Page 3 of 35

Important Installation Considerations

1. The metering device must be removed from the indoor coil.

2. The liquid line and the gas line from the outdoor unit to the indoor coil must be

insulated.

3. The thermostat must be used or configured as a 2 stage heat cool thermostat

and the furnace type is “Electric Furnace” to ensure the fan comes on with the

first stage heat. You may wire two stage cooling to utilize fan speed changed on

EC motor systems.

4. The interface box power wiring must be wired with approved cabling complying

with the Canadian Electrical Code and the Provincial Electrical code in which the

equipment is being installed. The power wiring must comply with the wiring type

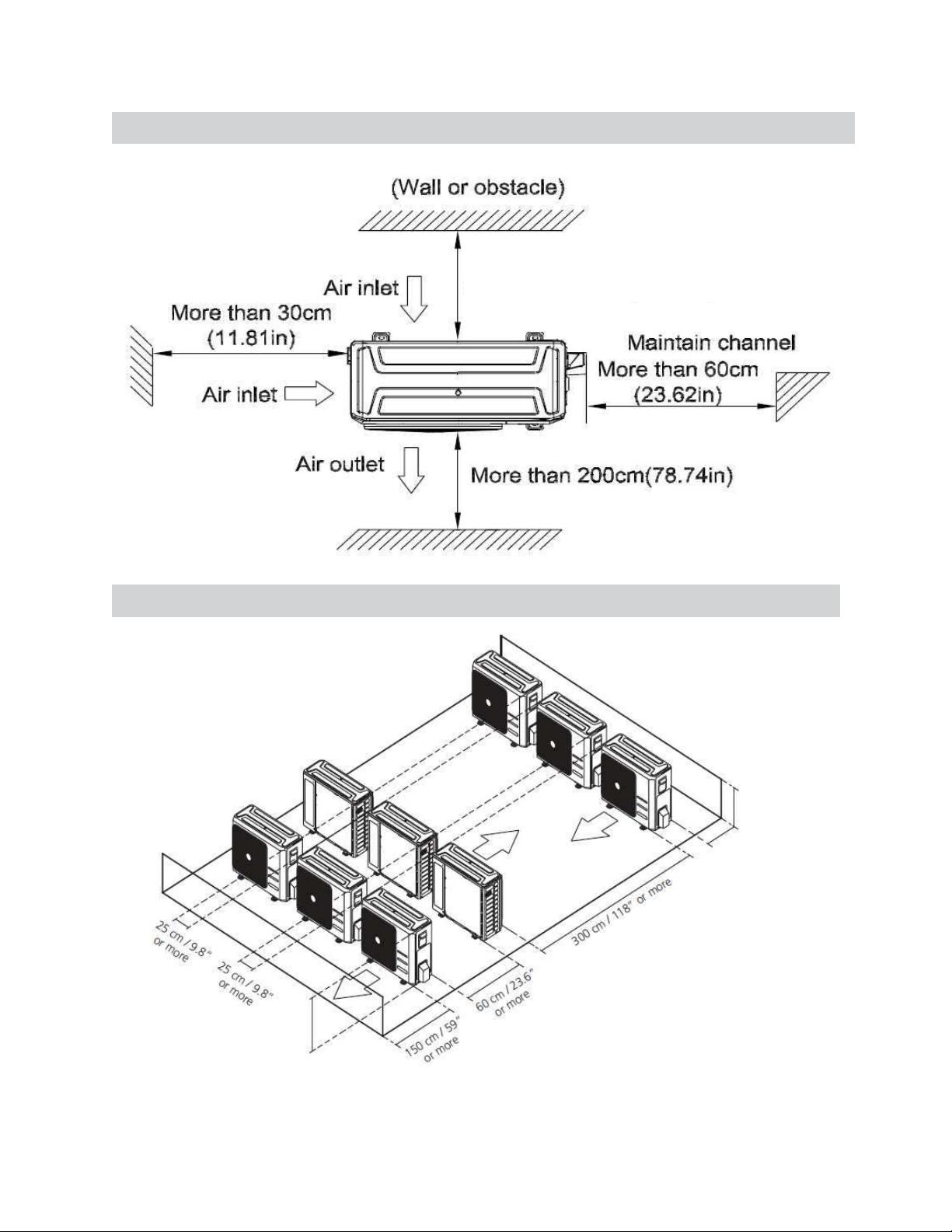

and applicable conduits as required by these codes.

5. All wiring and installation work must be properly arranged to ensure that the

control board cover can close properly. If the control board cover is not closed

properly, it can lead to corrosion and cause the connection to fail.

6. For all electrical work, follow all local and national wiring standards, regulations,

and the Installation Manual. An independent circuit to supply power must be

used. Do not connect other appliances to the same circuit. Insufficient electrical

capacity or defects in electrical work can cause electrical shock or fire or cause

the appliance to fail.

7. For all electrical work, use the specified cables and conform to all applicable

codes and ordinances. Improper electrical connections can overheat and cause

fire, and may also cause shock.

8. Installation must be performed by an authorized dealer or specialist that is

licensed under all applicable statues, regulations, codes, ordinances, and

bylaws.

9. Installation must be performed according to the installation instructions. Improper

installation can cause water leakage, electrical shock, or fire. Equipment must be

installed in accordance with applicable building codes, ordinances, B51, B52, the

Canadian Electrical Code, and the Electrical Code of the Province in which the

system is installed.

10.An authorized and appropriately licensed service technician must be contacted

for repair or maintenance of this unit.

11.Only use the included accessories, parts, and specified parts for installation.

Using non-standard parts can cause water leakage, electrical shock, fire, and

can cause the unit to fail.

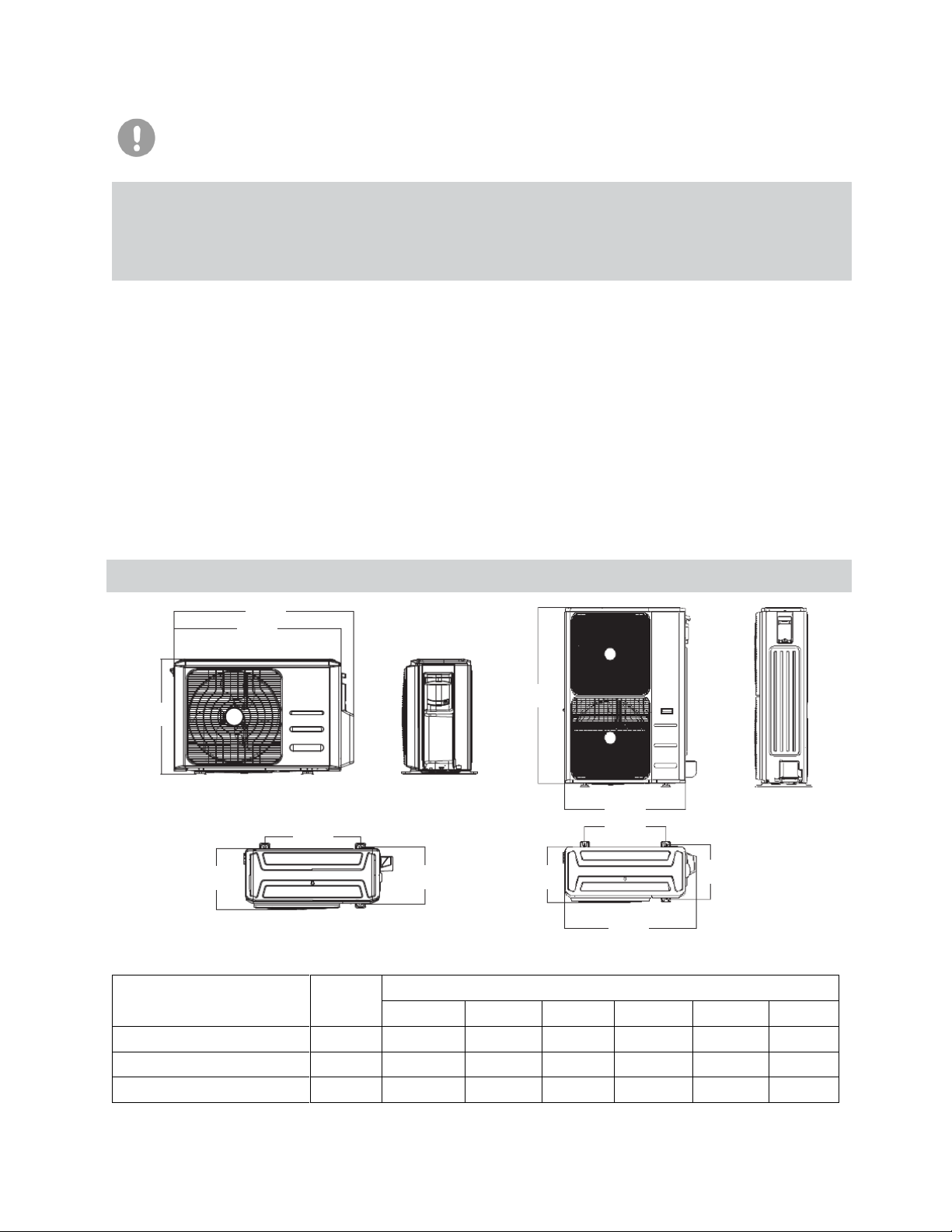

12.Install the unit in a firm location that can support the unit’s weight. If the chosen

location cannot support the unit’s weight, or the installation is not done properly,

the unit may drop and cause serious injury and damage.