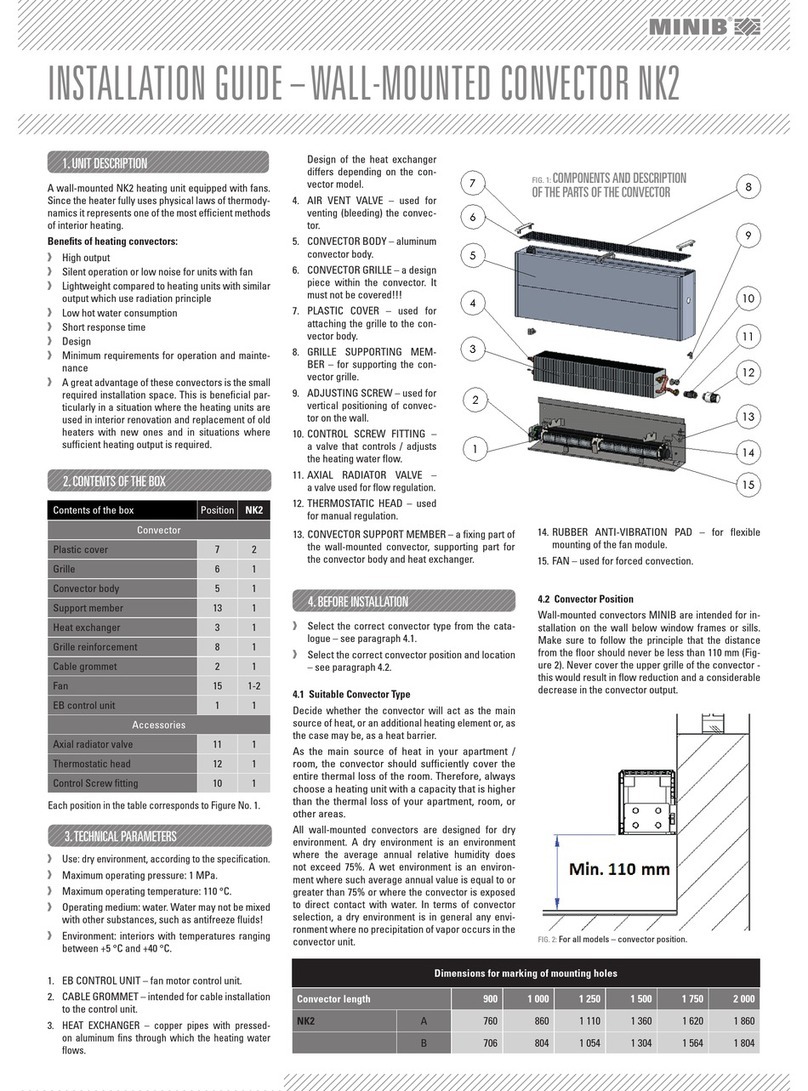

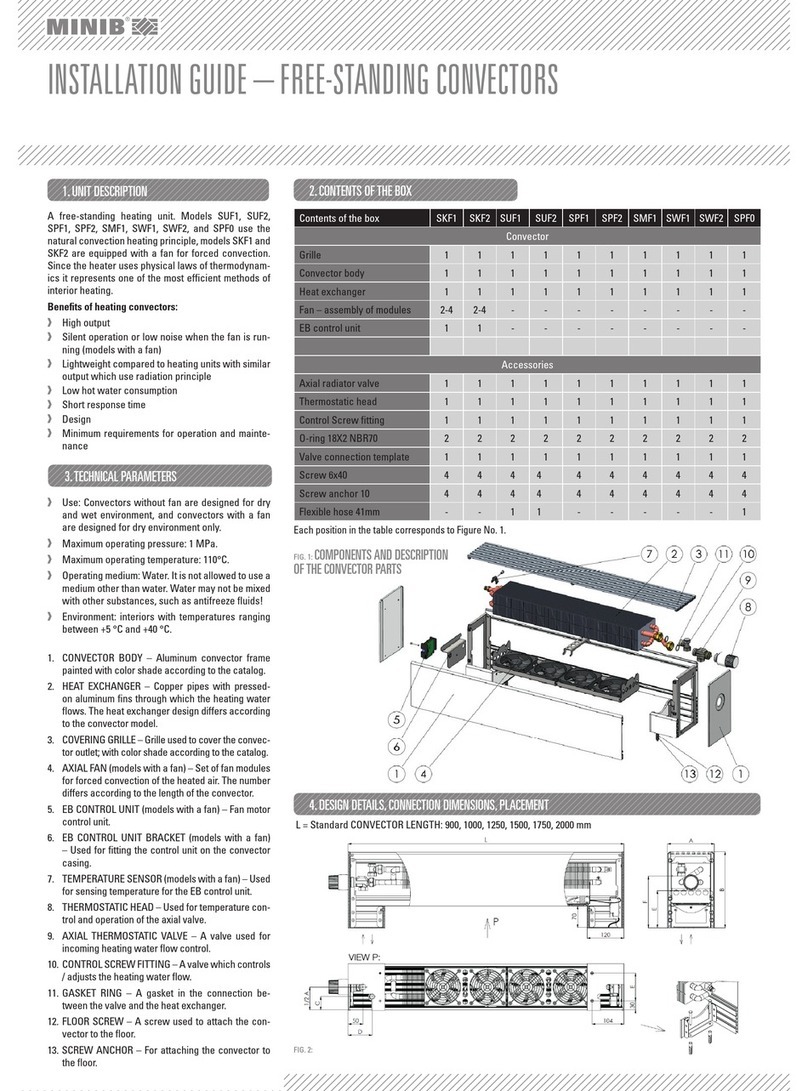

INSTALLATION GUIDE

–

DP CONVECTORS

1. UNIT DESCRIPTION

An all-wood free-standing heater which uses the con-

vection heating principle. Since the heater fully uses

physical laws of thermodynamics it represents one of

the most effi cient methods of interior heating.

Benefi ts of free-standing DP convectors:

High output

Silent operation

Low hot water consumption

Short response time

Design

Minimum requirements for operation and mainte-

nance

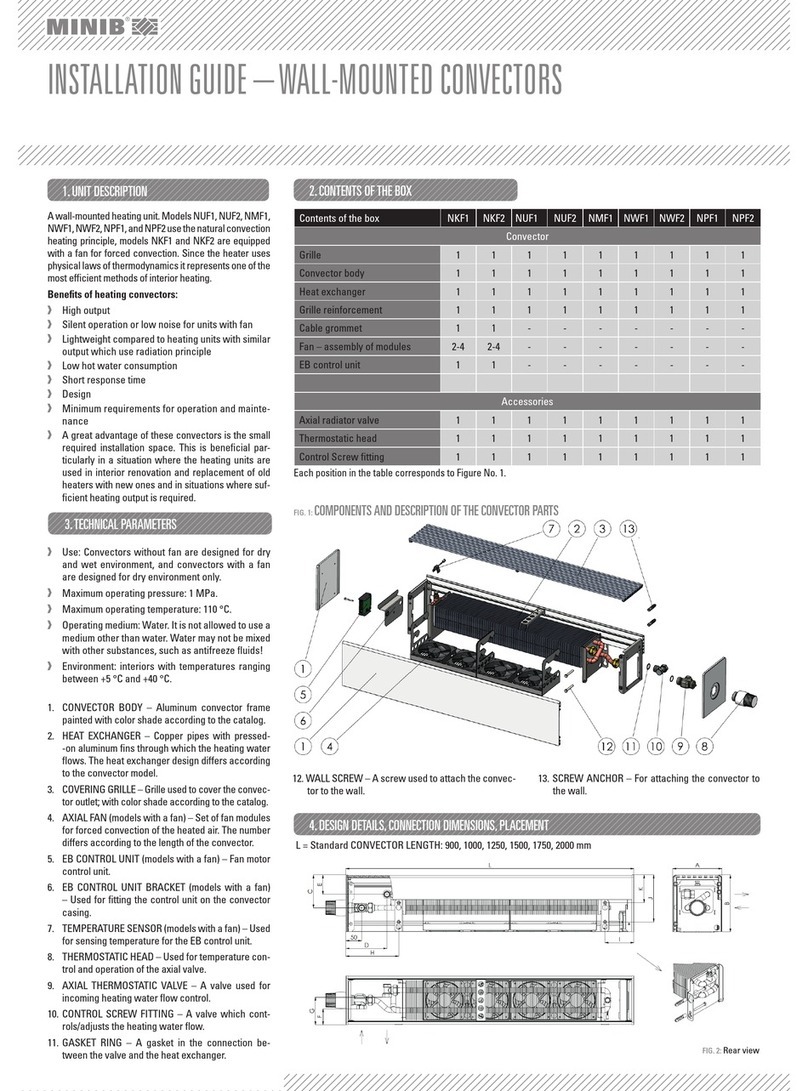

Contents of the box Position DP

Convector

All-wood casing 1 1

All-wood grille 2 1

Heat exchanger 3 1

Accessories

Ball valve - straight ½´´ 4 1

Screw fi tting - angular ½´´ 5 1

Contents of the box Position DP

Příslušenství

Hose G ½´´ - 41 mm 6 1

Hose G ½´´ - 65 mm 7 1

Gasket KLINGERSIL C4400 8 4

Screw anchor No. 10 *) 9 2-3

Wood screw 6 x 50 *) 10 2-3

DP template 11 1

3. TECHNICAL PARAMETERS

Use: dry environment.

Maximum operating pressure: 1 MPa.

Maximum operating temperature: 90 °C.

Operating medium: water. The use of other media

is prohibited. Water may not be mixed with other

substances, such as antifreeze fl uids!

Environment: interiors with temperatures ranging

between +5 °C and +40 °C.

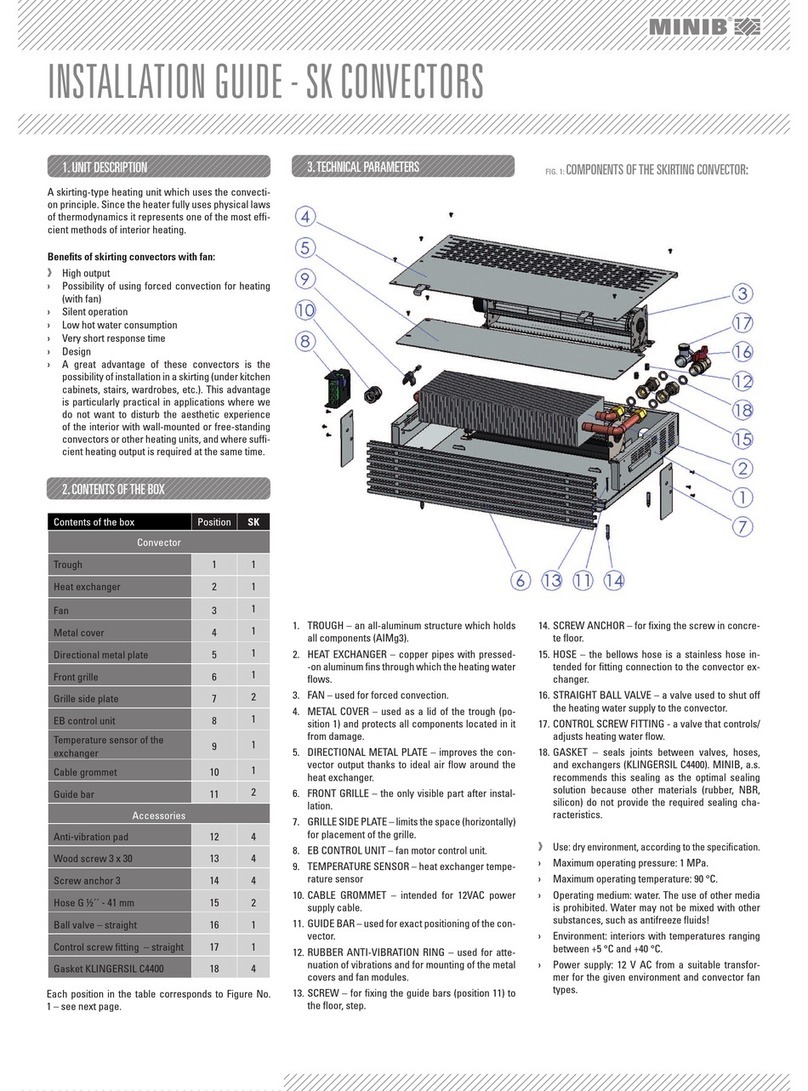

1.

WOODEN CONVECTOR CASING – the all-wood cas-

ing of the convector is a design piece and encases

the heat exchanger.

2. CONVECTOR GRILLE – a design piece protecting the

convector outlet. It must not be covered!!!

3. HEAT EXCHANGER – copper pipes with pressed-

Each position in the table corresponds to Figure No. 1

on aluminum fi ns through which the heating water

fl ows.

4. STRAIGHT BALL VALVE – used to shut off water

supply.

5. SCREW FITTING – a valve that controls/adjusts

heating water fl ow.

6. HOSE 41 mm

7. HOSE 65 mm – the bellows hose is a stainless hose

intended for fi tting the connection to the convector

exchanger.

8. GASKET – seals joints between valves, hoses, and

exchangers (KLINGERSIL C4400). MINIB, a.s. rec-

ommends this sealing as the optimal sealing solu-

*For lengths of 1 500 mm and 2 000 mm 3 pieces

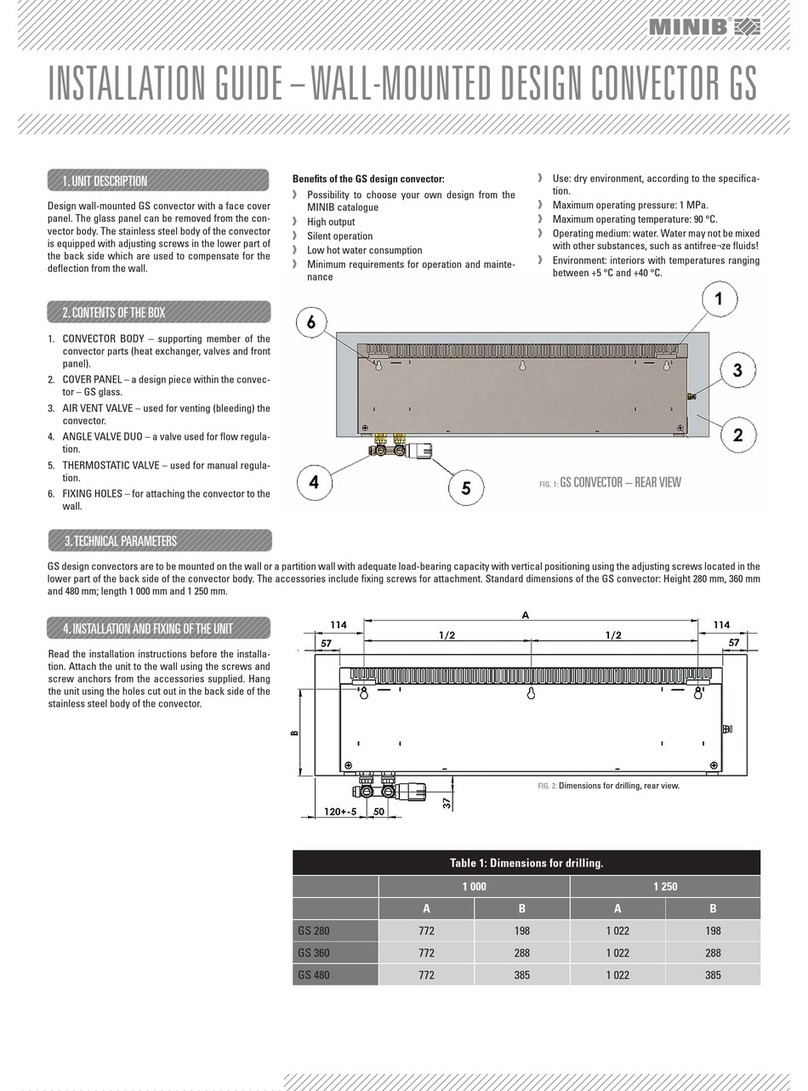

4.1 Convector Position

The free-standing DP convector made by MINIB is

to be fl oor-mounted. Place the convector so that it

does not disturb the overall aesthetic experience of

the room. We recommend leaving a 50–150 mm space

between the convector and the wall - Figure 2. Never

cover the top grille - this would result in fl ow reduction

and a considerable decrease in the convector output

(Figure 2).

FIG. 1: COMPONENTS OF DP CONVECTOR:

tion because other materials (rubber, NBR, silicon)

do not provide the required sealing characteristics.

9. SCREW ANCHOR – for anchoring the screw.

10. SCREW – for fi xing the convector to the fl oor.

11. TEMPLATE – for marking the positions of the inlet

and return pipes and for marking the convector fi x-

ing holes on the fl oor.

Select the correct convector position and location

– see paragraph 4.1.

Free-standing DP convectors are designed for instal-

lation right on the fl oor. Please read the following in-

structions before you start.

Plan the exact position before installation. The

convector unit (all-wood body) is to be used for

determination of the exact position.

2. CONTENTS OF THE BOX

4. BEFORE INSTALLATION FIG. 2: Convector position

5. INSTALLATION