MIZUHOSI 2009 NW0498 Rev E

3

TABLE OF CONTENTS

1.0 INTRODUCTION..................................................................................................................................................5

1.1 General Description.........................................................................................................................................5

1.2 Specifications....................................................................................................................................................5

1.3 Shipping.............................................................................................................................................................5

1.4 Storage ..............................................................................................................................................................6

1.5 Acceptance & Transfer....................................................................................................................................6

1.6 Inspection and Transfer...................................................................................................................................6

2.0 GLOSSARY of TERMS......................................................................................................................................7

3.0 CONTROLS IDENTIFICATION.........................................................................................................................8

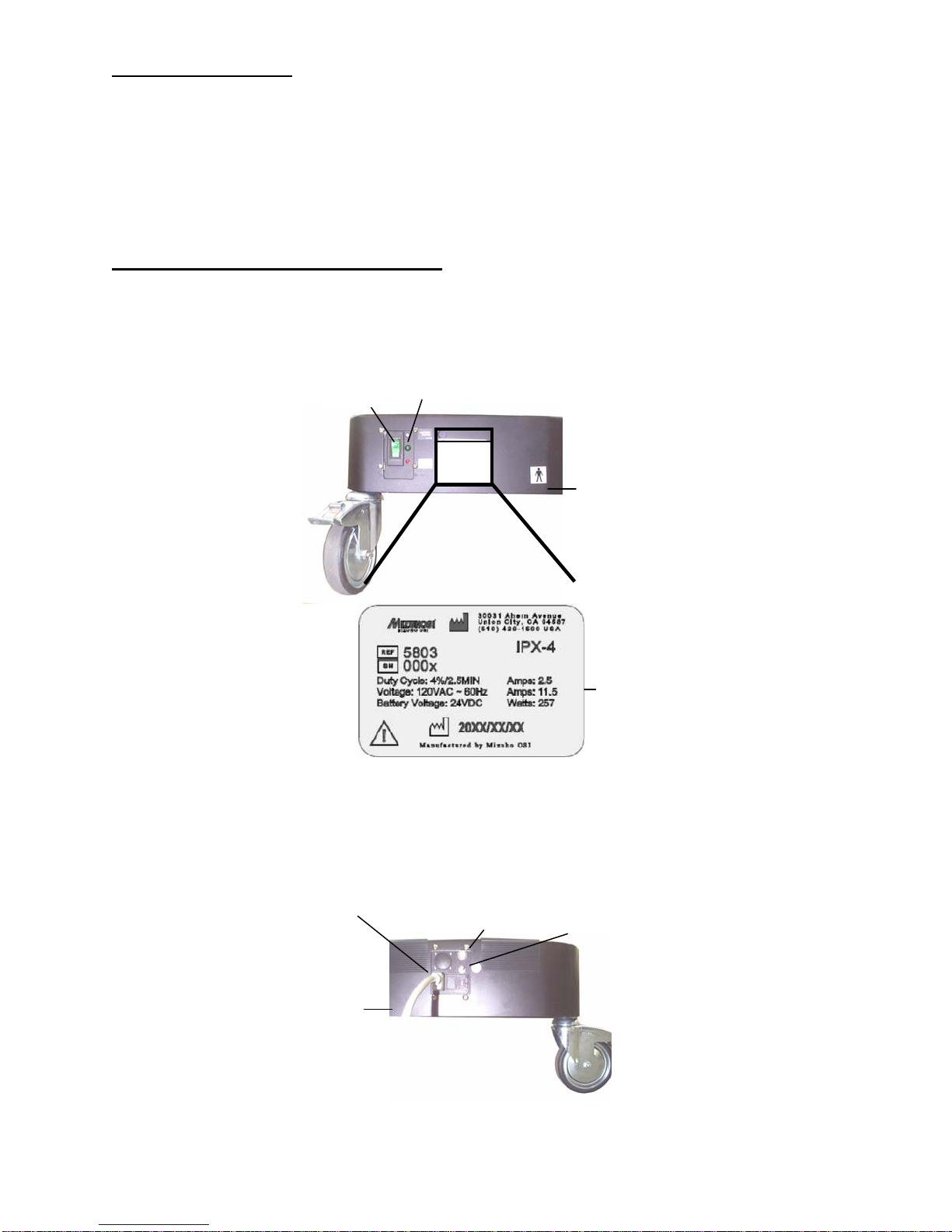

3.1 Base Orientation...............................................................................................................................................9

3.2 Model Number and Serial Number................................................................................................................9

4.0 BASIC OPERATION.........................................................................................................................................10

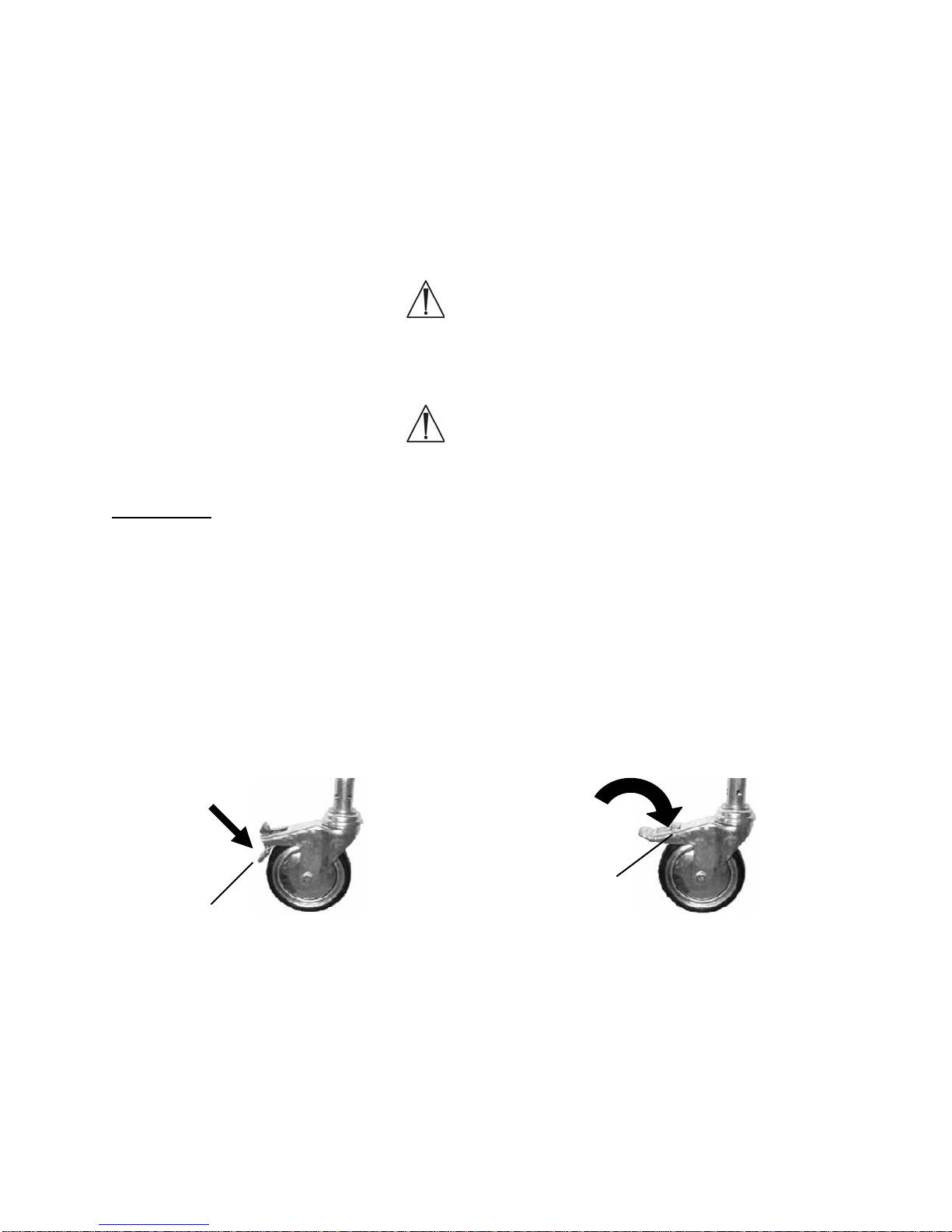

4.1 Casters.............................................................................................................................................................10

4.2 Hand Pendant.................................................................................................................................................11

4.3 5803 Advanced Base Controls.....................................................................................................................13

4.3.1 Rotation Safety Lock ..................................................................................................................................13

4.3.2 180° Rotation Lock Indicator.....................................................................................................................14

4.3.3 Tilt Drive Status Indicator...........................................................................................................................14

4.4 Synchronizing The Lateral Tilt Function......................................................................................................15

4.5 Tabletop Coupling Procedure.......................................................................................................................17

4.6 Patient Transfer..............................................................................................................................................19

4.7 Table Top Coupling Procedure With Top In Place....................................................................................19

4.8 Patient Rotation..............................................................................................................................................20

4.9 Rotation Lock System....................................................................................................................................20

4.10 Rotation Procedure......................................................................................................................................20

4.11 Retracting The Base For Storage..............................................................................................................21

4.12 Table Top on the Base................................................................................................................................22

5.0 PRE-OPERATIONAL FUNCTION CHECK...................................................................................................23

6.0 CLEANING and MAINTENANCE...................................................................................................................24

6.1 Cleaning and Disinfecting.............................................................................................................................24

6.2 Lubrication.......................................................................................................................................................24

6.3 Preventative Maintenance ............................................................................................................................25

7.0 THE ELECTRICAL SYSTEM...........................................................................................................................26

7.1 Power Cord.....................................................................................................................................................26

7.2 ON/OFF Power/Circuit-Breaker Switch.......................................................................................................26

7.3 Power ON / Fault / Battery Status Lights....................................................................................................26

7.4 Battery Recharging........................................................................................................................................26

8.0 TROUBLESHOOTING......................................................................................................................................27

8.1 Electrical System............................................................................................................................................27

8.2 Functional Guide............................................................................................................................................28

9.0 REMOVAL and REPLACEMENT of COMPONENTS.................................................................................30

9.1 Head end Cover .............................................................................................................................................30

9.2 Foot End Cover...............................................................................................................................................31

9.3 Hand Pendant Module...................................................................................................................................31

9.4 Batteries...........................................................................................................................................................32

9.5 Power Supply Replacement.........................................................................................................................34

9.6 Controller Circuit Board Replacement.........................................................................................................34

9.7 On-Off Power Switch / Circuit Breaker Replacement...............................................................................35

9.8 Head End Assembly ......................................................................................................................................35

9.9 Head End Tilt Motor.......................................................................................................................................35

9.10 Foot End Rotation Safety Lock Motor.......................................................................................................35

9.11 Head End or Foot End Column..................................................................................................................36

9.12 Retractable Center Beam...........................................................................................................................36

9.13 Casters ..........................................................................................................................................................36