10

1.2 Do not use sealing compounds on any pipe ttings or joints.

1.3 To avoid damage to the case when soldered ttings are used, pre-solder the

pipework and ttings before connecting them to the inlet connector assembly.

1.4 Avoid layouts where the shower hose will be sharply kinked. This may reduce

the life of the hose.

1.5 Supply pipework MUST be ushed to clear debris BEFORE connecting the

appliance. Debris will reduce the performance of the shower.

Avoid running the pipework through excessively hot or cold areas such as hot

loft spaces, airing cupboards, or in close proximity to hot water pipes. If this

cannot be avoided, we would recommend insulating the pipes.

1.6 The shower must be tted onto a tiled or sealed nished surface, i.e. on top of

the tiles. DO NOT tile up to the sides of the shower or use a sealant around the

case. Failure to do this may cause appliance failure. To ensure the case and

other components are not put under strain during installation always provide

mechanical support when making plumbing connections. Upon completion of

the installation ensure connections and back case are not under any stress

due to misaligned pipework or electrical cables.

1.7 We recommend that a non-restrictive (free owing) isolating valve is tted in

the cold water supply pipe from the cistern to the shower, to allow maintenance

of the shower.

1.8 When installed in very hard water areas (above 200 ppm temporary hardness)

your installer may advise the installation of a water treatment device, to reduce

the effects of limescale formation. Any malfunction due to limescale is not

covered by the manufacturer's guarantee. Your local water company will be

able to advise the hardness of water in your area.

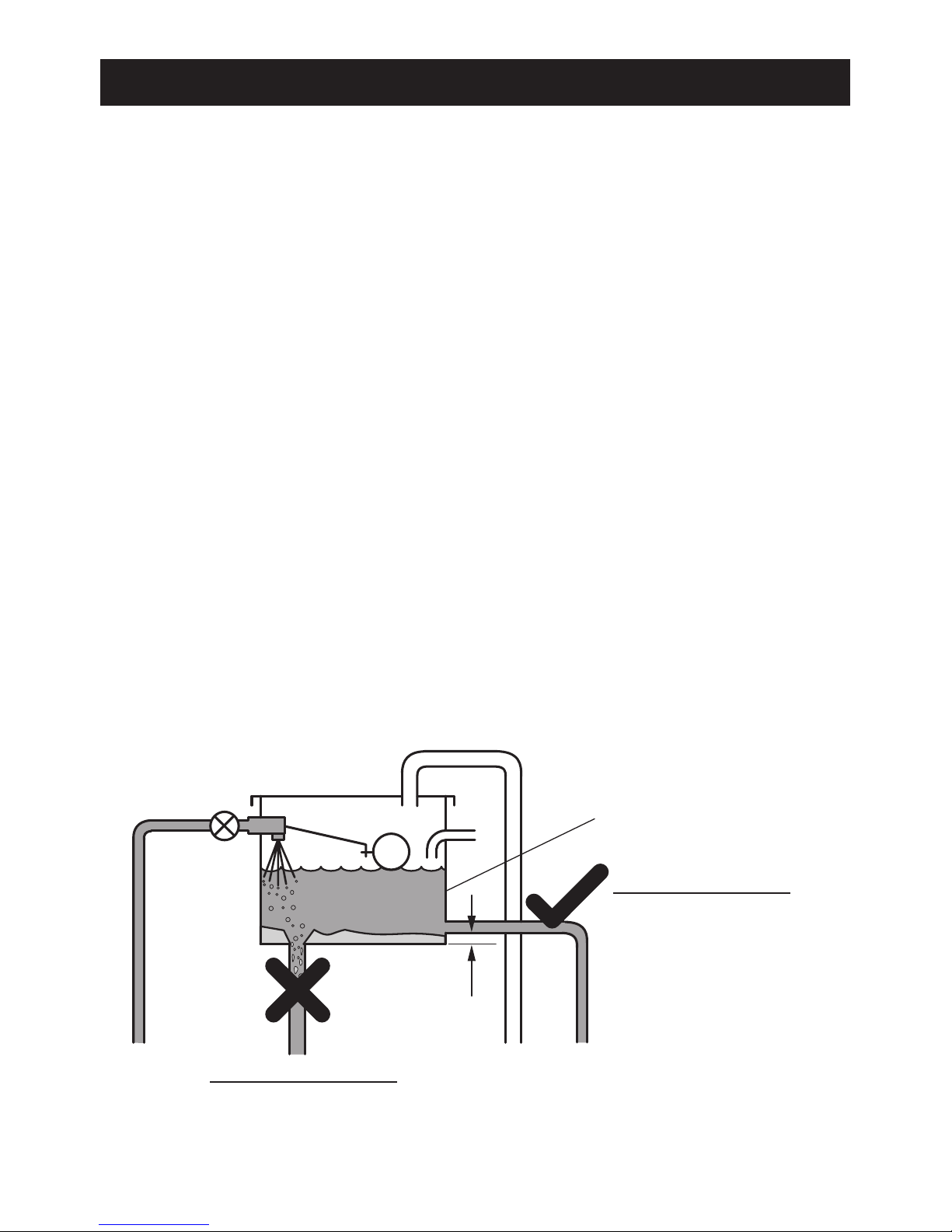

1.9 To prevent the possibility of backsiphonage, the handset must be prevented

from reaching within 25 mm of the spillover level of any bath, shower tray or

washbasin. The supplied hose retaining ring should enable this to be achieved

for the majority of shower installations. However, there will be occasions when

the hose retaining ring will not provide a suitable solution. In these instances,

a double checkvalve must be tted to the outlet. Double checkvalves tted in

the shower's inlet supply can cause a pressure build-up, which could exceed

the maximum static inlet pressure for the appliance. The handset must be

prevented from reaching within 30 mm of the spillover level of any WC, bidet

or other basin that is classied higher than uid category 3.

1.10 Rear entry plumbing is accommodated without the need to recess the 15 mm

inlet compression connector. If pipework and/or electrical cables enter the

shower from the rear through a hole in the wall provision must be made to

prevent water ingress back into the wall structure.

1.11 The shower is tted with a pump motor, and some mechanical noise can be

expected in addition to the noise generated by the spray from the handset. The

type of wall surface will affect the perceived sound levels. Stud partition and

panel walls have a tendency to resonate, whilst solid walls provide the quietest