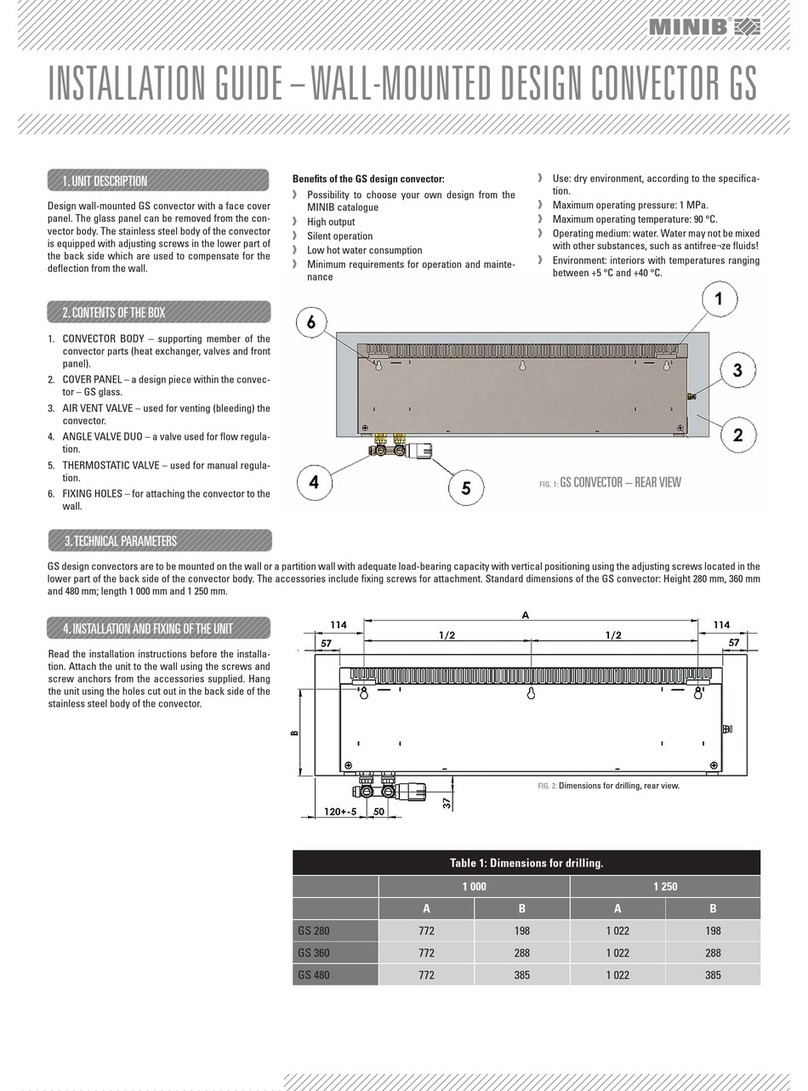

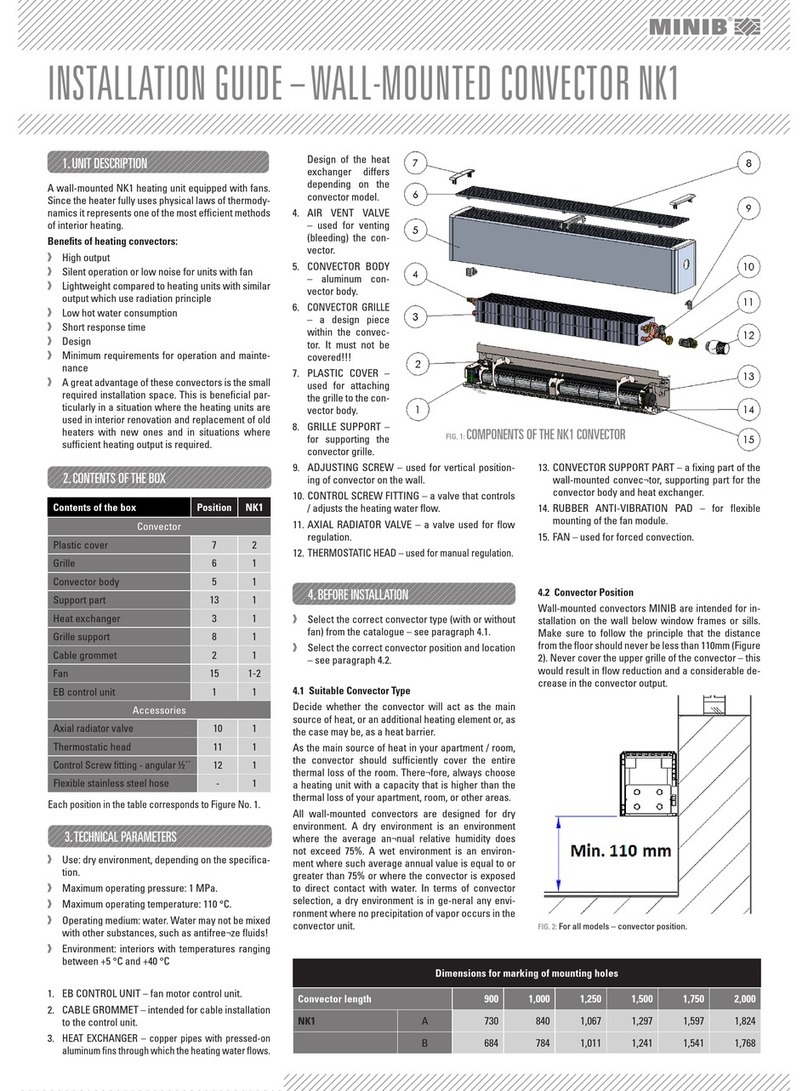

28

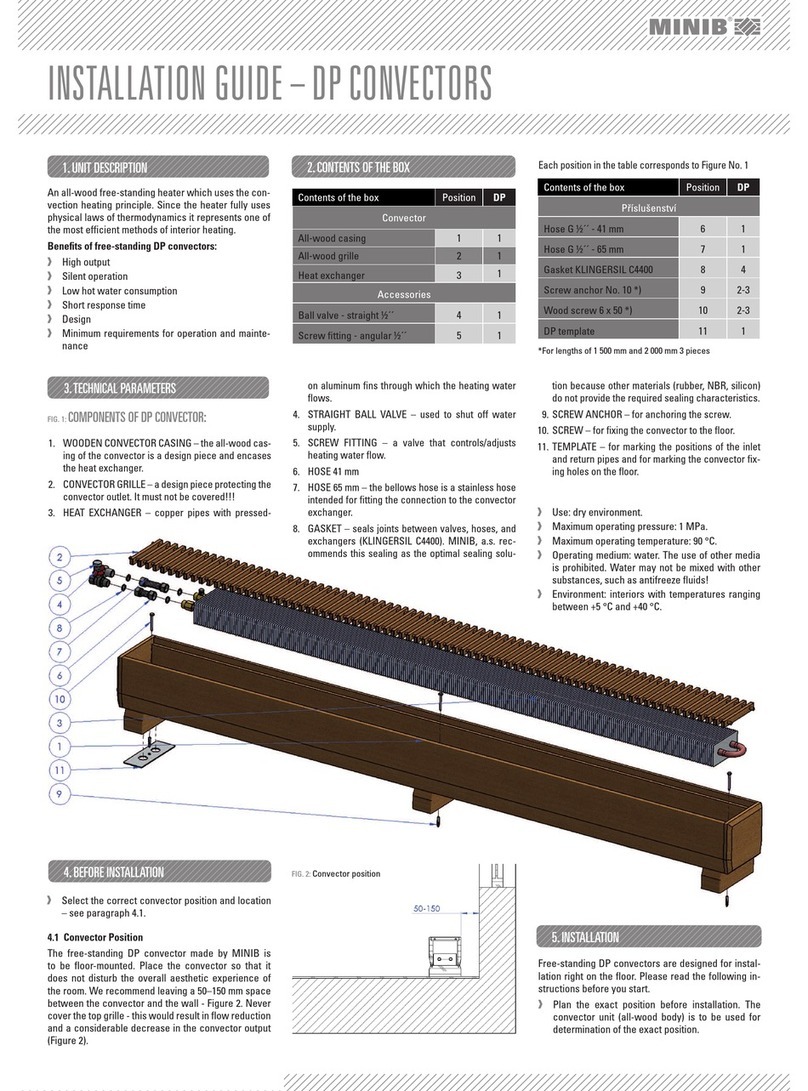

4. BEFORE INSTALLATION

Use the catalogue to choose a suitable convector for wet or dry

environment - see paragraph 4.1.

Select correct convector position - see paragraph 4.2.

Leave enough space for placement and installation - see paragra-

ph 4.3. Consider using thermal insulation, anti-vibration foil, or bra-

ces into

hollow floors - see paragraph 4.4.

Do not forget drainage pipes or other condensate removal sys-

tems - see paragraph 4.5.

4.1 Suitable Convector Type

Decide whether the convector will act as the main source of heat, an

additional heating element or a thermal barrier.

As the main source of heat in your apartment / room, the convector

should sufficiently cover the entire thermal loss of the room. Therefore,

choose a heating unit with a capacity that is higher than the thermal

loss of your apartment, room, or other premises.

Make sure that you have enough space for convector installation - both

from the wall (window) and in the floor (see paragraph 4.3).

Determine whether the convector will be used in a dry or wet envi-

ronment. A dry environment is an environment where the average

annual relative humidity does not exceed 85%. A wet environment is

an environment where such average annual value is equal or greater

than 85%. In terms of convector selection, a dry environment is in ge-

neral any environment where no precipitation of vapor occurs in the

convector unit. Convectors intended for a wet environment have more

resistant stainless material and a feature for condensate drainage.

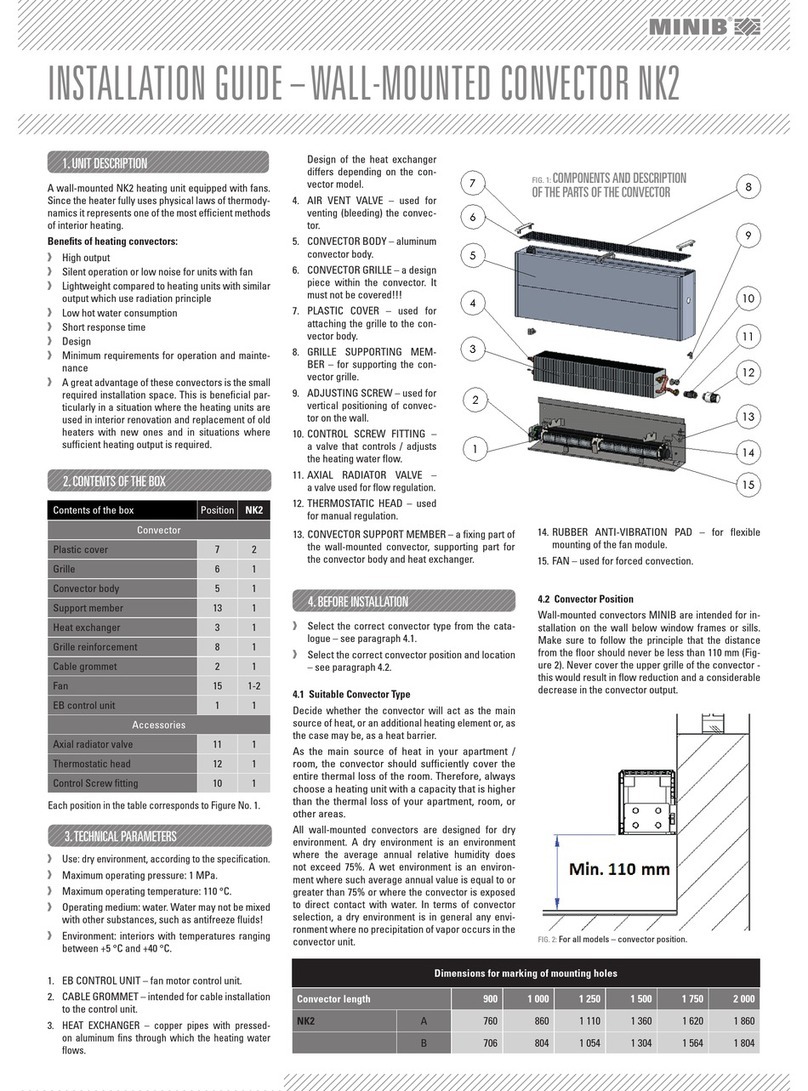

4.2 Convector Position

Consult the convector position with an expert or your designer.

MINIB floor convectors are intended for embedding in floors in order

to avoid disturbance to the overall aesthetic appearance of the room.

If the convector is intended to be the main source of heat, it must be

placed with a heat exchanger in the room (Figure 2). If the convector

serves as an additional source of heat or as a thermal barrier, it is

placed with a heat exchanger towards the window (Figure 3). If the

convector is equipped with a heat exchanger over its entire width, it

is recommended that the convector be positioned with the fan facing

into the room.

4.3 Installation Space

MINIB, s.r.o. recommends leaving sufficient space for convector

installation. For installation in older floors, during reconstruction, or

whenever sufficient space is not available, the dimensions of the in-

stallation hole should be equal to the convector height + at least 20

mm. The width and/or length (if only 1 convector is concerned) of the

installation hole should correspond to the convector width (length) +

at least 60 mm - see Figure 4. Clearance around the convector should

provide enough space for the connection of water, cabling, and con-

vector embedding in concrete. For new floors, MINIB recommends at

least +100 mm of free space around the convector; the height remains

identical to the previous case (H + at least 20 mm).

The position and location of the convector fully depend on the client's

requirements, particularly, what and how they need to heat or cool.

MINIB, s.r.o. recommends installing convectors acting as the main

source of heat under windows with a heat exchanger into the room.

The recommended distance from the wall is 200 – 350mm. If the

customer wishes to use the convector as an additional source of heat

only (i.e., the convector does not serve as the main source of heat),

the heat exchanger can be turned towards the window. The exchan-

ger location on the window side is recommended in cases where the

convector is used as an additional source of heat or when it acts as a

thermal barrier in front of the window.

4.4 Principles of Convector Installation in Floors

MINIB floor convectors are intended for installation in solid or hollow

floors where certain principles apply. Before you start, please read

the following instructions.

At your own discretion (parquet, floating, or wooden floors), install

thermal insulation on the outside of the convector vat on the heat

exchanger side. (Figure 6).

If the convector is installed at a frequented spot where people of-

ten step on the cover grille or walk past the convector, it is recom-

mended that anti-vibration foil be used to reduce structure-borne

noise, particularly, in multi-story buildings (Figure 7).

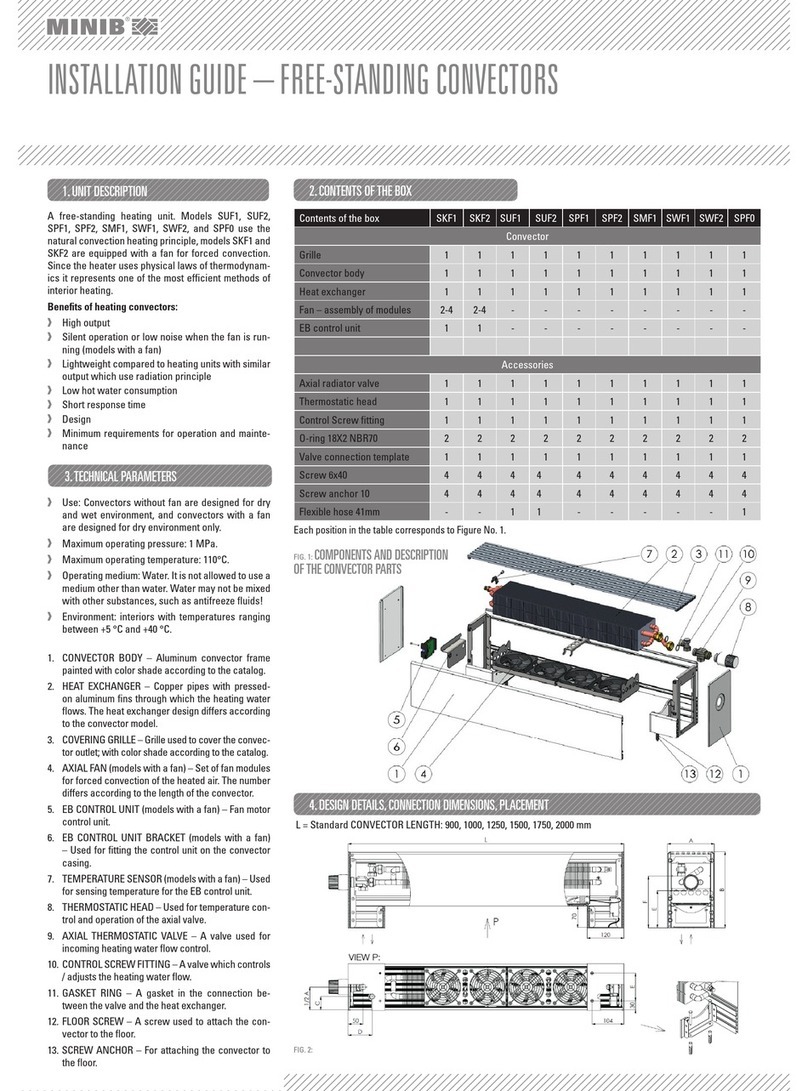

installation manuals - floor convectors with fan

Figure 4: B - maximum width of convector; L - convector length; H - convector

height (without adjustment legs)

Recommended MINIMUM clearance for installation: B + 60 mm; L + 60 mm;

H + 20 mm

Figure 2: Convector with exchanger

in the room as the main source of

heat.

Figure 3: Convector with exchan-

ger towards the window as an

additional source of heat.

window

exchanger

window

exchanger

Figure 3-1