3

AIR 3-500.3

UNIT LOCATION / INSTALLATION

To Convert Multiply By To Obtain

"W.C. 0.24 kPa

psig 6.893 kPa

°F

(°F-32)x0.555

°C

inches 25.4 mm

feet 0.305 meters

CFM 0.028 m3/min

To Convert Multiply By To Obtain

CFH 1.699 m3/min

Btu/ft30.0374 mJ/m3

pound 0.453 kg

Btu/hr 0.000293 kW/hr

gallons 3.785 liters

psig 27.7 "W.C.

Table 3.1 - SI (Metric) Conversion Factors

Handling

Each unit will be shipped to the site on a wood skid. Whenever

possible, all lifting and handling of the unit should be done with

the packing and skid in position.

When slinging or using a forklift to lift the unit, the support points

shouldbesucientlyaparttogivestabilitywhenlifting.Unless

otherwise noted, the lifting points should be equidistant from the

centerline. Extreme care should be taken not to drop the unit.

Considerable damage can occur to the unit during positioning,

in particular, to the paneling and exterior paint. Use an adequate

number of personnel and the correct tools when moving the unit.

The unit is designed to remain upright so care should be taken

when lifting the unit up steps.

The use of torque screwdrivers on panel, cover or component

mounting screws is not recommended. Hand-start all screws.

If electric drills are used – set at the lowest possible torque.

Preparation

1. Before installation, ensure that the correct electrical power

supply is available for the unit.

2. Each unit requires an independently fused and isolated power

supply.

3. If the installation has multiple units, check that unit

identicationscorrespondwiththenetworkdiagrams.Advise

Modine immediately if discrepancies are noted.

4. Check to make sure that the units will have adequate

installation clearance around them.

5. Note that each unit has a condensate connection at the

rear and suitable provisions should be made for draining. If

multiple units tee into a common drain manifold, the drain

line must be sized to ensure free draining with all the units in

operation.

6. Inspect the wall sleeve installation for gaps that would allow

leakage of outdoor air into the space. All joints and abutments

should be sealed with waterproof sealant.

Drainage

Each unit has an internal condensate drain, terminating

internally to the unit. A 1-3/8" condensate drain hole is available

onthebacksideoftheunit(seeFigure9.1forthelocation).

This must be connected to the main drain system in accordance

with any local codes and general good piping practice.

Electrical

Electrical wiring should be done in accordance with all

applicable national and local codes. It is the responsibility of the

electrical contractor to adhere to such codes. The warranty will

bevoidedifwiringisnotinaccordancewiththespecicationsof

the unit. Modine recommends using copper conductors only.

All power supply wiring must be capable of carrying the

maximum current load under no fault conditions at the stipulated

voltages.Careshouldbetakentoavoidsignicantvoltage

drops.

A 1.38" diameter knockout for power connection is provided at

the top of the unit.

Plumbing

If the unit provided has a hot water or steam coil, all plumbing

connectionsintheeldmustbecompliantwithlocalbuilding

codes.Whenleaktestingconnectionsintheeld,components

will be leak tight up to 125PSIG water pressure, or 50PSIG of

Nitrogen.

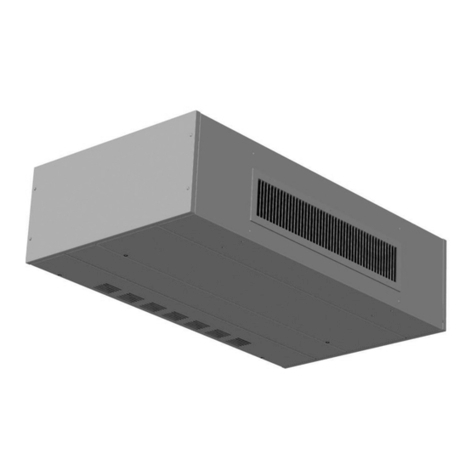

INSTALLATION

The instructions detailed below are for the Installation of a

“Standard” unit. Accommodations and adjustments will be

required for the usage of additional unit accessories. Should

assistance be required for the installation of these additional

items, consult Modine at the phone number listed on the back

cover of this manual.

1.Checktheoorforlevelnessandchecktoensurethewallis

atarightangletotheoor.Shouldtherebeanyirregularity,

the placement of foam tape on the outside edges of the unit

willllthegapsbetweentheunitandthewall,allowingforthe

use of a sealant, to create a smooth transition from the unit to

the wall.

2. After adjusting for any irregularity in the location site, locate

thepositionfortheoormountingbolts(seegures8.1-11.1).

Drill the appropriate sized holes, for the fasteners that are to

be utilized, and insert the anchors that are to be used.

3. Remove the backing strip from the gasket on the wall sleeve.

Place the unit in the correct location, ensuring a tight seal with

the wall sleeve and the wall.

4. Check to ensure that the unit is plumb and level in both

directions. If adjustment is necessary, Modine recommends

the placement of metal shims in the outer most corners of the

base.

5. The cabinet must be secured to either the back wall or the

oor.Theoorofthecabinethasfourpre-punchedholesand

the back of the cabinet has a hole on each side. The type of

materialsusedfortheoorandthewallswilldeterminethe

typeoffastenertouse.Ifunitismountedonaoorstand,use

mounting hardware supplied by the factory, otherwise Modine

recommends the use of 1/2" diameter fasteners with 1-1/2"

diameterwashers.Securingthecabinettotheoororwall

helps to reduce movement and noise due to vibration.

6. Once the cabinet is secured, seal any gaps caused by

unevenoorsorwallsurfacestopreventnoisefromescaping

through these openings.

7. Make the condensate drain connection and the necessary

electrical connections to the unit.

8.Whenconnectingaductangeorductworkdirectlytothetop

of the unit, do not drill or put screws into the area immediately

surroundingthesupplyairopening(s).SeeFigure4.1

(dimensionsininches).Holesinthetopofthecabinet

indicate recommended mounting locations.

DANGER

Appliances must not be installed where they may be exposed to

potentiallyexplosiveorammableatmosphere.

UNIT LOCATION