TABLE OF CONTENTS

1Introduction 5

1.1 Warnings............................................................................................................................. 6

1.2 Abbreviations and definitions.............................................................................................. 6

1.3 Reference documentation................................................................................................... 7

1.4 How to contact Miros AS..................................................................................................... 7

2Quick start guides for advanced users 8

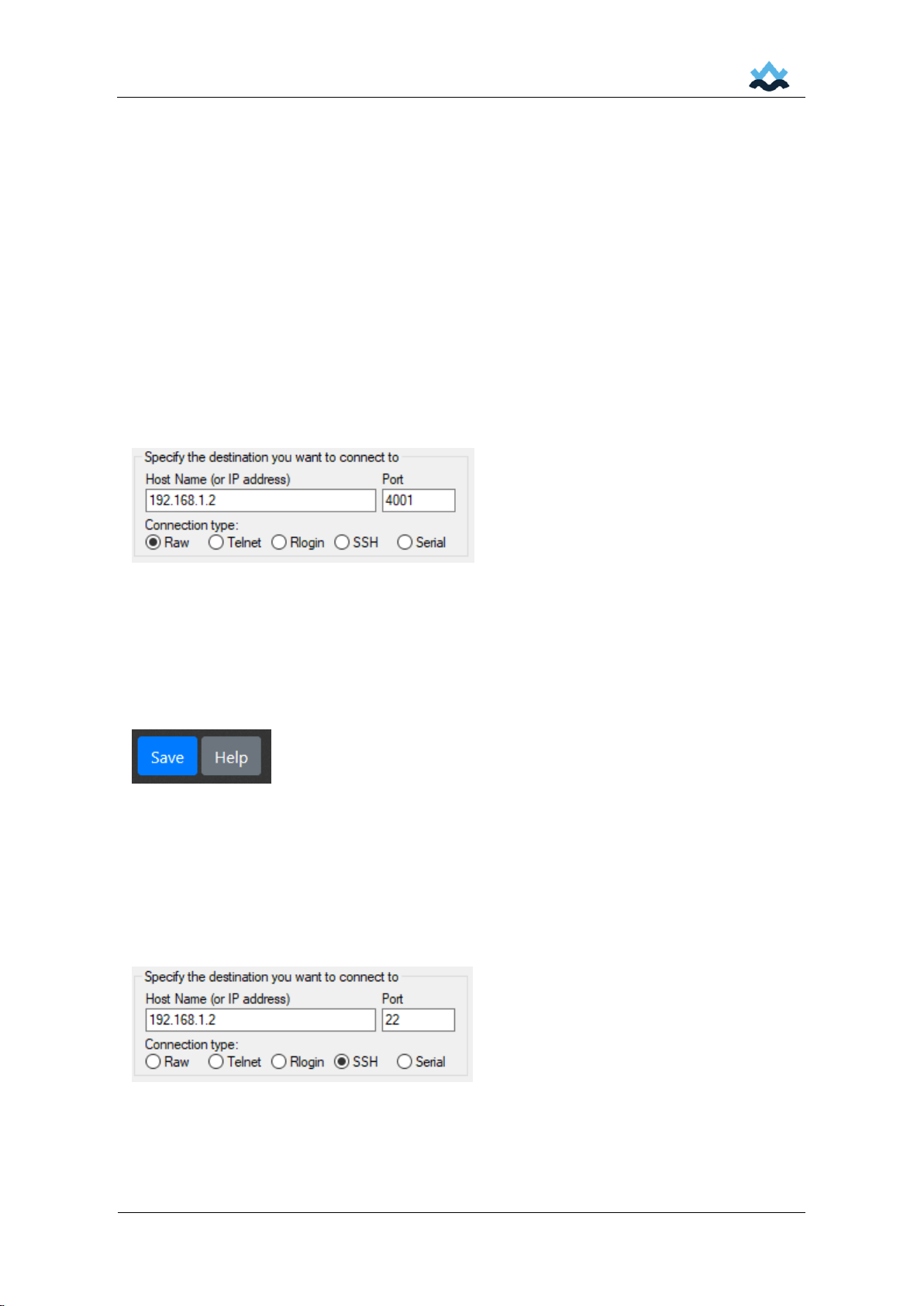

2.1 How to log on ...................................................................................................................... 8

2.2 How to get data (NMEA and/or SER formats) .................................................................... 8

2.3 How to configure using the Web GUI.................................................................................. 8

2.4 How to configure via the command line interface ............................................................... 8

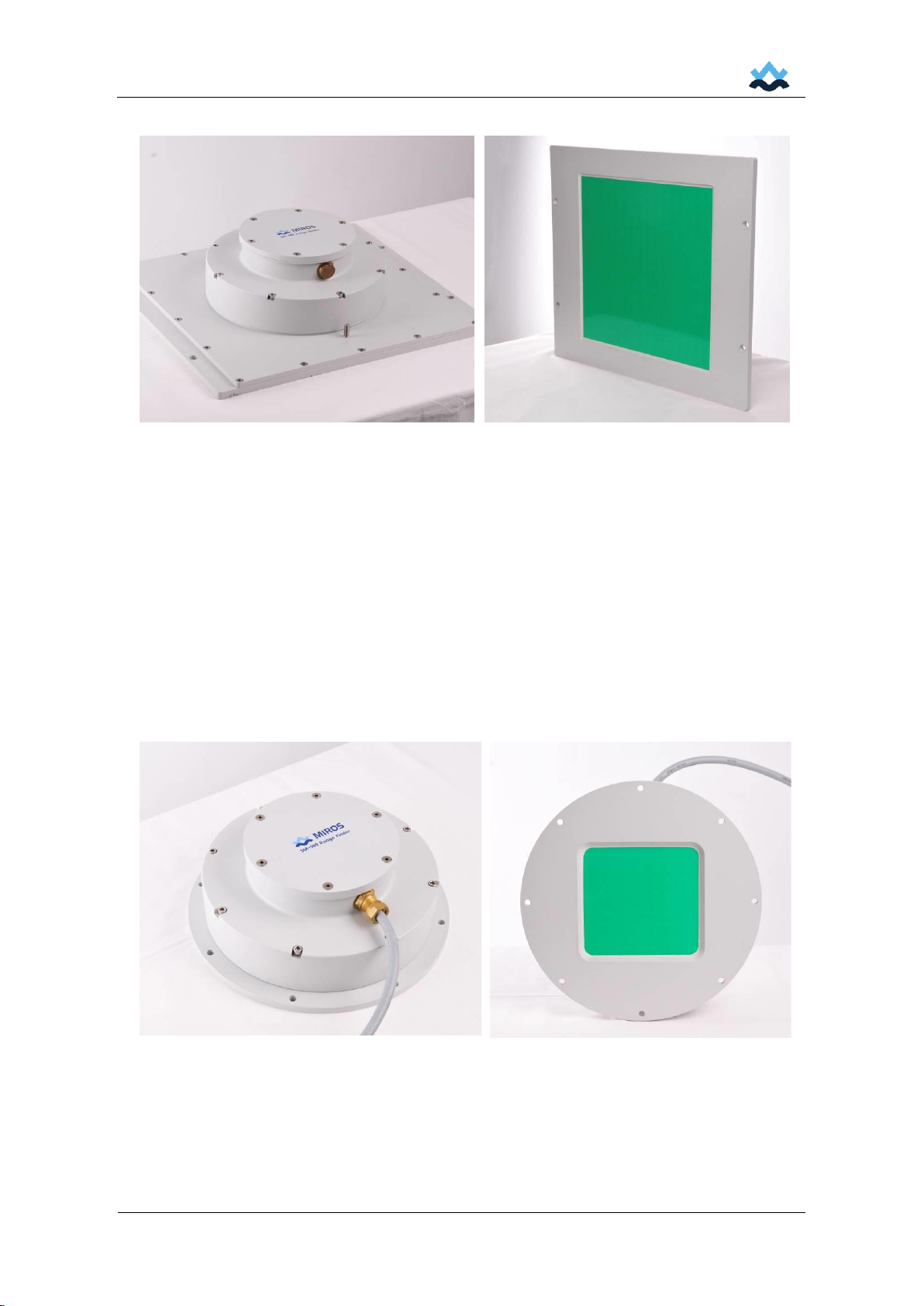

3Product overview 9

3.1 General description............................................................................................................. 9

3.3 Principles of operation....................................................................................................... 12

3.4 Sensor location and orientation ........................................................................................ 16

3.5 Mechanical installation...................................................................................................... 16

3.6 Electrical installation.......................................................................................................... 19

4Operation and configuration using local GUI 24

4.1 Start-up check................................................................................................................... 25

4.2 Overview tab ..................................................................................................................... 25

4.3 Wave tab........................................................................................................................... 26

4.4 WL + Draught tab.............................................................................................................. 27

4.5 Motion tab.......................................................................................................................... 28

4.6 Site configuration tab ........................................................................................................ 29

4.7 Network configuration tab ................................................................................................. 30

4.8 Output configuration tab.................................................................................................... 31

4.9 Time configuration tab....................................................................................................... 32

4.10 Wave configuration tab ..................................................................................................... 32

4.11 WL + Draught configuration tab........................................................................................ 33

4.12 Advanced configuration tab............................................................................................... 34

4.13 Display tab......................................................................................................................... 35

4.14 Firmware upgrade tab....................................................................................................... 35

5Maintenance 36