Toro 41135 User manual

FormNo.3364-446RevA

ElectricHoseReelKit

2005andAfterMulti-Pro®1200/1250TurfSprayer

ModelNo.41135—SerialNo.310000001andUp

InstallationInstructions

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Thisattachmentisahoseextendedhandsprayerwithan

electricreelintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarily

designedforsprayinggolfcourseapplications,parks,

sportselds,andoncommercialgrounds.Itisdesigned

toonlybeusedinconjunctionwithmachinesdesignated

bythemanufacturer.

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Important:Teontapeisrequiredforthe

installationofthiskit.Thetapeisusedtowrap

threadsofttingsbeforeassembly.Threadsshould

bewrappedstartingatthebaseandtravelingtothe

tipofttingtoensureawaterproofseal.

Important:Anon-petroleumbasedlubricant,such

asvegetableoil,willberequiredfortheinstallation

ofthiskit.

Note:Ifyouareinstallingthiskitonasprayerwitha

coveredboomkit,youwillneedadditionalpartsand

instructions;contactyourAuthorizedToroDistributor

formoreinformation.

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationin

thismanualcanhelpyouandothersavoidinjuryand

productdamage.AlthoughTorodesignsandproduces

safeproducts,youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

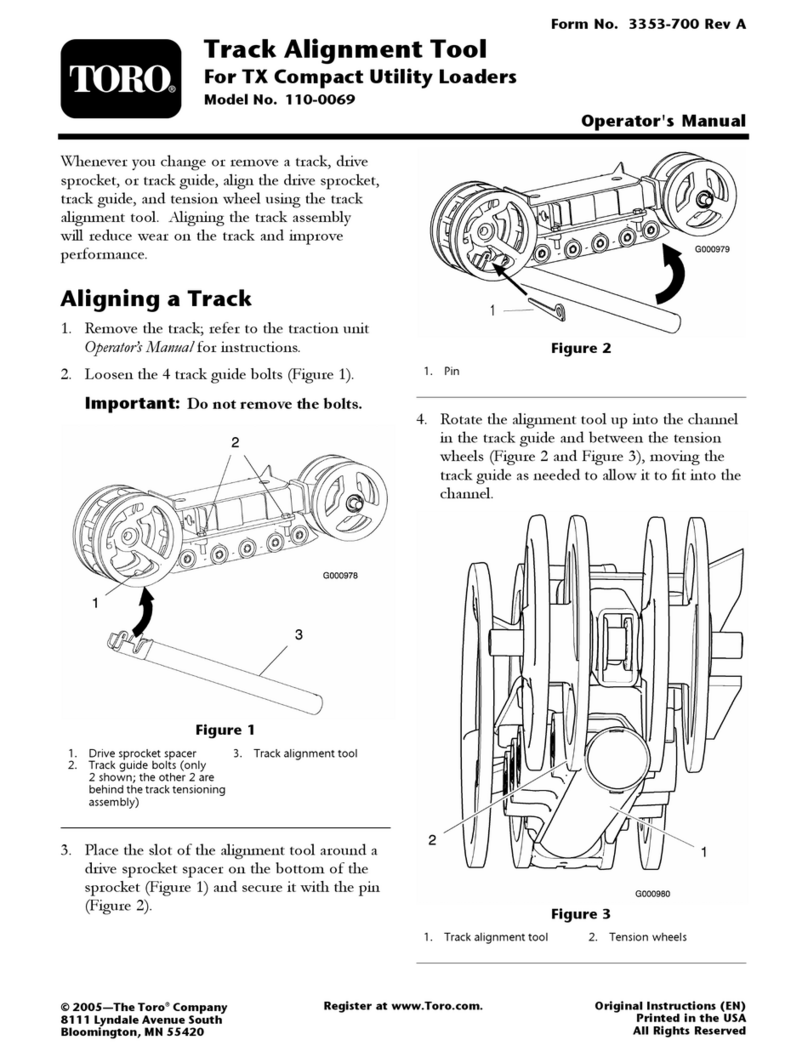

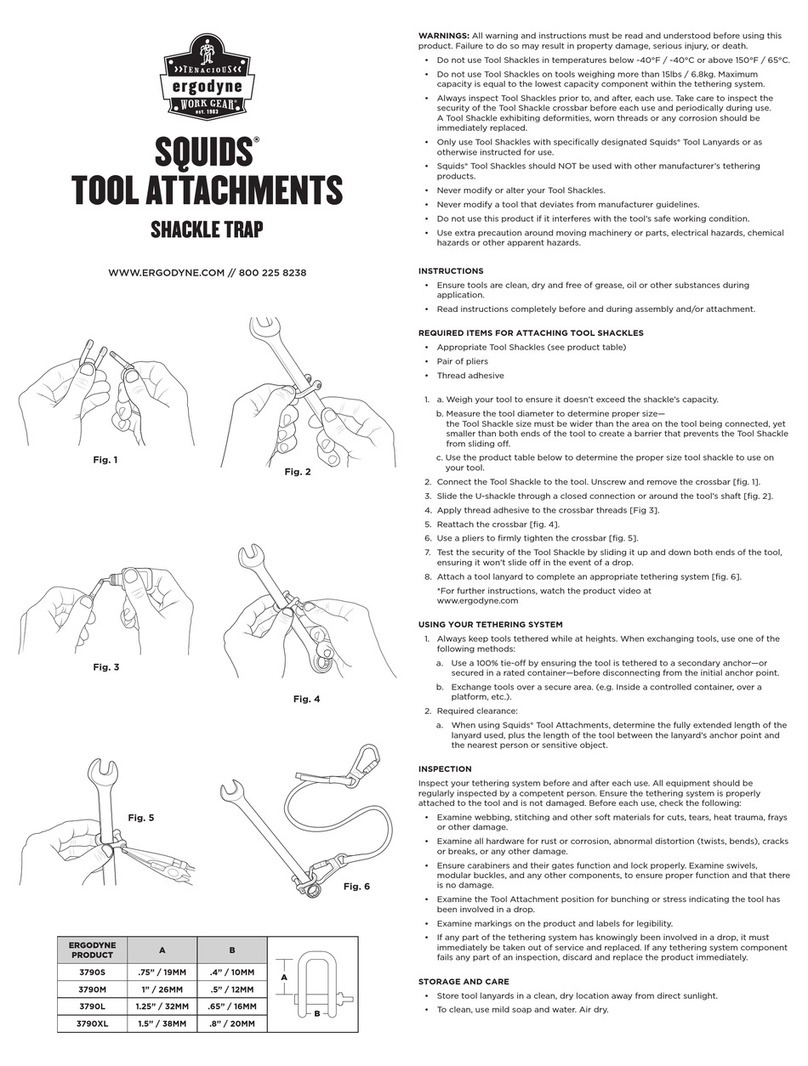

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

©2009—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

Readalsothesafetyandoperationinstructionsinthe

vehicleOperator’sManual.

•Donotaimthehandsprayeratanypersonoranimal.

Fluidsunderhighpressurecanpenetrateskinand

causesevereinjury,possiblyresultinginamputation

ordeath.Hotliquidsandchemicalscanalsocause

burnsorinjury.Ifanypartofthebodycomesin

contactwiththespraystream,immediatelyconsulta

physicianfamiliarwithinjecteduidinjuries.

•Donotplaceyourhandoranyotherpartofyour

bodyinfrontofthespraynozzle.

•Donotleavetheequipmentunderpressurewhen

youarenotpresent.

•Donotusethehandsprayerifthehose,triggerlock,

nozzle,oranyotherpartisdamagedormissing.

•Donotusethehandsprayerifthereareanyleaksin

anyhoses,ttings,orothercomponents.

•Donotspraynearpowerlines.

•Donotdrivewhilesprayingwithahandsprayer.

•Wearrubbergloves,safetygoggles,andafullbody

protectivesuitwhensprayingchemicalswiththe

handsprayer.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

CAUTION

Chemicalsarehazardousandcancausepersonal

injury.

•Readthedirectionsonthechemicallabels

beforehandlingthechemicalsandfollow

allmanufacturerrecommendationsand

precautions.

•Keepchemicalsawayfromyourskin.Should

contactoccur,washtheaffectedareathoroughly

withsoapandcleanwater.

•Weargogglesandanyotherprotective

equipmentrecommendedbythechemical

manufacturer.

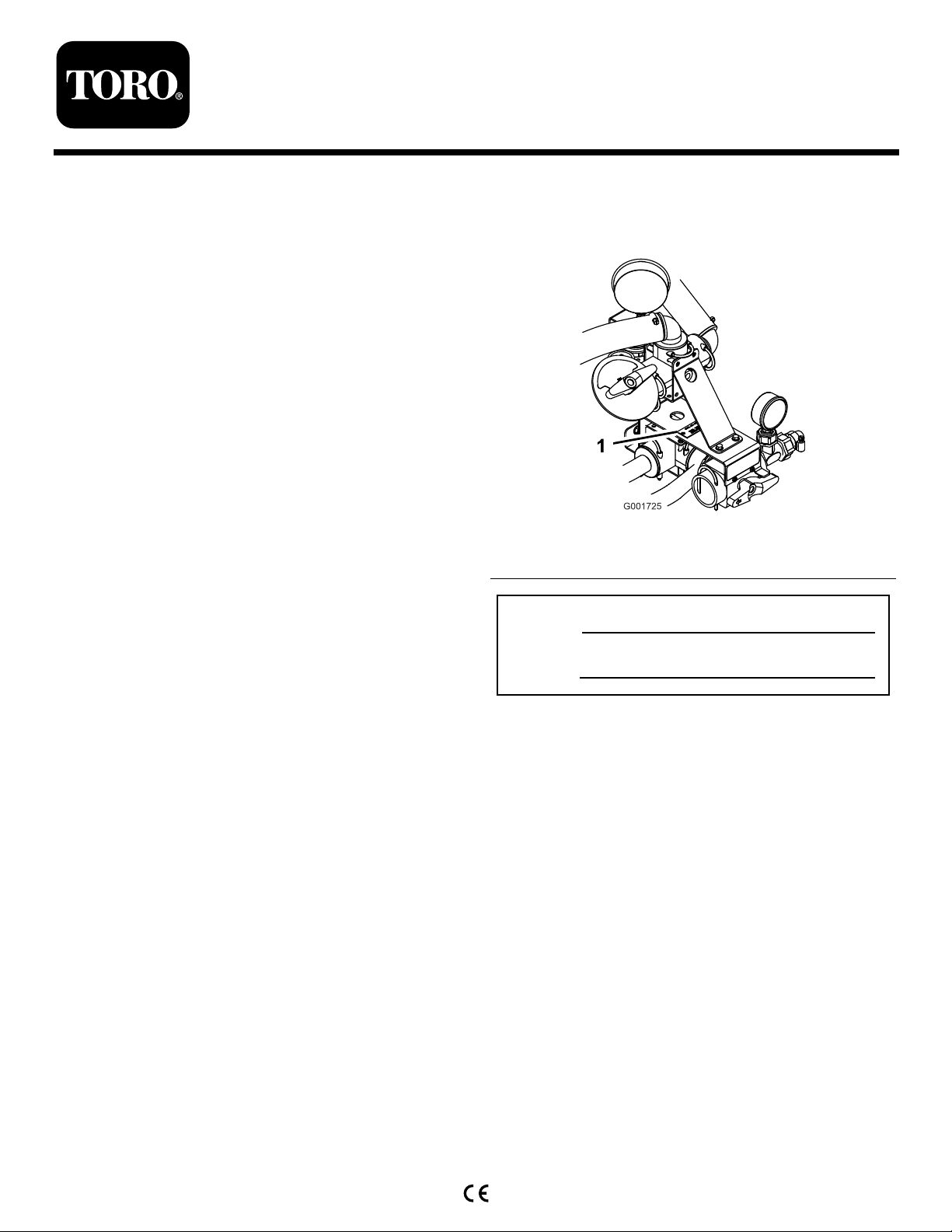

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

106-5081

1.Boomspray3.Continuousvariable

setting

2.Handspray

107-8757

1.Hosereelrewind;pushtoengage.

2

Installation

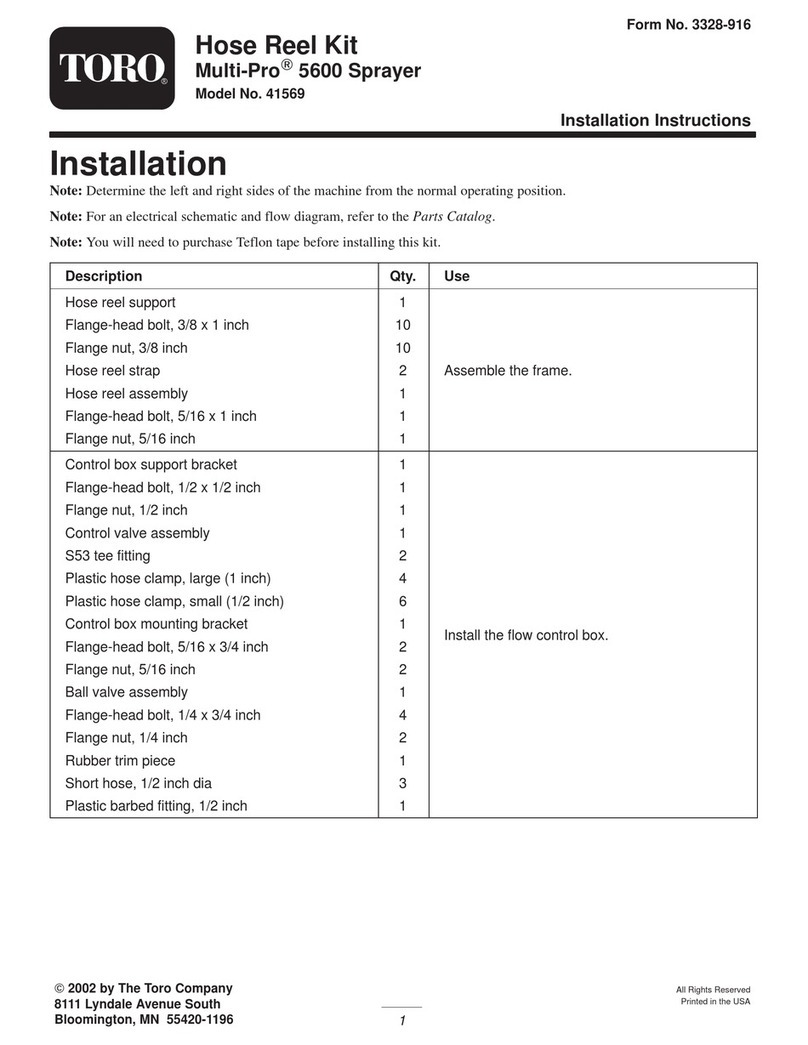

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Nopartsrequired–Preparethemachine.

Hosereelmount,left1

Hosereelmount,right1

Flangebolt(1/2x1-1/4inches)4

Flangenut(1/2inch)4

Hosereelmountingtubes2

Bolt(5/16x3-1/2inch)4

Washer8

Flangenut,(5/16inch)8

Hosereelassembly1

Bolt(5/16x1-1/2inches)4

2

Plastictie8

Assembletheframe.

Controlvalve1

Retainingfork1

Controlvalvebracket1

Flangebolt(1/4x3/4inch)2

Flangenut(1/4inch)2

Screw2

Pressuregauge1

Plasticnut1

Reducer1

Tee1

PlasticO-ring2

Adapter1

Plasticnut,large1

3

Hoseassembly1

Installthecontrolvalve.

Longhosewithtting1

Spraygun1

4Plastichoseclamp,small1

Connectthesprayhose.

3

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Ensurethatthemachineisemptyofalluids.If

chemicalshavebeenusedinthemachine,ushthe

systemthoroughlywithcleanwater;refertoyour

vehicleOperator’sManualforinstructions.

2.Disconnectthenegativebatteryterminalfromthe

battery.

2

AssemblingtheFrame

Partsneededforthisprocedure:

1Hosereelmount,left

1Hosereelmount,right

4Flangebolt(1/2x1-1/4inches)

4Flangenut(1/2inch)

2Hosereelmountingtubes

4Bolt(5/16x3-1/2inch)

8Washer

8Flangenut,(5/16inch)

1Hosereelassembly

4Bolt(5/16x1-1/2inches)

8Plastictie

Procedure

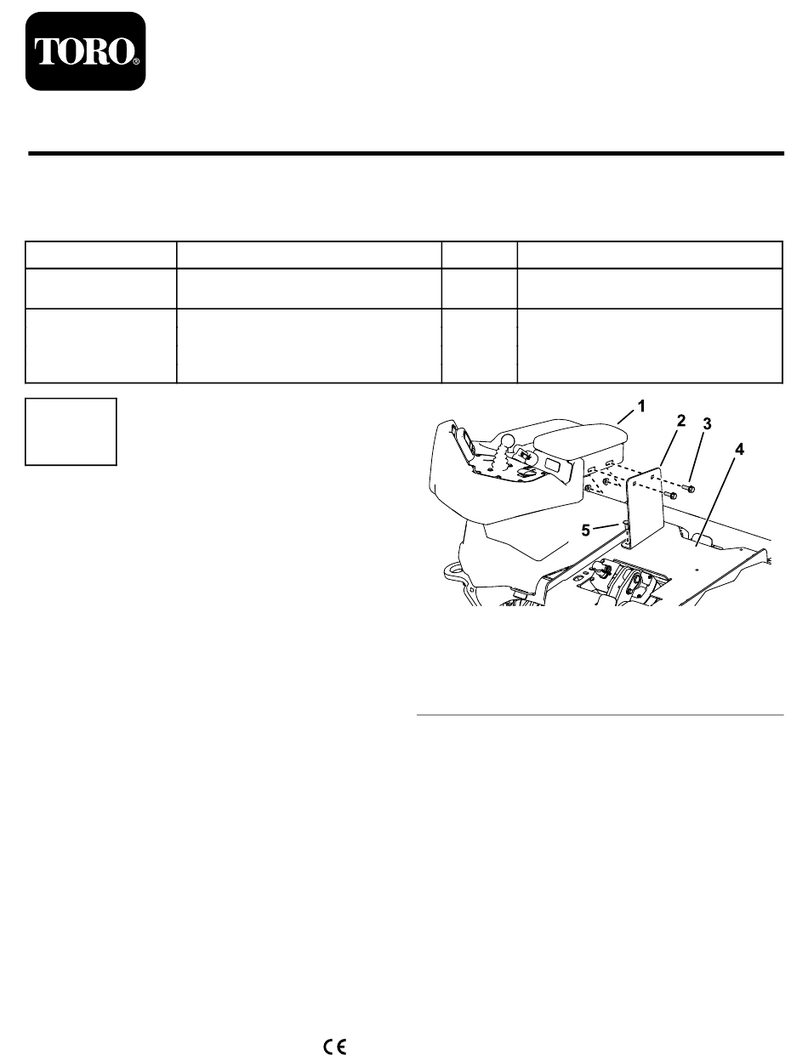

1.Install2U-bolts,andaspacertotheboomframeas

showninFigure2.Positiontheassemblyforward

ontheboomframesothatitisincontactwiththe

boomframepin.

Figure2

Boomframe,rightside

1.U-bolt3.Boomframe,rightside

2.Spacerbracket4.Pin,boomframe

2.Installtherighthosereelsupport(supportwiththe

spraygunholdertubeonit)tothevehicleframe

atthe2U-boltsandspacerinstalledpreviously

(Figure3).Securetheframeswith4angenuts(3/8

inch).Thesupportshouldwraparoundtherearend

ofthetank.

Donotfullytightentheangenutstoallowforlater

adjustment.

Figure3

1.U-bolt4.Flangenut,(3/8inch)

2.Spacerbracket5.Boomframe,rightside

3.Hosereelframe,rightside6.Spraygunholder

4

3.Installthelefthosereelsupport(supportwithout

thespraygunholdertube)tothevehicleframeusing

2U-bolts,spacerand4angenuts(3/8inch)as

describedinsteps1and2.Donotfullytightenthe

angenutstoallowforlateradjustment.

4.Thesupportsshouldwraparoundtherearendof

thetank(Figure4).

Figure4

1.Hosereelsupport,right3.Spraygunholder

2.Hosereelsupport,left4.Boomframe

5.Installthe2hosereelmountingtubestothetopof

thehosereelframes(Figure5)using4bolts(5/16x

3-1/4inch),4washers(11/16inchoutsidedia),and

4angenuts(5/16inch).Donotfullytightenthe

fastenerstoallowforlateradjustment.

Figure5

1.Hosereelsupport,right5.Flangenut,5/16inch

2.Hosereelsupport,left6.Flange-headbolt,5/16x

1-1/2inch

3.Bolt,5/16x3-1/4inch7.Washer,7/8inchoutside

dia

4.Washer,11/16inchoutside

dia

8.Hosereelassembly

6.Installthehosereelassemblyontothehosereel

mountingtubes(Figure5)using4ange-headbolts

(5/16x1-1/2inches),4washers(7/8inchoutside

dia),and4angenuts(5/16inch).Donotfully

tightenthefastenerstoallowforlateradjustment.

7.Levelthehosereelassemblyandthentightenall

fastenersinthereverseordertheywereinstalled.

8.Routethewiringharnessundertherighthosereel

support,downalongthevehicleframe,tothestarter

solenoidandgroundterminalblocklocatedinthe

enginecompartmentandseatbox.

9.Securethewiringharnesstotheexistingwiresand

hosestoremoveanyslackusingplastictiesincluded

inthekit.

Important:Securetheharnessasafedistance

fromanyhotormovingpartsthatmaydamage

thewiringharness.

10.Connecttheredpowerwiretotheleftsideofthe

solenoid(Figure6),locatedundertheseat.

5

Figure6

1.Powerwirefromthe

electricalboxonthehose

reel.

2.Solenoid

11.Connecttheblackwiretoapostontheground

terminalblock,locatedunderthesolenoid.

3

InstallingtheControlValve

Partsneededforthisprocedure:

1Controlvalve

1Retainingfork

1Controlvalvebracket

2Flangebolt(1/4x3/4inch)

2Flangenut(1/4inch)

2Screw

1Pressuregauge

1Plasticnut

1Reducer

1Tee

2PlasticO-ring

1Adapter

1Plasticnut,large

1Hoseassembly

Procedure

1.Locatethevalveassemblyontherightsideofthe

tank,removetheretainingforktodisconnectthe

boomsupplyhosefromthesupplytee(Figure7).

Figure7

1.Supplytee3.Boomsupplyhose

2.Retainingfork

2.OnaMulti-Pro1200Sprayer,disconnectthesmall

redpressuregaugetubefromthegreentubetting

ontopofthesupplytee(Fig.8).Todisconnect,

pressdownonthetubettingwhilepullingupon

thetube.

3.Removethetwoboltsandtwonutssecuringthe

supplyteeandsupplyteemountingbrackettothe

vehicle(Figure8).Retainthefastenersforlateruse.

Figure8

1.Supplyteemounting

bracket

3.Bolt

2.Tankstrap4.Nut

4.Installthenewcontrolvalveintotherearfacing

openportonthesupplyteeandsecureitwithanew

retainingfork(Figure9).

6

Figure9

1.ControlValve3.Boomsupplyhose

2.Retainingfork,new4.Retainingfork,existing

5.Connecttheboomsupplyhosetotheopenport

onthecontrolvalveandsecureitwiththeretainer

removedpreviously(Figure9).

6.Installthecontrolvalvebracketbetweenthesupply

teebracketandthemountingframe(Figure10)using

thefastenersremovedpreviously.

Figure10

Valveassembliesnotdepictedforclarity.

1.Tankstrap4.Bolt

2.Controlvalvebracket5.Nut

3.Supplyteebracket

7.Turnthecontrolvalvehandlesothatthearrowis

pointingrearward.

8.Installthesupportbracketoverthecontrolvalve

bracket.Usethetwoexistingscrewssecuringthe

upperteeassemblytosecureupperportionof

thesupportbracket(Figure11).Securethelower

portionofthesupportbracketusingtwoange-head

bolts(1/4x3/4inch)andtwoangenuts(1/4inch).

Figure11

1.Controlvalvebracket4.Flange-headbolt(1/4x

3/4inch)

2.Supportbracket5.Flangenut(1/4inch)

3.Screw,existing

9.Securethenewcontrolvalvetothebracketusing

twoscrews(Figure12).

Figure12

1.Screw2.Controlvalvehandle,

pointingrearward

10.OnaMulti-Pro1200sprayer,installthesmallred

pressuregaugetubeintothegreentubettingon

topofthesupplytee.Pressdownonthetubetting

whileinsertingtheredtube.

11.LightlylubricatealltheO-ringsinthekitwitha

non-petroleumbasedlubricant,suchasvegetableoil.

12.WrapthepressuregaugethreadswithTeontape.

Installthesmallplasticnutandreducerassemblyto

7

thepressuregauge.Useahexwrenchtoscrewthe

reducerassemblytothepressuregauge(Figure13).

Figure13

1.Pressuregauge4.Reducer

2.Wrappedthreads5.LubricateO-ring

3.Plasticnut6.Tee

13.Installthepressuregaugeassemblytotheplastictee

(Figure13).

14.Installthelargeplasticnutoverthepressuregauge

andteeassembly.InstallaplasticO-ringandadapter

totheassemblyasshowninFigure14.

Figure14

1.Gaugeteeassembly3.O-ring,plastic

2.Adapter4.Largeplasticnut

15.LubricatetheO-ringintheadapterwitha

non-petroleumbasedlubricant,suchasvegetable

oil(Figure15).

16.Installthepressuregaugeassemblytotheforward

facingopeninginthecontrolvalveinstalled

previously(Figure15).Tighttheplasticnuttosecure

theassemblytothevalve.

Figure15

1.Pressuregaugeassembly3.Controlvalve,open

2.Largeplasticnut4.LubricateO-ring

17.InstallaplasticO-ringbetweenthepressuregauge

assemblyandhoseleadingtothereelassembly.

Connectthehosetotheassembly(Figure16).

Tightentheplasticnutonthehosetosecureittothe

pressuregaugeassembly.

Figure16

1.Hose,fromreel3.Gaugeassembly

2.Controlvalve4.O-ring,plastic

8

4

ConnectingtheSprayHose

Partsneededforthisprocedure:

1Longhosewithtting

1Spraygun

1Plastichoseclamp,small

Procedure

1.WrapTeontapearoundthethreadsofthehose

ttingonthelonghoseandinstallthettingintothe

connectingtubeonthereel(Figure17).

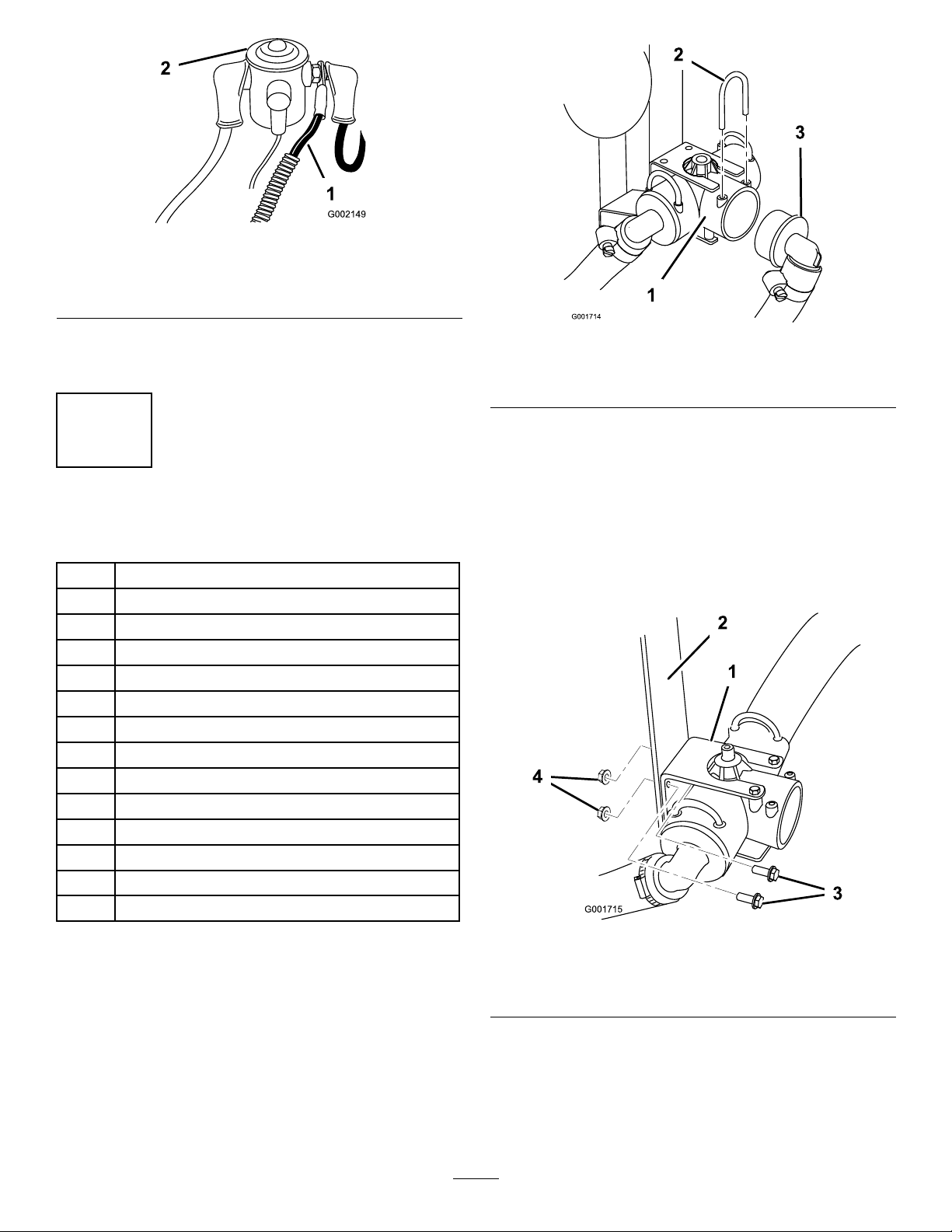

Figure17

2.Connectthefreeendofthelonghosetothetting

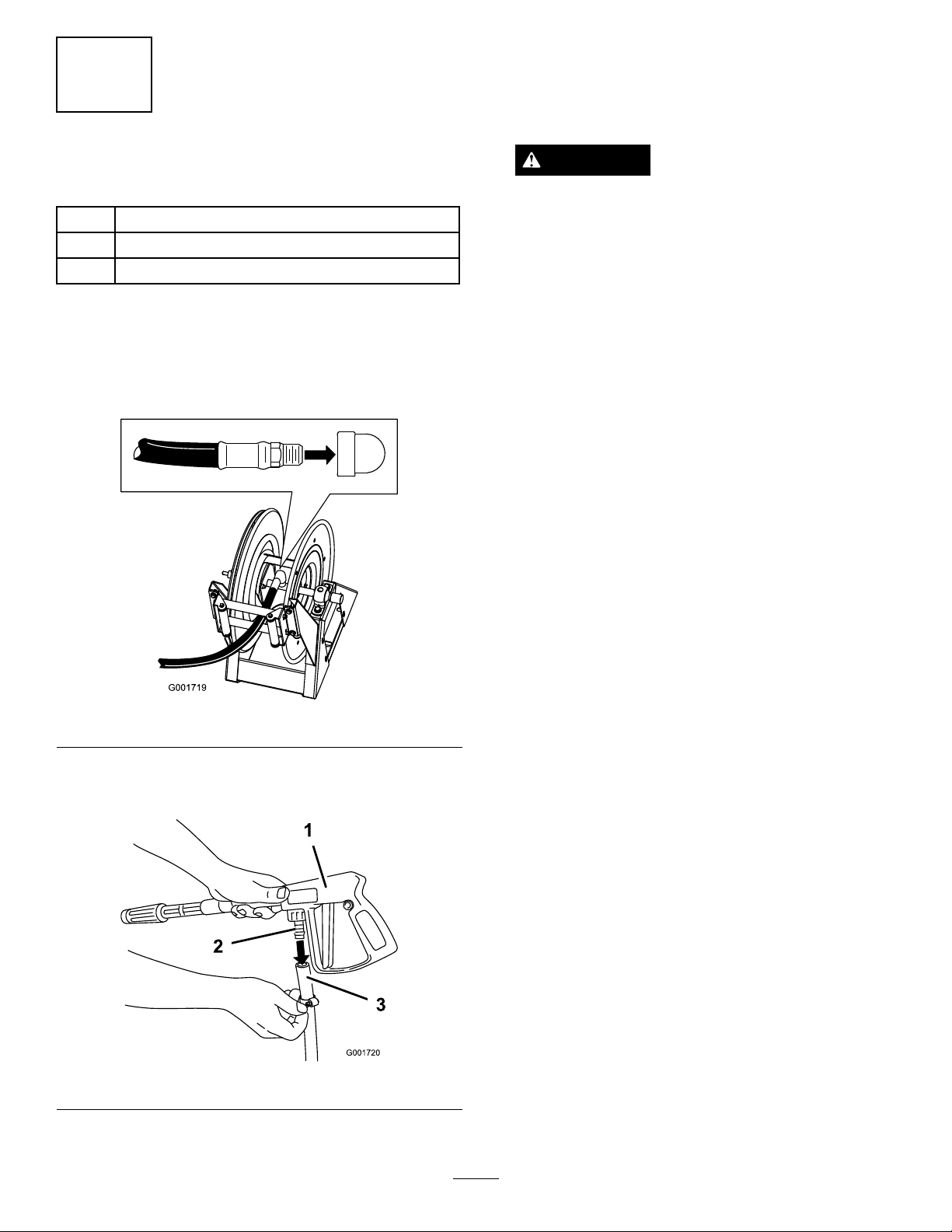

onthespraygun(Figure18).

Figure18

3.Securetheendofthehosewithasmallhoseclamp.

4.Connectthenegativebatterywiretothebattery.

5.Pressthehosewindbuttonandcarefullyguidethe

hoseontothereelmovingthehosefromsidetoside

toevenlydistributethehose.

CAUTION

Hands,looseclothing,longhair,andjewelry

couldgetcaughtinthehoseandreelwhile

rewindingandcauseinjury.

•Keepyourhandsclearofthereelandhose

whileitisrewinding.

•Donotwearlooseclothingorjewelryandtie

uplonghair.

9

Operation

WARNING

Fluidunderpressurecanpenetrateskinandcause

injury.

•Keepyourbodyandhandsawayfromnozzles

thatejecthighpressureuid.

•Donotaimthesprayeratanypersonoranimal.

•Makesurealluidhosesandlinesareingood

conditionandallconnectionsandttingsare

tightbeforeapplyingpressuretothesystem.

•Usecardboardorpapertondleaks.

•Safelyrelieveallpressureinthesystembefore

performinganyworkonit.

•Getimmediatemedicalhelpifuidisinjected

intoskin.

•Hotliquidsandchemicalscancauseburnsor

otherharm.

Important:Youmustalwaysemptyandcleanthe

sprayerimmediatelyaftereachuse.Failuretodo

somaycausethechemicalstodryorthickeninthe

lines,cloggingthepumpandothercomponents.

Cleanthespraysystemaftereachsprayingsession.To

properlycleanthespraysystem:

•Usethreeseparaterinses.

•Useaminimumof50gallonsforeachrinse.

•Usethecleanersandneutralizersasrecommended

bythechemicalmanufacturers.

•Usepurecleanwater(nocleanersorneutralizers)

forthelastrinse.

SwitchingfromBoomSpray

ModetoHandSprayMode

1.Stopthemachine,turntheboomsoffandsetthe

parkingbrake.

WARNING

Drivingwhileusingthehandsprayercancause

lossofcontrol,resultingininjuryordeath.Do

notoperatethehandsprayerwhiledriving.

2.Atthebackofthemachine,Ensurethatthetrigger

lockonthespraygunislocked.

3.Turnthehandleonthefaceofthecontrolvalve

clockwisetotheHandSprayposition.

4.Attheoperator’sposition,turnthepumpon.

5.Increasetheenginespeeduntilthepressuregauge

readsthedesiredpsiandengagetheneutralengine

speedlock.

Important:Donotuseapressuresetting

higherthan150psiwiththehandsprayer.

Note:Usethepressuregaugewhileturningthe

controlvalvehandletoachievethedesiredamount

ofpressureathandsprayer.

SprayingwiththeHand

Sprayer

1.Pulloutthedesiredamountofhosefromthereel.

Important:Donotpullthehosewiththe

spraygun.Alwaysholdthehoseandpullonit

directly.Pullingonthehosewiththegunmay

breakthettingonthegunordamagethehose.

2.Releasethetriggerlock.

3.Directthespraygunnozzleattheareatobesprayed

andpullthetrigger.

4.Releasethetriggerandsetthetriggerlockwhen

nished.

SwitchingfromHandSpray

ModetoBoomSprayMode

1.Presstherewindbuttononthehosereeluntilonly

afewfeetofhoseisoutofthereel.

CAUTION

Hands,looseclothing,longhair,andjewelry

couldgetcaughtinthehoseandreelwhile

rewindingandcauseinjury.

•Keepyourhandsclearofthereelandhose

whileitisrewinding.

•Donotwearlooseclothingorjewelryand

tieuplonghair.

2.Turnthehandleonthefaceofthecontrolvalve

counterclockwisetotheBoomSprayposition.

3.Directthespraygunnozzleatanareawhereitis

safetospray,releasethetriggerlock,andpullthe

triggeruntilallremaininguidisoutofthehose,

thensetthetriggerlock.

4.Returnthesprayguntotheholderonthebackof

thereel.

10

5.Returntheenginetoidlespeed.

6.Stopthepump.

Important:Ensurethatyouushthespray

gunwithfreshcleanwaterduringyour

dailycleaningroutine(refertoyoursprayer

Operator’ s Man ual

).Failuretoproperlyclean

thespraygunmaydegradetheperformance

andreliabilityofthehosereelkitandspraygun.

11

Table of contents

Other Toro Tools manuals