9

INSTALLATION TERMS AND CONDITIONS

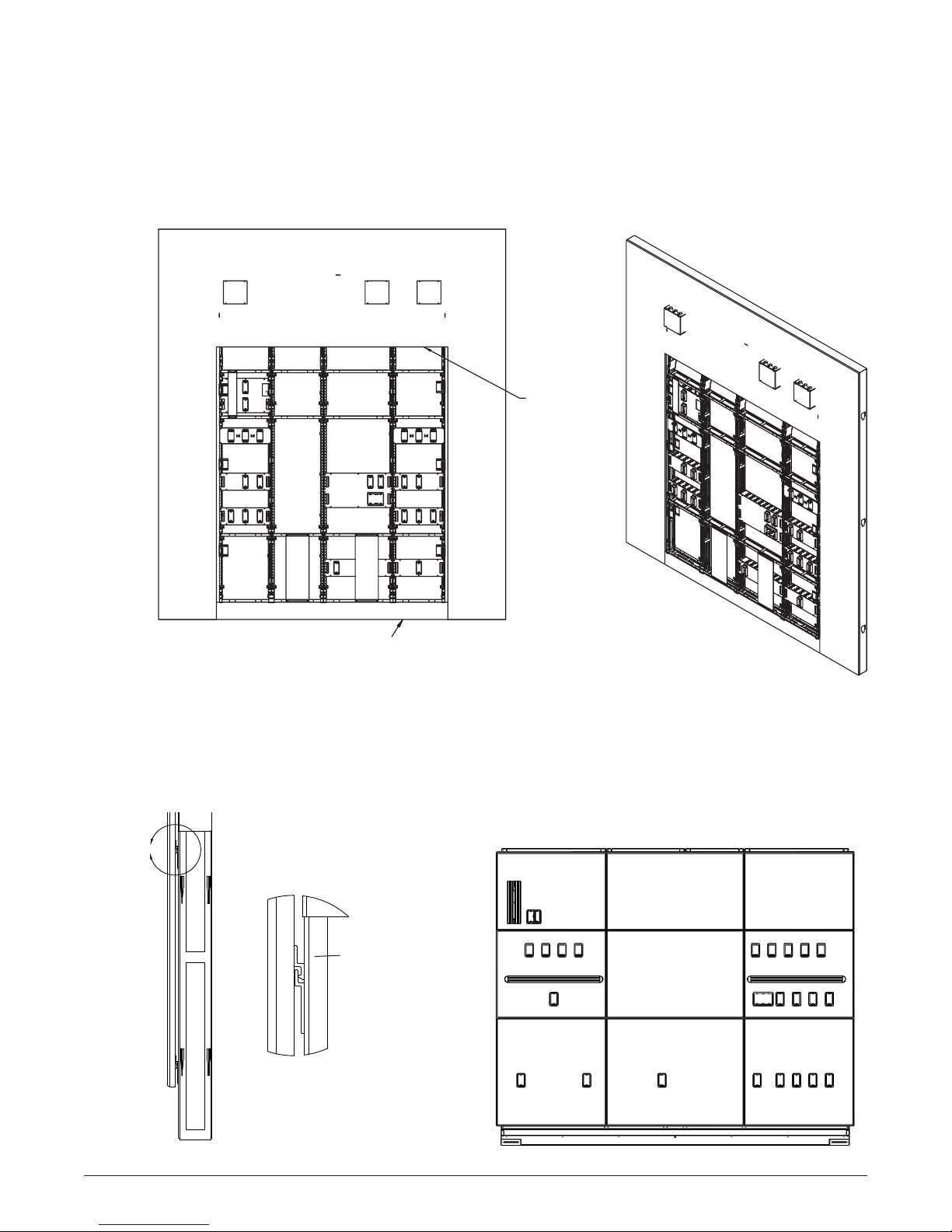

EachModularServicesunit,orunitsection,shallbecompletelypre-wiredfornormal,emergencyandlowvoltage

according to the approved submittal. Communication devices and wiring shall be supplied by others. These

devices include nurse call, television, code blue, telephone, monitor jacks, etc.

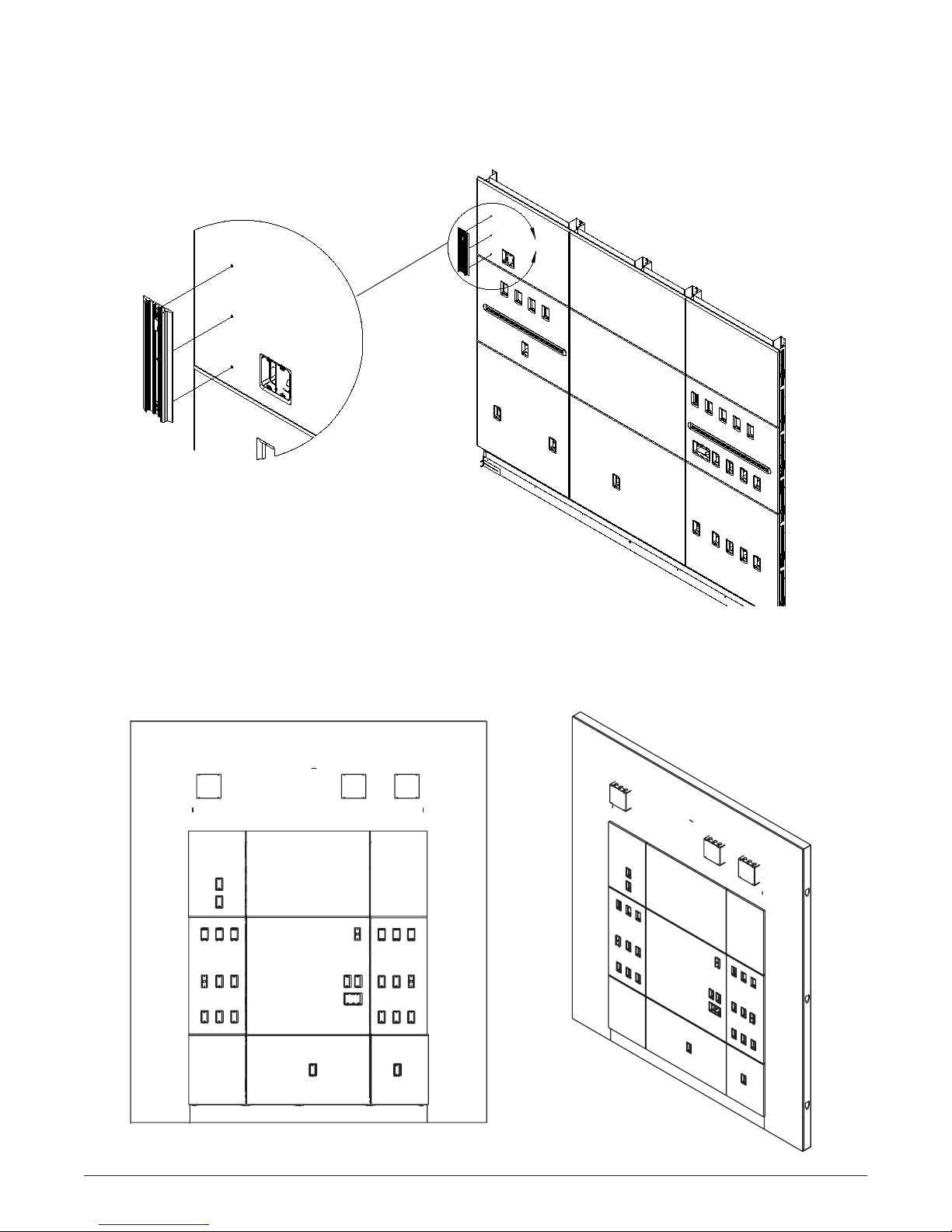

The customer shall be responsible for all incoming electrical conduits, wiring hook-up of electrical services, and if

applicable, interconnect wiring between sections. All hardware light fixtures shall be installed, connected and

lamped by contractor. After installation is complete, the customer shall test equipment functions, as well as

electricalreceptaclesandground,inaccordancewiththeNationalElectricalCode.

Medical gas contractor shall be responsible for incoming piping and hook-up of all medical gas services. The

medical gas contractor shall be responsible for purging, pressure testing, gas identification, and system

certification in accordance with NFPA 99.

Modular Services Company shall have no responsibility or liability for delays, however caused. Owner shall hold

Modular Services harmless from damages or injury related to any failure or neglect of owner, its employees,

agents or licensees. Modular Services shall not be liable for consequential damages; makes no warranties,

expressed or implied; and assumes no obligation other than those expressly contained herein.

WARRANTY

Modular Services Company warrants that all equipment assemblies shall be free from defects in material and

workmanship for a period of 12 months from date of the owner’s acceptance to the installing contractor or the

date the equipment is put into service, whichever comes first. Warranty excludes electric lamps and/or any

material not furnished by Modular Services. Warranty does not cover damage due to improper installation

and/or abuse.

It is the responsibility of the customer to report any noted product deficiencies to Modular Services immediately

upon discovery. It is the responsibility of Modular Services to expediently resolve the discrepancy. Any modification

made to the product without the written authorization from Modular Services will void this warranty.

Also, in the event product modifications or repairs are made without the written consent of Modular Services,

Modular Services shall not be held liable for any cost associated with the modification or repair.

There are no warranties of fitness which extend beyond the description on the face hereof.

DCN# 50-1077 — Rev. 6/2016©2016 Modular Services Company

500E.BrittonRd.•OklahomaCity,OK73114

Tel:800.687.0938•Fax:405.528.0368

www.modularservices.com

info@modularservices.com