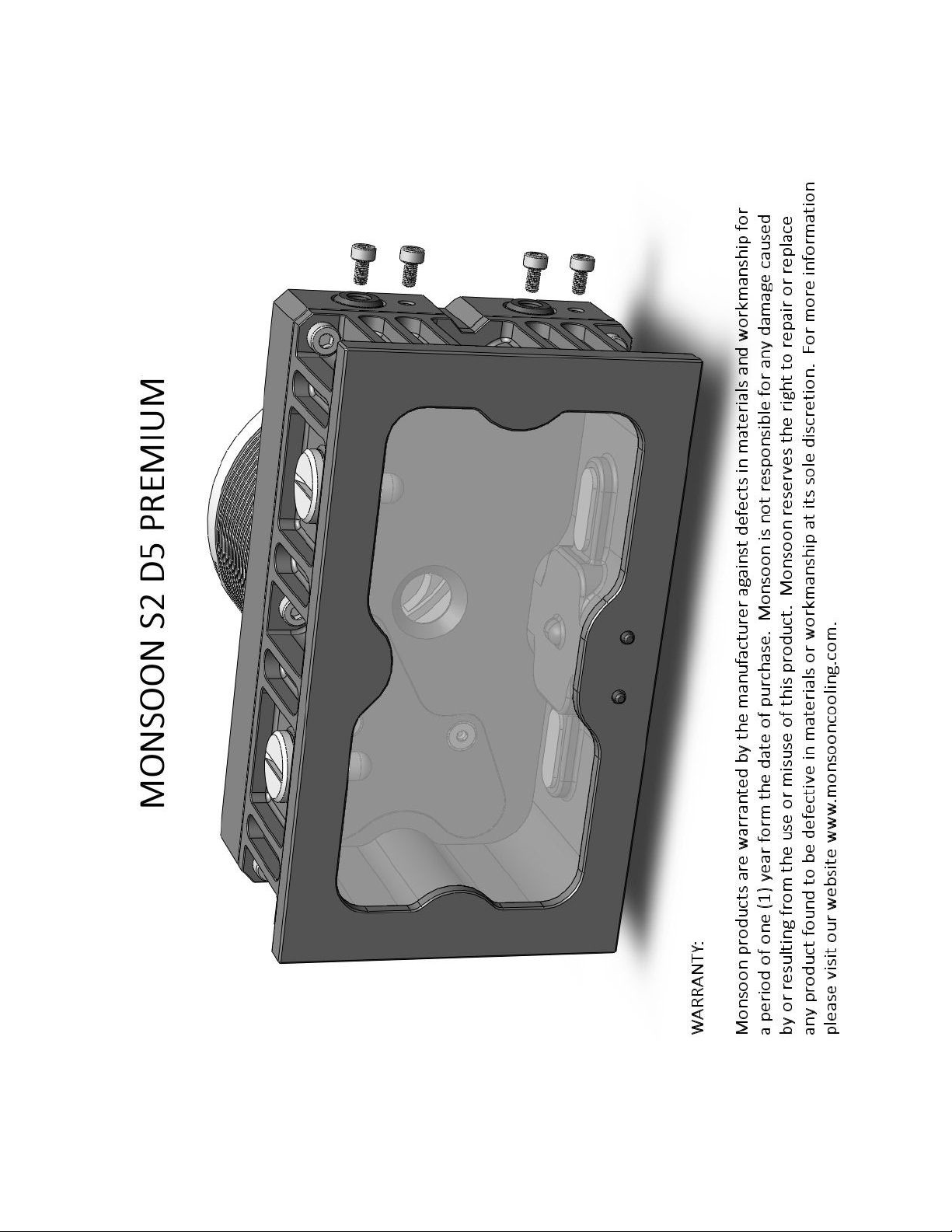

Monsoon S2 Dual Bay Reservoir Instructions: M2-D5P

CAUTION: our new reservoir has arrived assembled and ready for pump installation. We do

not recommend that you disassemble the reservoir unless necessary or you have previous

mechanical experience. Novice users or those unfamiliar with threads cut in plastic parts may

have a tendency to over tighten screws and could possibly strip out the threads. Every effort has

been made to provide the strongest threads possible within the limitations of the materials used.

To ensure all threads are in working order, we populate all threaded holes and ports prior to

shipping. Monsoon is not responsible for damage caused by over tightening of screws or fittings

and all returned parts will be inspected prior to the resolution of an RMA. If you have damaged

threads, replacement parts are available at your favorite reseller or directly from Monsoon.

Monsoon (like all manufacturers) assumes no responsibility for damage to your system caused by

misuse or leaks. It is the end user's responsibility to test for leaks prior to installation into their

system and we highly recommend the use of a non-conductive fluid such as distilled water.

Although we try to test our products for compatibility with every cooling fluid available, it is the

responsibility of the end user to ensure that the fluid they choose to use is safe for use in this

reservoir. Materials used include plastics such as glass filled nylons, PVC, and acrylic. Metals

used include Aluminum (not usually in contact with fluid), Brass, and SAE 316 Stainless. Rubber

used in O rings is premium Silicone.

BOX CONTENTS:

1. Assembled reservoir x 1

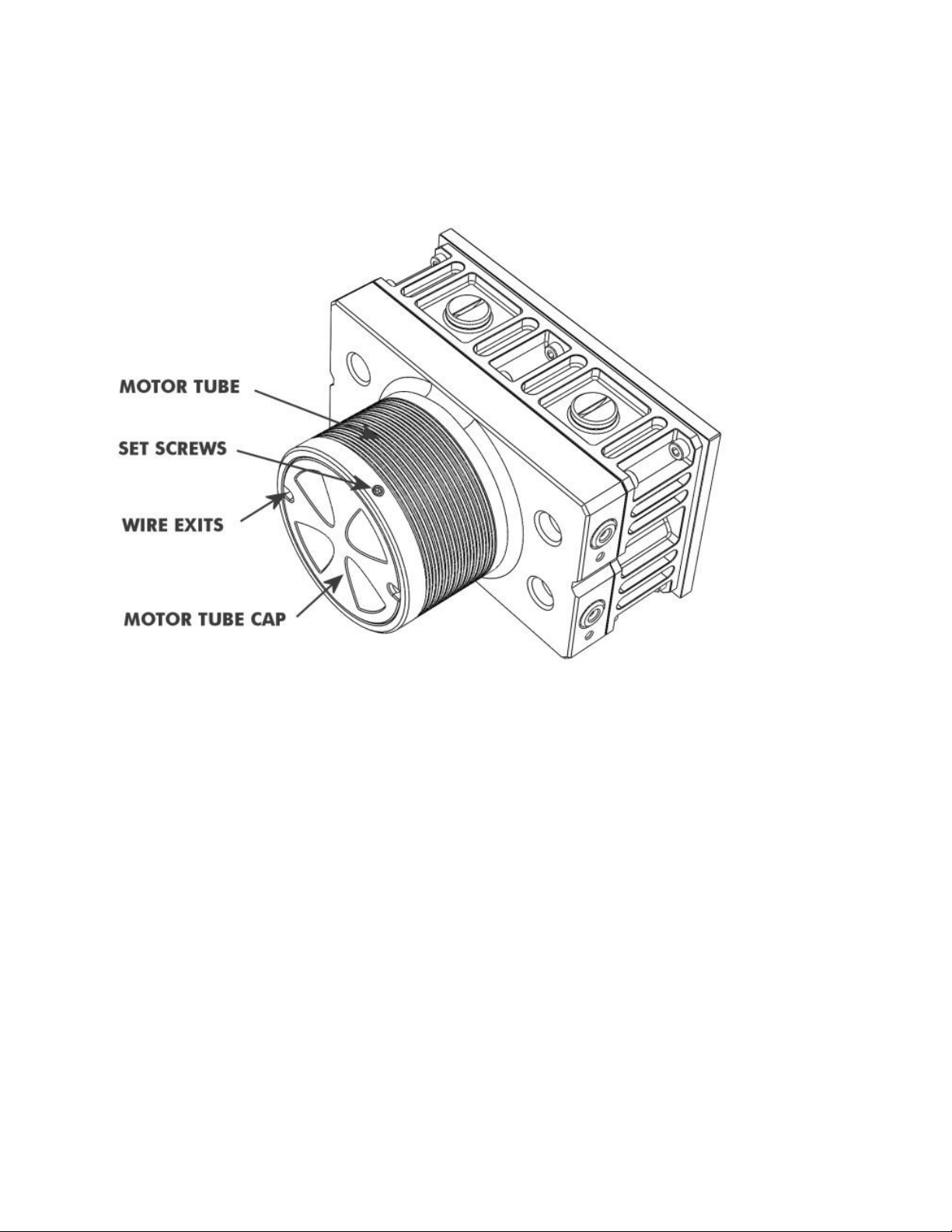

2. Machined aluminum motor mounting tube x 1

3. Machined aluminum motor mounting tube cap x 1

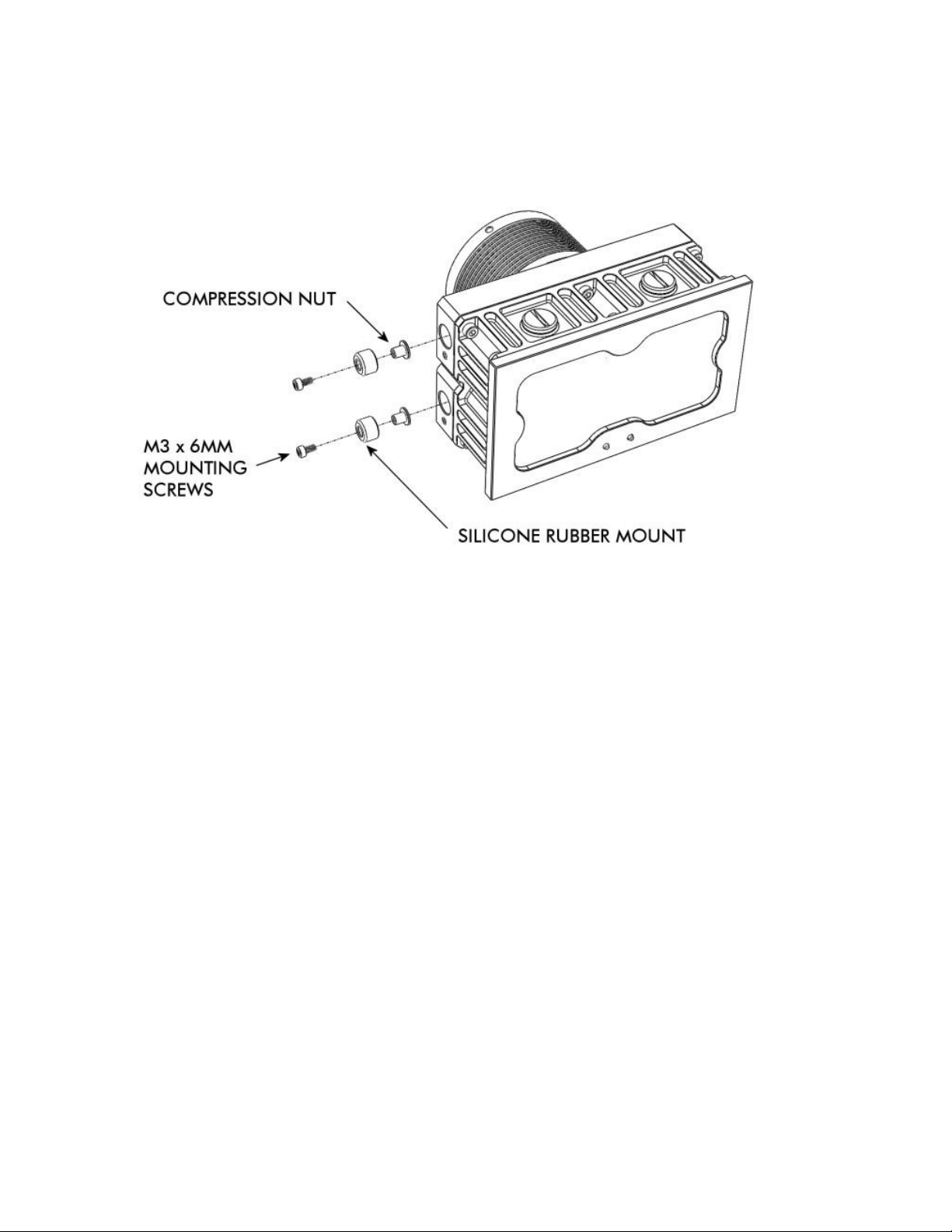

4. M3 x 6mm stainless case mounting screws x 8

5. M3 stainless compression nuts or case mounting x 4

6. M3 black nylon washers or case mounting x 8

7. M4 x 4mm stainless motor tube cap set screws x 2

8. G ¼ machined brass plugs x 4

9. Limited time only—Monsoon Silver Bullet Antimicrobial plugs x 2

10. Allen wrenches x 3

Please take a moment to look over your new reservoir and make sure and con irm all the parts listed

above are present.

PUMP MOUNTING:

Since your reservoir ships with the machined aluminum pump mounting tube already installed onto the

reservoir body, it is a good idea to rotate the mounting tube back and orth 3 or 4 turns be ore removing

till you get an idea o how it “ eels” when threaded on correctly. Because the pump mounting tube has

a large diameter with ine threads (M70 x 1mm) it is easier than normal to cross thread (locking the

threads together in an uneven way) so extra care should be taken to ensure that you're threading the

pump mounting tube on correctly.

PAGE 1