The Interface Solution Experts 7

HIM

Smart HARTLoop

Interface and Monitor

Performance Indicators

(Continued)

Performance

(Continued)

Specications

Input Accuracy: Reects the

accuracy of the HART eld

device

Input Impedance: Transmit

Mode: 150 ohms;

Receive Mode: Less than

5 kohms

ANALOG OUTPUTS

Output Accuracy: ±0.015%

of maximum output span

(20mA). Includes the

combined eects of linearity,

hysteresis, repeatability and

adjustment resolution)

Output Response Time:

<120msec, 10-90%

Isolation: 500Vrms

channel-to-channel isolation;

1000Vrms between case,

input, outputs and power

terminals, and will withstand

1500Vac dielectric strength

test for one minute with no

breakdown

Ripple: Less than 10mV

peak-to-peak when measured

across a 250 ohm resistor

Output Limiting: 130% of

span maximum; 125% of

span typical

Output Protection:

Transient protection on output

Load Capability:

0-20mA, 1100 ohms

maximum

Load Eect: ±0.01% of

span from 0 to maximum load

resistance

Line Voltage Eect:

±0.005% of output span for a

1% change in line voltage

Input Fail Modes: PC

programmable to fail high, fail

low, hold last, hold last then

fail high, or hold last then fail

low (congurable hold time,

0-60 seconds)

Output Limits on Input

Failure:

0-20mA: Fail Low to 0mA or

Fail High to 23.6mA

4-20mA: Fail Low to 3.6mA

or Fail High to 23.6mA

X-20mA (0<X<4): Fail Low to

90% of XmA or Fail High to

23.6mA

+TX Power Supply: 24.0Vdc

±10%@24mA

ALARM OUTPUTS

Digital Response Time:

Dened by HART protocol as

500msec maximum in Normal

HART Mode;

333msec maximum in HART

Burst Mode

Alarm Response Time:

Digital Response Time +

150msec (Dened as time

from the eld instrument’s

reporting a fault until the HIM

alarm is tripped)

Alarm Trip Delay:

Programmable from 0-120

seconds

MODBUS OUTPUTS

Type: Standard MODBUS

RTU protocol interface over

RS-485 (parameters as

specied in U.S. Standard

EIA-RS485)

Address Range:

Congurable from 1 to 247.

Unit will assume a MODBUS

address of 01 by default

Baud Rate: Interface

supports the following: 300,

600, 1200, 4800, 9600,

19.2k. MODBUS interface

will support even, odd and

no parities. Unit will assume

a baud rate of 9600 and no

parity by default

Character Format: One

start bit, 8 data bits and one

stop bit

Data Format: User-

selectable Standard LSW

(Least Signicant Word)

or Swapped MSW (Most

Signicant Word). Unit will

assume Standard LSW by

default

Transmission Range: Using

24AWG twisted pair wiring,

maximum of 2 mi. (3.2km)@

4800 baud or less; maximum

of 1 mi. (1.6km)@9600 baud;

maximum of 0.5 mi. (0.8km)

@19200 baud

Power Consumption:

2-3.5W, nominal;

4.5W@24Vdc maximum

for units using transmitter

excitation to supply loop

power a 2-wire instrument

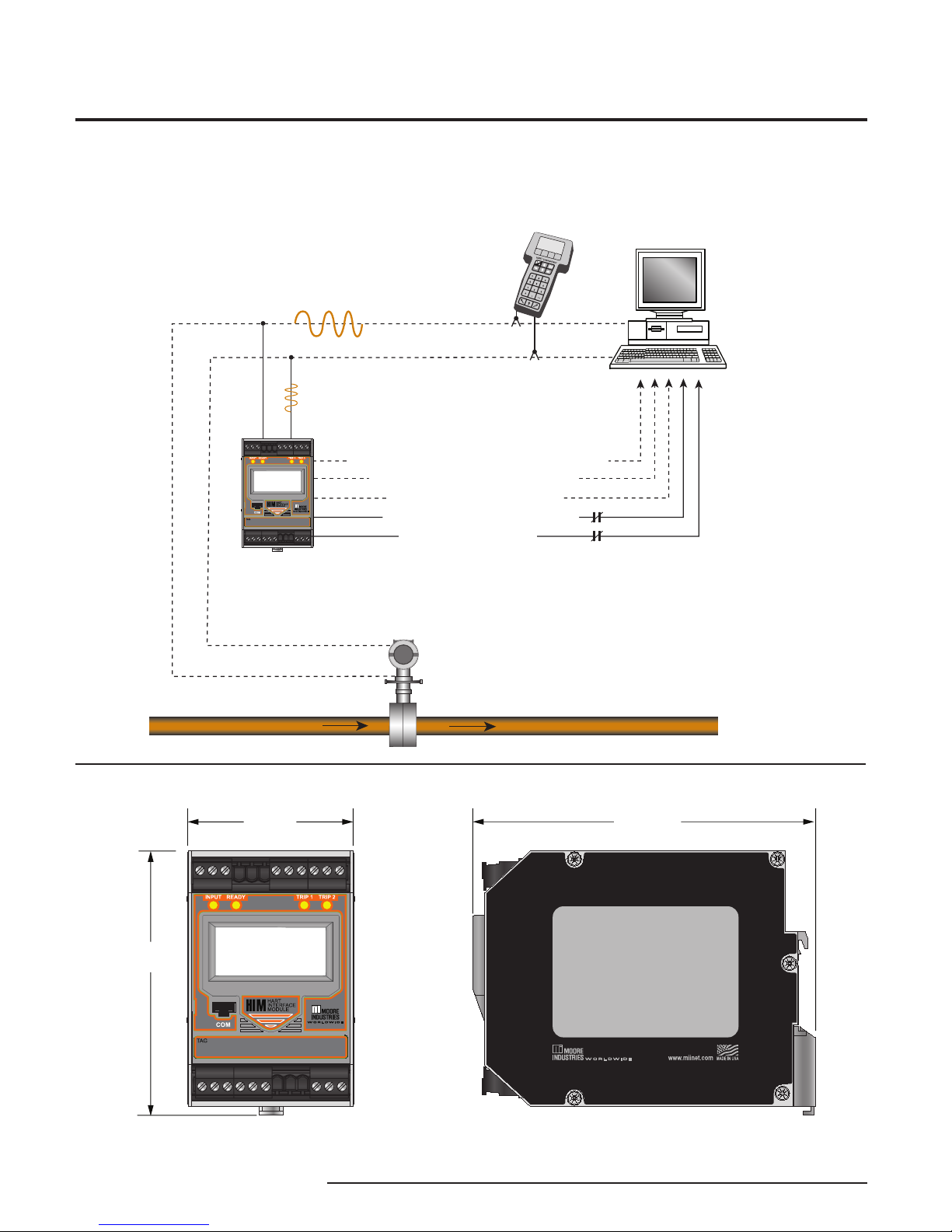

LCD Type: Two-line LCD;

Top Row, 10mm (0.4 in) high

black digits on a reective

background; Bottom Row,

Indicators

Ambient

Conditions

Weight

6mm (0.225 in) high digits on

a reective background; two-

digit HART address indicator

Format: Top row is ve

alphanumeric characters,

plus sign and decimal

point; bottom row is ve

alphanumeric characters

Decimal Points: User-

selectable for 0, 1, 2 or 3

places after the decimal point

or automatically adjusting

with a four decimal point

maximum

Range: -99999 to 99999

Minimum Display Span:

1.00

Display Update Rate:

100msec

LED Type: Dual color

red/green indicate:

INPUT LED: Whether

(green) or not (red) the

HART input is connected and

functioning properly

READY LED: Whether

(green) or not (red) the HIM

is initialized and operating

properly

TRIP 1 and 2 LED: Shows

the status of alarm o (green)

or alarm on (red)

Operating & Storage

Range:

-40°C to +85°C

(-40°F to +185°F)

Display Range:

-25°C to +85°C

(-13°F to +185°F)

Relay Range:

-25°C to +70°C

(-13°F to +158°F)

Relative Humidity:

0-95%, non-condensing

Ambient Temperature

Eect: ±0.0065% of

span/°C maximum

RFI/EMI Immunity:

STANDARD:

10V/m@80-1000MHz, 1kHz

AM, when tested according

to IEC61000-4-3

WITH -RF OPTION:

20V/m@80-1000MHz, 1kHz,

when tested according to

IEC61000-4-3

Noise Rejection: Common

Mode: 100dB@50/60Hz

567 grams (16 ounces)