Mitsubishi Electric Mr. Slim PED-2EJA1.UK Operating manual

Other Mitsubishi Electric Air Conditioner manuals

Mitsubishi Electric

Mitsubishi Electric Mr.SLIM PLA-ZM EA Series User manual

Mitsubishi Electric

Mitsubishi Electric PUHY-P72THMU-A How to use

Mitsubishi Electric

Mitsubishi Electric PEAD-A24 User manual

Mitsubishi Electric

Mitsubishi Electric MSZ-FD VA Series User manual

Mitsubishi Electric

Mitsubishi Electric PUMY-P36NHMU User manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP-HA4 User manual

Mitsubishi Electric

Mitsubishi Electric CITY MULTI PKFY-WL18NKMU-E Operating manual

Mitsubishi Electric

Mitsubishi Electric PLFY-P NCMU-E Product guide

Mitsubishi Electric

Mitsubishi Electric Mr. Slim PUHZ-FRP71VHA2 User manual

Mitsubishi Electric

Mitsubishi Electric PEFY-WL06NMAU-A User manual

Mitsubishi Electric

Mitsubishi Electric Mr.Slim MCF-GN13VA User manual

Mitsubishi Electric

Mitsubishi Electric Mr. SLIM PEAD-RP60JA User manual

Mitsubishi Electric

Mitsubishi Electric Mr.Slim PUHZ-RP-HA2 User manual

Mitsubishi Electric

Mitsubishi Electric PKA-A12GA User manual

Mitsubishi Electric

Mitsubishi Electric MSH-07RV User manual

Mitsubishi Electric

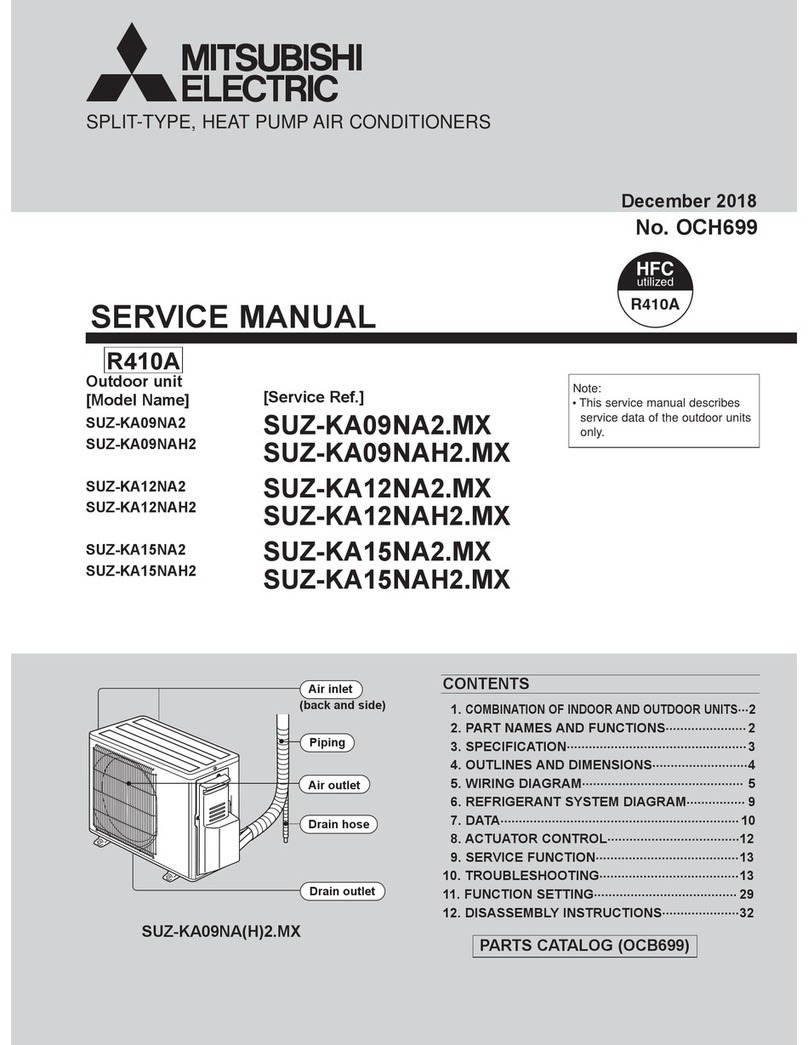

Mitsubishi Electric SUZ-KA09NAH2.MX User manual

Mitsubishi Electric

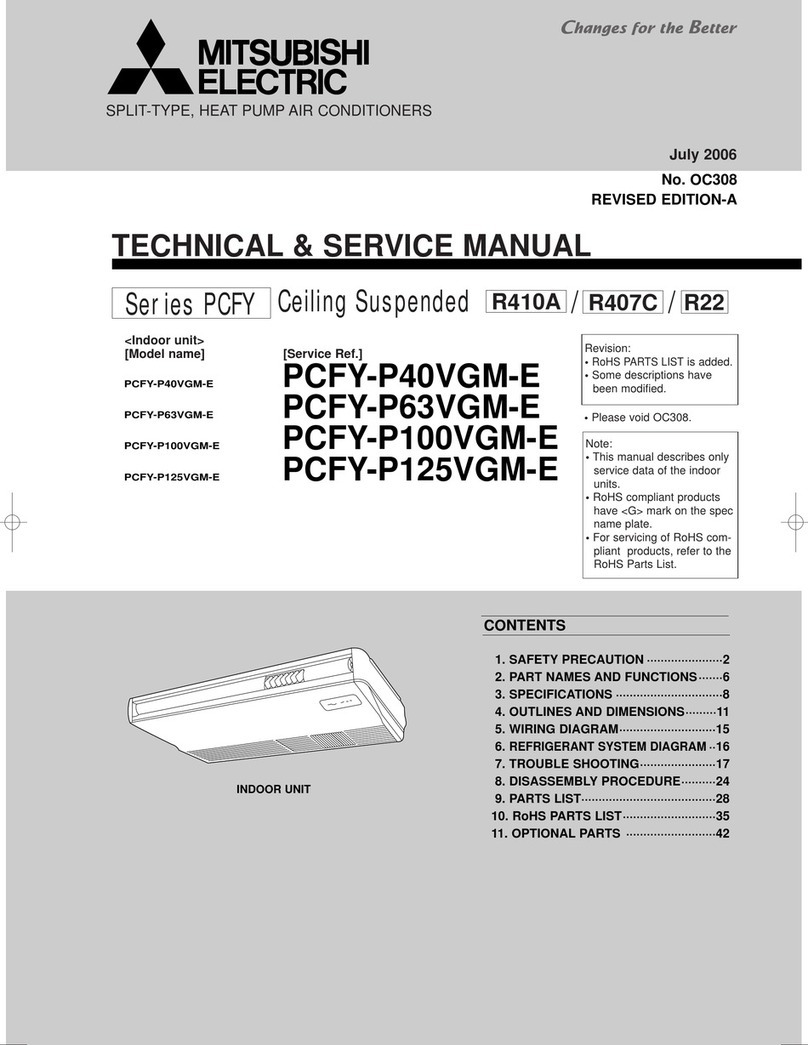

Mitsubishi Electric PCFY-P40VGM-E Operating manual

Mitsubishi Electric

Mitsubishi Electric Mr. Slim PEAD-M100JA User manual

Mitsubishi Electric

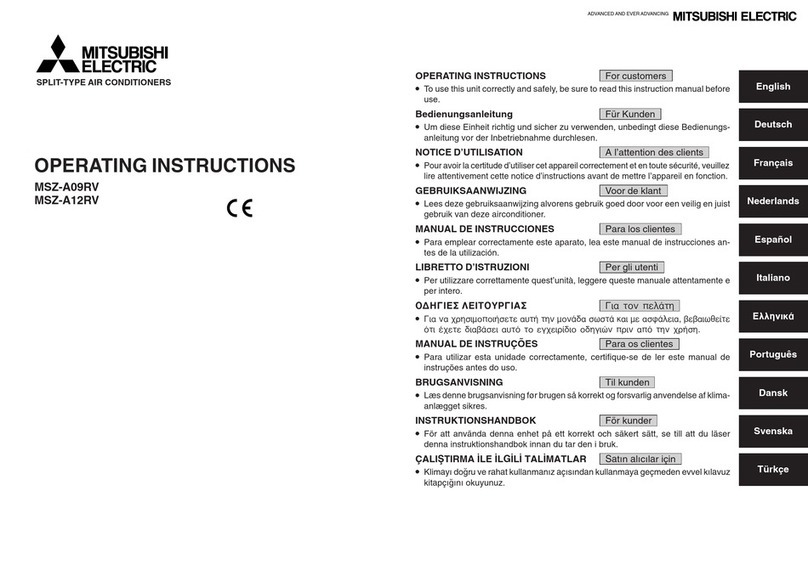

Mitsubishi Electric MSZ-A09RV User manual

Mitsubishi Electric

Mitsubishi Electric SUZ-KA24NAHZ User manual