shaft speed (RPM). It should be 4 digits

and ignore any decimal point present.

RPM = Revolutions per minute of the monitored shaft at the

time when the DDN is known.

PPR = Pulses per revolution of the pickup, encoder or trans-

ducer. This is the number of teeth on the pickup wheel or lines

on the optical encoder.

13

Programming

Fig. 7. VT7 Rotary DIP Switches

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 13

Programming

14

Mode 1 (tachometer mode). The time base (t) is a variable

which scales the RPM of the monitored shaft at the location

of the speed transducer.

The RPM and DDN in the above equation are arbitrary val-

ues. Any RPM value may be chosen. The desired display

number for the RPM selected is then determined by the user’s

application.

Mode 2 (totalizer mode). Mode 2 has no time base.

Mode 3 (rate monitor mode). To calculate the time base in

mode 3 use the equation below:

Mode 4 (rate monitor mode (min:sec/hour:min format)).

In this mode we must convert the DDN to an hours and min-

utes (or minutes and seconds) format. This is done with the

following equation:

DDN = 60X + Y

where X = hours and Y = minutes when operating in the

hours and minutes mode, and X = minutes and Y = seconds

when operating in the minutes and seconds mode.

Calculate the time base with the following equation using the

DDN calculated with the equation above:

250,000 60

(DDN)(RPM) X

t= PPR

250,000 60

(DDN)(RPM) X

t= PPR

(DDN)(60)

(RPM)(PPR)

t=

250-0257 rev 1.qxd 4/9/01 10:42 AM Page 14

This manual suits for next models

5

Table of contents

Other Minarik Music Equipment manuals