CONTENTS

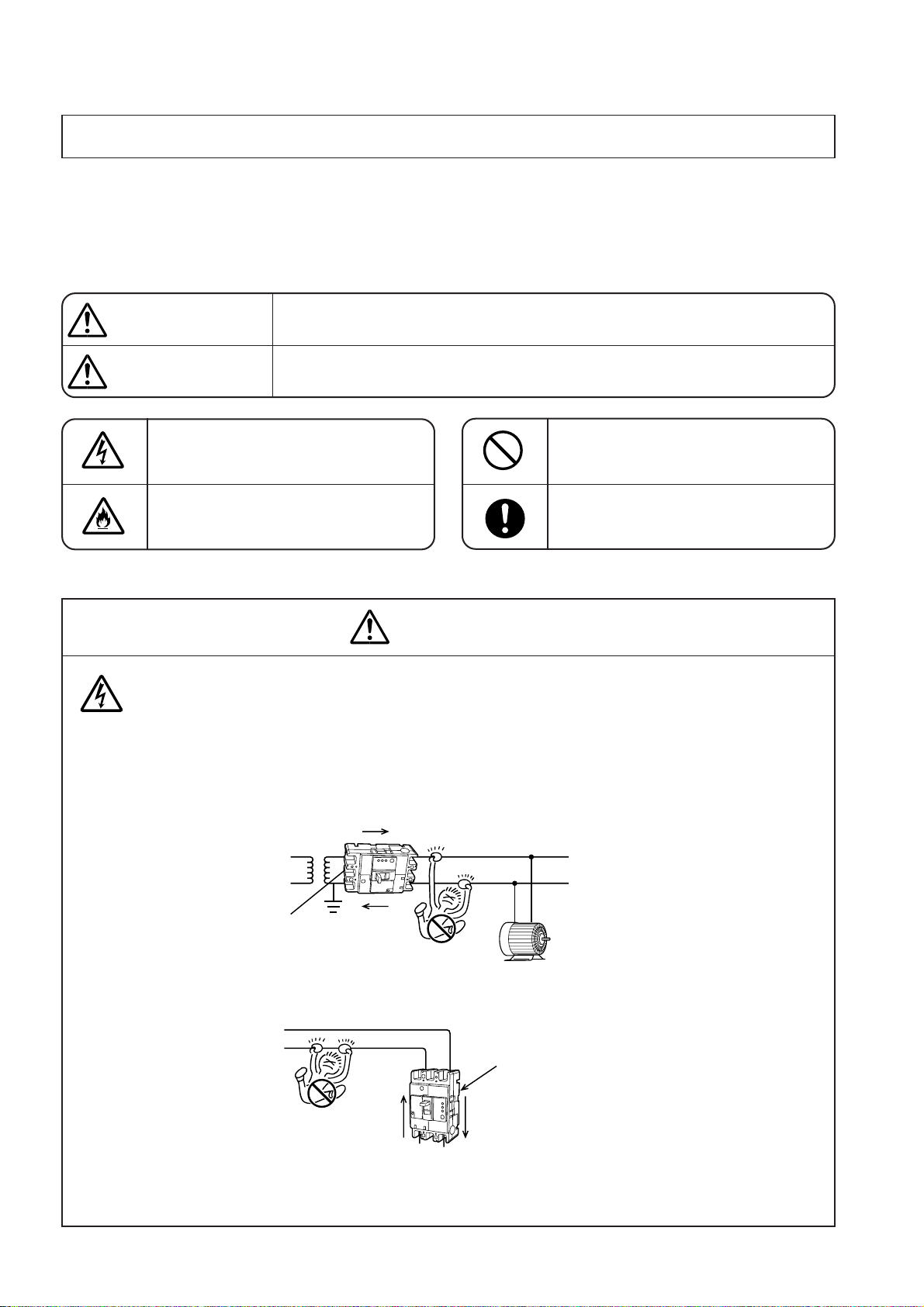

1. Items to be practiced without fail for safety

1.1 Cautionary instructions for operation ................................................................................................................................................................ 1

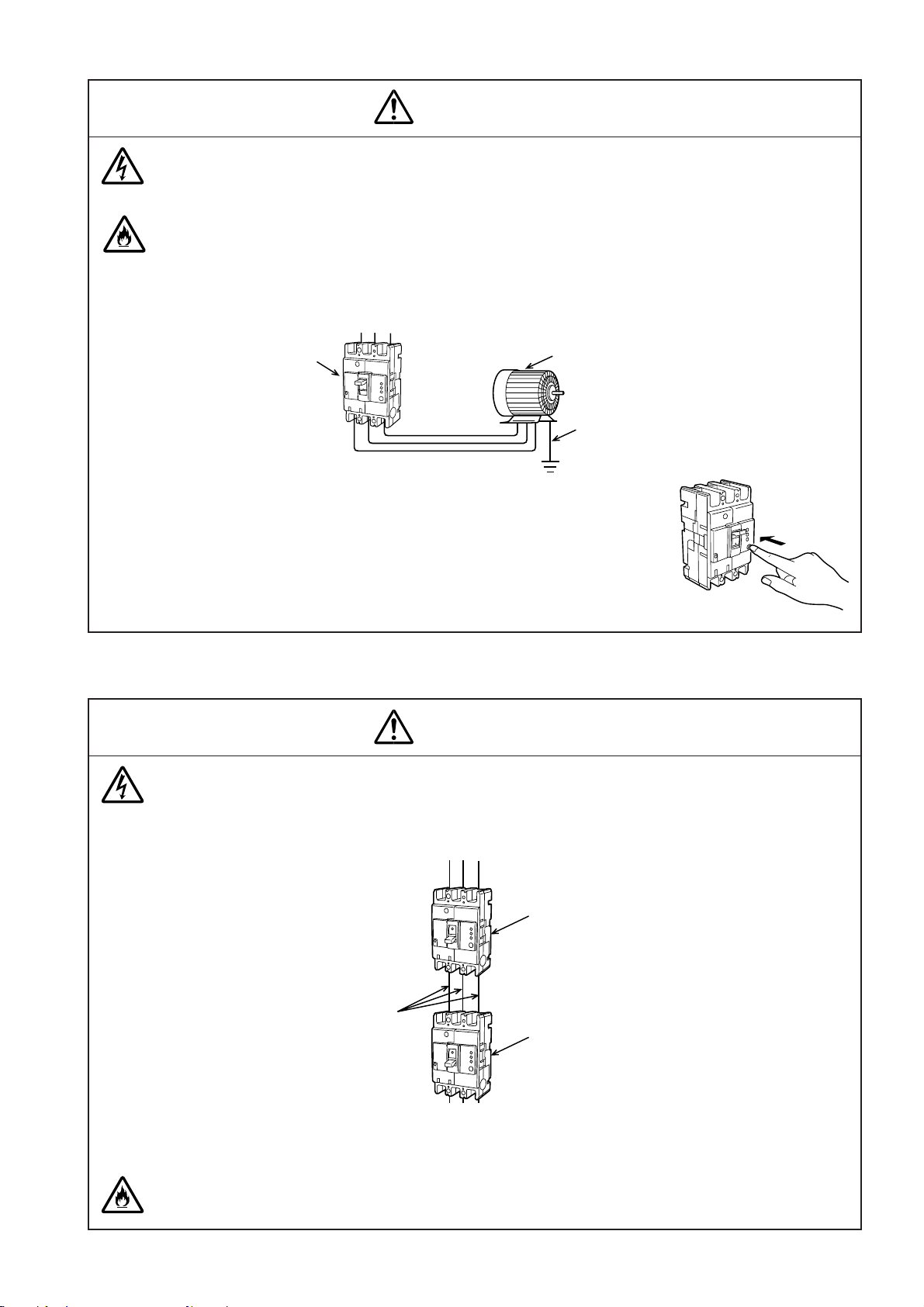

1.2 Cautionary instructions for maintenance & inspection .................................................................................................................................... 2

1.3 Cautionary instructions for work ........................................................................................................................................................................3

2. Before using

2.1 Cautionary instructions in general .....................................................................................................................................................................5

2.2 Operation ...............................................................................................................................................................................................................6

2.2.1 Switching operation ......................................................................................................................................................................................... 6

2.2.2 Trip and reset operation ..................................................................................................................................................................................7

2.3 How to set current rating, trip characteristic, sensitive current and operating time .................................................................................. 10

2.3.1 Cautionary instructions for setting .............................................................................................................................................................. 10

2.3.2 How to set characteristics of molded-case circuit breakers [electronic overcurrent tripping type] ..................................................... 10

2.3.3 How to set characteristics of molded-case circuit breakers [electronic overcurrent tripping type] ..................................................... 12

2.3.4 How to set characteristics of molded-case circuit breakers [Applicable models: NFE2000-S, NFE3000-S, NFE4000-S] .................... 12

2.3.5 How to set inverse time-delay or instantaneous tripping characteristics of circuit breakers

[Adjustable thermal or magnetic type] ........................................................................................................................................................ 13

2.3.6 How to switch voltage, sensitivity current and operating time (time delay type) of earth leakage circuit breakers ........................... 13

2.3.7 How to change rated current, tripping characteristic and leak tripping characteristic series earth leakage

circuit breakers (electronic overcurrent tripping type) .............................................................................................................................. 14

2.3.8 How to switch voltage, sensitivity current and operating time of earth-leakage relay .......................................................................... 16

3. Installation

3.1 Notice for selection ............................................................................................................................................................................................17

3.2 Normal service conditions .................................................................................................................................................................................17

3.3 Non-standard conditions ...................................................................................................................................................................................18

3.4 Inspection at arrival ............................................................................................................................................................................................19

3.5 Conditions during transport and storage ........................................................................................................................................................ 19

3.5.1 Transport ........................................................................................................................................................................................................ 19

3.5.2 Storage ............................................................................................................................................................................................................19

3.6 Installation and connection ...............................................................................................................................................................................20

3.6.1 General ............................................................................................................................................................................................................20

3.6.2 Installation ......................................................................................................................................................................................................20

3.6.3 Connection ......................................................................................................................................................................................................21

3.6.4 Mounting direction ......................................................................................................................................................................................... 22

3.6.5 Distances between circuit breaker and earthed metal parts ...................................................................................................................... 23

3.6.6 Current-carrying capacity and operating temperature ............................................................................................................................... 24

3.6.7 Breaker arrangements ...................................................................................................................................................................................26

3.6.8 Instruction for connections .......................................................................................................................................................................... 32

3.6.9 Instruction for accessories .......................................................................................................................................................................... 41

3.6.10 External accessories ..................................................................................................................................................................................... 53

4. Maintenance and inspection

4.1 Initial inspection ................................................................................................................................................................................................ 73

4.2 Periodical inspection ..........................................................................................................................................................................................77

4.3 Inspection after tripping .................................................................................................................................................................................... 77

4.4 Yardstick service life ..........................................................................................................................................................................................78

4.5 Standard tools and measuring instruments .................................................................................................................................................... 78

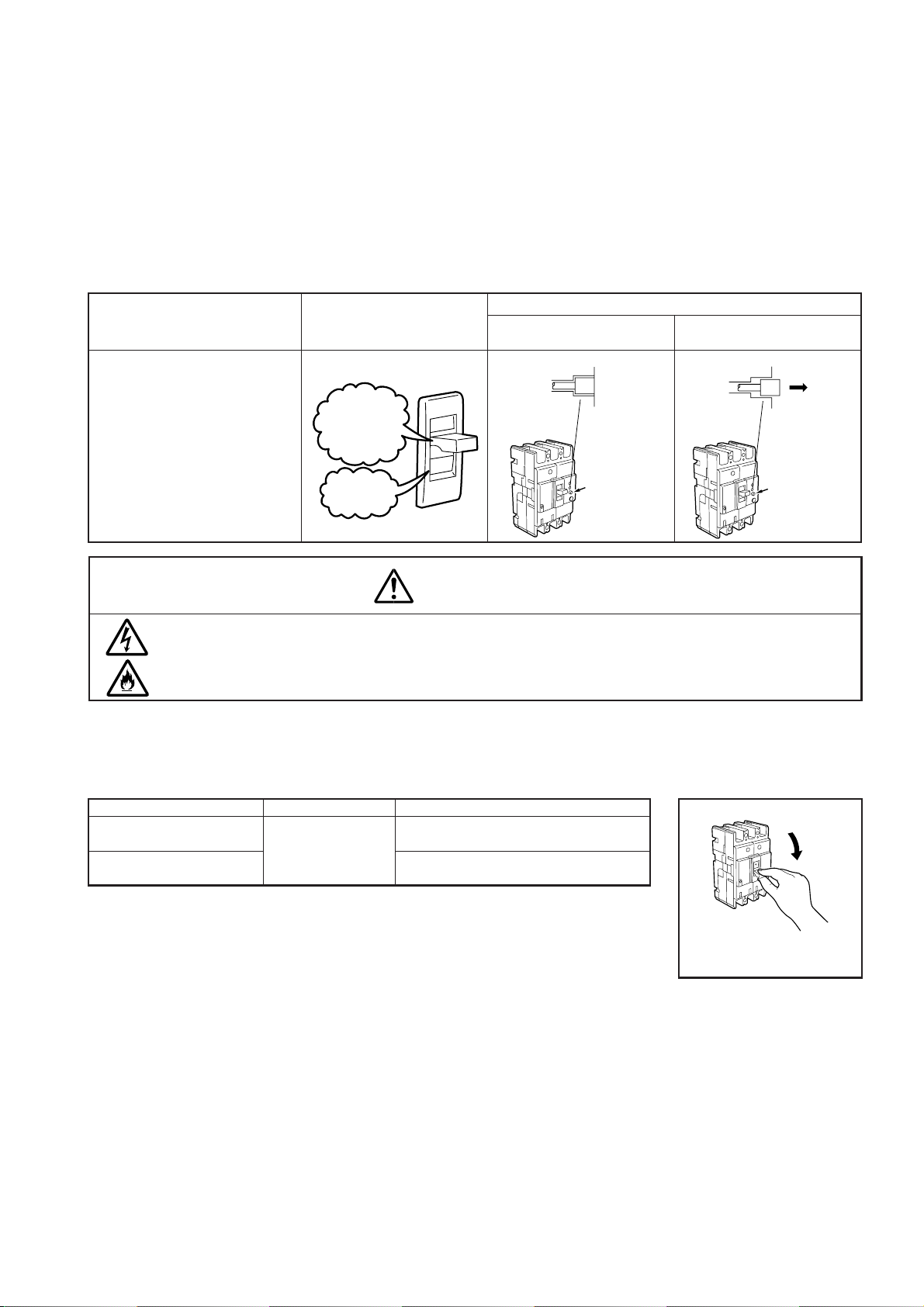

5. Troubleshooting

5.1 Troubleshooting for circuit-breaker proper (MCCB/ELCB) ........................................................................................................................... 79

5.2 Troubleshooting for leakage operation portion .............................................................................................................................................. 80

5.3 Troubleshooting of accessories ........................................................................................................................................................................ 80

5.4 Analysis of unnecessary operation ................................................................................................................................................................. 81

5.4.1 Classification of ELCB operation ................................................................................................................................................................ 81

5.4.2 Detail of operation ..........................................................................................................................................................................................81

6. After-sales service

6.1 Countermeasures to be taken in case of anomaly .......................................................................................................................................... 85

6.2 After-sales service system ................................................................................................................................................................................85

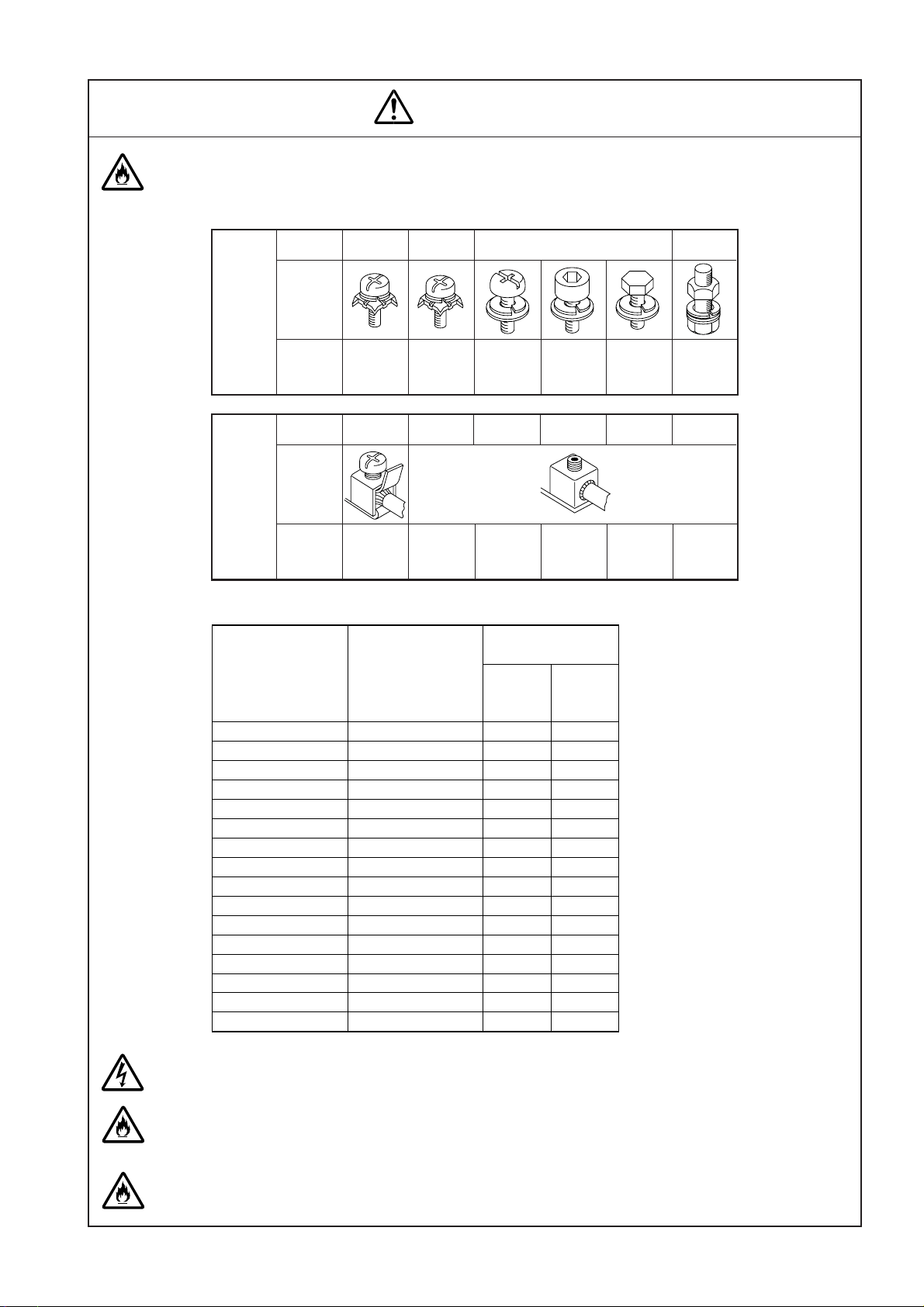

APPENDIX 1 Breaker mounting screws .......................................................................................................................................................................... 86

APPENDIX 2 Standard tightening torque for connections ............................................................................................................................................ 87

APPENDIX 3 Operating force of handle .......................................................................................................................................................................... 88

APPENDIX 4 Service network ...........................................................................................................................................................................................89