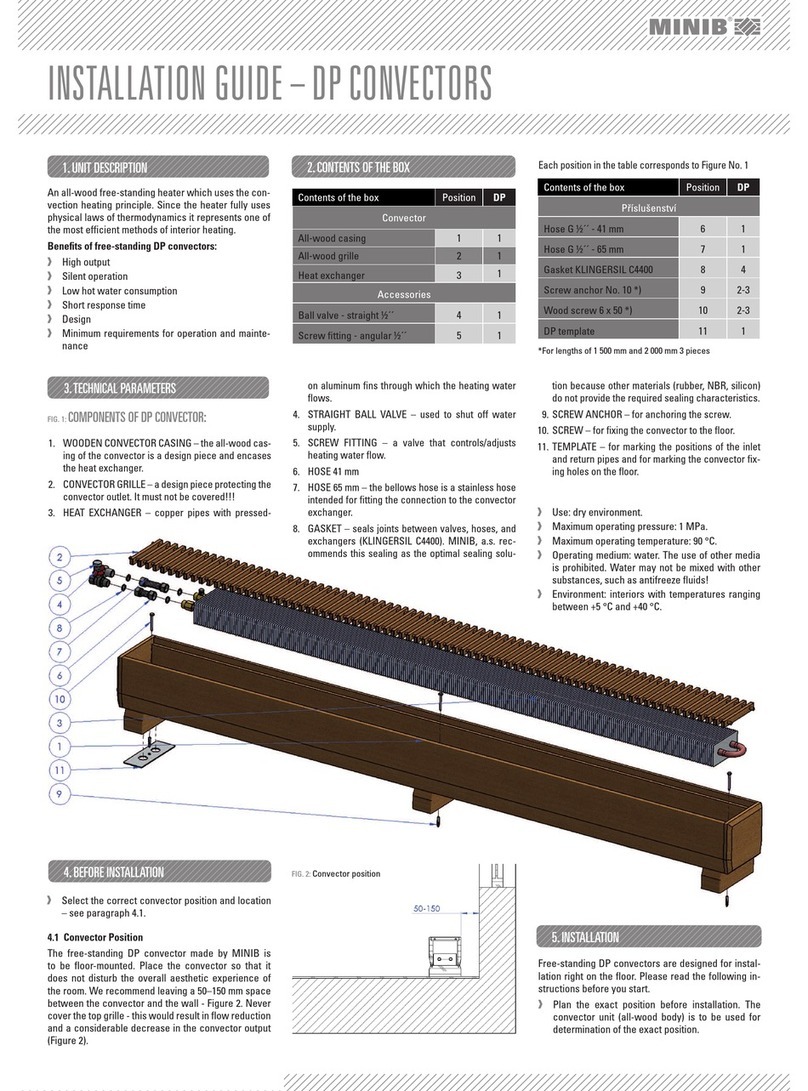

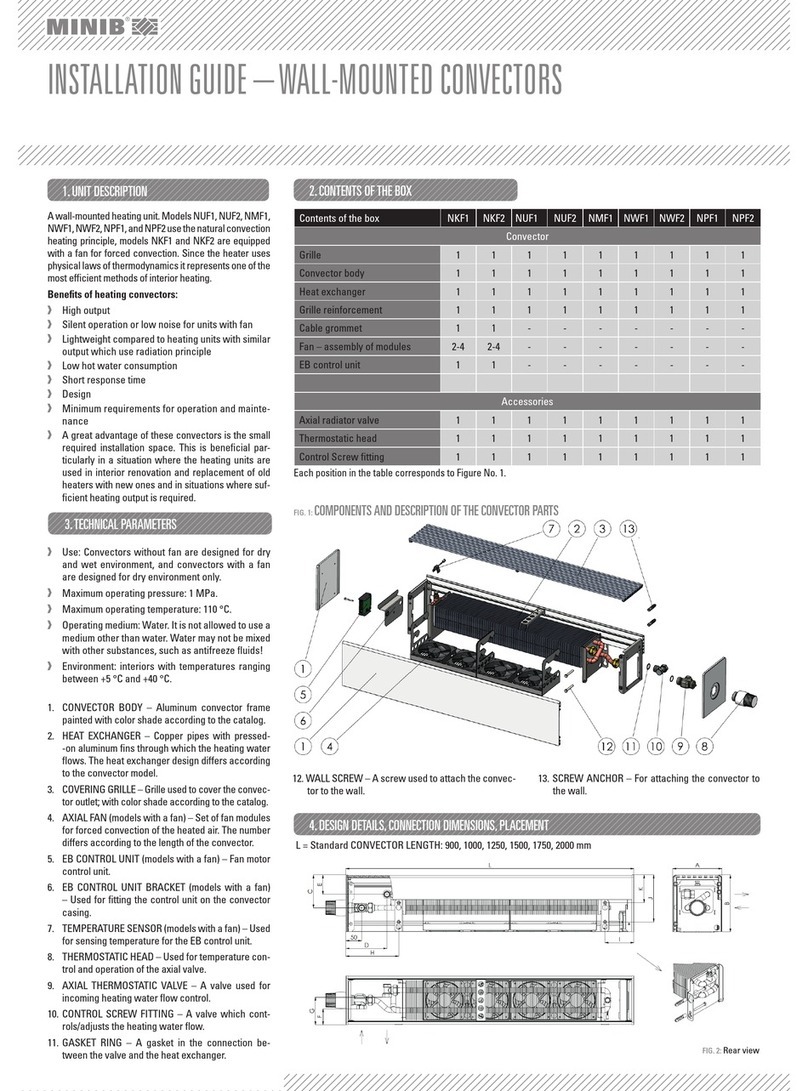

TABLE 1: applies to all lengths L 900, 1000, 1250, 1500, 1750, 2000 mm

50–150

(by the valves, position 1) and remove it in the direc-

tion of the arrows (position 2) on Fig. 4.

For models with a fan loosen the screws (see the

previous paragraph) in the opposite side wall and

remove it for access to the EB control unit.

Move the strut (y) of grille A to the side and remove

the heat exchanger from the convector casing.

Install the valves (axial valve and the control screw

fi tting) on the heating pipe according to the dimen-

sions on Fig. 2 and Table 1. Adhere to the dimensions

for the particular model.

Fit the convector on the prepared pipes with valves

and fi x it to the fl oor at the fi xing points.

Replace the heat exchanger in the casing and con-

nect it to the installed valves on the heating water

pipes, Fig. 5.

For models SUF1, SUF2, SPF0 – connect the heat ex-

changer with the control screw fi tting using the sup-

plied fl exible hose, Fig. 5a.

For models with a fan - connect the power line to the

EB control unit, Fig. 6.

Place back the side wall(s) and tighten the screws

and install the thermostatic head on the axial valve.

Move back the grille strut(s) and place back the

cover grille.

Vent (bleed) the convector according to section 7 if

necessary.

HEAD OFFICE

MINIB,a.s.

Střešovická 465/49, 162 00 Prague 6

Czech Republic

Tel.: +420 220 180 780, Fax: +420 220 180 779

PRODUCTION

Manufacturing plant of MINIB, a.s.

Býkev u Mělníka 84, 276 01 Býkev

Czech Republic

WWW.MINIB.COM

FIG. 5: Close-up view of the connection between the valves

and the heat exchanger (the heat exchanger design differs

according to the model).

Union nut

Union nut

Supply pipe

Supply cabel

FIG. 6: Close-up view of the power line

connection to the EB control unit.

FIG. 5a: Only for models SUF1, SUF2, SPF0

Please read the following instructions before you start.

Free-standing convectors made by MINIB are to be fl oor-

mounted. We recommend leaving a 50–150 mm space be-

tween the convector and the wall - Figure 3. Never cover

the top grille - this would result in fl ow reduction and a

considerable decrease in the convector output.

Decide whether the convector will act as the main

source of heat, or an additional heating element or, if ap-

plicable, as a thermal barrier.

As the main source of heat in your apartment or room,

the convector should suffi ciently cover the entire ther-

mal loss of the room. Therefore, always choose a heat-

ing unit with a capacity that is higher than the thermal

loss of your apartment, room, or other areas.

All free-standing convectors with a fan are designed

for dry environment. A dry environment is an environ-

ment where the average annual relative humidity does

not exceed 75%. A wet environment is an environment

where such average annual value is equal to or greater

than 75% or where the convector is exposed to direct

contact with water. In terms of convector selection,

a dry environment is in general any environment where

no precipitation of vapor occurs in the convector unit.

5.1 Use the supplied fi xing elements to fi x the free-

standing convector.

A correctly installed convector is in horizontal position

and fi rmly supported along the entire width of the leg.

5.2 Installation process

Plan the placement on the fl oor according to the con-

vector dimensions in table 1 and on Fig. 2.

Use the template for the particular model (Fig. 4)

to mark the heating water supply pipe position, the

power supply position (models with a fan). The outer

dimension of the template = dimension of the leg of

the particular model.

Drill the holes, insert the screw anchors, install the

heating water supply pipe, power supply cable (mod-

els with a fan).

Remove the cover grille. Loosen (do not remove!) the

2 top screws (1) of the right side wall of the convector

5. INSTALLATION

6. CONNECTION OF THE FITTINGS

7. VENTING THE UNIT

FIG. 3: Recommended placement of the free-standing convec-

tor (model with a fan / without fan).

An axial radiator valve is connected to the water inlet

of the heat exchanger. Control screw fi tting is to be

installed on the outlet line. Insert O-rings between the

axial radiator valve / control screw fi tting and the heat

exchanger. Use gaskets for all the other connections.

Vent (bleed) the unit using the air vent valve during the

fi rst use as necessary. In free-standing convectors, the

location of air vent valve on the heat exchanger pipe de-

pends on the model.

For additional options see the catalog or visit:

www.minib.com.

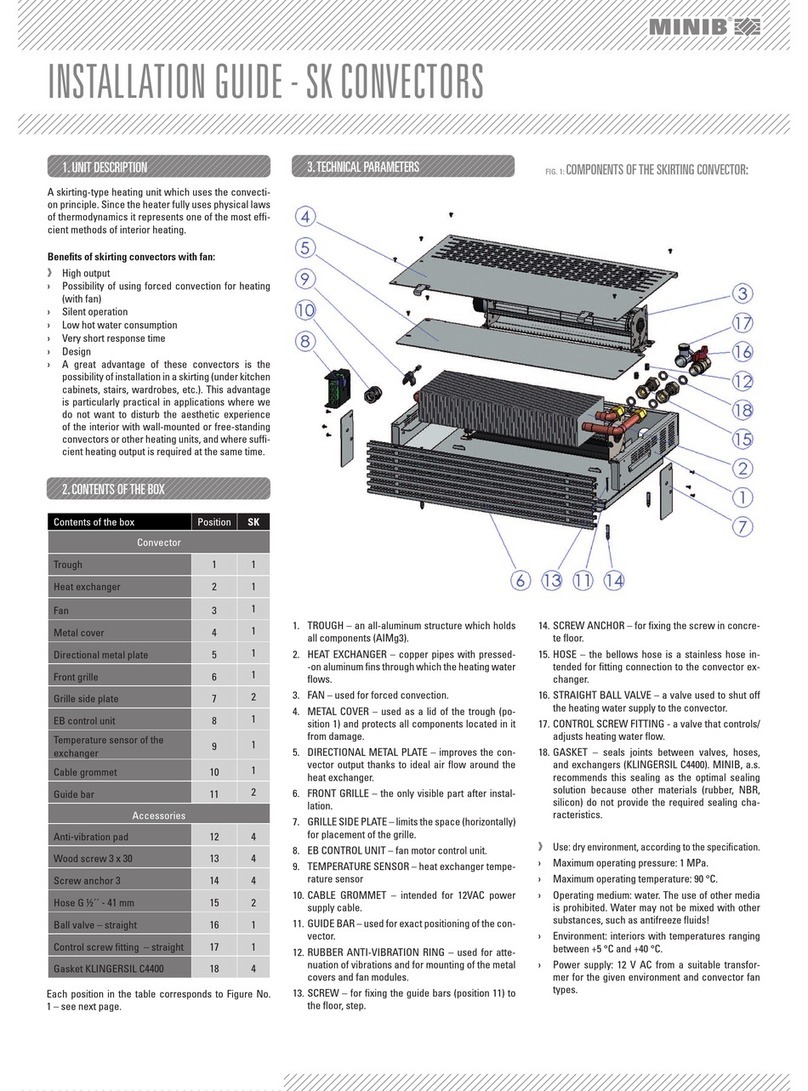

A B C D E F

SKF1 150 248 45 80 120 170

SKF2 150 418 45 80 120 190

SUF1 115 248 30 35 70 145

SUF2 115 418 30 35 70 145

SPF0 150 148 45 30 70 75

SPF1 150 248 45 50 70 115

SPF2 150 418 45 50 195 75

SMF1 195 248 35 85 110 85

SWF1 220 248 45 50 80 145

SWF2 220 418 45 50 80 145

FIG. 4