29

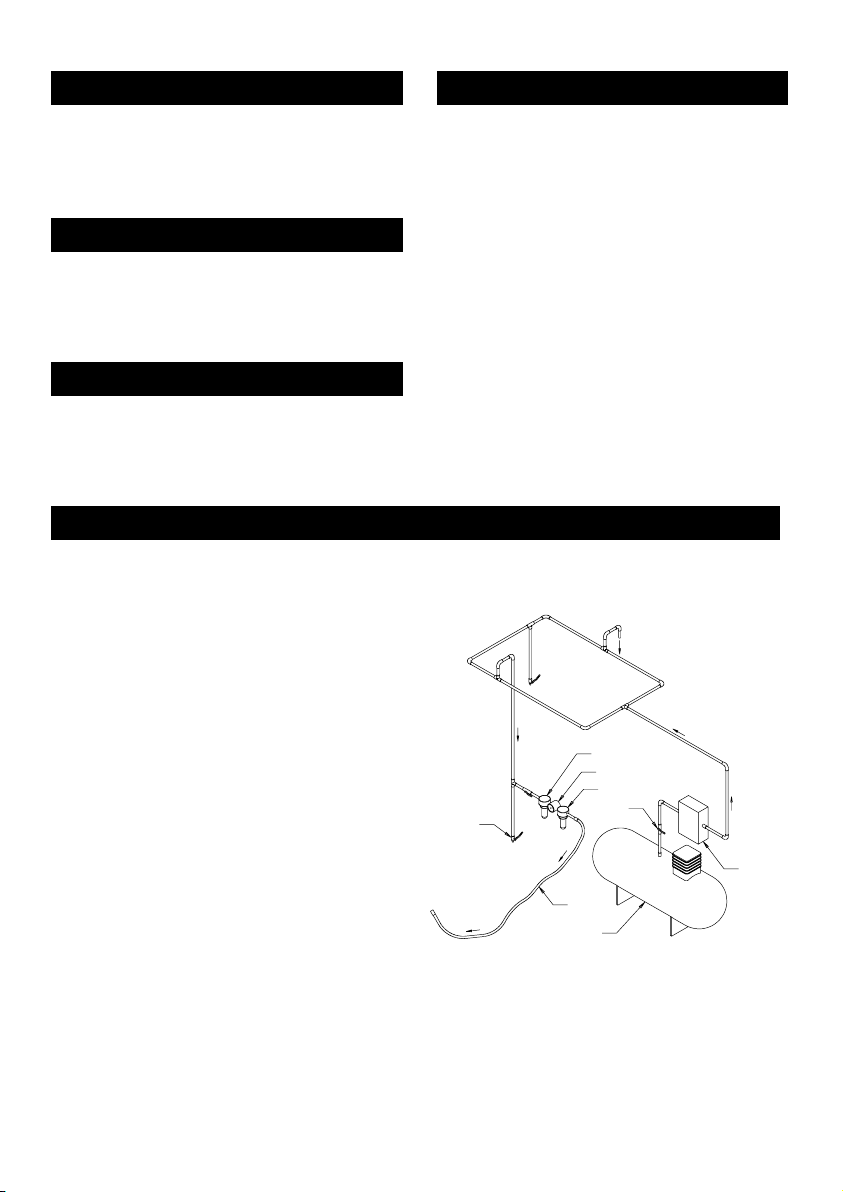

Closed Loop Pipe System

Sloped in the direction of air flow

Drain Leg

Ball Valve

To Tool Station

Filter

Drain Valve

Regulator

Lubricator

Ball

Valve

Ball Valve Air Flow

Air Dryer

Air Compressor

and Tank

Air Hose

To Coupler

at or near Tool

PleaseReadandComplywith PuttingtheToolintoService

Operating Instructions

WorkStations

ProperUseofTool

Figure 1

1)GeneralIndustrySafety&HealthRegulations,Part1910,

OSHA2206,availablefrom:SuperintendentofDocuments;

GovernmentPrintingOce;WashingtonDC20402.

2)SafetyCodeforPortableAirTools,ANSIB186.1availablefrom:

AmericanNationalStandardsInstitute,Inc.;1430Broadway;

New York, New York 10018.

3)StateandLocalRegulations.

Thissanderisdesignedforsandingalltypesofmaterialsi.e.

metals, wood, stone, plastics, etc. using abrasive designed for this

purpose.Donotusethissanderforanyotherpurposethanthat

speciedwithoutconsultingthemanufacturerorthemanufac-

turer’s authorized supplier. Do not use backing pads that have a

working speed less than 8,000 rpm free speed.

Useacleanlubricatedairsupplythatwillgiveameasuredair

pressureatthetoolof6.2bar(90psig)barwhenthetoolisrun-

ningwiththeleverfullydepressed.Itisrecommendedtousean

approved10mm(3/8in.)x8m(25ft)maximumlengthairline.It

isrecommendedthatthetoolbeconnectedtotheairsupplyas

shown in Figure 1.

Donotconnectthetooltotheairlinesystemwithoutincorporating

aneasytoreachandoperateairshutovalve.Theairsupply

shouldbelubricated.Itisstronglyrecommendedthatanairlter,

regulatorandlubricator(FRL)beusedasshowninFigure1as

thiswillsupplyclean,lubricatedairatthecorrectpressureto

thetool.Detailsofsuchequipmentcanbeobtainedfromyour

supplier. If such equipment is not used then the tool should be

manuallylubricated

Tomanuallylubricatethetool,disconnecttheairlineandput2to

3 drops of suitable pneumatic motor lubricating oil such as Fuji

KosanFK-20,MobilALMO525orShellTORCULA®32intothe

hoseend(inlet)ofthemachine.Reconnecttooltotheairsupply

andruntoolslowlyforafewsecondstoallowairtocirculatethe

oil.Ifthetoolisusedfrequently,lubricateitonadailybasisor

lubricate it if the tool starts to slow or lose power.

Itisrecommendedthattheairpressureatthetoolis6.2bar(90

psig)whilethetoolisrunning.Thetoolcanrunatlowerpressures

butneverhigherthan6.2bar(90psig).

Thetoolisintendedtobeoperatedasahand-heldtool.Itis

alwaysrecommendedthatthetoolbeusedwhenstandingona

solidoor.Itcanbeusedinanypositionbutbeforeanysuchuse,

theoperatormustbeinasecurepositionandhavearmgrip

and footing, and be aware that the sander can develop a torque

reaction.Seethesection“OperatingInstructions”.

1) Readallinstructionsbeforeusingthistool.Alloperatorsmustbefullytrainedinitsuse

andbeawareofthesesafetyrules.Allservicingandrepairsmustbecarriedoutbytrained

personnel.

2) Makesurethetoolisdisconnectedfromtheairsupply.

Selectasuitableabrasiveand

secureittothebackingpad.Takecaretocenterthe

abrasive on the backing pad.

3) Alwaysweartherequiredsafetyequipmentwhenusing

this tool.

4) Whensandingalwaysplacethetoolontheworkthen

startthetool.Alwaysremovethetoolfromthework

beforestopping.Thiswillpreventgougingofthework

duetoexcessspeedoftheabrasive.

5) Alwaysdisconnecttheairsupplyfromthesanderbefore

tting,adjustingorremovingtheabrasiveorbacking

pad.

6) Alwaysadoptarmfootingand/orpositionandbeaware

ofthetorquereactiondevelopedbythesander.

7) Useonlycorrectspareparts.

8) Alwaysensurethatthematerialtobesandedisrmly

xedtopreventitsmovement.

9) Checkthehoseandttingsregularlyforwear.Donot

carrythetoolbyitshose;alwaysbecarefultoprevent

thetoolfrombeingstartedwhencarryingthetoolwith

theairsupplyconnected.

10) Donotexceedmaximumrecommendedairpressure.

Usesafetyequipmentasrecommended.

11)Thetoolisnotelectricallyinsulated.Donotusewhere

thereisapossibilityofcomingintocontactwithlive

electricity,gaspipes,waterpipes,etc.Checktheworkingareabeforeoperation.

12)Takecaretoavoidentanglementofthemovingpartsofthetoolwithclothing,ties,hair,

cleaningrags,etc.Ifentangled,itwillcausethebodytobepulledtowardstheworkand

movingpartsofthemachineandcanbeverydangerous.

13) Keep hands clear of the spinning pad during use.

14) Ifthetoolappearstomalfunction,removefromuseimmediatelyandarrangeforservicing

and repair.

15) Donotallowthetooltofreespeedwithouttakingprecautionstoprotectanypersonsor

objects from the loss of the abrasive or pad.