Page 2 (41)

CONTENTS

CONTENTS........................................................................................................................................2

1. INTRODUCTION...................................................................................................................4

1.1 ADVANTAGES AND FEATURES....................................................................................4

1.2 DIFFERENT LASER MODELS .........................................................................................5

1.3 APPLICATIONS FOR DIFFERENT LASER MODELS....................................................6

2. THEORY OF OPERATION .................................................................................................6

2.1 OPACITY DEFINITION.....................................................................................................7

2.2 D-VALUE DEFINITION ....................................................................................................7

2.3 MASS-VALUE DEFINITION ............................................................................................7

3. INTRODUCTION OF LASER DUST MONITOR LM 3188.................................................9

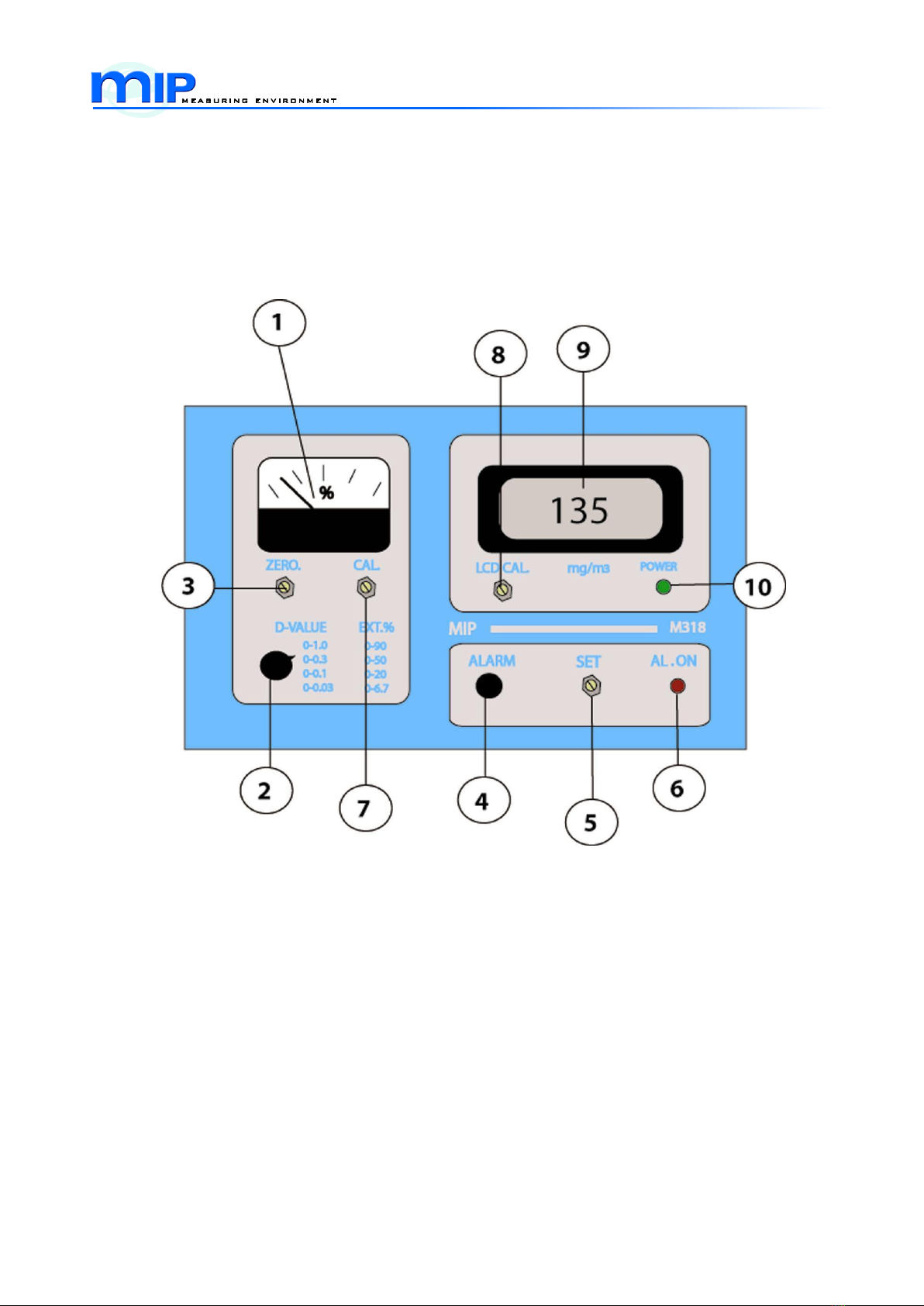

3.1 CONTROLS, DISPLAYS AND SETTINGS ....................................................................10

3.1.1 Indicating meter [1]...............................................................................................10

3.1.2 Range selector [2].................................................................................................10

3.1.3 Zero set screw [3]..................................................................................................11

3.1.4 Alarm test button [4].............................................................................................11

3.1.5 Alarm set screw [5]...............................................................................................11

3.1.6 Alarm indicator lamp [6]......................................................................................11

3.1.7 Calibration screw [7] ............................................................................................11

3.1.8 Mass calibration screw (LCD cal) [8]...............................................................11

3.1.9 Digital LCD-display [9].........................................................................................11

3.1.10 Power indicator lamp [10]...................................................................................11

4. INSTALLATION AND CALIBRATION............................................................................12

4.1. INSTALLATION...............................................................................................................12

4.2 CALIBRATION.................................................................................................................15

4.2.1 Filter set for the dust monitors instructions for the use............................16

4.2.2 Mass calibration....................................................................................................16

4.2.3 Output check..........................................................................................................16

4.3 QUALITY ASSURANCE PROGRAM.............................................................................18

5. SPECIFICATIONS..................................................................................................................19

6. WARRANTY CERTIFICATE.................................................................................................20

7. MANUFACTURER´S CERTIFICATE OF CONFORMANCE TO EC-LABELLING

PROCEDURE..................................................................................................................................22

8. CERTIFICATE OF ORIGIN...................................................................................................23

APPENDIX 1: MONITOR UNIT M 318 MECH. DRAWING.....................................................24

APPENDIX 2: RECEIVER UNIT R318 MECH. DRAWING.....................................................25

APPENDIX 3: RECEIVER UNIT R318 MECH. DRAWING.....................................................26

APPENDIX 4: RECEIVER UNIT R318 MECH. DRAWING.....................................................27

APPENDIX 5: RECEIVER UNIT R318 MECH. DRAWING.....................................................28