When

thehandle

barisin

tnansport

location,

fheclufch

controllever

will only operofe by pulling

the lever

bock.This

engoges

the driveto the wheels

ond the

tiller movesforword of tronsporl

speed. When re-

leosed,

fhecontrolleverrefurns

to neulrol.

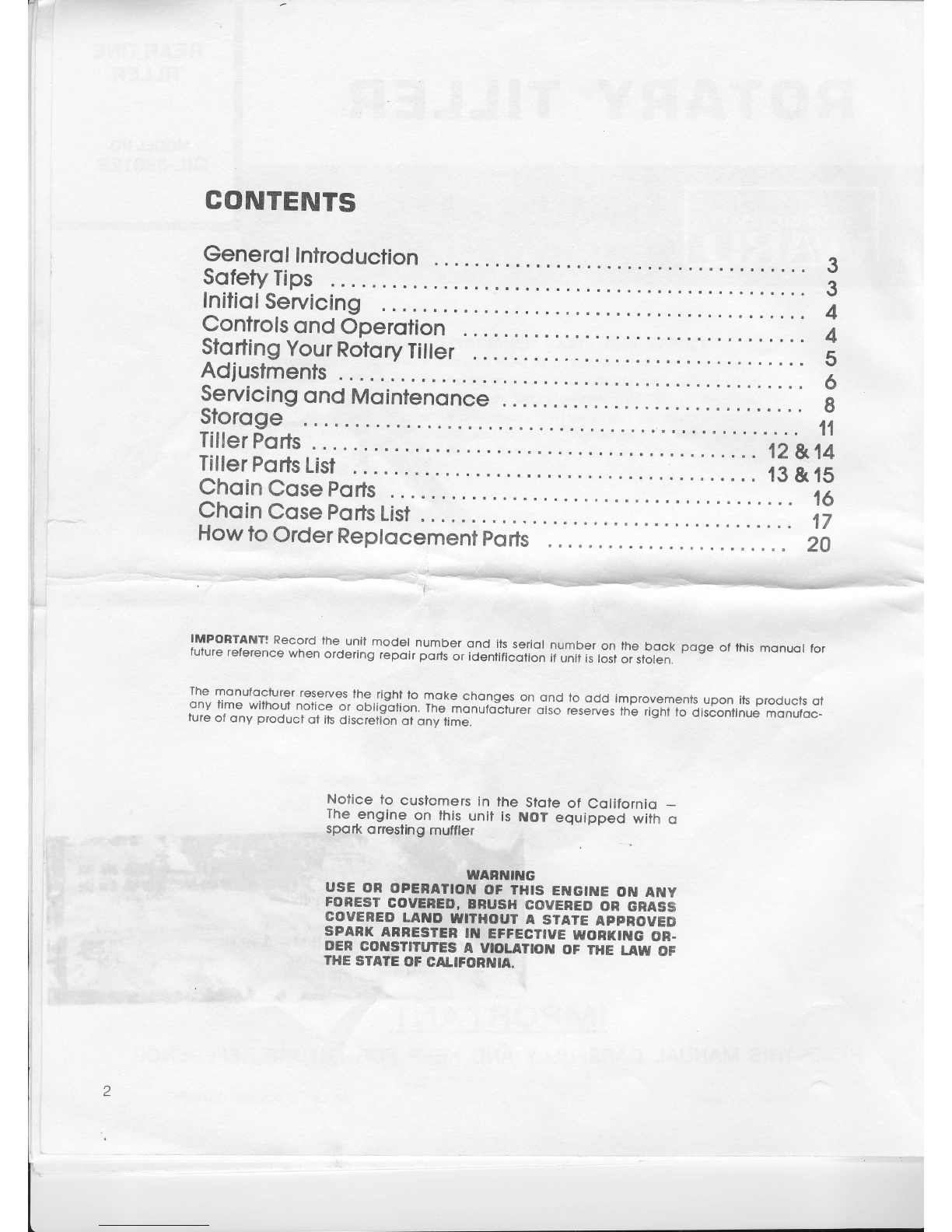

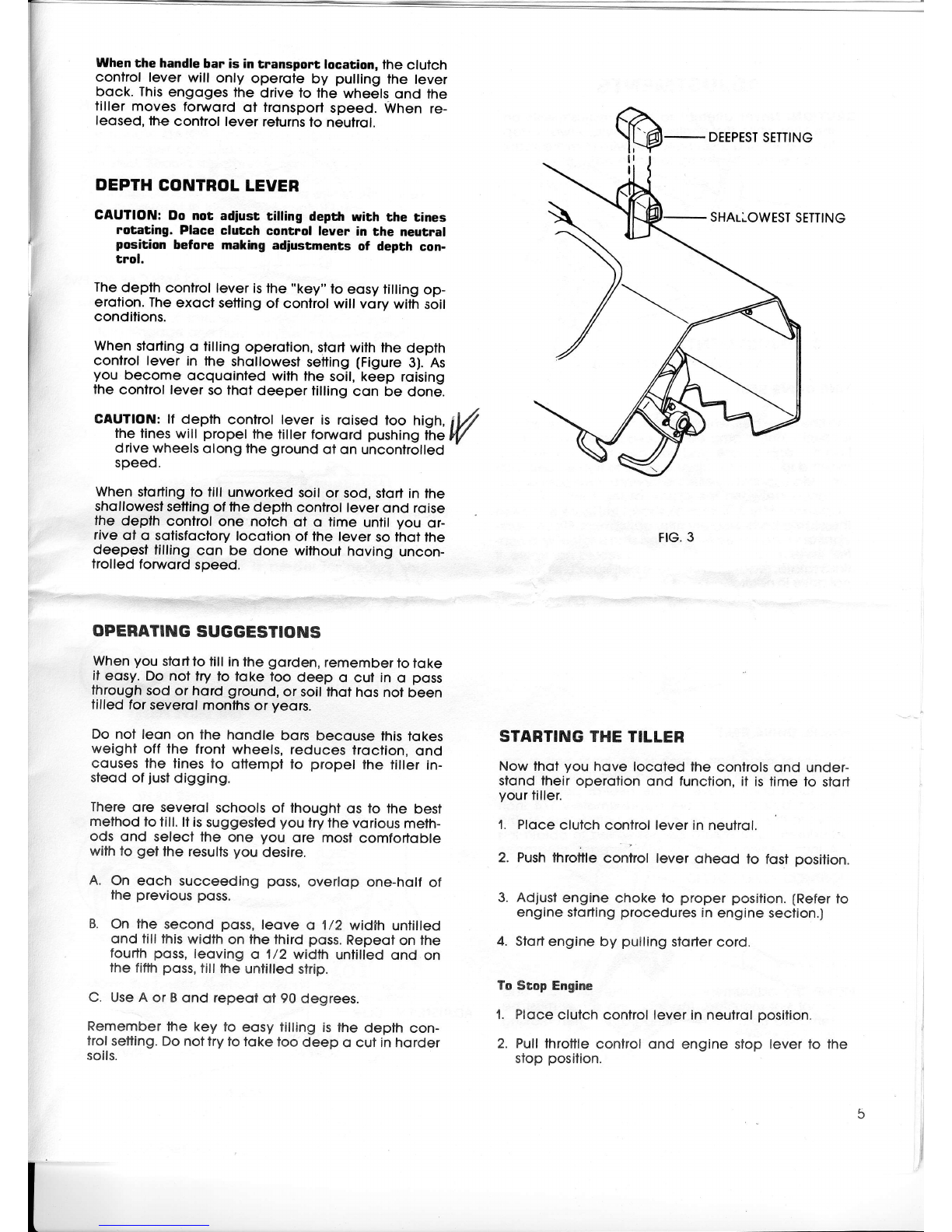

DEPTH

CONTROL

LEVER

GAUTION:

Do nor adiust rilling depthwfth rhe tines

rotatang.

Place

clutch control leyerin the neutral

position before makhrg

adiustmentsof depth con-

trol.

The

depth conirollever

isthe"key"to eosytillingop-

erotion.The

exoct setting

of controlwill vorywilh soil

condilions.

When

storling

o tilling operotion,

stortwiththe depth

confrol lever in lhe shollowesf

setting

(Figure

3).As

you become ocquointedwith

thesoil,

keep roising

thecontrollever

sothofdeepertilling

con be done.

CAUTfON:ff depth control lever is roised loo high,

iV

thelineswill propel the tillerfonruord

pushing

the

lV

drivewheels

olong

the

ground

ofon uncontrolled

speed.

When

sfortingto till unworked

soilor sod,sfortinthe

shqllowest

setting

offhedepth confrollever

ond roise

lhe depth control one notch ol o time unlil you or-

riveol o sofistocfory

locolion of the leversothotthe

deepest

tilling

con be done withouthovinguncon-

frolledfonvordspeed.

OPEBATING SUGGESTIONS

When

you

slortfotill

inthe

gorden,

remember

to

toke

it eosy.Do nol lry to loke too deep o cul in o poss

through

sodor hord ground,

or soilthothosnolbeen

tilled forseverol

monfhs

or yeors.

Donol leon on the hondle borsbecouse

fhistokes

weight off the front

wheels,reducestroction,

ond

cousesthe tines

to ottempl to propel the filler in-

steodofjust

digging.

There

ore severolschoolsof thoughtos to the best

method

totill.ltis

suggested

youlrythevorious

meth-

ods ond selectthe one you ore most

comfortoble

withlo getlhe resulfs

you desire.

A. On eoch succeeding poss,

overlop one-holf

of

theprevious

poss.

B. On the second poss,

leove o 1/2 width untilled

ond tilllhis

width

onlhethird

poss.

Repeot

onihe

fourth

poss,

leovingo 1/2 widthuntilledond on

thefiflh

poss,

tilltheuntilled

strip.

C. Use

A or B

ond repeoi ot 90degrees.

Remember

the key to eosytillingisthe depth con-

trol

setting.Do

nottrylotoke

loodeep o cutinhorder

soils.

FIG.

3

STARTING THE TILLER

Nowthotyouhove locotedthecontrolsond under-

sfondlheiroperotion

ond function,il is

timeto stort

your

tiller.

1. Ploce

clutch

confrolleverinneulrol.

2. Push

throttle

control lever oheod to fosl position.

3. Adjust

enginechokelo properposilion.

(Refer

to

engineslorting

procedures

inengineseclion.)

4. Slort

engineby pulling

slorler

cord.

ToStopEngine

1. Ploce

clutch

control

lever

inneutrol

position.

2. Pull

fhrottle

controlond engine slop lever

to the

stopposilion.

SHAULOWEST

SETTING