MoonLite High Resolution Stepper Motor

MoonLite’s high resolution stepper motor option comes in three configurations.

•Stepper motor only or stand alone for $190.00 (customer pro ides controller)

•Stepper motor with MoonLite Mini V2 Controller for $440.00 (mini V2 controller by itself is $250.00)

•Stepper motor with MoonLite Dual Port DRO Display Focus Controller for $685.00 (controller by itself is

$495.00)

MoonLite’s high resolution stepper motor options use a premium, low backlash Hurst stepper motor. This pro ides ery

fine .00016” resolution (full step) and accurate position repeatability required for today’s high end imaging systems. The

stepper motor can also be ran in half step mode pro iding .00008” resolution, but it is recommended to run in full step

mode with most ASCOM software. The high resolution stepper motor is offered on all single rate focuser configurations.

It has such a fine ariable rate that the reduction unit is not needed, so it is not offered on dual rate focusers. Adding a

stepper motor gi es the CS and CF focusers a 7 lb. lifting capacity. Large format focusers such as the CRL, CSL, and

CFL are rated at 8 lb. ertical lifting capacity. Our small CR focuser has a 6 lb. load rating once installed. The stepper

motor option features an adjustable slip clutch system so the focuser can be used manually or operated on motor at the

same time. The stepper motor’s 9-pin DBA connector is compatible with other stepper motor controllers such as ROBO

focus, as well as MoonLite’s controllers. A controller of some type must be used; the stepper motor cannot be directly

connected to a PC.

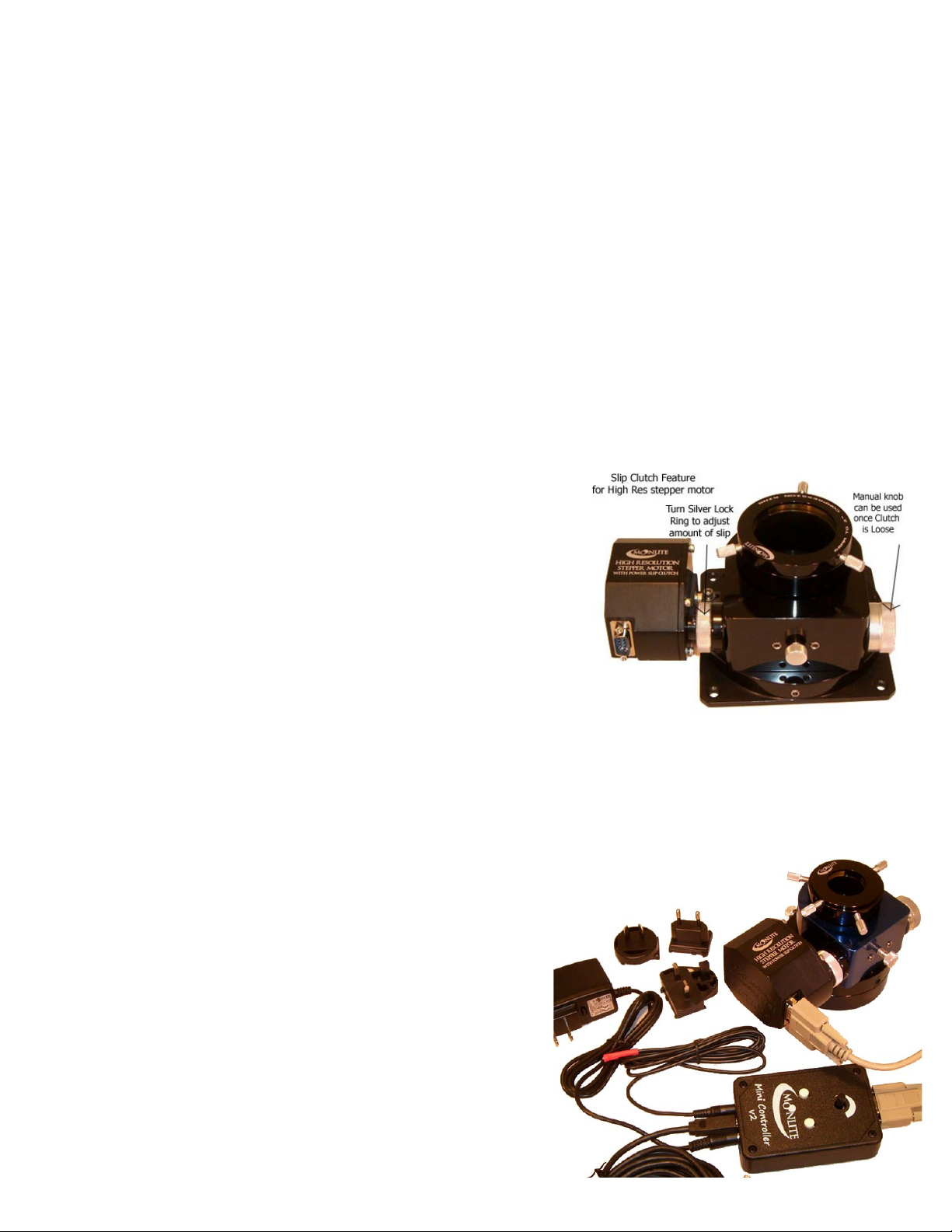

The amount of slip can be adjusted on the slip clutch by adjusting the

tightness of the slip clutch ring. For manual knob operation of the focuser,

turn the sil er knurled ring loose. For motor operation of the focuser,

tighten the sil er knurled ring. To adjust the knurled rings tension, it helps

to hold the manual knob still with your right hand and turn the clutch ring

with your left hand. Holding the manual knob in place will keep the shaft

from turning, allowing the clutch ring to tighten/loosen the clutch Note:

No damage will be done if the focuser motor continues to run past the

mechanical stops of the drawtubes tra el. E en if the clutch is tight, it will

simply slip when the tra el runs out.

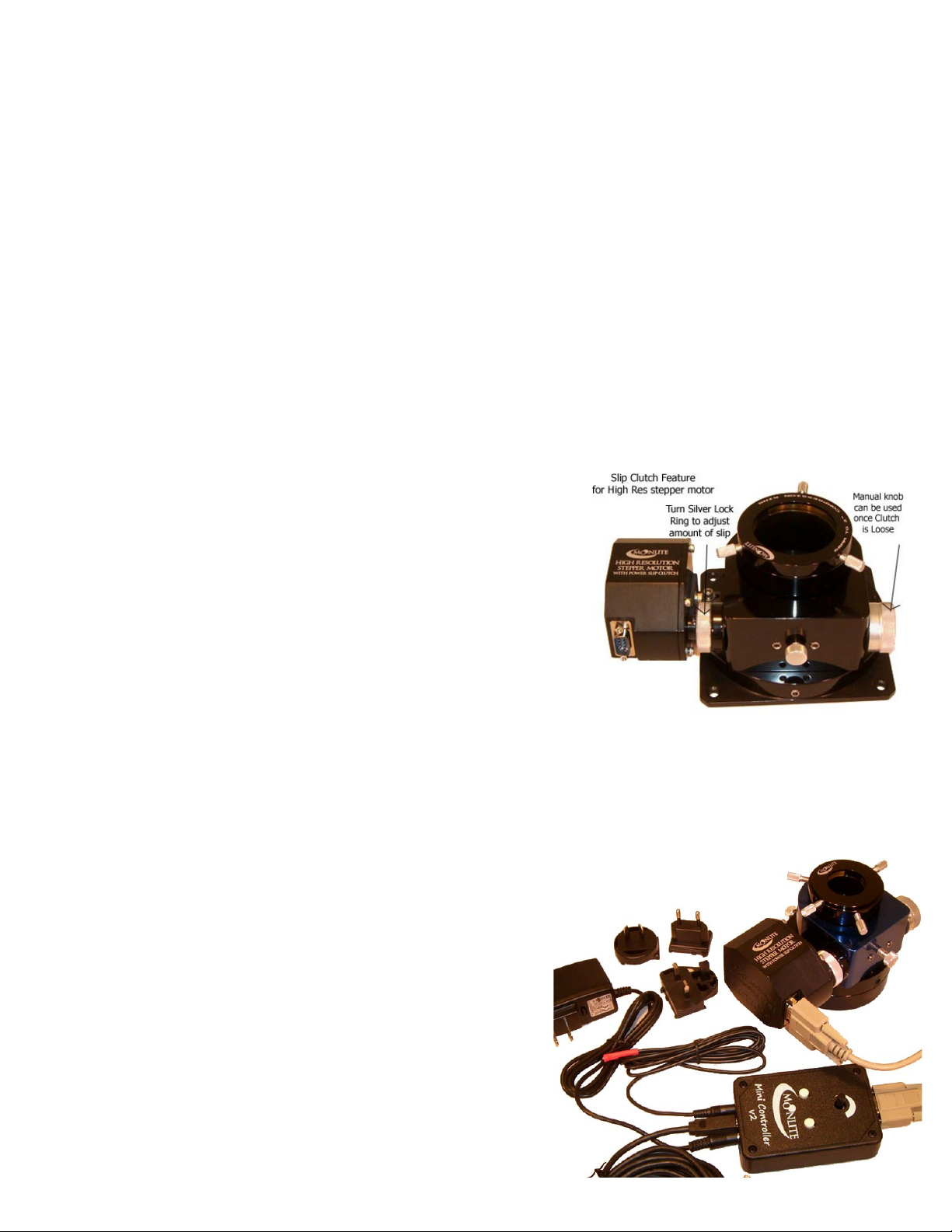

In most cases, the stepper motor option is picked at the time of focuser purchase; howe er, we do offer a user installed

High Resolution Stepper Motor Kit for existing MoonLite focusers. The kit comes with different mounting brackets to fit

different MoonLite focuser models. Please see our web site for additional kit information showing the different brackets

a ailable for different model MoonLite focusers.

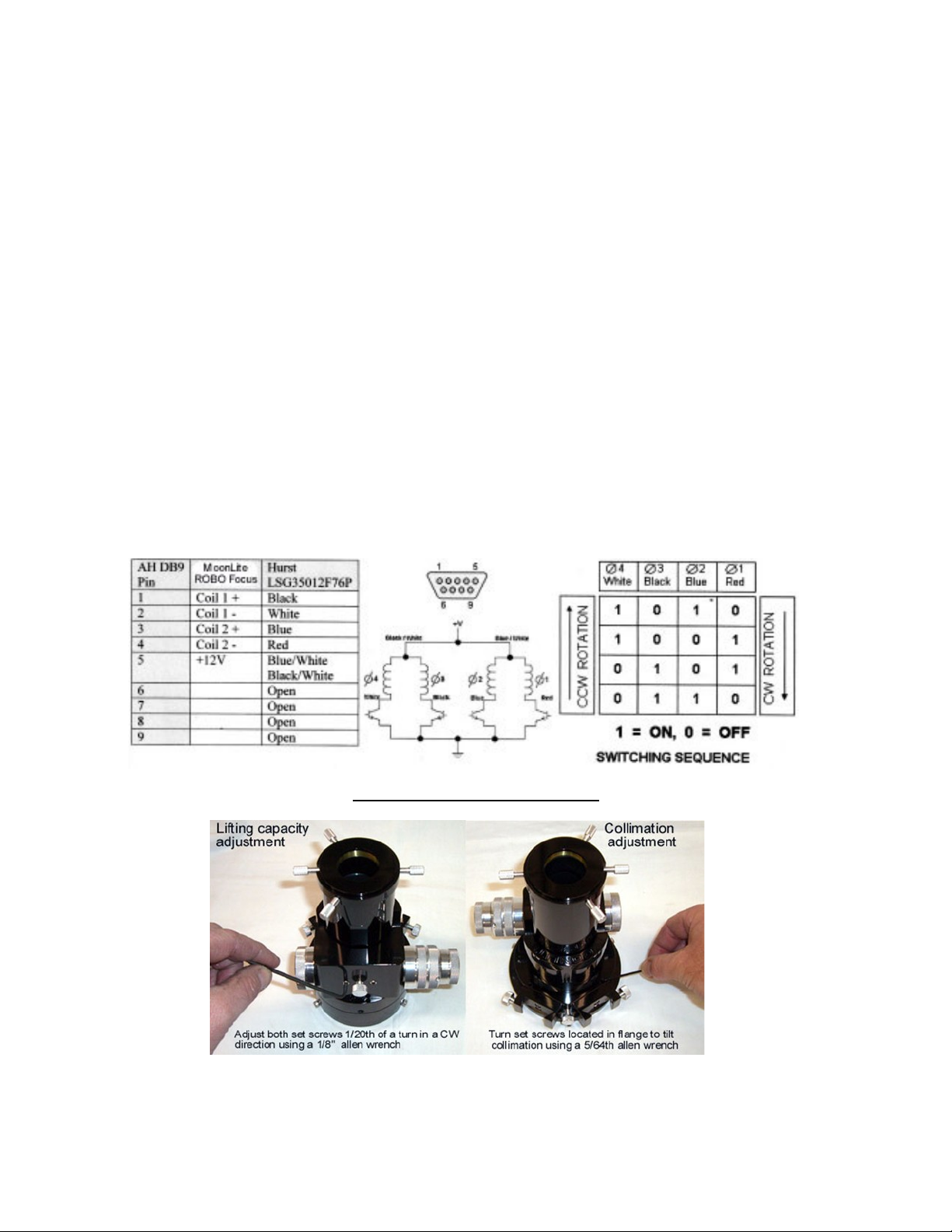

•The high resolution stepper motor only or stand alone option

is for customers that already ha e a ROBO focus controller or

other brand controller and do not need a stepper motor

controller. The stepper motor’s DB9 connector pin out is

100% compatible with the ROBO focus controller.

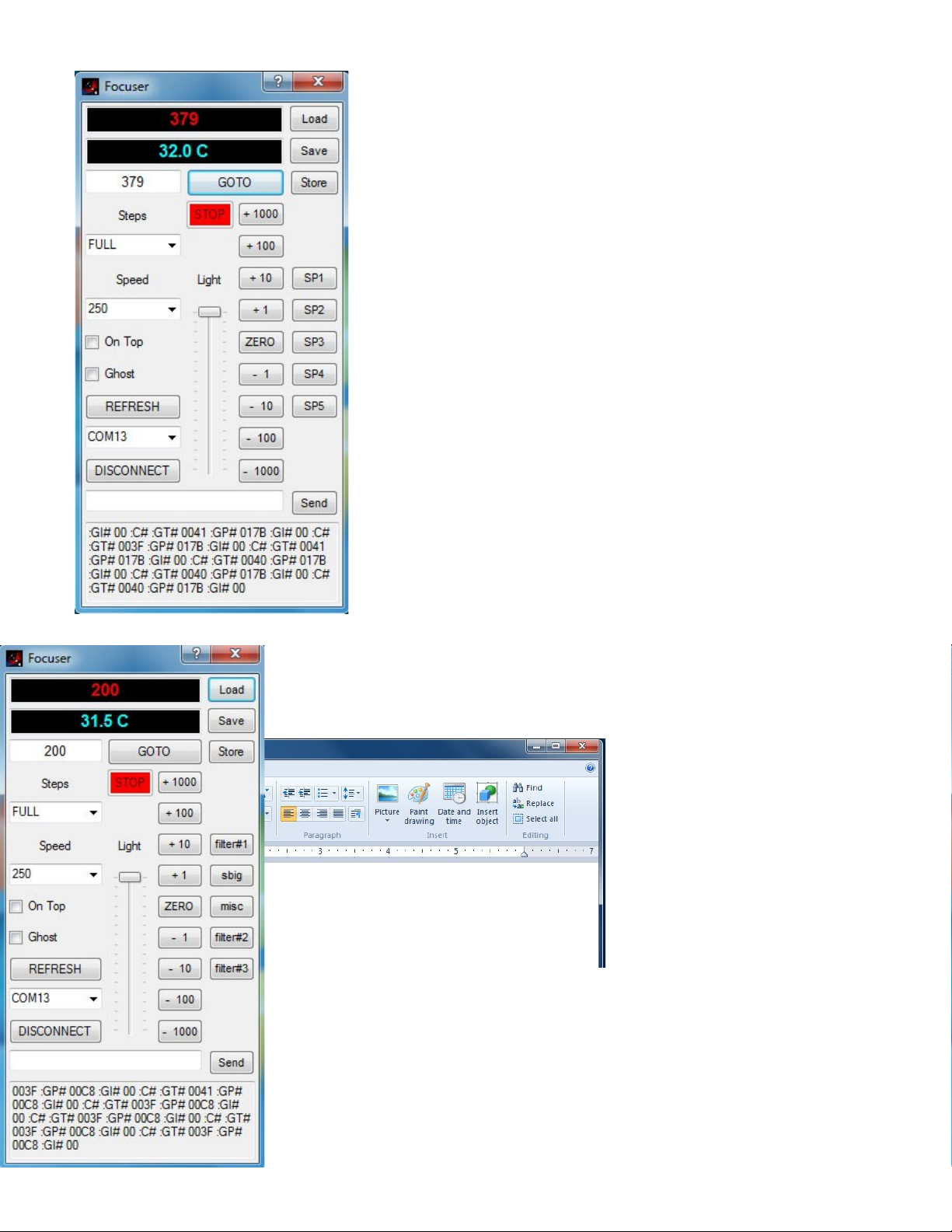

•The high resolution stepper motor with MoonLite Mini V2

controller uses an ASCOM compliant stepper motor

controller from MoonLite. The “Mini V2” controller works

with all ASCOM based software packages such as Focus

Max, CCDSoft, MaximDL, etc. It features a built in temp

sensor and also comes with a remote temp probe. We include

a USB cable and 12 olt AC adapter that has all the different

plug configurations (US, Europe, UK, and Australia);

howe er, most customers will simply use 12- olt power off

their mount. This mini V2 controller is designed to be used

remotely by a PC, or by the up /down buttons and speed

control knob on the controller. It has all the functions of our