4

Commissioning

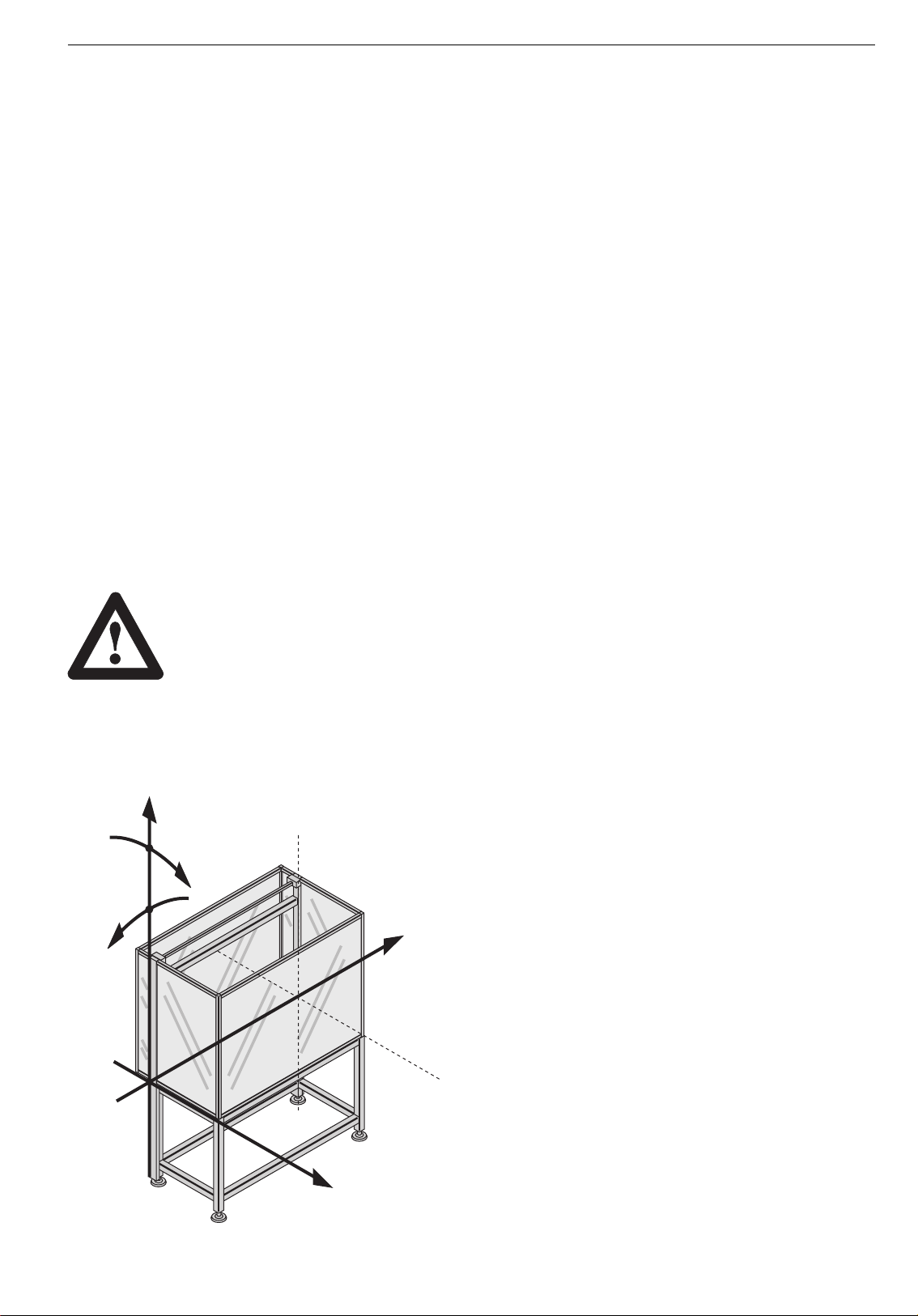

Transport Guard

In the state as delivered, every pillar of the protective hood is locked in its clo-

sed position by transport guard elements, which prevent the supporting spars

(20, Fig.16) from being moved.

Every time a hood is transported these guards must be fitted to secure the

moving parts.

Fitting the transport guards

On both pillars of the hood proceed as follows:

•If the columns are equipped with drop guards (43236, Fig. 12), the drop

guards must be secured by mounting the assembly aids (45459, Fig. 12) to

prevent unintentional catching.

•Move the supporting spar (20 in Fig.16) down and push the rod (120,

Fig.16) through the holes provided for it in the spar until it projects about

15 mm out at both ends. The guide roller holder (30, Fig.16) located bet-

ween the stop (230, Fig.16) of the supporting spar and the inserted rod

(120, Fig.16) secures the spar.

•To fix the counterweights of each pillar insert the rod (130, Fig.16) through

the hole through the bearing block (10, Fig.16) until it strikes the counter-

weight. The rod is then secured by tightening the screw (190, Fig.16).

To remove the transport guard

Caution: Before removing the transport guard, make sure the hood is properly

attached to the supporting spars (20, Fig.16) and that half the weight of the

hood is equal to the mass of the counterweight of each pillar to within 2 kg.

•Undo screw (190, Fig.16) so that the rod (130, Fig.16) can be pulled out at

the top.

•Pull out the rod (120, Fig.16).

•If the columns are equipped with drop guards (43236, Fig. 12), the assembly

aids (45459, Fig. 12) must be removed by loosening and unscrewing the two

M5 screws.