5

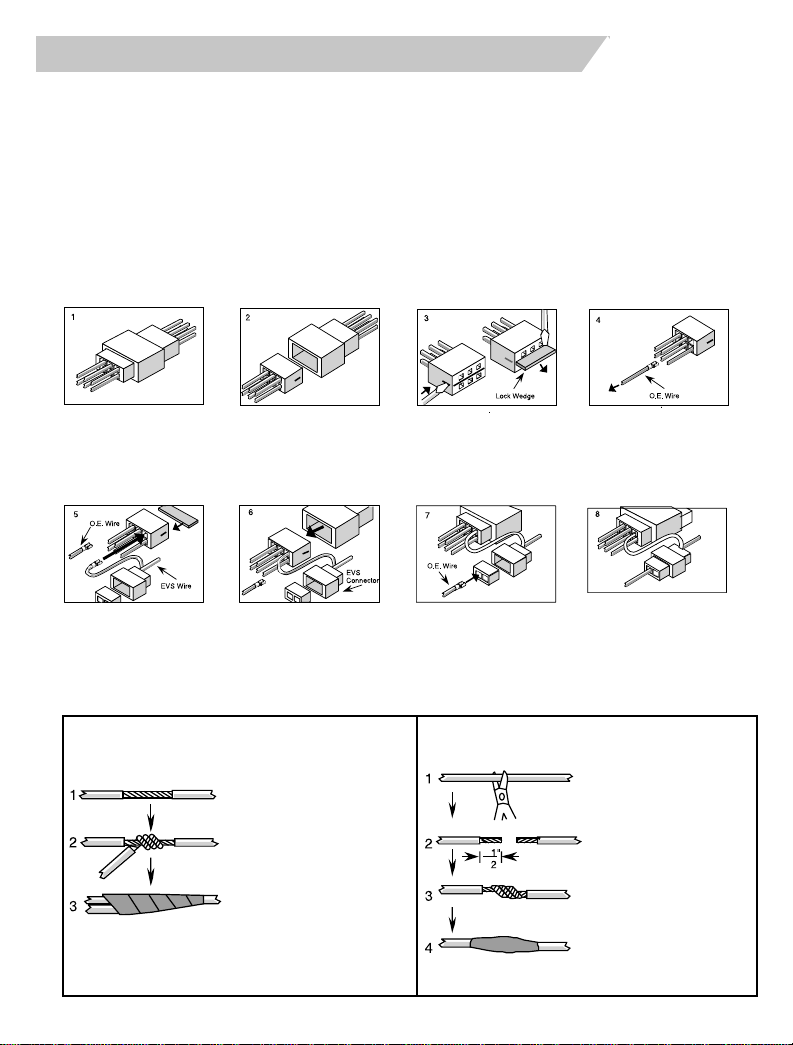

2. Main Harness Connection

8. Locate the YELLOW 20-gauge wire located in cavity #4 of the ignition switch

connector. This wire should measure +12v only when the vehicle is cranked with

the key.

9. Using wire cutters, cut the 20-gaugeYELLOW wire in half.Try to create this cut

about 2 or 3”s away from the ignition switch connector, remove more harness

tape wrap if necessary.

THE FOLLOWING CONNECTIONS MUST BE

MADE INTHE PROPER POLARITY.IFTHE

WRONGWIRES ARE CONNECTED THEVE-

HICLE WILL NOT START AND THE CONNEC-

TIONSWILL HAVETO BE REVERSED. READ

THE FOLLOWING CAREFULLY.

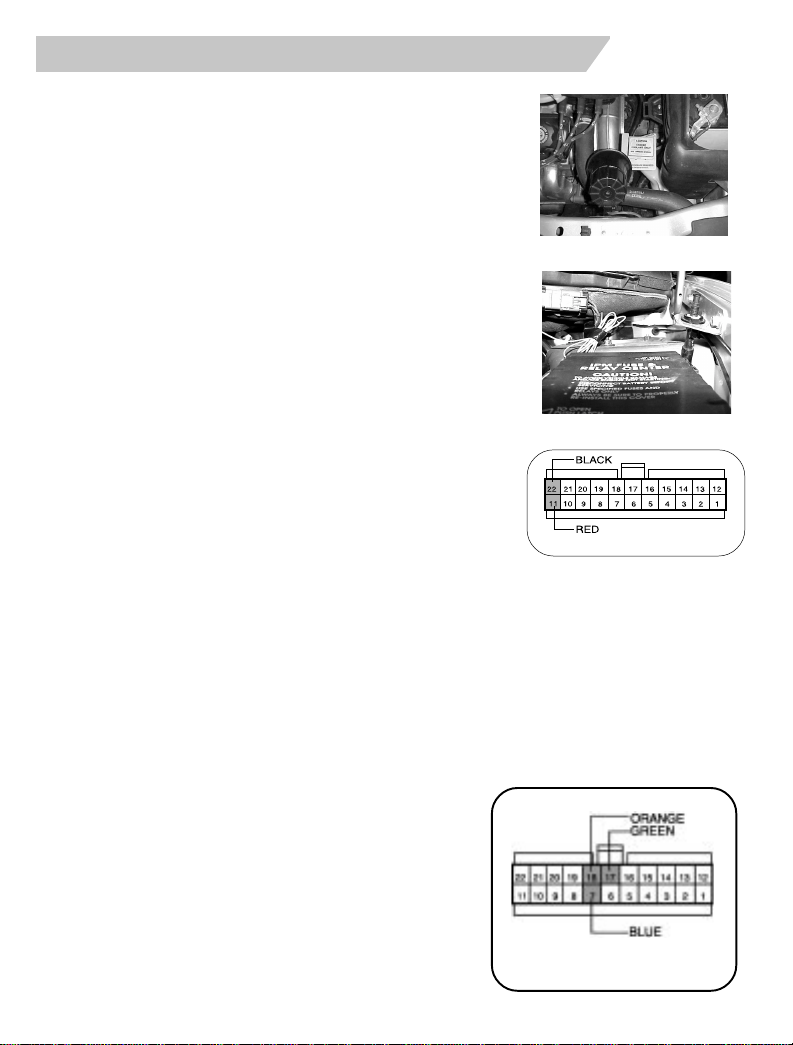

10. Using the supplied RED butt connectors, splice

the EVS 20-gauge YELLOW/BLACK wire to the

previously cut 20-gauge YELLOW wire coming

from the ignition switch connector.

(Follow crimping procedure outlined on page 4).

11. Splice the EVS 20-gauge YELLOW wire to the previously

cut YELLOW wire which goes toward the wire harness.

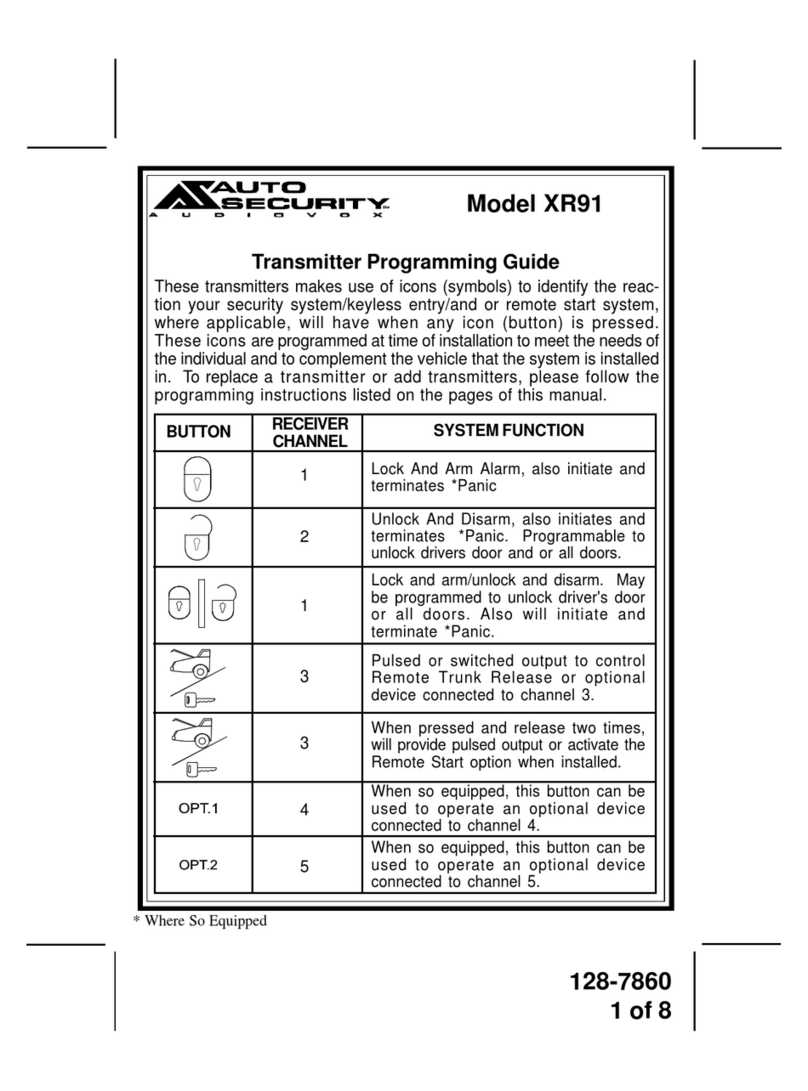

FIG. 2.3

Ground Connection

1. Locate a vacant area of metal on the support brace to use as a chassis ground.

2 Attach the EVS BLACK ground wire to the area chosen by inserting the supplied

screw through the ground ringlet and into this area.

3. Make sure the ringlet is securely tightened.

Dome Light Connection

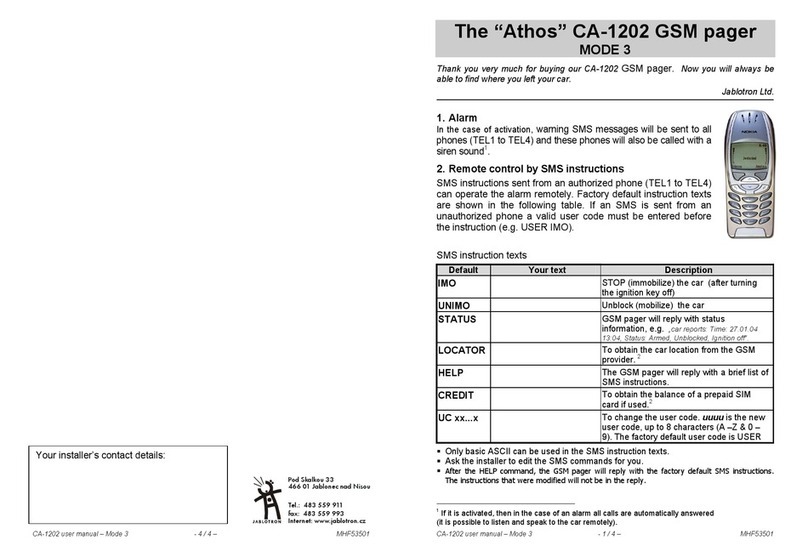

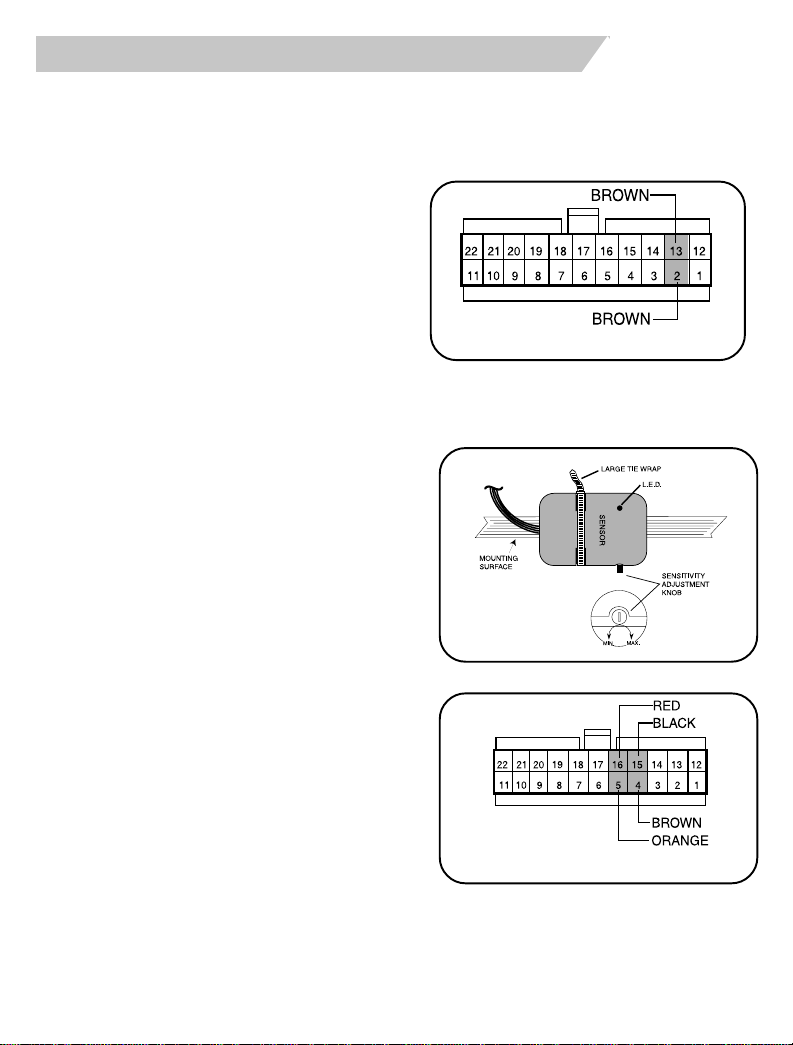

1. Locate the BCM against the drivers side

bulkhead. Locate the 34-way C2 connector

which is the second connector from the top

on the BCM. (FIGURE 2.4)

2. Locate the 20-gauge YELLOW/ORANGE wire

located in cavity #25 of the C2 connector.This

wire will register 12V+ when the dome light is

on and ground when the dome light is off.

3. Center splice the singular EVS 20-gauge

YELLOW/ORANGE wire that is tapped to the

EVS harness into this vehicle’s YELLOW/

ORANGE wire.

(Follow the Center Splice procedure on page 3)

4. Insert the terminal on the other end of the EVS

wire into pin position #1 of the EVS module’s

22-way connector. (see diagram on page 13)

FIG. 2.4

Viewed from wire end

DOMELIGHT