6

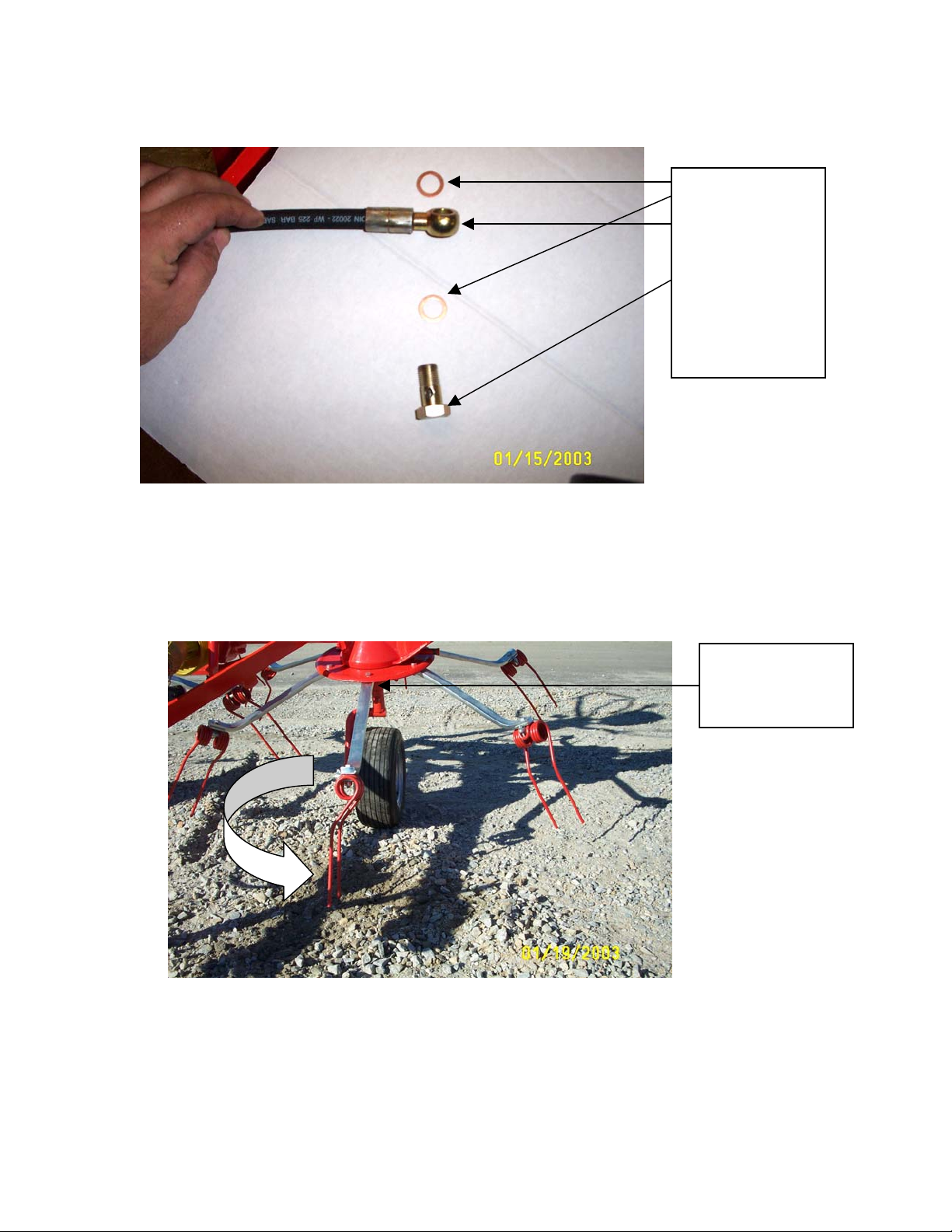

9. Install the dust covers and outer tire & wheels onto the spindles

the outer arms. The bearings in these wheels are sealed but it is still

is a good idea to put grease in the dust cap. Align the wheel in the

travel position.

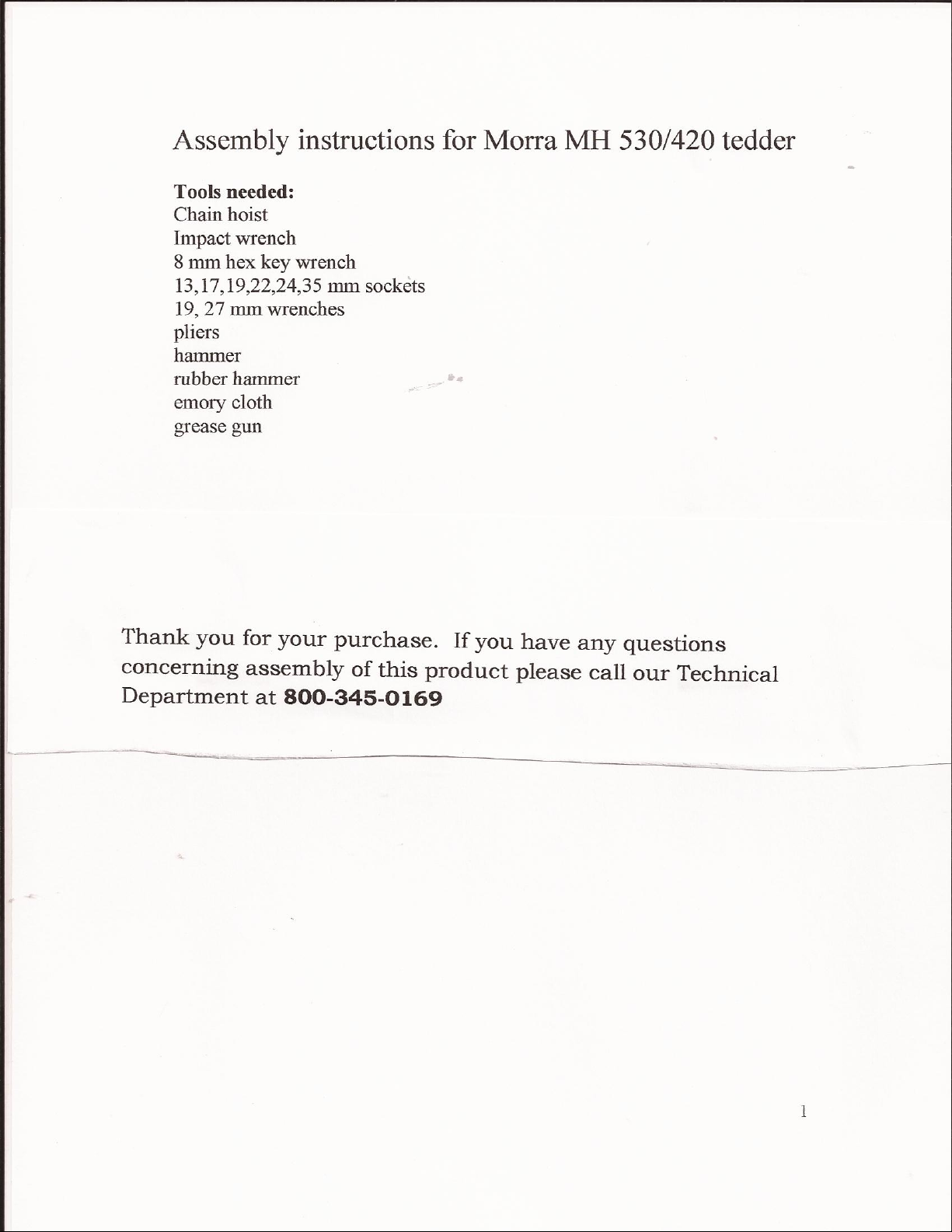

There is a left and a right arm. They are easy to recognize by the

position of the bracket for the hydraulic cylinder mount.

10. To attach the arm to the central unit, turn the rotor on the

central unit until the keyway on the shaft is at 12:00 and install the

keyway provided. It is also important to be sure there is no paint on

the shaft. You will also need to buff the paint from the yokes (inside

of central unit, outside of the arm)so that there is no problem with

fitting.

*This is also a good time to grease the universal joints on the arm.

Before installing the arm to the central unit, with the keyway at 12:00

and the arm yoke in line, you will want to notice the “timing” of the

unit to be sure that the inner and outer rake teeth will not collide.

You will need to start the yokes of the arm onto the shaft & tamp them

on with a rubber hammer until it is completely in position.