EN

9

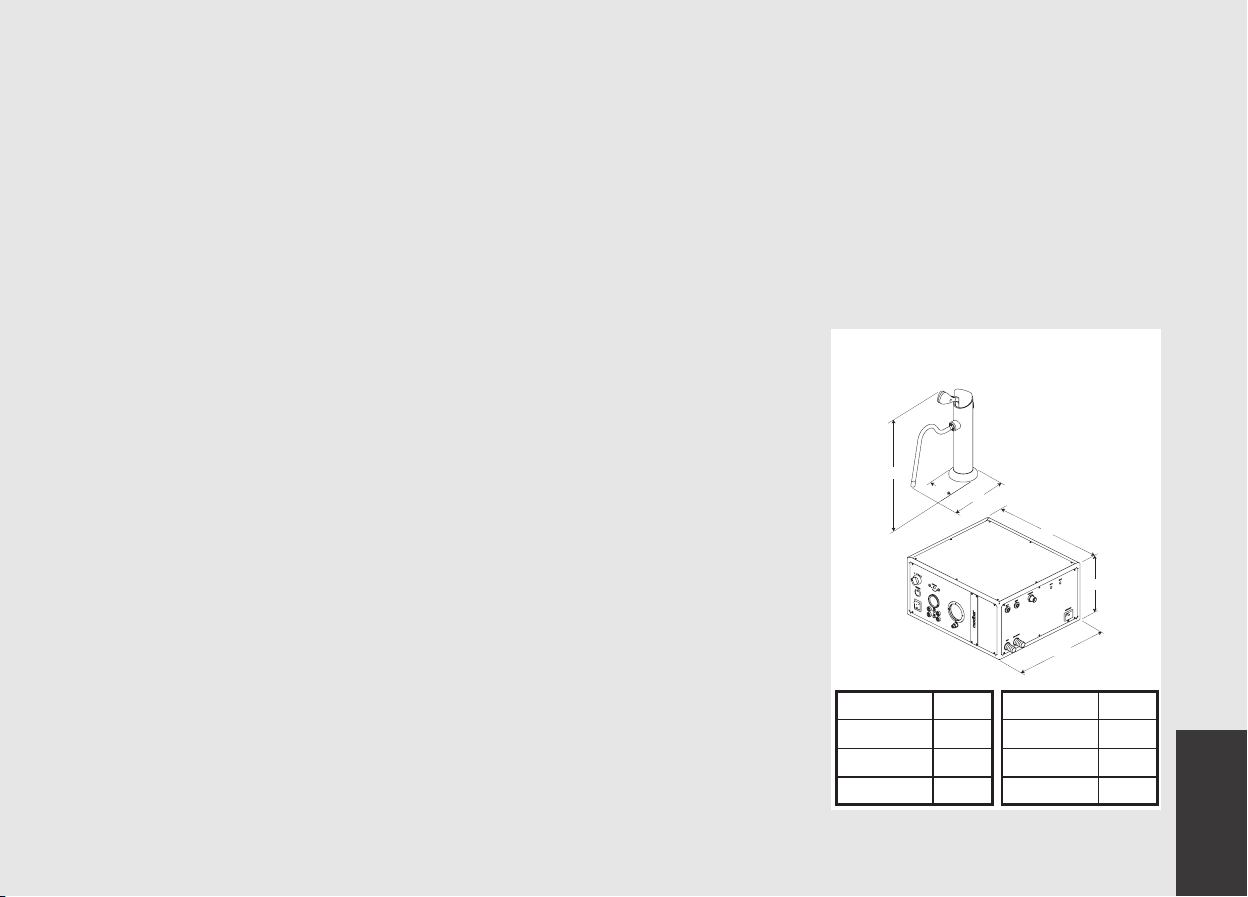

1) General Description

The machine is built in 1 and 2 steam

group versions and is essentially composed

of the following parts:

• Dispensing tap(s).

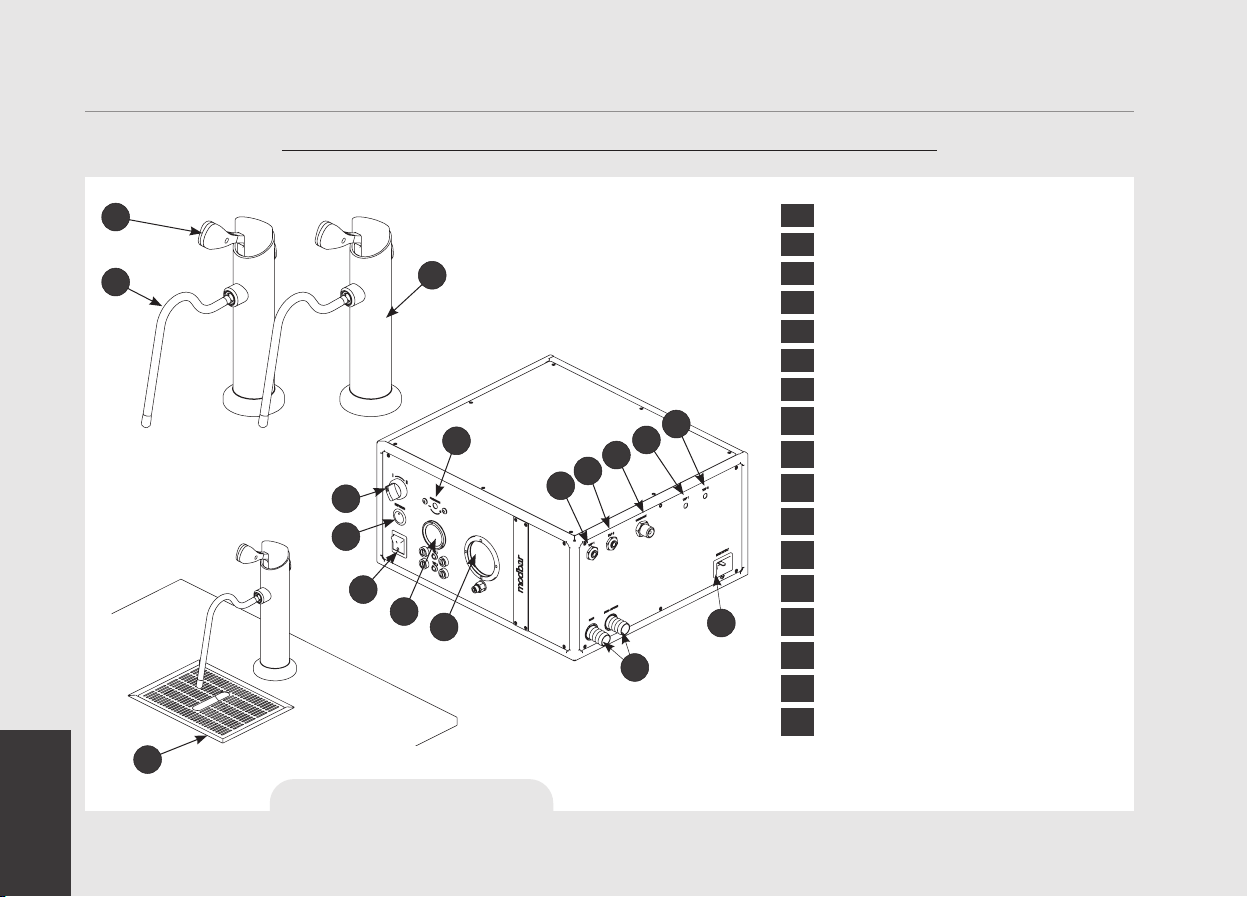

2) Description of the various parts

• Steam Boiler

The Steam Boiler consists of a cylindrical

tank, which is made of AISI 300 series

stainless steel. Each unit is subjected to a

hydraulic test, at a pressure of 6 bar, and

has an operating pressure of 1.7-1.8 bar.

The following is a list of effective volumes

and power ratings according to the number

of groups installed:

1 steam boiler 4,6 liters 3600 Watts

Covers are welded at either end of the

cylindrical tank and on one of them there

is a housing for the water heating element,

which allows the steam boiler to reach

operating pressure within approximately

10 minutes. The steam boiler has various

ttings used for safety devices, for

supplying hot water and steam, and for the

heating element.

It consists of AISI 300 stainless steel

tubes. Heating is accomplished through an

immersion-type plated heating element.

• Operating pressure of 1.7-1.8 bar,

controlled automatically through a

pressure switch.

• The pressure is displayed by means of a

pressure gauge with a scale of 0 to 3 bar.

• Safety device, based on an expansion

type mechanical valve, with counter-acting

spring adjusted to 2.5 bar.

• Testing: hydraulic test at 6 bar performed

on ready-to-use small boilers, at our

factory.

• Dispensing groups

They consist of a precision casting made

of stainless steel. The Modbar steam tap

is operated via a lever handle located on

top of the tap. This handle actuates a

valve that allows steam to pass through

the steam wand. To dispense steam, move

the lever handle from the closed position

to the open position.

• Exterior cover

The exterior consists of painted and

stainless sheet steel panels. To provide

good aesthetics, to optimize ergonometrics

for the operator and to reduce the chance

of damage to a minimum.

•Machine ETL plate:

•Machine CE plate:

MODEL: MFG. DATE:

MAX. PRESSURE: 0.25 MPaCAPACITY: 4.6L

208 Vac / 13A / 2,704W / 60hz. / 1-Phase

220-240 Vac / 14,4A / 3,306W / 60hz. / 1-Phase

READ OPERATING

MANUAL BEFORE USING

THIS EQUIPMENT

WATERSUPPLY:

3.8 l/min

MIN 0.24 MPa - MAX 0.6 MPa

CONFORMS TO UL STD 197

CERTIFIED TO CSA STD C22.2 NO.109

New Steam System 08/01/2018

SERIAL #:

PR000000

MADE IN

ITALY

MODEL: MFG. DATE:

MAX. PRESSURE: 0.25 MPaCAPACITY: 4.6L

220-240 V / 50/60Hz

READ OPERATING

MANUAL BEFORE USING

THIS EQUIPMENT

WATERSUPPLY:

3.8 l/min

MIN 0.24 MPa - MAX 0.6 MPa

New Steam System 01/08/2018

SERIAL #:

PR000000

14.4A / 3306W

MADE IN

ITALY

CONFORMS TO UL STD 197

CERTIFIED TO CSA STD C22.2 NO.109