Page Number - 5

Form 822844

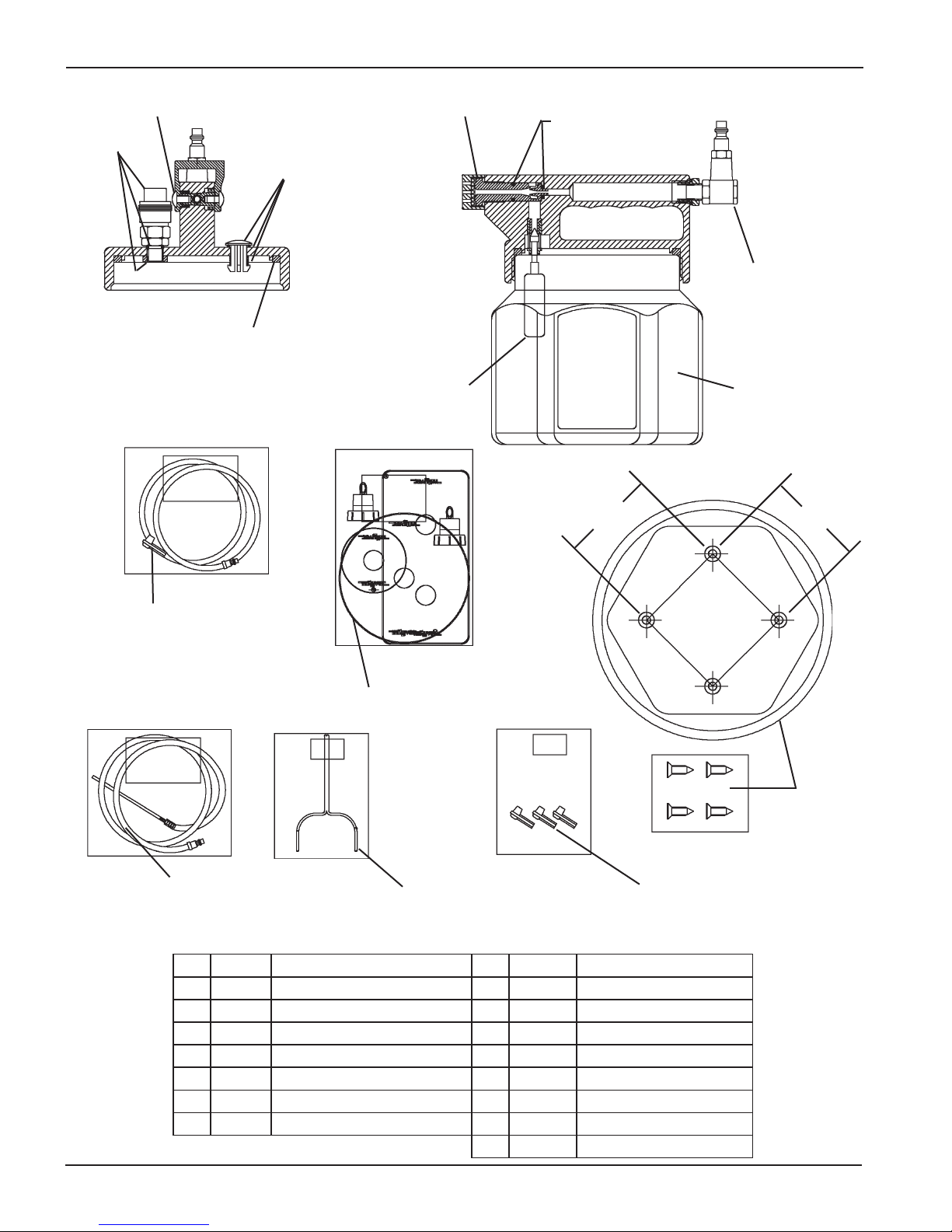

4. Connect clean, regulated (60 psi (4.1 bar) to 150

psi (10.3 bar)) compressed air to the male quick

disconnect nipple attached to the swivel air

inlet, located on one end of the vacuum bleeder

handle.

5. Connect the appropriate end of the evac tube

assembly to the female quick disconnect coupler

located on top of the vacuum bleeder.

6. Insert the other end of the evac tube assembly

into the master cylinder fluid reservoir, and push

the vacuum bleeder throttle forward to start the

vacuum (allow a few seconds for vacuum to

build in the bleeder reservoir before suction oc-

curs). While evacuating the old fluid, stir it up to

break loose and remove any sludge that has ac-

cumulated on the bottom and walls of the master

cylinder.

7. Once all fluid is removed, turn off the bleeder

and refill the master cylinder with new manufac-

turer’s recommended brake fluid.

Vacuum bleed clutch master cylinder,

slave cylinder, and hydraulic lines

Note: Prior to bleeding, ensure the master cyl-

inder is full of new manufacture’s recommended

brake fluid. An automatic master cylinder refill kit

is included with the vacuum bleeder to maintain

the level of new fluid in the master cylinder during

the clutch bleeding process. Follow the instruc-

tions included with the kit to prevent air from being

introduced into the master cylinder pistons, slave

cylinder, and fluid lines while bleeding the hydraulic

clutch system. Additional automatic refill kits are

available from Mityvac.

1. Properly position the vehicle for safe convenient

access to the clutch bleed screw located on the

slave cylinder.

2. Make sure that the slave cylinderbleed screw is

clean.

3. Connect clean, regulated (60 psi (4.1 bar) to 150

psi (10.3 bar)) compressed air to the male quick

disconnect nipple attached to the swivel air

inlet, located on one end of the vacuum bleeder

handle.

4. Connect the appropriate end of the bleed tube

assembly to the female quick disconnect cou-

pler located on top of the vacuum bleeder.

Note: Consult the vehicle manufacturer’s guide-

lines for the proper clutch vacuum bleeding

procedure.

5. Slip the universal bleed screw adapter located

on the opposite end of the bleed tube assembly,

over the nipple of the bleed screw.

6. Operate the vacuum bleeder by pushing the

throttle forward (allow a few seconds for vacuum

to build in the bleeder reservoir before suction

occurs), and with the appropriate wrench, loos-

en/open the bleed screw slightly, until fluid is

visibly draining through the bleed hose and into

the reservoir.

Note: During the bleeding process, as brake

fluid is being vacuumed through the bleed

screw, air will also be sucked into the bleeder

hose from around the bleed screw threads. This

can give the misconception that air is bleeding

from the lines, however it is normal and does

not indicate a malfunction. To prevent or reduce

this introduction of air, coat the bleed screw

threads with silicon grease prior to bleeding.

7. Keep the bleed screw open until new fluid is

visibly flowing through the bleed hose.

8. Close the bleed screw firmly, without over tight-

ening, prior to removing the bleed screw adapter

or shutting off the bleeder.

Note: It is important to ensure that the bleed

screw adapter remains connected to the bleed

screw, and the bleeder is still pulling a vacuum

while the bleed screw is closed. This prevents

air from being sucked back into the slave cylin-

der from around the bleed screw threads, before

the bleed screw is tightened and sealed.

Note: If an automatic refiller such as the one

provided with this unit, is not used, be sure to

periodically check the level and top off the brake

fluid in the master cylinder.

Shop for other automotive tools on our website.